Main-track train derailment

Canadian National Railway Company

Freight train G89641-05

Mile 34.3, Rivers Subdivision

Near Elie, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

On 05 March 2024 at about 2350 Central Standard Time, Canadian National Railway Company (CN) unit grain train G89641-05 departed the Canwheat loading facility in Bloom, Manitoba,All locations are in the province of Manitoba, unless otherwise indicated. en route for Winnipeg, travelling eastward on the north track of the CN Rivers Subdivision. About 36 minutes later, at 0026 on 06 March, while the train was travelling at 55 mph, a train-initiated emergency application of the train brakes occurred at Mile 34.3, near Elie. After the train came to a stop, the crew conducted an inspection and found that 17 cars had derailed. No cars were breached, but grain had spilled from the top hatches of the overturned cars. No one was injured.

Site examination

A post-derailment on-site examination determined that car NKLX 200817 (position 93) was the first to derail; only its trailing truck had derailed. The L2 wheel on this car was broken (figures 1 and 2). About 90% of the wheel rim and plate was recovered and sent to the wheel manufacturer’s facility for further examination and analysis.

At Mile 34.3, the north rail was broken, indicating the point of derailment. Half a mile of the north track leading up to the broken rail was inspected; there were no signs of impact on the rail head or other track-related issues. The south track was not affected and remained in operation.

Recorded information

On the day of the occurrence, the train passed through an automated equipment inspection portalAutomated equipment inspection portals are wayside systems based on machine vision technology that are used to monitor rolling stock conditions in real time to detect various mechanical defects. at Mile 50.27 of the Rivers Subdivision (about 16 miles west of the derailment location). No defects were identified on the train. After the occurrence, the TSB reviewed the portal images; the L2 wheel of car NKLX 200817 appeared intact at the time of passing the portal.

Manufacturer examination of the broken wheel

The manufacturer examined the recovered fragments from the L2 wheel at its facility, and its findings were reviewed by the investigation.

Below are some key characteristics of the wheel:

- 36-inch diameter, 1-wear cast steel wheel manufactured to meet Association of American Railroads (AAR) Specification M-107/M-208 for Class C freight cars wheels.Association of American Railroads, Manual of Standards and Recommended Practices: Wheels and Axles, Manual G, Specification M-107/M-208: Wheels, Carbon Steel (last revised September 2020).

- Manufactured in November 2022 by the Griffin Wheel Company, in Winnipeg.

- Assembled as part of a wheel set in December 2022 at Progress Rail in Chicago, Illinois.

- In service for approximately 11 900 miles at the time of failure.

The L2 wheel had a dent (plastic deformation) to the back side of the plate, and there was a surface crack on the front side of the plate, directly opposite the dent location.

The dent was about 6 inches away from the wheel centre hub. It was 0.18 inch deep and 1 inch wide. Its length could not be determined because 1 of the wheel fragments adjacent to the dent was not found at the occurrence site.

According to the manufacturer, the dent on the back side of the plate initiated cracking on the front side. The crack then progressed by fatigue, under service loads, through the plate; turned radially through the thinner portion of the plate; and propagated into the rim until the wheel failed during operational loading.

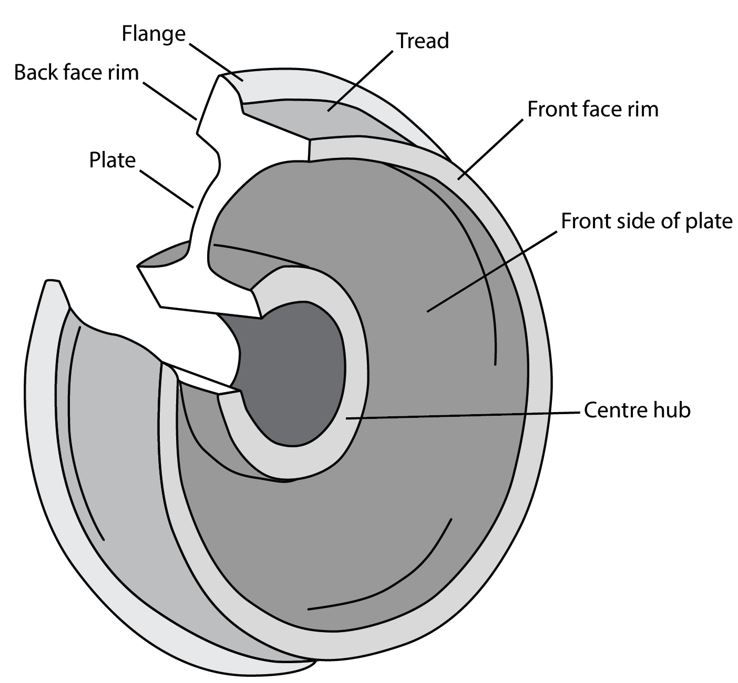

Figure 3 illustrates the various parts of a freight car wheel.

Wheel plate overview

The wheel plate is a critical structural element of a freight car wheel. It is the thinnest section of the wheel.

The wheel plate serves to transmit mechanical and thermal forces from the tread and rim to the axle. While not subjected to direct wheel–rail contact, the plate experiences significant radial and circumferential tensile stresses under normal operating loads, as well as thermal stresses during extended braking.

To maintain performance, the plate must balance robustness and elasticity—sufficiently robust to support deflections caused by loading, yet elastic enough to accommodate rim expansion due to braking without introducing harmful tensile stresses. To improve fatigue resistance, wheel plates are typically shot-peenedShot peening is a cold-working method to resist cracking under fatigue conditions, such as repeated bending. The peening process involves striking the surface to be protected with repeated blows of propelled shots to put the surface under residual compression. (Source: E. P. DeGarmo, Materials and Processes in Manufacturing, MacMillan Publishing Co., 1979).,The procedure, intensity, and coverage requirements of shot peening for the wheel plate are described in detail in Association of American Railroads (AAR) Specification M-107/M-208. during manufacturing to introduce beneficial compressive surface stresses. Wheel plates must also undergo stress analysis during the design phase, in accordance with AAR Specification S-660.Association of American Railroads, Manual of Standards and Recommended Practices: Wheels and Axles, Manual G, Standard S-660: Analytic Evaluation of Locomotive and Freight Car Wheel Designs (last revised 2007).

Because of its location and relative thinness, the wheel plate is vulnerable to damage from handling. Even minor dents or gouges can act as a stress riser under service loads.

Source and timing of the damage to the L2 wheel of car NKLX 200817

It is not possible to determine with certainty when the dent on the back side of the plate of the L2 wheel occurred.

A review of the manufacturer data indicates that the wheel steel met AAR requirements for microcleanliness, steel hardness, and chemical composition stipulated in Specification M-107/M-208. The damage that caused the dent also removed part of a paper label placed on the plate at the time of manufacturing. It can therefore be inferred that the damage occurred after the wheel was manufactured.

The location of the dent makes it unlikely that the damage occurred while installing the wheel set under the car. The apparatus used during installation grips the wheels just below the rim, where the plate begins—well away from the location of the observed dent.

It is therefore most likely that the damage occurred while handling either the wheel or the wheel set after the label was applied to the wheel, before or after installation under the car. During wheel set transport and storage, various equipment is used that comes in contact with the wheels. Similarly, rail cars are sometimes handled at third-party facilities using equipment such as forklifts and tractors that can push against the wheels.

Wheel plate failures initiated by plastic deformation

The industry has gained significant experience with broken wheel failures, and substantial research has been directed at understanding and mitigating them.

However, the specifics of the wheel failure in this occurrence do not align with common wheel failure modes. Further testing is planned by the manufacturer to better understand this failure mode.

Similar damage-induced fractures have been reported to manufacturer in recent years; 5 occurred in the years 2022 to 2024. In each case, the failed wheels exhibited varying degrees of visible damage on the back side of the wheel plate. The damage ranged from surface flattening to pronounced mechanical indentations.

At the time of the occurrence, there was no guidance indicating that impact causing plastic deformation to the plate can lead to fracture, and the potential consequences of such damage may not have been well known to the industry.

There is no requirement to report this type of damage when it occurs.

Rules regarding condemnable defects on wheels

Rule 41 of the Field Manual of the AAR Interchange Rules states that any scrape, dent, or gouge on a wheel—regardless of location, including the plate—is condemnable if the depth of the defect is ⅛-inch or greater.Association of American Railroads, Field Manual of the AAR Interchange Rules (2024), Rule 41: Wheels.

The dent on the L2 wheel exceeded the condemning limit by 44%. However, this area of the wheel is not typically inspected for damage after a wheel set is mounted on a car.

Rules regarding wheel set handling

Rule 44 of the Field Manual of the AAR Interchange Rules addresses wheel set handling. The rule was revised on 01 January 2024 and now states, in part:

When handling wheel sets, care must be taken that handling devices do not damage the wheel set components.Ibid., Rule 44, section E.20: General Requirements.

In previous versions of the manual, this guidance applied only to axles and bearings, rather than to wheel set components more broadly. The change was first announced in Circular Letter C-14247, issued on 02 November 2023, to provide advance notice to the industry.

Association of American Railroads Circular Letter C-14561

On 30 April 2025, the AAR issued Circular Letter C-14561, in which it states that North American railways have experienced several catastrophic wheel failures due to broken plates resulting in derailments. These failures are directly attributed to mechanical or impact damage (from fork truck strikes or other objects hitting the wheel plate), welding arc strikes, welding deposits, or torch cut spatter. This damage may occur during handling and transport of wheels or wheel sets, anywhere along the wheel's lifecycle: from manufacturer, to wheel mount shop, to railway line, to repair shop.

The letter indicates that extreme care must be taken during the handling, transport, loading, and unloading of wheels and wheel sets. If any metal-to-metal contact occurs on the wheel plate between the hub and the rim, the wheel must be identified as scrap.

Safety message

Plastic deformation on the back side of a wheel plate can initiate a crack that propagates, under normal rail car operating conditions, to wheel failure. Since an in-service wheel failure can lead to derailment, it is critical that the railway industry understands the potential consequences of unintentional damage sustained by wheels—particularly to the plate area—and the importance of avoiding contact with the wheels.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 04 June 2025. It was officially released on 29 July 2025.