Place du Centre, 4th floor

200 Promenade du Portage

Gatineau QC K1A 1K8

29 May 2023

The Honourable Bill Blair, P.C., M.P.

President of the King’s Privy Council for Canada

House of Commons

Ottawa ON K1A 0A3

Dear Minister,

In accordance with subsection 13(3) of the Canadian Transportation Accident Investigation and Safety Board Act, the Board is pleased to submit, through you, its Annual Report to Parliament for the period 1 April 2022 to 31 March 2023.

Yours sincerely,

Original signed by

Kathleen Fox

Chair

Message from the Chair

The end of fiscal year (FY) 2022–23 marks the completion of a busy year for the Transportation Safety Board of Canada (TSB). We focused on completing many of our long-running investigations, some of which have highlighted significant safety issues present in Canada’s transportation system.

This year we released 59 investigation reports, well exceeding the output of 39 in FY 2021–22, including five reports in which the TSB issued a total of nine recommendations on needed changes in the air, marine, and rail sectors. Additionally, the TSB assessed the responses to 62 previous recommendations to ensure progress is being made.

In May 2022, we released our investigation report into the 2019 fatal sinking of the small fishing vessel Sarah Anne, off the coast of Newfoundland. The investigation prompted a recommendation to Fisheries and Oceans Canada to require that any Canadian vessel that is used to commercially harvest marine resources have a current and accurate Transport Canada (TC) registration. In August, we released our report into a 2019 collision between two freight trains near Portage la Prairie, Manitoba, in which we released two recommendations to TC, one of which builds on outstanding recommendations going back more than two decades. This accident highlights major issues in the rail industry and reinforces TSB’s call for physical fail-safe train controls.

In March 2023, we released our report into the fatal 2021 collision with terrain of a private aircraft near Lacombe, Alberta, in which we issued a recommendation to TC to routinely review and update the Handbook for Civil Aviation Medical Examiners to ensure it contains the most effective screening tools for assessing medical conditions, including cardiovascular disease. In the same month, we also released our report into the fatal sinking of the tug Ingenika, in which we issued four recommendations. The first two recommendations were addressed to TC to improve and expand regulatory surveillance of tugs under 15 gross tonnage. The other two recommendations were to the Pacific Pilotage Authority to address gaps in the issuance of pilotage waivers.

In October 2022, we released the most recent edition of the TSB Watchlist, putting the spotlight on key safety issues and actions that need to be addressed to make Canada’s transportation system even safer. The Watchlist highlights eight key safety issues that require government and industry attention, and are the result of hundreds of investigations, compelling findings and data, and active TSB recommendations. Some of these issues date back to well over a decade – a stark indication that while progress has been made, more needs to be done. Realizing that these issues are complex and take time to resolve, the Watchlist is moving to a three-year cycle to allow time for meaningful progress to be made by industry and the regulators.

To ensure industry stakeholders are well-informed on the work of the TSB, we conducted a series of outreach events, with TSB personnel sharing important safety messages at more than 50 industry events across the country.

This last fiscal year and the coming one will see some changes to the Board. On December 31, 2022, long-standing Board Member Faye Ackermans retired after serving a total of three terms.

My second term as Chair will come to an end this August and I have announced my intention to retire. It has been an honour to serve as the Chair of the TSB and I am proud of the progress the TSB has made as a world-leading safety investigation organization that influences change. Regardless of who serves on the Board in the future, the mandate and focus of the TSB’s work to advance transportation safety will not change, and nor will the dedication and professionalism of our staff.

Kathleen Fox

The year in results

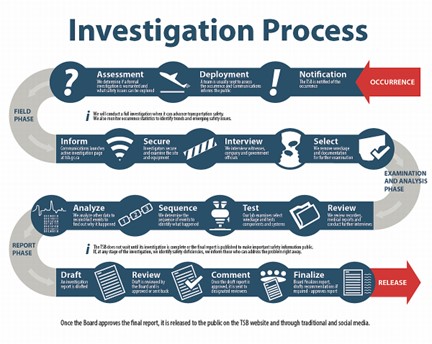

In 2022–23, staff from the Transportation Safety Board of Canada (TSB) assessed thousands of accidents and incidents that occurred across Canada in the air, marine, pipeline, and rail transportation sectors (see the definitions in the Policy on Occurrence Classification).

TSB personnel deployed to the sites of some of these occurrences to collect data and carry out analysis in order to identify what happened and why, and to highlight known and emerging safety issues—all in an effort to improve transportation safety in Canada.

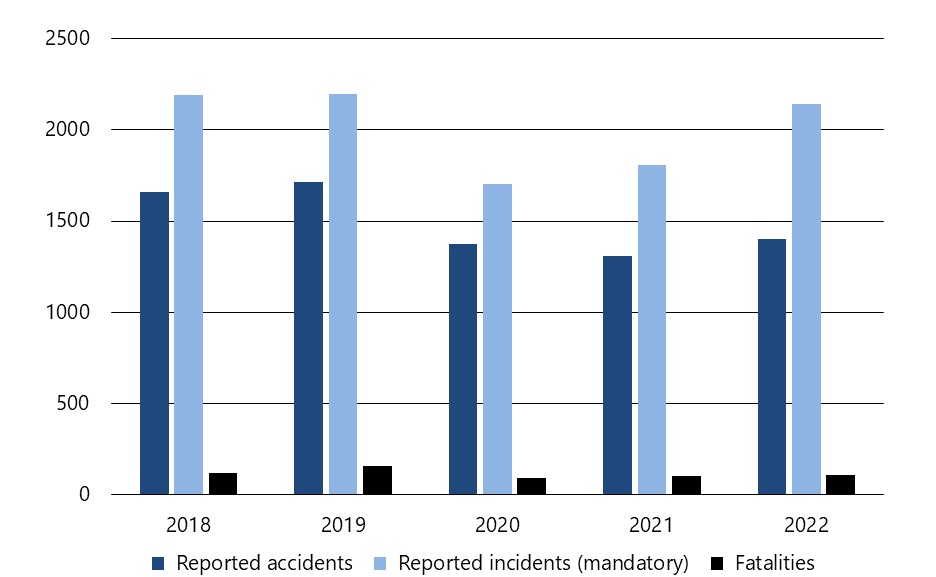

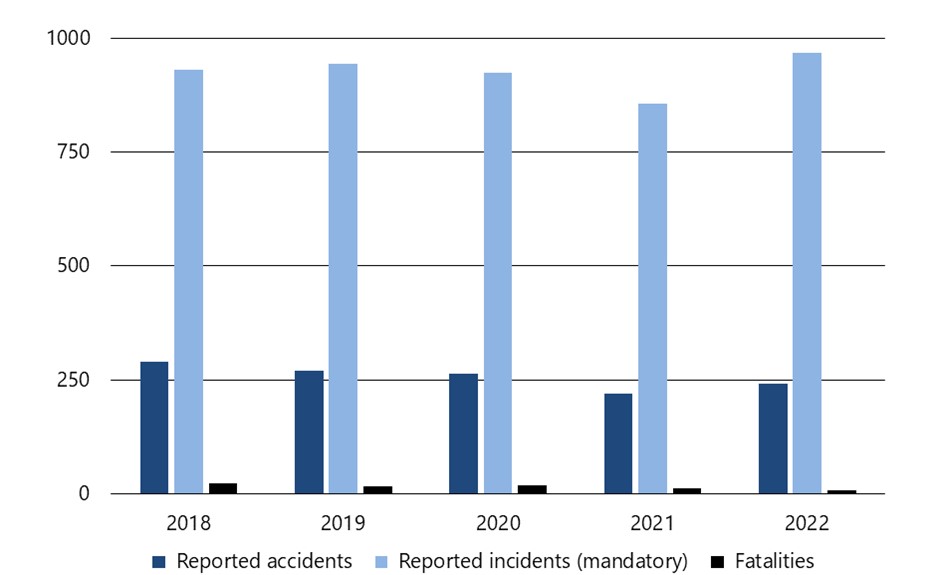

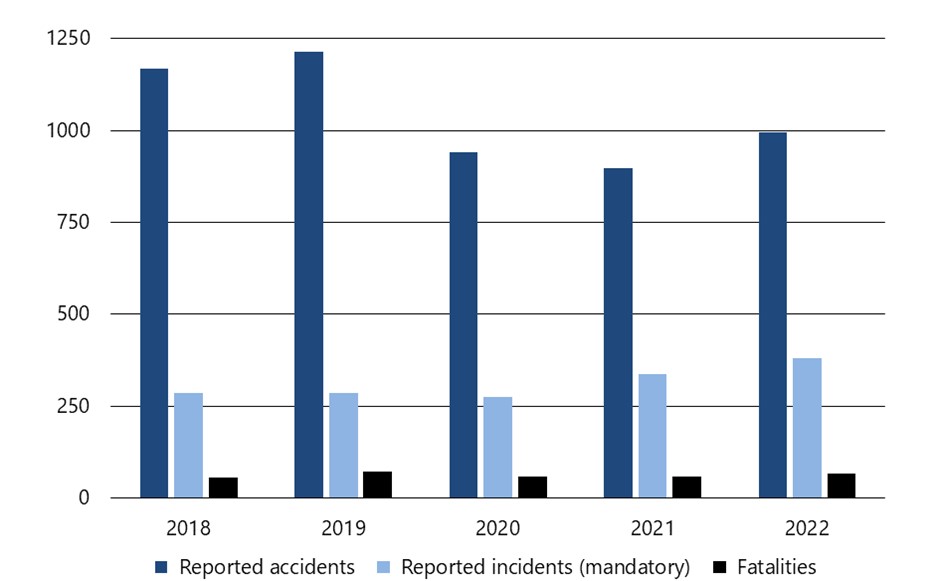

The total number of occurrences reported to the TSB (as required under the Transportation Safety Board Regulations) in the 2022 calendar year (3541) was 14% higher than the 2021 total of 3118 (Figure 1).

Figure 1. Data table

| Occurrences reported to the TSB | 2018 | 2019 | 2020 | 2021 | 2022 |

|---|---|---|---|---|---|

| Reported accidents | 1,659 | 1,713 | 1,376 | 1,311 | 1,402 |

| Reported incidents (mandatory) | 2,188 | 2,197 | 1,704 | 1,807 | 2,139 |

| Fatalities | 117 | 159 | 94 | 102 | 107 |

In 2022, there were 1402 accidents reported, 7% above the 2021 total of 1311, but 10% below the 10‑year average of 1555.

There were 5% more fatalities (107) across all transportation sectors in 2022 than there were in 2021 (102). However, the 2022 total represents a 16% decrease in fatalities from the 10-year average of 128.

The total of 2139 incidents reported to the TSB in 2022 was an 18% increase from the 2021 total of 1807 and a 12% increase from the 10-year average of 1915.The TSB at work

Deployments

TSB investigators deployed 69 times during 2022–23 (up from 46 the previous year) in response to occurrences in all sectors. These deployments took staff from the TSB regional offices and head office to locations across the country.

Investigations

In 2022–23, the TSB began 50 new investigations and completed 59 across all four transportation sectors (air, marine, pipeline, and rail) and in four classes of investigations (from in-depth and complex to limited scope) (Table 1).

| Investigations | 2021–22 | 2022–23 |

|---|---|---|

| Started during year | 55 | 50 |

| Completed during year | 39 | 59 |

| In progress on 31 March | 75 | 66 |

Average completion times increased, both overall and for the various classes of investigations. Class 4 investigations accounted for 41% of the total investigations completed during the reporting year. In these limited scope investigations, the TSB gathers data, conducts limited analysis, and reports the facts regarding less complex occurrences to raise awareness of relevant safety issues.

In support of TSB investigations, engineers, technical specialists, and human factors investigators began 145 projects and completed 152 technical reports in 2022–23. They also began three projects and completed eight technical reports for foreign investigation agencies.

Safety communications products

| Safety advisories | Safety information letters | Safety concerns | Recommendations |

|---|---|---|---|

| 11 | 6 | 2 | 9 |

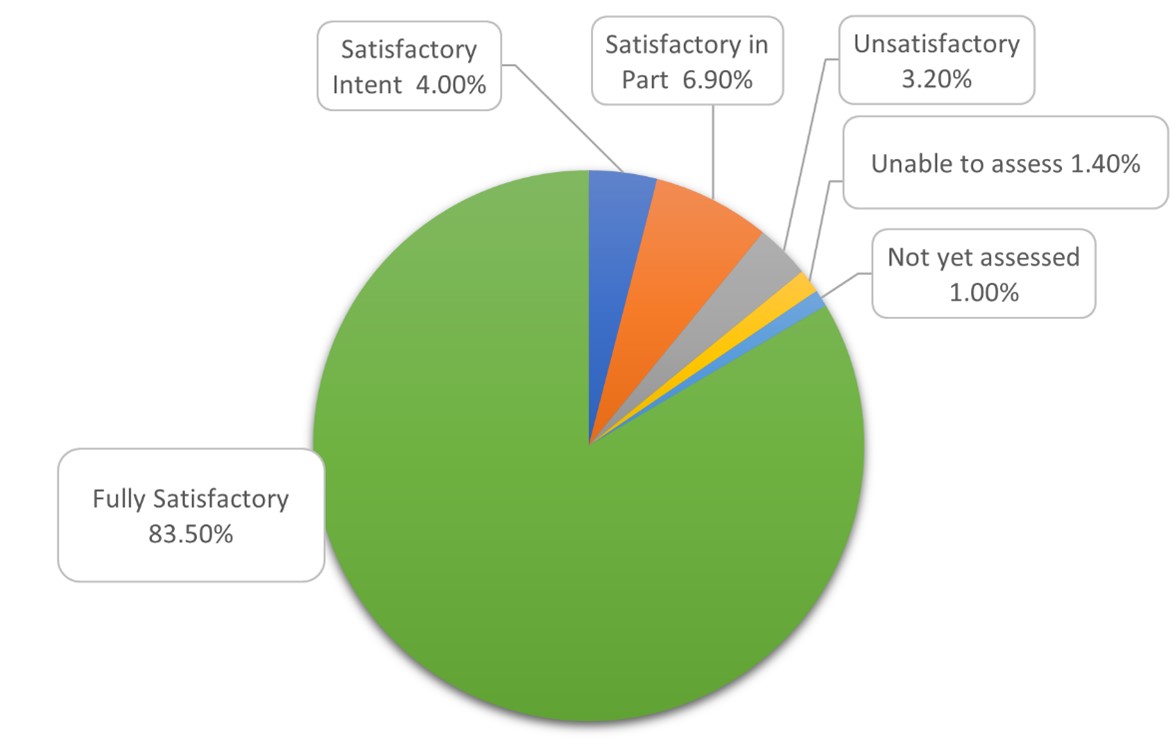

Each year, the Board assesses progress made on outstanding recommendations as part of ongoing efforts to urge stakeholders to act on the safety issues identified in TSB investigations. In 2022–23, the Board assessed four responses to outstanding recommendations as Fully Satisfactory: three air transportation safety recommendations and one rail transportation safety recommendation.

Since 1990, the Board has made 626 recommendations. By the end of 2022–23, it had given 83.5% of the responses to these recommendations the highest rating of Fully Satisfactory. This means that stakeholders, including TC, have acted to substantially reduce the safety deficiencies the Board has identified (Figure 2).

Figure 2. Data table

| Fully satisfactory | 83.50% |

|---|---|

| Satisfactory intent | 4.00% |

| Satisfactory in part | 6.90% |

| Unsatisfactory | 3.20% |

| Unable to assess | 1.40% |

| Not yet assessed | 1.00% |

At 31 March 2023, there were 87 outstanding recommendations, less than half of which date from 10 years ago or more (Table 3).

| Age of recommendations | Air transportation safety | Marine transportation safety | Rail transportation safety | Total (%) |

|---|---|---|---|---|

| Less than 1 year | 1 | 6 | 2 | 9 (10.30%) |

| 1 year to less than 7 years | 20 | 10 | 5 | 35 (40.20%) |

| 7 years to less than 10 years | 3 | 0 | 6 | 9 (10.30%) |

| Sub-total | 24 | 16 | 13 | 53 (60.92%) |

| 10 years to less than 15 years | 4 | 3 | 0 | 7 (8.05%) |

| 15 years to less than 20 years | 11 | 2 | 0 | 13 (14.94%) |

| 20 years or more | 8 | 3 | 3 | 14 (16.09%) |

| Sub-total | 23 | 8 | 3 | 34(39.08%) |

| Total | 47 | 24 | 16 | 87 (100.00%) |

Watchlist 2022

In October 2022, the TSB published the latest edition of its Watchlist, which identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer. These issues are supported by investigation reports, Board safety concerns, and recommendations.

There are eight issues currently on the Watchlist. Some of these issues date back to well over a decade—a stark indication that while efforts have been made, more needs to be done.

Leading up to the development of the current Watchlist, the TSB organized a series of discussions with its stakeholders at industry events to gauge progress made and discuss any emerging issues. These events included meetings of the Air Transport Association of Canada, the Helicopter Association of Canada, the Canadian Marine Advisory Council, and a TSB-led discussion session with the rail sector. The results of these discussions were used to inform Watchlist 2022.

Realizing that these issues are complex and take time, the Watchlist is moving to a three-year cycle to allow time for meaningful progress to be made by industry and TC.

SECURITAS

Through the TSB’s SECURITAS program, transportation industry employees and the public can report, in confidence, unsafe actions and conditions they observe.

The TSB received a total of 188 SECURITAS reports in 2022–23 (Table 4). This number is slightly higher than the 172 reports received the previous year.

| Air transportation safety | Marine transportation safety | Pipeline transportation safety | Rail transportation safety | |

|---|---|---|---|---|

| Reports received | 81 | 29 | 0 | 78 |

| Reports closed | 81 | 29 | 0 | 76 |

Of the 81 SECURITAS reports concerning air transportation safety , 80 were of a regulatory nature. These reports were redirected to TC. The other report submitted was about information related to an ongoing investigation and the reporter did not wish to remain anonymous, therefore the information was relayed to the investigator-in-charge.

In 2022–23, the TSB received 29 reports concerning marine transportation safety, a decrease of 35% from the previous year (44). The trusted agents responsible for handling SECURITAS matters on behalf of the Marine Branch closed all 29 reports. The reports covered a wide range of unsafe conditions on commercial fishing, passenger, and cargo vessels. These regulatory matters were resolved in collaboration with TC.

This year, the TSB received 78 SECURITAS reports on rail transportation safety. These included reports about inadequate railway employee familiarization and misaligned rail signals. By year-end, the trusted agents had closed all but two of the SECURITAS reports that the TSB had received.

Communications and outreach

Regular communications and outreach are important aspects of the TSB’s efforts to advance transportation safety. Through its website, social media channels, and participation in in-person and virtual events, the TSB reaches industry and government stakeholders as well as media and members of the public across Canada and around the world (tables 5, 6, and 7).

| Media requests | Interviews | News conferences | Industry outreach events |

|---|---|---|---|

| 430 | 58 | 4 | 54 |

| Deployment notices | Investigation webpages | Media advisories | News releases | Investigation reports |

|---|---|---|---|---|

| 47 | 37 | 5 | 64 | 59 |

| YouTube followers | Flickr followers | Twitter followers | LinkedIn followers | Facebook followers |

|---|---|---|---|---|

| 5362 | 607 | 26 087 | 5186 | 1192 |

Outreach activities

The TSB took part in over 50 industry events and meetings during the year, some online and others in person, to discuss matters in transportation safety including:

- Air Line Pilots Association annual conference

- Association québécoise du transport aérien annual conference

- Air Transport Association of Canada annual conference

- Helicopter Association of Canada annual conference

- Canadian Owners and Pilots Association annual conference

- Canadian Ferry Association annual conference

- Canadian Maritime Advisory Council annual and semi-annual conferences

- Passenger & Commercial Vessel Association

- Crude-by-Rail conference

- National Railway Day

- Wheel Rail Interface Conference 2022

Behind the scenes

Working toward the TSB’s strategic objective of becoming digital by default, we continued implementation of our new project tracking tool to support TSB project tracking, monitoring, searching, and reporting. This new tool will provide a single location for recording project information and a means of standardizing project information across the organization. After having onboarded our Engineering Laboratory to support the TSB’s engineering and human factors projects in 2021–22, this fiscal year the IT team completed its work on the tool to onboard the Communications Branch to track the lifecycle of investigation reports and related communications products.

Air transportation safety

The year in review

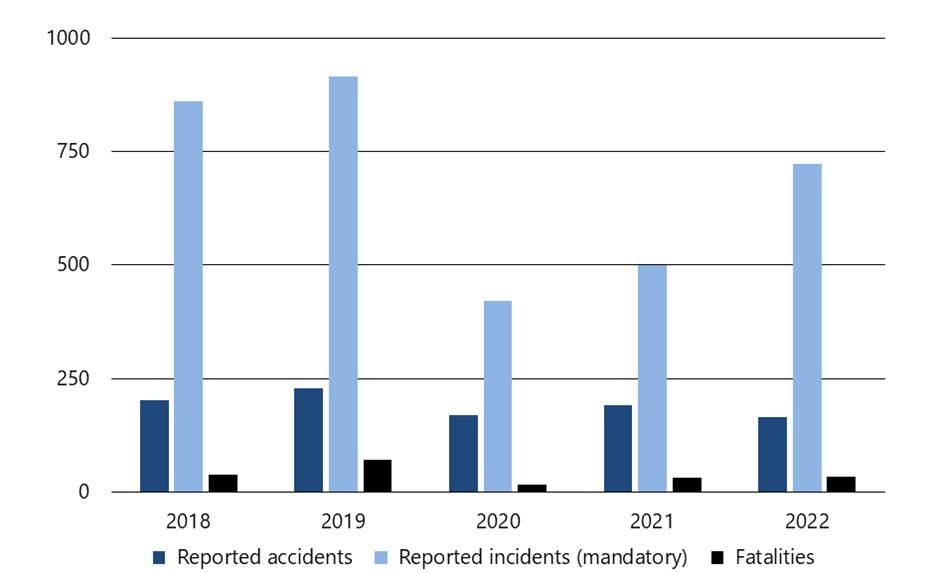

The TSB received 889 reports of air occurrences in 2022 (165 accidents and 724 incidents), including 34 fatalities (Figure 3).

Figure 3. Data table

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Reported accidents | 201 | 228 | 170 | 191 | 165 |

| Reported incidents (mandatory) | 860 | 915 | 421 | 500 | 724 |

| Fatalities | 38 | 70 | 16 | 31 | 34 |

A total of 165 accidents were reported in 2022. This number is 14% lower than the previous year’s total of 191 accidents and 29% below the yearly average of 233 accidents reported in the prior 10 years, 2012 to 2021. Most (152) of the accidents in 2022 took place in Canada and involved Canadian-registered aircraft. In general, the number of air transportation accidents has been decreasing in the last decade.

The TSB recorded 24 fatal air transportation accidents involving 34 fatalities in 2022. This is up slightly from 22 fatal accidents involving 31 fatalities in 2021, but is still 9% below the average of 26.4 fatal accidents involving 43 fatalities over the ten years from 2012 to 2021. Ten of the 34 air transportation fatalities in 2022 involved commercial operations: 3 of them under air taxi regulations (Civil Aviation Regulations Subpart 703 [CARs 703]), 6 under aerial work (CARs 702), and 1 under flight training operations (CARs 406). There were no fatalities involving airliner operations (CARs 705), or commuter operations (CARs 704) in 2022. The remaining 24 (of 34) fatalities in 2022 were linked to privately registered aircraft and involved recreational operators.

Seven accidents in 2022 involved a release of dangerous goods. This is above the average of 5 per year over the previous 10 years.

In addition, 724 air transportation incidents were reported. This represents an increase of 45% from the 500 that were reported in 2021, and it is 1% below the average of 733 incidents per year between 2012 and 2021. The majority of incidents in 2022 (490 or 68%) occurred in Canada and involved Canadian-registered aircraft.

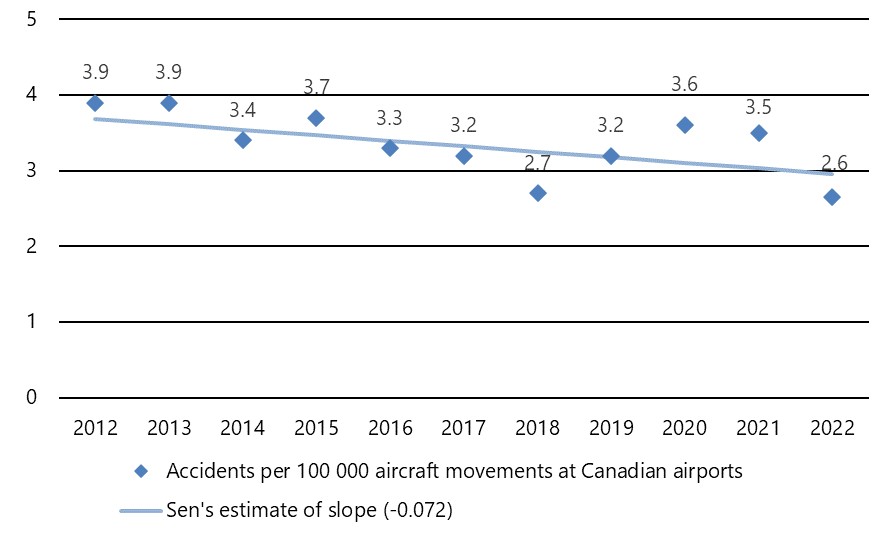

Accident rate: A measure of air transportation safety

The overall air transportation accident rate of 2.6 accidents per 100 000 aircraft movements in 2022 is based on 138 accidents in Canada involving Canadian- and foreign-registered airplanes and helicopters (ultralights, gyroplanes, gliders, and remotely piloted aircraft are excluded) and the estimated 5.211 million movements at Canadian airports. The accident rate has fallen from 3.9 accidents per 100 000 aircraft movements in 2012 to a low of 2.6 in 2022. This accident rate is the lowest that the TSB has recorded since 2007, when it began publishing a rate based on movements (Figure 4).

Past editions of the TSB Annual Report used an accident rate based on the number of hours flown by Canadian aircraft. However, TC has indicated that it has temporarily suspended the collection of the data for the 2022 Annual Airworthiness Information Report (AAIR), which has been the source for information on hours flown. The air accident rate based on aircraft movements relies on data collected from multiple sources. While this metric represents most of the flying activity in Canada and is used by the TSB in other publications, it lacks information about aircraft movement activity that takes place at many small aerodromes or away from aerodromes entirely.

Figure 4. Data table

| Year | Accidents per 100 000 aircraft movements at Canadian airports | Sen's estimate of slope (-0.072) |

|---|---|---|

| 2012 | 3.9 | 3.68 |

| 2013 | 3.9 | 3.61 |

| 2014 | 3.4 | 3.54 |

| 2015 | 3.7 | 3.47 |

| 2016 | 3.3 | 3.40 |

| 2017 | 3.2 | 3.32 |

| 2018 | 2.7 | 3.25 |

| 2019 | 3.2 | 3.18 |

| 2020 | 3.6 | 3.11 |

| 2021 | 3.5 | 3.03 |

| 2022 | 2.6 | 2.96 |

Investigations

TSB staff deployed to 48 air transportation occurrences in 2022–23 (21 more than in 2021–22), began 34 investigations, and completed 39 (tables 8 and 9).

| Activities | 2021–22 | 2022–23 |

|---|---|---|

| Deployments | 27 | 48 |

| Investigations started | 37 | 34 |

| Investigations completed | 21 | 39 |

| Investigations in progress on 31 March of each year | 37 | 32 |

| Class (investigation type) | Completed investigations | Completion target (days) | Average duration (days) | ||

|---|---|---|---|---|---|

| 2021–22 | 2022–23 | 2021–22 | 2022–23 | ||

| 1 (safety issue) | 1 | n/a | 730 | 1219 | n/a |

| 2 (complex) | 3 | 2 | 600 | 1007 | 1073 |

| 3 (detailed) | 7 | 17 | 450 | 491 | 517 |

| 4 (limited scope) | 10 | 20 | 220 | 203 | 208 |

Deficiencies in regulatory surveillance and safety management highlighted following collision with terrain in instrument meteorological conditions

The TSB investigation into the December 2019 loss of control and collision with terrain of a Douglas DC3C Basler Turbo Conversions TP67 aircraft operated by North Star Air, near Sachigo Lake, Ontario, found that the decision to depart on, and continue, a daytime visual flight rules (VFR) flight in instrument meteorological conditions (IMC) was influenced by a distorted perception of risk resulting from successful past experience in similar situations (A19C0145).

The aircraft was scheduled to conduct a VFR cargo flight in northern Ontario. Weather conditions obtained by the captain for the flight route were marginal for VFR, with reports of IMC. During the descent from cruising altitude, the aircraft passed through cloud cover and broke out of cloud at very low level, and the aircraft was not in a position to continue with the planned visual approach. The captain made low-level manoeuvres in an attempt to land, before colliding with terrain southwest of the runway.

A results-oriented subculture of some of North Star Air’s DC3-TP67 pilots, which emphasized mission completion over regulatory compliance, resulted in VFR flights, such as the occurrence flight, being conducted in IMC.

Safety management is an issue on the TSB Watchlist, and is a concern in the air, marine, and rail transportation modes.

A lack of timely and effective regulatory surveillance to ensure operators in all modes are compliant is also an issue on the TSB Watchlist.

The report includes findings related to safety management and regulatory surveillance, two continuing issues on the TSB Watchlist. North Star Air’s safety management system did not identify the underlying factors that led to the reported instances of company aircraft operating VFR flights into IMC, nor were any additional measures taken to monitor its operation to ensure flights were being conducted in accordance with regulations. As a result, previously identified unsafe practices persisted and played a direct role in this occurrence.

In 2017, TC had provided information to the company of allegations regarding VFR flights in IMC for its internal investigation. A 2018 TC inspection of company operations did not include information about these allegations, about corrective action, or that the company investigation into these allegations was still open after almost two years. As seen in this occurrence, the unsafe practice of operating under VFR in IMC persisted unbeknownst to the regulator. If TC relies on operators to investigate allegations of regulatory non-compliance without monitoring them, there is an increased risk that the unsafe practices that are being investigated will persist.

The results of this investigation reflect the TSB’s ongoing concerns about safety management and regulatory surveillance, both issues on the TSB Watchlist for 2022.

Safety culture and medical examinations for pilots identified as issues in the investigation into main rotor blade failure during emergency landing

The TSB investigation into the September 2019 loss of control and collision with terrain of a Bell helicopter in Campbell River, British Columbia (A19P0142), found that an engine power anomaly likely occurred while the helicopter was in cruise flight and, as a result, the pilot reversed course and entered a descent consistent with an autorotation. At some point during the flight, the main rotors became deformed. In the last moments of the flight, likely as a result of the deformed blades, the main rotor rpm decreased to a point that could not sustain autorotational flight, and the helicopter fell vertically to the ground, striking a building and two vehicles. The pilot was fatally injured. The helicopter was destroyed by the impact forces and a post-impact fire.

The investigation revealed that the engine fuel system did not have the appropriate accumulators and double check valve for installation on the Bell 206 helicopter. During the installation of the engine, the company maintenance control system was ineffective at ensuring that the engine installation complied with the manufacturer’s recommendations.

The investigation examined the air operator’s safety culture. The pilot was the company’s owner, accountable executive, and operations manager. The investigation revealed that many operational and maintenance-related decisions were being made based on a single opinion, rather than a process of validation by a hierarchy of independent and skilled supervisors. In addition, several opportunities to improve the safety of the flight had been missed.

Finally, the investigation examined TC’s approach to managing cardiovascular health and hypertension in pilots. Using a variety of different risk calculators and all available medical information about the occurrence pilot, an independent cardiology review was conducted as part of this investigation and revealed that the pilot possessed many of the key indicators for a high-risk cardiac event. In this occurrence, TC’s civil aviation medical examination to assess pilot fitness did not identify the level of risk presented by the pilot. If TC guidance material and the civil aviation medical examination report do not require a Civil Aviation Medical Examiner to perform a global cardiovascular assessment, when appropriate, there is an increased risk that a pilot with high cardiovascular risk factors will be incapacitated while operating an aircraft as a result of a medical event.

Runway incursion and risk of collision at Toronto/Lester B. Pearson International Airport

The TSB investigation into the March 2020 runway incursion and risk of collision between an Air Canada Embraer 190 and an Air Canada Boeing 777 at Toronto/Lester B. Pearson International Airport, Ontario (A20O0029), found that the Embraer 190’s transponder transmitted that the aircraft was in the air after it accelerated past 50 knots, even though it was still on the runway. As it was accelerating during its take-off roll, the Embraer 190 struck a bird, and the flight crew initiated a rejected takeoff. At about the same time, the Boeing 777 was cleared for takeoff on the same runway. As the aircraft was accelerating on its take-off roll, the flight crew observed that the Embraer 190 was still on the runway and initiated a rejected takeoff. Both aircraft eventually exited the runway and returned to the terminal. There were no injuries to passengers or crew members. There was no damage to either aircraft.

The transponders on both the Embraer 190 and the Boeing 777 transmitted inaccurate in-air statuses during their respective take-off rolls. Based on this data, NAV CANADA’s runway incursion monitoring and conflict alert sub-system (RIMCAS) inaccurately identified both aircraft as being in air when in fact they were still on the ground. This resulted in late and inaccurate RIMCAS alerts and delayed the air traffic controller’s response to the risk of collision. The risk was only mitigated when the Boeing 777 flight crew rejected their takeoff after recognizing that the Embraer 190 was still on the runway ahead of them.

Runway incursions lead to an ongoing risk of aircraft colliding with vehicles or other aircraft. This issue has been on the TSB Watchlist since 2010.

The risk of collisions from runway incursions has been on the TSB Watchlist since its inception in 2010. The Watchlist calls for effective defences tailored to address identified hazards at airports and in aircraft, vehicles, and air traffic service facilities across Canada.

Following the occurrence, the TSB issued Aviation Safety Advisory A20O0029-D1-A1 to highlight the importance of accurate flight status data being validated and transmitted by transponders and how this data is received, validated, and used by runway monitoring and conflict alert systems to ensure maximum safety benefit.

Joint air/marine transportation safety investigation into an aircraft and water taxi collision

The TSB conducted a joint air/marine transportation safety investigation (A21P0111/M21P0290) into the October 2021 collision between a float-equipped de Havilland DHC-2 MK. I (Beaver) aircraft and a water taxi (Rocky Pass) in the vicinity of the First Street dock in the harbour at Tofino, British Columbia. The aircraft was substantially damaged and came to rest inverted with just the floats above the surface of the water. The five passengers and pilot on board the aircraft were able to egress safely. Three of the aircraft passengers received minor injuries. The vessel sustained minor damage and one passenger on it received minor injuries. The emergency locator transmitter on the aircraft did not transmit a signal.

The investigation found that the visual perception of both the aircraft pilot and the vessel operator was affected by several factors leading up to the collision, including

- the aircraft’s lowered left wing during the turn to final, coupled with the pilot’s seating position, interfered with the pilot’s view out the left-side window;

- the Rocky Pass’s entry into the harbour, which was unexpected in an otherwise clear area;

- the pilot’s attention, which was primarily focused straight ahead, combined with the little or no relative movement of the vessel in the left windscreen and the obstructions caused by the aircraft’s nose and left window post; and

- the speed at which the vessel was travelling and the relatively stationary position of the aircraft in the vessel operator’s peripheral vision.

As a result, neither the aircraft pilot nor the vessel operator recognized that their routes would conflict until it was too late for evasive action to be effective.

Framework for routine review of and improvement to Transport Canada’s guidelines for civil aviation medical examiners

As a result of its investigation into the fatal collision with terrain of a privately registered, amateur-built Cavalier SA102.5 aircraft near Lacombe Aerodrome, Alberta (A21W0089), the Board issued a recommendation to TC aimed at improving the guidelines for civil aviation medical examiners. The investigation report concluded that cardiovascular disease was a contributing factor to the pilot’s death; however, it could not be determined whether this resulted in an in-flight incapacitation or his death before or after the collision with terrain.

Since 2000, the TSB has investigated eight accidents, including this one, involving commercial pilots in which cardiovascular disease was identified as a finding as to risk or finding as to cause.

At March 2023, there was no framework in place at TC to routinely review the guidance document for medical examiners to ensure it contains the most effective screening tools for assessing medical conditions. Therefore, the Board recommended that the Department of Transport establish a framework for routine review and improvement to the Handbook for Civil Aviation Medical Examiners to ensure it contains the most effective screening tools for assessing medical conditions such as cardiovascular health issues (TSB Recommendation A23-01).

Following the occurrence, the Board issued Air Transportation Safety Advisory Letter A21W0089-D2-A1 (referenced below) to TC in January 2023 concerning physicians’ requirement to report to TC.

Safety advisories and safety information letters

The TSB issued one air transportation safety advisory letter as part of its investigations in 2022–23.

Physicians’ requirement to report to Transport Canada

As part of Air Transportation Safety Investigation A21W0089, the TSB issued Air Transportation Safety Advisory Letter A21W0089-D2-A1 to TC.

The investigation into this occurrence revealed that the pilot had been prescribed medications that may have affected his cardiovascular health and, therefore, could have affected flight safety. The family physician was not aware of the requirement under the Aeronautics Act to provide such information to TC; therefore, neither the medications nor the condition for which they were prescribed were reported. The pilot also did not report either the condition or the medications. The safety advisory letter encouraged the TC Civil Aviation Medical Branch, in cooperation with the Canadian Medical Association, to develop communication strategies to increase the awareness of the reporting requirements for physicians.

Progress on outstanding recommendations

Of the 30 responses to air transportation safety recommendations the Board assessed in 2022–23, five were closed. Of the five closed recommendations, three were closed after being rated Fully Satisfactory, and the other two were closed Satisfactory in Part. The remaining 25 recommendations obtained the following ratings: Satisfactory Intent (11), Satisfactory in Part (10), and Unable to Assess (four). No responses were assessed as Unsatisfactory.

This year, the responses to three recommendations issued as a result of the Swissair investigation (A98H0003) were assessed as Fully Satisfactory and closed:

- Recommendation A00-19 related to deficiencies regarding in-flight odour/smoke checklists. In the time since this recommendation was issued, many actions have been taken by TC and industry that the Board believes will substantially reduce the safety deficiency identified. These changes in industry, which are reflected in emergency checklists that use the voluntary guidelines developed in 2005, should assist flight crews in optimizing their response to conditions of smoke, fire, or fume events of unknown origin, and thus reduce the risk of an in-flight fire being ignited or sustained.

- Recommendation A01-03 related to material flammability test requirements for aircraft wiring. In the time since this recommendation was issued, a number of actions have been taken by TC and the United States Federal Aviation Administration to address the safety deficiency identified in this recommendation regarding mandating a certification test regime that evaluates aircraft electrical wire failure characteristics under realistic operating conditions and against specified performance criteria, with the goal of mitigating the risk of ignition. The Board believes these actions have been effective in addressing the risks identified in the recommendation. Similar actions have been adopted by the European Union Aviation Safety Agency.

- Recommendation A01-04 related to evaluating all aircraft systems in the pressurized portion of an aircraft to ensure that systems whose failure could exacerbate a fire in progress are designed to mitigate the risk of fire-induced failures. Many regulatory and industry actions have been taken over the years that have addressed the safety deficiencies identified in this and other recommendations issued as a result of the Swissair investigation. The Board believes these actions have been effective in addressing the risks identified in the recommendation. Similar actions have been adopted by the European Union Aviation Safety Agency.

As part of Air Transportation Safety Issue Investigation A17O0038, the Board issued Recommendation A18-07 to the Greater Toronto Airports Authority in January 2019. It was recommended that physical changes be made to the taxiway layout at Toronto/Lester B. Pearson International Airport to address the risk of incursions between the closely spaced parallel runways known as the south complex and that further improvements be made in the meantime to increase the conspicuity of the runway holding positions. An operational trial of angled hold position installations on two taxiways was launched in April 2021, and by February 2023, approximately 29 000 aircraft had used the new hold positions with no runway incursions. This, plus the proposed expansion of the trial to three additional taxiways, was encouraging and showed meaningful progress. However, until the trial has concluded and the results are assessed, there remains a residual risk for runway incursions on taxiways that adjoin the south complex runways. Therefore, the Board considers the response to Recommendation A18-07 to show Satisfactory Intent.

The issue of runway overruns is on the TSB Watchlist 2022 and is the subject of Recommendation A07-06, which was issued as a result of Air Transportation Safety Investigation A05H0002. The Board is encouraged to see that activity to meet the International Civil Aviation Organization’s (ICAO’s) 150 m runway end safety area (RESA) standard has begun at some airports, and that others have already implemented ICAO’s 300 m RESA recommendation. However, the Board is not convinced that the residual risk at airports with runways not required to comply with ICAO’s standard is as low as reasonably practicable. Additionally, the Board believes that TC should require operators of airports with runways longer than 1800 m that have a RESA shorter than ICAO’s recommended length of 300 m to conduct formal runway-specific risk assessments and to take action to mitigate the risks of overruns to the public, property, and the environment. The Board is of the opinion that, despite the actions taken to date, the safety risks associated with this recommendation remain. Therefore, the Board considers the response to Recommendation A07-06 to be Satisfactory in Part.

Recommendation A16-12, one of 14 recommendations issued as a result of Air Transportation Safety Investigation A13H0001, recommends that TC require all commercial aviation operators in Canada to implement a formal safety management system (SMS). The issue of safety management has been on the Watchlist since 2010. As highlighted in the most recent Watchlist, released in 2022, progress has been slow to extend the application of SMS beyond CARs Subpart 705 operators. While the Board is encouraged that TC is conducting a policy review that will assist in developing recommendations to modernize and expand SMS requirements, until this review is complete and changes are implemented to the requirements, it is unclear whether these efforts will address the safety deficiency identified in the recommendation. Therefore, the Board considers the response to Recommendation A16-12 to be Satisfactory in Part.

For all active recommendations, the TSB will continue to monitor the progress of planned actions and call for action to reduce or eliminate these deficiencies.

Marine transportation safety

The year in review

The TSB received 1209 reports of marine transportation occurrences in 2022 (241 accidents and 968 incidents), including seven fatalities.

Figure 5. Data table

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Reported accidents | 290 | 271 | 264 | 220 | 241 |

| Reported incidents (mandatory) | 931 | 945 | 925 | 856 | 968 |

| Fatalities | 22 | 17 | 18 | 11 | 7 |

The total of 241 marine transportation accidents represents an increase from the 220 accidents in 2021 but is lower than the 10-year average of 276. In 2022, 82% of accidents were shipping accidents (when a ship, for example, sinks, founders, or capsizes), the same as the previous 10-year average (82%). The remaining 18% of accidents in 2022 were aboard a ship (when a person is killed or seriously injured when, for example, boarding a ship or by falling overboard), also the same as the previous 10-year average (18%).

There were seven marine transportation fatalities in 2022, fewer than the 11 in 2021 and lower than the 10-year average of 15. Of the 7 fatalities, 2 involved shipping accidents. Over the previous 10 years, fatalities were fairly evenly divided between shipping accidents and accidents aboard ship.

As in previous years, the highest proportion of the fatalities (three of the seven) was related to commercial fishing (Canadian-flag vessels in Canadian waters). Due to this continuing trend, commercial fishing safety remains a key safety issue on the TSB Watchlist.

There were 229 vessels involved in the 197 shipping accidents that took place in 2022. In 2021, 200 vessels were involved in 177 shipping accidents. The increase was observed in all regions.

The 968 marine transportation incidents reported to the TSB in 2022 represent a 13% increase from 2021 and a 25% increase from the 10-year average of 776. As in previous years, most reportable incidents (82%) were related to the total failure of machinery or technical systems. The increase in incidents of this type is due largely to changes made in 2014 to TSB reporting requirements.

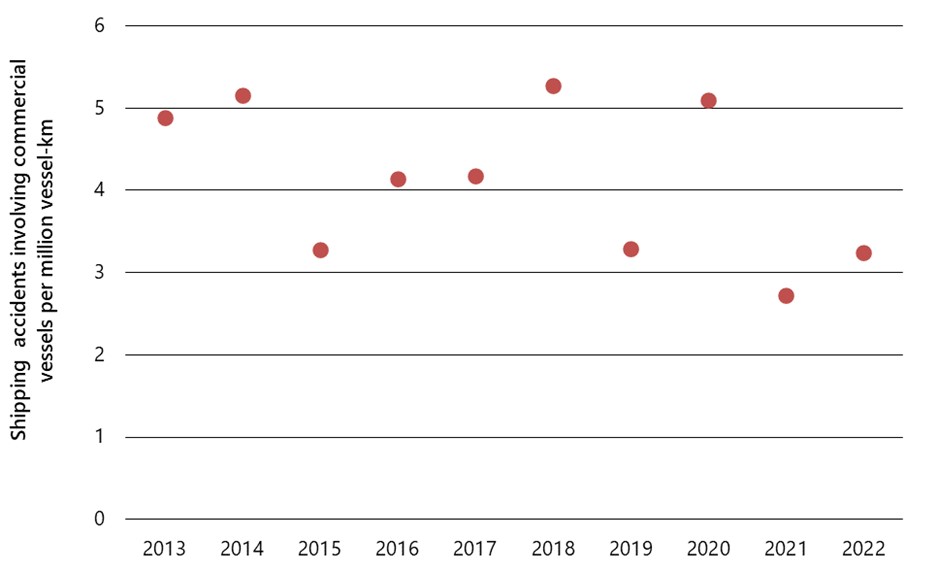

Accident rate: A measure of marine transportation safety

According to TC, 2022 marine activity (commercial vessel-kilometres) for Canadian commercial non-fishing vessels with a gross tonnage of over 15 (excluding passenger vessels and cruise ships) was 10% above the 2013-to-2021 average. The 2022 accident rate was 3.0 accidents per million commercial vessel-kilometres, lower than the 2013-to-2021 average of 4.0.

Figure 6. Data table

| Year | Shipping accident rate |

|---|---|

| 2013 | 4.9 |

| 2014 | 5.2 |

| 2015 | 3.3 |

| 2016 | 4.1 |

| 2017 | 4.2 |

| 2018 | 5.3 |

| 2019 | 3.3 |

| 2020 | 5.1 |

| 2021 | 2.7 |

| 2022 | 3.2 |

Investigations

In 2022–23, TSB staff deployed to 12 marine transportation occurrences (five more than in 2021–22), began nine investigations, and completed 10 (Table 10).

| Activities | 2021–22 | 2022–23 |

|---|---|---|

| Deployments | 7 | 12 |

| Investigations started | 9 | 9 |

| Investigations completed | 8 | 10 |

| Investigations in progress on 31 March of each year | 18 | 17 |

| Class (investigation type) | Completed investigations | Completion target (days) | Average duration (days) | ||

|---|---|---|---|---|---|

| 2021–22 | 2022–23 | 2021–22 | 2022–23 | ||

| 1 (safety issue) | 0 | 0 | 730 | n/a | n/a |

| 2 (complex) | 1 | 1 | 600 | 1001 | 1208 |

| 3 (detailed) | 6 | 7 | 450 | 771 | 791 |

| 4 (limited scope) | 1 | 2 | 220 | 234 | 345 |

Industry-wide surveillance issue related to written safety procedures

Following its investigation into the fatal 2020 sinking of the fishing vessel Chief William Saulis (M20A0434) near Digby, Nova Scotia, the TSB issued a recommendation to the Department of Transport to ensure that each inspection of a commercial fishing vessel verifies that each required written safety procedure is available to the crew and that the crew are knowledgeable of these procedures (M23-05). Both the Canada Shipping Act, 2001 and the Fishing Vessel Safety Regulations require a vessel’s authorized representative to provide written safety procedures that familiarize vessel crews with operational and emergency activities. While the vessel owner had provided a manual for vessel operations and safety, most of the safety procedures were based on templates provided by TC. The investigation found that these templates did not include all procedures required by regulation.

As seen with the Chief William Saulis, many company manuals may be incomplete if based mostly on these TC templates. Without TC oversight to validate that the written procedures required by regulation on board fishing vessels have been developed and that crew are knowledgeable of their content, there is a risk that fishing operations will continue without guidance critical to support the safety of the crew and the vessel.

The TSB has been monitoring commercial fishing safety since 1999, and this issue has been on the TSB Watchlist since 2010. Every year, the same safety deficiencies on board fishing vessels continue to put at risk the lives of thousands of Canadian commercial fish harvesters and the livelihoods of their families and communities.

The issue of fatigue management has been on the TSB Watchlist for rail transportation since 2016 and was expanded in 2018 to include air and marine operations.

A lack of timely and effective regulatory surveillance to ensure operators in all modes are compliant is an issue on the TSB Watchlist.

Safety management is an issue on the TSB Watchlist and is a concern in the air, marine, and rail transportation modes.

The ongoing lack of regulatory oversight means that fishing crews are routinely operating on vessels without even knowing how to stay safe or how to respond when things go wrong.

This occurrence raised concerns around four systemic safety issues identified on the TSB Watchlist: regulatory surveillance, commercial fishing safety, fatigue management, and safety management.

Enhancing the safety of tugs of 15 gross tonnage or less

Following its investigation into the fatal 2021 sinking of the tug Ingenika in the Gardner Canal, British Columbia (M21P0030), the TSB issued four recommendations aimed at enhancing the safety of tugs of 15 gross tonnage (GT) or less.

Currently, TC does not certify tugs of 15 GT or less, nor are these vessels required to undergo regular inspections. There were no records to indicate that TC had inspected the Ingenika at any point during its 50 years of operation.

Numerous TSB investigations have found that while vessel owners and operators have the primary responsibility to manage safety, it is vital that TC provide effective oversight. Although the TSB issued a safety concern to TC in 2016, the issue of regulatory surveillance for tugs of 15 GT or less persists and investigation findings continue to show that without adequate surveillance by the regulator, shortcomings in the safety management and operations of such tugs will continue to go unaddressed, leading to more accidents.

The TSB has also noted that there is currently no requirement for towing companies to assess any of the risks that might be present in their operations. This means that risks in towing operations will continue to go undetected and unmitigated, placing crews, tugs, tows, and the environment at risk.

Therefore, the Board recommended that the Department of Transport

- expand its surveillance program to include regular inspections of tugs of 15 GT or less to verify that these vessels are complying with regulatory requirements (M23-01); and

- require authorized representatives of tugs of 15 GT or less to assess the risks present in their operations, including the suitability of their tugs for the specific towing operations they are undertaking (M23-02).

At the time of the occurrence, the Ingenika was operating in a compulsory pilotage area that falls under the responsibility of the Pacific Pilotage Authority, which is mandated to establish, operate, maintain, and administer safe and efficient pilotage services in British Columbia.

The Pacific Pilotage Authority has a system under which vessels may obtain pilotage waivers that exempt them from having to take a licensed pilot on board if the operators and vessels meet certain requirements. However, it does not verify that the information submitted meets regulatory requirements, which leads to an increased risk that non-compliance will go undetected and compromise safety in compulsory pilotage waters.

The TSB identified similar issues regarding the Pacific Pilotage Authority’s pilotage waiver process in occurrences involving the Ocean Monarch (M17P0244) in 2017 and the Nathan E. Stewart (M16P0378) in 2016.

Therefore, the Board recommended that the Pacific Pilotage Authority

- verify that eligibility requirements are met before issuing pilotage waivers to companies operating tugs in compulsory pilotage areas (M23-03); and

- implement a process to verify ongoing compliance with waiver conditions by companies operating tugs in compulsory pilotage areas (M23-04).

Improving coordination between federal departments to improve the safety of commercial fishing in Canada

As a result of its investigation into the fatal 2020 sinking of the fishing vessel Sarah Anne in Placentia Bay, Newfoundland and Labrador (M20A0160), the TSB recommended that the Department of Fisheries and Oceans require all commercial fishing vessels to have a current and accurate TC registration (M22-01). Vessel registration gives TC the opportunity to provide safety oversight and guidance to fishing vessel owners. This recommendation is meant to push for improved coordination between the two primary federal departments that interact with the commercial fishing sector. Their combined efforts can work to increase the awareness and compliance with safety requirements among all commercial fish harvesters.

This investigation highlighted a number of systemic factors that were identified by the TSB’s 2009–2012 safety issues investigation into fishing safety in Canada (M09Z0001). These include vessel modifications and their impact on stability; the lack of, or failure to use, lifesaving equipment, such as personal flotation devices (PFDs), immersion suits, and emergency signaling devices; and inadequate regulatory oversight.

The investigation found that the vessel likely capsized suddenly, resulting in all crew members entering the water unexpectedly, before they had the chance to put on lifejackets, personal flotation devices or immersion suits, deploy the life raft, or make a distress call. Without critical pieces of lifesaving equipment, the crew would have remained in the cold water, likely unassisted, and drowned. Also, the Sarah Anne did not have a formal stability assessment, and there was no information available regarding its stability. Without this critical information, the crew made operating decisions without knowing the vessel’s actual safe operating limits. This may have negatively affected the vessel’s stability and led to it capsizing and sinking. The voyage of the Sarah Anne was not actively monitored by any external system and no distress signal was received. This resulted in a delay of several hours in the search and rescue response, severely reducing the crew’s chances of survival.

Regulators, vessel owners, and fish harvesters each must take ownership of safety to reduce accidents and preventable loss of life. Vessel owners can have their vessels assessed for stability, and equip them with the proper lifesaving equipment to survive a sudden capsizing. Crew members aboard fishing vessels can greatly increase their likelihood of survival by carrying a personal locator beacon, to signal for help to get out of the water as soon as possible, and by wearing a PFD to remain afloat until help arrives.

Safety advisories and safety information letters

The TSB issued three marine transportation safety advisories and information letters as part of its investigations in 2022–23.

Safety during docking and undocking operations

As part of Marine Transportation Safety Investigation M22C0005 into the fatal injury of a crew member on the Canadian-flagged roll-on/roll-off ferry Madeleine II in the Cap-aux-Meules harbour, Québec, the TSB issued Marine Transportation Safety Advisory Letter 03/22 to TC in October 2022. The letter identified that according to statistics from the TSB database, from January 2017 to March 2022, 13 occurrences (including the Madeleine II) were reported in Canada on Canadian- and foreign-flagged vessels. As a result of these occurrences, 12 people were seriously injured and two people were fatally injured.

The letter went on to explain that one of the main risks present during mooring operations is snap-back, which is the sudden release of built-up energy in a mooring line under tension. A common practice to mitigate this risk is to paint snap-back zones on the deck at mooring stations. The latest version of the UK Maritime & Coastguard Agency’s Code of Safe Working Practices for Merchant Seafarers now recommends considering the entire mooring deck be considered a snap-back zone and that clear and visible signage be posted to alert the crew. TC was provided this information for whatever follow-up action was deemed appropriate.

Safety issues on passenger vessels owned by the City of Toronto

The TSB conducted Marine Transportation Safety Investigation M22C0231 into the passenger ferry Sam McBride striking the dock while berthing at the Jack Layton Ferry Terminal in Toronto, Ontario. As part of the investigation, the TSB issued Marine Transportation Safety Advisory Letter 02/22 to the City of Toronto. Important safety issues were identified, relating to emergency preparedness, passenger safety management, and lifesaving equipment on one or more vessels operated by the city. For example, pre-departure safety briefings were not being consistently provided to passengers, the vessel’s crew complement for the maximum number of passengers did not allow tasks set out on the evacuation plan and muster list to be completed simultaneously, and passengers were counted using a hand-held tally counter. Furthermore, children, infants, and other passengers who may require extra assistance were not counted separately, and no infant lifejackets were on board.

The safety issues identified in this letter were communicated before the investigation was complete to ensure that those best able to take remedial action and effect change were made aware of the identified safety issues in a timely manner. Resulting from the communication of these safety issues, the City of Toronto’s website was updated to encourage caregivers to bring lifejackets for infants weighing less than 15 kg.

Failure of personal flotation devices to inflate

The TSB conducted Marine Transportation Safety Investigation M22A0332 into a fatality involving the pilot vessel APA No. 18 near St. John’s, Newfoundland and Labrador. A deckhand wearing an auto-inflating personal floatation device (PFD) fell overboard, but the device did not actually inflate. TSB laboratory inspection revealed that the inflator cap and body of the PFD were not mated, causing it to not be sealed and thus not inflate.

As a result, the TSB issued Marine Transportation Safety Advisory Letter 01/23 to the Atlantic Pilotage Authority in February 2023. The letter referred to TC’s Ship Safety Bulletin 12/2019, which highlighted the need to inspect and service inflatable lifejackets regularly and according to the manufacturer’s instructions.

Progress on outstanding recommendations

Of the 18 responses to marine transportation safety recommendations the Board assessed in 2022–23, none were closed, and no recommendations received a rating of Fully Satisfactory. The responses assessed were rated as Satisfactory Intent (six), Satisfactory in Part (nine), and Unsatisfactory (three).

In Recommendation M99-02, issued in November 1999, the Board recommended that the provinces review their workplace legislation with a view to presenting it in a manner that will be readily understood by those to whom it applies, and to help ensure that the enforcement mechanism and the regulatory regime complement each other. By 2021–22, all but two provinces had submitted responses that were assessed as Fully Satisfactory. In 2022–23, the Province of New Brunswick’s response was assessed as Fully Satisfactory with the passing of the bill An Act Respecting the Health and Safety of Fishers. This leaves the Province of Ontario, which continues to conduct consultations with stakeholders and partners to ensure that employers of the commercial fishing sector understand health and safety requirements but still does not have occupational health and safety regulations or guidance in place that is specific to the fishing sector. The Province of Ontario’s response was therefore assessed as being Satisfactory in Part.

For all active recommendations, the TSB will continue to monitor the progress of planned actions and call for action to reduce or eliminate these deficiencies.

Pipeline transportation safety

The year in review

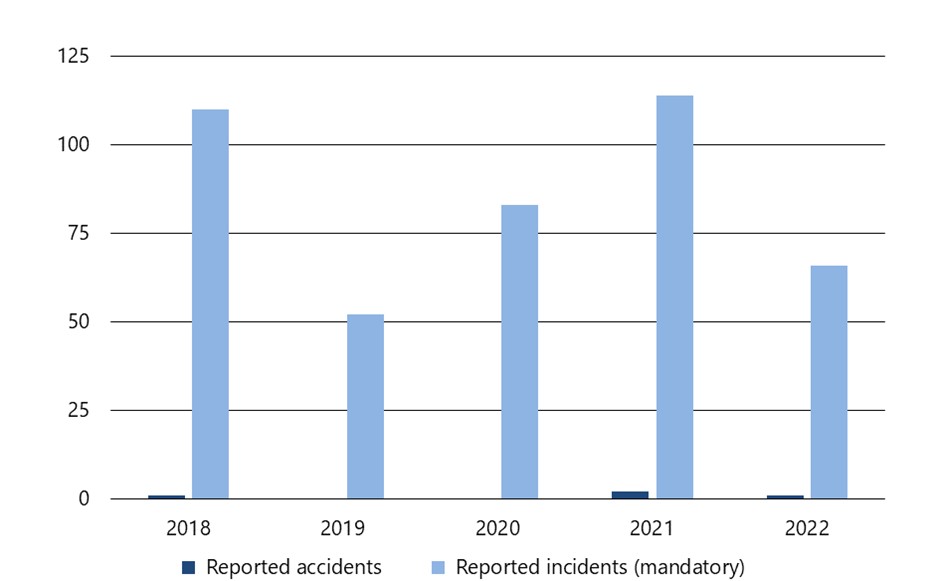

The TSB received 67 reports of pipeline transportation occurrences in 2022–23, of which 66 were incidents and one was an accident. There were no fatalities arising directly from the operation of any federally regulated pipeline, as has been the case since the TSB’s inception in 1990.

Figure 7. Data table

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Reported accidents | 1 | 0 | 0 | 2 | 1 |

| Reported incidents (mandatory) | 110 | 52 | 83 | 114 | 66 |

| Fatalities | 0 | 0 | 0 | 0 | 0 |

This number of occurrences in 2022 (67) is 42% below the number reported in 2021 (116) and 40% below the average of 112 for the previous 10 years. The one accident in 2022 represented a decline from the two in 2021 and is also below the average of three accidents per year over the previous decade. Changes that were introduced in 2014 to the occurrence reporting criteria continue to distinguish more recent years from the years prior to the change.

Of the 67 occurrences in 2022, 25 involved a release of product:

- This was the highest number of occurrences with product release since 2018 (41), but lower than any of the years from 2012 to 2017.

- These occurrences represent 37% of those reported in 2022, and 57% below the 10-year average.

- The majority of these occurrences involved a release of hydrocarbon gas (60%), as has been the case each year since 2015.

- Seven occurrences involved the release of low vapour pressure hydrocarbons, namely crude oil; this was the highest number of such releases since 2014.

The TSB’s Statistical Summary: Pipeline Transportation Occurrences in 2022 contains more information on product releases during the year.

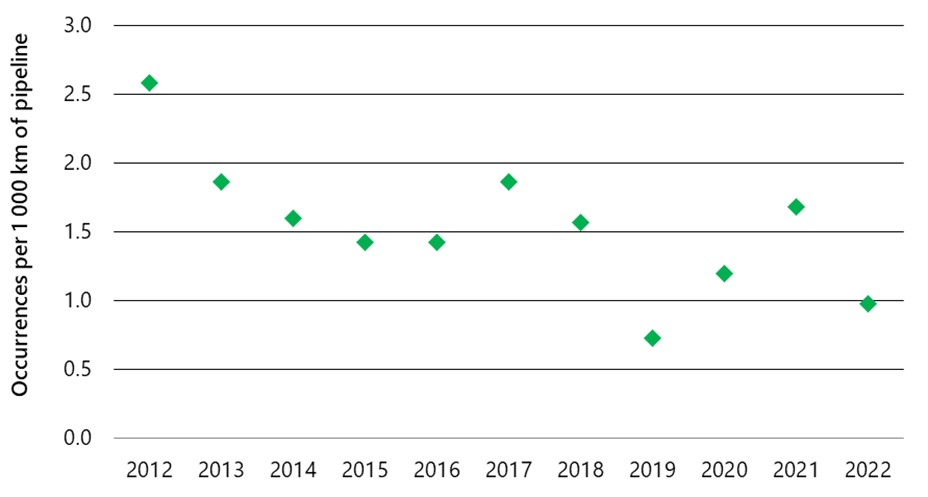

In 2022, 14 occurrences involved geotechnical, hydrotechnical or environmental activity—slope movements or river erosion, for example—roughly one-quarter the number reported in 2021, and slightly below the average of 17 such events per year over the previous 10 years. There were 13 reports of pipelines being contacted by an object in 2022 compared with the average of eight reports per year during the previous 10 years; there were also six occurrences with unauthorized third-party activity, compared with a 10-year average of three per year.Occurrence rate: A measure of pipeline transportation safety

There were 68 700 km of federally regulated pipeline operating in Canada in 2022, according to the Canada Energy Regulator. The 67 pipeline transportation occurrences reported to the TSB for the year resulted in a rate of 1 occurrence per 1000 km of operating pipeline. This is below the 2021 rate of 1.7 and the average rate of 1.6 from 2012 to 2021.

Figure 8. Data table

| Year | Occurrences per 1000 km |

|---|---|

| 2012 | 2.6 |

| 2013 | 1.9 |

| 2014 | 1.6 |

| 2015 | 1.4 |

| 2016 | 1.4 |

| 2017 | 1.9 |

| 2018 | 1.6 |

| 2019 | 0.7 |

| 2020 | 1.2 |

| 2021 | 1.7 |

| 2022 | 1.0 |

Investigations

TSB staff deployed to one pipeline transportation occurrence in 2022–23 and began one investigation (Table 12).

| Activities | 2021–22 | 2022-23 |

|---|---|---|

| Deployments | 1 | 1 |

| Investigations started | 1 | 1 |

| Investigations completed | 1 | 1 |

| Investigations in progress on 31 March of each year | 1 | 1 |

The TSB completed one pipeline investigation in 2022–23, a detailed class 3 investigation that took 527 days (Table 13).

| Class (investigation type) | Completed Investigations | Completion target (days) | Average duration (days) | ||

|---|---|---|---|---|---|

| 2021–22 | 2022–23 | 2021–22 | 2022–23 | ||

| 1 (safety issue) | 0 | 0 | 730 | n/a | n/a |

| 2 (complex) | 0 | 0 | 600 | n/a | n/a |

| 3 (detailed) | 0 | 1 | 450 | n/a | 527 |

| 4 (limited scope) | 1 | 0 | 220 | 304 | n/a |

Natural gas pipeline rupture

The TSB released one pipeline transportation safety investigation report in 2022–23, concerning the 2021 rupture of a natural gas pipeline near McAuley, Manitoba (P21H0143).

The Minell pipeline, a 6-inch natural gas pipeline operated by Manitoba Hydro, was struck by a farm tractor blade as it was scraping the ground in an agricultural field. The pipeline ruptured and released approximately 84 000 m³ of natural gas.

The investigation found that the depth of ground cover over the pipeline at the occurrence location was insufficient to prevent the ground-scraping blade from contacting the pipeline. Over time, the removal of weeds and silt from the drainage ditch gradually reduced the depth of cover over the pipeline. This was not identified by Manitoba Hydro’s damage prevention program, and, as a result, the pipeline kept operating with reduced ground cover.

The investigation analyzed the response time from when the rupture took place until the ruptured section of the pipeline was isolated. The rupture occurred near TC Energy’s Moosomin compressor station, which supplies the Minell pipeline. However, Manitoba Hydro’s procedures at the time of the occurrence did not identify TC Energy as a possible resource in the response to an occurrence, and the flow of gas continued into the ruptured section of pipeline until Manitoba Hydro was able to isolate it, 106 minutes after the rupture was suspected.

Following the occurrence, the TSB issued Pipeline Transportation Safety Advisory Letter 01/22 to Manitoba Hydro and indicated that pipeline operators need to be aware of the depth of cover over their pipelines to ensure they are adequately protected against normal agricultural activities that do not require explicit authorization. Manitoba Hydro completed a depth of cover survey for the entire Minell pipeline, in response to an order issued by the Canada Energy Regulator with respect to the occurrence. Ten locations were found to have cover less than 0.65 m, and these were staked and/or barricaded. The company also met with the affected landowners and provided written notifications in November 2021 prohibiting agricultural work, vehicle crossings, and other ground disturbance activities in these locations.

Safety advisories and safety information letters

The TSB did not issue any pipeline transportation safety advisories or safety information letters as part of an investigation in 2022–23.

Progress on outstanding recommendations

The Board did not issue any pipeline transportation safety recommendations in 2022–23 and had previously assessed all responses to pipeline transportation safety recommendations as Fully Satisfactory.

Rail transportation safety

The year in review

The TSB received 1376 reports of rail transportation occurrences in 2022 (995 accidents and 381 incidents), including 66 fatalities.

Figure 9. Data table

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Reported accidents | 1167 | 1214 | 942 | 898 | 995 |

| Reported incidents (mandatory) | 287 | 285 | 275 | 337 | 381 |

| Fatalities | 57 | 72 | 60 | 60 | 66 |

The 995 accidents represent an 11% increase from 2021 (898), but a 5% decrease from the 10-year average of 1043.

The 66 rail transportation-related fatalities reported in 2022 are up compared to 60 in 2021 but below the 10 year average of 70. Among the fatalities, 52 involved trespassers, compared to 41 in 2021 and the 10-year average of 40. There were no railway employee fatalities in 2022.

The number of crossing accident fatalities decreased in 2022 (14) compared to 2021 (17) and is lower than the 10-year average of 22.

Among all rail transportation accidents, 111 involved dangerous goods. This is up from 86 in 2021 but is lower than the 10-year average of 121. Two accidents in 2022 resulted in dangerous goods being released.

There were 381 rail transportation incidents reported to the TSB in 2022, a 13% increase from 2021 (337). Incidents involving movements that exceeded limits of authority accounted for 35% (134) of all rail transportation incidents in 2022, 25 more than in 2021 and above the 10-year average of 128.

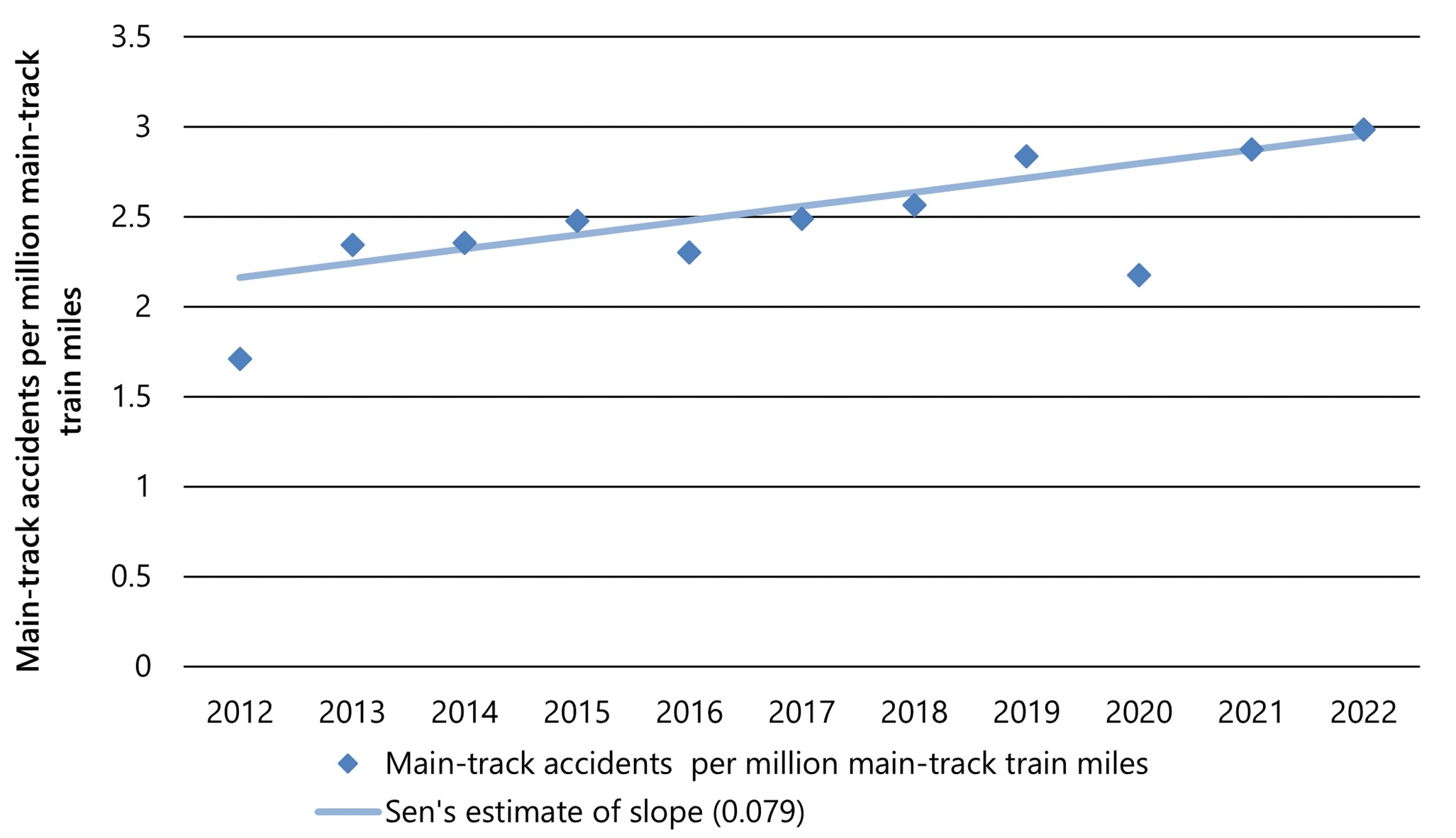

Accident rate: A measure of rail transportation safety

According to TC data, 2022 main-track (non-yard) rail activity increased by 2% from 2021. The main-track accident rate in 2022 was 3 accidents per million main-track train-miles, up from 2.9 in 2021 and above the 10-year average of 2.4.

Figure 10. Data table

| 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Main-track accidents per million main-track train miles | 1.7 | 2.3 | 2.4 | 2.5 | 2.3 | 2.5 | 2.6 | 2.8 | 2.2 | 2.9 | 3.0 |

| Sen's estimate of slope (0.079) | 2.16 | 2.24 | 2.32 | 2.40 | 2.48 | 2.56 | 2.64 | 2.72 | 2.79 | 2.87 | 2.95 |

Investigations

TSB staff deployed to eight rail transportation occurrences in 2022–23, three fewer than in 2021–22, and began six investigations (Table 14).

| Activities | 2021–22 | 2022-23 |

|---|---|---|

| Deployments | 11 | 8 |

| Investigations started | 8 | 6 |

| Investigations completed | 9 | 9 |

| Investigations in progress on 31 March of each year | 19 | 16 |

| Class (investigation type) | Completed investigations | Completion target (days) | Average duration (days) | ||

|---|---|---|---|---|---|

| 2021–22 | 2022–23 | 2021–22 | 2022–23 | ||

| 1 (safety issue) | 0 | 0 | 730 | n/a | n/a |

| 2 (complex) | 1 | 4 | 600 | 1151 | 1161 |

| 3 (detailed) | 3 | 3 | 450 | 658 | 759 |

| 4 (limited scope) | 5 | 2 | 220 | 299 | 398 |

Automated train control systems and formal crew resource management training

As a result of its investigation into the 2019 collision of two Canadian National Railway Company (CN) freight trains near Portage la Prairie, Manitoba (R19W0002), the Board issued two recommendations to TC regarding the implementation of physical fail-safe train control systems and formal crew resource management training for railway operating employees.

First, the Board recommended that TC require all major Canadian railways to expedite the implementation of physical fail-safe train controls on Canada’s high-speed rail corridors and on all key routes (R22-04). The United States has fully implemented a positive train control system on all high-hazard track required by its federal legislation. This includes the United States operations of both CN and Canadian Pacific Kansas City Railway Company (CPKC), which have invested significantly in their locomotive fleets and infrastructure. This accident highlighted major issues in the rail industry and reinforced the TSB’s call for physical fail-safe train controls for over two decades through recommendations R13-01 and R00-04. The railway industry must act more quickly to implement a similar form of automated or enhanced train control system on Canada’s key routes to improve rail safety and avoid future rail disasters.

Second, the Board recommended that TC require Canadian railways to develop and implement formal crew resource management as part of the qualification training for railway operating employees (R22-05). This type of training could provide additional tools and strategies to train crews to mitigate inevitable human errors, and provide significant safety benefits in the rail industry.

The issue of following railway signal indications has been on the TSB Watchlist since 2012. If railway signals are not consistently recognized or followed, there is a risk of train collisions or derailments that can have catastrophic consequences.

The issue of fatigue management in freight train operations has been on the TSB Watchlist since 2016.

The issues identified in this investigation also highlighted two recurring TSB Watchlist issues: following railway signal indications and fatigue management.

Following this occurrence, CN distributed a system notice throughout its Canadian operations warning train crews that there was an increase in occurrences where crews failed to stop at signal indications requiring them to do so, primarily due to a lack of focus on situational awareness.

Failure of a misaligned rail joint led to the derailment of a crude oil train

In its investigation report, the TSB determined that a recently replaced rail joint failed as a result of a misaligned joint bar, causing the derailment of a crude oil train near St-Lazare, Manitoba, in 2019 (R19W0050).

The misalignment led to a loosening of the joint and initiated fatigue cracking in the joint bars that failed beneath the train as it traversed the area. A total of 17 of the derailed tank cars were breached, which resulted in the release of about 815 000 litres of product. About 1000 feet of track was damaged or destroyed.

The failed joint had been repaired about six weeks prior to the accident. However, during the repair, a compromise joint bar, an offset joint bar used for joining two rails of different sizes that looks similar to a standard joint bar, was inadvertently installed with a standard joint bar. A joint assembled in this manner is unstable, will loosen over time, and can result in premature failure such as in this occurrence.

Following this accident and two additional serious CP crude oil unit train derailments near Guernsey, Saskatchewan (R19W0320 and R20W0025), the TSB issued Rail Safety Advisory Letter 02/20 and Rail Safety Advisory Letter 03/20 to TC . In response, TC issued Ministerial Orders instructing the industry to develop revised Rules Respecting Key Trains and Key Routes and Rules Respecting Track Safety. The rules were subsequently revised and now contain a number of safety improvements related to the operation of key trains and track infrastructure.

Since this accident, CN now requires the outside surface of all compromise joint bars that are exposed when installed in track to be spray-painted royal blue by the supplier. This allows compromise joint bars to be more easily differentiated from standard joint bars.

From 01 March to 31 December 2019, on the Rivers Subdivision, CN eliminated a total of 1019 temporary plug rails (2038 rail joints) and installed 192 867 feet of continuous welded rail.

Board safety concern about Ontario’s safety oversight of its provincially regulated railways

As a result of its investigation into a 2019 accident in which a GO Transit commuter train struck and seriously injured an adult and a child at a public crossing in Kitchener, Ontario (R19T0191), the Board issued a safety concern stating that the Province of Ontario does not provide effective safety oversight of provincially regulated railways.

The investigation was completed by the TSB at the request of the Ministry of Transportation of Ontario (MTO), as provincial railways fall outside of the mandate of the TSB.

Although the MTO is responsible for the safety oversight of provincially regulated railways such as Metrolinx, it has no overall provincial regulatory framework in place and relies on inspection agreements with TC and Metrolinx to aid in complying with the standards set out in federal rules and regulations. Moreover, the MTO does not have employees with technical railway knowledge, experience, and expertise.

While the MTO can outsource inspections to TC, it cannot outsource the responsibility for the safety of rail operations. Therefore, while TC inspectors can identify safety hazards and aid Metrolinx in mitigating the risks, it does not have the authority to compel them to take remedial action.

Despite the clear need for thorough safety oversight, as it is vital in identifying and addressing risks present at crossings, none of the parties involved – CN, Metrolinx, the Region of Waterloo, or the MTO – were aware of the observed hazards that existed at the crossing.

Given the complexity of multiple separate agreements with different parties, this accident demonstrates that there are gaps in the Province of Ontario’s regulatory surveillance of its provincially regulated railways.

In 2021, the TSB issued Rail Safety Advisory Letter 01/21 to TC regarding second-train events at multi-track level-grade crossings that have a high level of pedestrian traffic and experience frequent and extended grade crossing warning device activations. The advisory suggested assessing the likelihood of second-train events and implementing additional safety measures to minimize the risk of accidents.

Following the accident, Metrolinx made several physical safety improvements at the Lancaster Street West crossing, and now requires train operators approaching the crossing to sound the horn if it is occupied by another train.

Since the accident, the MTO identified a need to update the oversight framework for urban and regional rail transit that would better support the province’s growing rail network and the diversity of operators. In January 2022, the MTO updated its agreements with both TC and Metrolinx. In making these updates, the MTO worked closely with TC to strengthen the MTO’s accountability role in the agreement, with respect to Metrolinx, to verify that non-compliances and deficiencies that may arise are appropriately addressed.

Employee fatality at Canadian National Railway Company’s MacMillan Yard caused by a string-line derailment

In April 2022, the TSB released its investigation report into a 2019 derailment at CN’s MacMillan Yard, Vaughan, Ontario, that resulted in the death of a railway yard operating employee (R19T0147). The employee was manoeuvring a remote control locomotive system (RCLS) yard assignment using a beltpack and was stationed on the left side of the leading end of the 27th car of the movement. As the assignment negotiated a 15-degree left-hand curve, the trailing end of the 26th car behind the locomotives string-lined, causing it to derail along with the next eight cars. String-lining is the tendency of a long cut of cars to shortcut a curve when being pulled, a problem that is amplified in a heavier train when handling light cars that are followed by significantly heavier cars. All nine cars that derailed were empty multi-level autorack cars.

The investigation found that, when the trailing end of the 26th car string-lined, the car derailed to the inside of a 15-degree curve. As it derailed, the 26th car pulled sideways on the 27th car, causing cars 27 to 29 to overturn to the inside of the curve, pinning the employee and causing fatal injuries.

A series of train dynamic simulations were conducted in support of the investigation. The results identified that the RCLS programming caused an aggressive throttle response that, in turn, led to a rapid acceleration and run-out of train slack on the long tail-end heavy assignment. It was also determined that, since a lighter cut of autorack cars equipped with hydraulic end-of-car cushioning devices was placed between two heavy cuts, the devices were compressed during the previous deceleration. Therefore, the aggressive acceleration of the assignment likely resulted in a rapid run-out of train slack, which contributed to the string-line derailment. Additionally, it was found that the air brakes likely remained on the 63rd car, which also contributed to the accident.

If railways do not reinforce safe, smooth train handling options for RCLS use during yard operations and provide more specific guidance for identifying conditions that are conducive to string-line events, the risk for a string-line event will remain.

Following the accident, TC completed an investigation under the Canada Labour Code, Part II. CN, for its part, implemented several new processes system-wide, revised instructions for MacMillan Yard, and re-configured a portion of the track in an effort to prevent similar accidents from occurring in the future.

Safety advisories and safety information letters

The TSB issued six rail transportation safety advisories as part of its investigations in 2022–23.

Operational experience of employees paired for remote control locomotive system yard assignments

As part of Rail Transportation Safety Occurrence R22T0060 into a collision between an RCLS yard assignment and a stationary yard assignment in CPKC Railway’s Toronto Yard in Toronto, Ontario, the TSB issued Rail Transportation Safety Advisory Letter 02/22 to TC in July 2022. The letter stated that TC might wish to consider an alternate approach to the pairing of employees to work RCLS yard assignments to ensure that newly qualified employees are mentored by more experienced employees until they gain sufficient expertise to operate safely.

Trespassing on the Canadian Pacific Railway Company’s Outremont spur

As part of Rail Transportation Safety Occurrence R22D0058 into the striking of a pedestrian trespassing on the up track near the Outremont spur in Montréal, Québec, the TSB issued Rail Transportation Safety Advisory Letter 03/22 to TC in August 2022. The letter stated that TC might wish to consider reviewing the risk management measures in place against trespassing on the Outremont spur (monitoring by CP, no trespassing signage, community awareness programs, and a fence repair program) and updating these measures as necessary.

Procedures and guidelines relating to train operations

As part of two rail transportation safety occurrences (R22Q0095 and R22Q0062) into derailments of Quebec North Shore and Labrador Railway (QNS&L) trains with locomotives that were equipped with alternating current traction motors, the TSB issued Rail Transportation Safety Advisory Letter 04/22 in November 2022 to TC. Although the QNS&L general operating instructions contain guidelines for the use of air brakes and warnings about slack action when operating trains, there are currently no specific instructions for the use of dynamic brakes, particularly on AC locomotives. The letter stated that TC might wish to consider reviewing QNS&L’s procedures and guidelines for the use of dynamic braking, especially when operating trains that are equipped with locomotives with alternating current traction motors.

Ongoing failures of cartridge roller bearing assemblies on Ottawa Light Rail Transit vehicles

As part of Rail Transportation Safety Occurrence R22H0037 into the failure of a cartridge roller bearing assembly on an Ottawa Light Rail Transit (OLRT) light rail vehicle (LRV), the TSB issued Rail Transportation Safety Advisory Letter 01/23 in February 2023 to the City of Ottawa. At the time the letter was issued, there had been two serious main-track derailments and a near-catastrophic component failure that all involved OLRT LRV cartridge assemblies. While the materials used to manufacture the cartridge assemblies conformed to the manufacturer’s specifications, the three cartridge assemblies examined by the TSB exhibited numerous types of failures. The observed damage was widely spread throughout the assemblies and was not limited to any one particular component. Furthermore, areas of heat discolouration observed on several components and the condition of some grease samples suggested that the assemblies had been subjected to a higher-than-average heat event that was likely related to a deteriorating cartridge assembly condition that went undetected. The letter stated that the City of Ottawa might wish to ensure that all parties involved in the OLRT work together to resolve design, operational, and maintenance risks to safety, as they emerge. Furthermore, the parties involved should ensure that effective on-board monitoring systems for safety-critical LRV components, such as cartridge roller bearing assemblies, are put in place to protect the travelling public.

Deficient track conditions on Canadian Pacific Railway Company’s Swift Current Subdivision