Pipeline rupture and fire

Westcoast Energy Inc.

Prince George, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 09 October 2018, at about 1725 Pacific Daylight Time,Footnote 1 a 914.4 mm (36-inch) pipeline operated by Enbridge Inc. that was transporting sweet natural gas ruptured about 13 km northeast of Prince George, British Columbia (BC). Following the rupture, the natural gas ignited, resulting in a fire. Some 125 people within a 2 km radius of the occurrence location were evacuated as a precaution. There were no injuries.

1.0 Factual information

1.1 Occurrence location

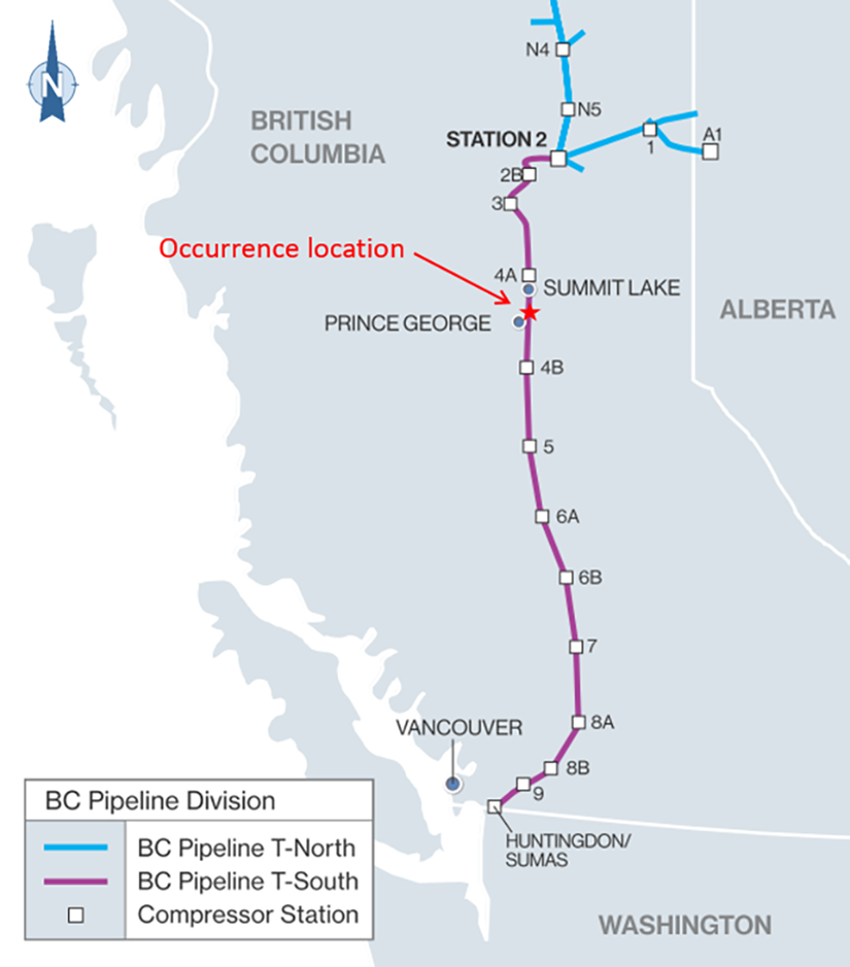

The occurrence took place in hilly, forested provincial Crown land in a remote area about 13 km northeast of Prince George, BC (Figure 1). The nearest private property is 500 to 600 m west of the occurrence location.

1.2 The pipeline network

The Westcoast Energy Inc. (Westcoast) system is an integrated network of natural gas gathering and transmission pipelines mainly in the province of BC.

Westcoast, which does business as Spectra Energy Transmission (Spectra), became a wholly owned subsidiary of Enbridge Inc. (Enbridge) following Enbridge’s merger with Spectra in February 2017. Organizational changes to transition from Spectra’s structure to Enbridge’s Canadian gas transmission and midstream structure began in spring 2017.

Two pipelines make up the Westcoast transmission south (T-South) system (Figure 1):

- the Westcoast nominal pipe size (NPS) 36 L2 natural gas pipeline (the occurrence pipeline)

- the Westcoast NPS 30 L1 natural gas pipeline

In the vicinity of the occurrence, the right-of-way of the Westcoast T-South system contains a 3rd pipeline, the Western NPS 12 crude oil pipeline owned by Pembina Pipeline Corporation (Pembina).

The 3 pipelines run parallel to each other in the Westcoast T-South right-of-way:

- The Westcoast NPS 36 L2 pipeline is on the east side of the right-of way.

- The Western NPS 12 pipeline is in the middle, about 5 m west of the NPS 36 L2 pipeline.Footnote 2

- The Westcoast NPS 30 L1 natural gas pipeline is about 9 m west of the NPS 36 L2 pipeline (Figure 2).

Compressor Station 4A is located upstream of the occurrence location and Compressor Station 4B is located downstream.

The T-South system and the NPS 36 L2 pipeline loop extend 917 km from Compressor Station 2 to the Huntingdon Meter Station in Huntingdon, BC. The NPS 36 L2 pipeline parallels the Westcoast NPS 30 L1 pipeline throughout the T-South sub-system in the same right-of-way.

Construction of the NPS 36 L2 pipeline was completed in 1972. It was successfully hydrostatically (strength and leak) tested by Westcoast prior to approval for service by the National Energy Board (NEB)Footnote 3 in October 1972. The location of the occurrence is part of the 4AL2 pipeline segment, defined as the section of the Westcoast NPS 36 L2 pipeline between compressor stations 4A and 4B. The average depth of cover for the Westcoast NPS 36 L2 pipeline in the vicinity of the occurrence location is about 1.34 m.

The Westcoast T-South system, south of Compressor Station 4A, supplies most of the natural gas to the southern mainland of BC and to Vancouver Island through the FortisBC Energy Inc. (FortisBC)Footnote 4 supply system. Third-party deliveries of natural gas are made throughout BC as well as to the U.S. Pacific Northwest through Huntingdon, BC.

1.3 The accident

On 09 October 2018, the Westcoast NPS 36 L2 pipeline was operating within the maximum operating pressure of 6453 kPa approved by the NEB. There were no pressure reductions or restrictions prior to the occurrence. Table 1 shows the sequence of events immediately following the occurrence.

| Time | Event |

|---|---|

| Approx. 1729 | An off-duty Westcoast employee contacted the Enbridge Calgary Gas Control (CGC) to report a large noise and fire near Shelley, BC, and the Fraser River. Immediately after this, the CGC noticed rapidly decreasing suction pressures from compressor 4B on the supervisory control and data acquisition (SCADA) system involving the Westcoast 4AL2 pipeline segment. |

| 1731 | The first SCADA alarm sounded in the control room. Within 5 seconds, the CGC acknowledged the alarm indicating the decreasing suction on compressor 4B. |

| 1734 | A local technician arrived at the 4AL2 segment valve site near Landooz Road (kilometre post [KP] 32.6) to investigate. |

| 1738 | It was decided to shut down the pipeline. CGC initiated the remote shutdown of Compressor Station 4B* for the NPS 36 L2 pipeline. |

| Approx. 1740 | Westcoast’s emergency response plan was activated. |

| 1744 | Prince George Fire Rescue arrived at the site. Since there was a constant fuel supply through the pipeline, it was not possible to attack the fire directly until the pipeline had been isolated and vented. |

| 1750 | Enbridge notified Pembina that a pipeline explosion had occurred in the same right-of-way as the Western NPS 12 pipeline. |

| 1753 | Shutdown of both Compressor Station 4A (upstream) and Compressor Station 4B (downstream) from the occurrence was initiated. |

| 1756 | Enbridge notified FortisBC of the pipeline rupture. |

| 1800 | A remote sectioning valve (at KP 32.6) was closed. As a result, the 4AL2 segment was effectively isolated. |

| Approx. 1800 | An incident command was established in the Prince George Enbridge office. |

| Approx. 1824 | An RCMP (Royal Canadian Mounted Police) helicopter, with Westcoast employees on board, surveyed the site. It was confirmed that a natural gas pipeline rupture** and ignition had occurred on the NPS 36 L2 pipeline. |

| 1845 | The decision was made to begin isolating the NPS 30 L1 segment between compressor stations 4A and 4B (4AL1 segment) by closing valves through the CGC. |

| 1900 | All regulatory agencies (local, provincial, and federal) had been notified of the occurrence. |

| 2200 | The affected segment of the Western NPS 12 pipeline had been isolated and drained into the Husky Energy Refinery using select block valves. |

| 2216 | The Westcoast NPS 30 L1 4AL1 pipeline segment*** (4AL1 segment) was shut down and isolated. |

* The shutdown included closing the line break valve at Compressor Station 4B as well as closing the station suction, discharge, and bypass valves.

** An instantaneous release that immediately impairs the operation of a pipeline such that pressure cannot be maintained.

*** The NPS 30 L1 4AL1 pipeline segment is defined as the section of the Westcoast NPS 30 L1 pipeline between Compressor Station 4A and downstream Compressor Station 4B.

It was estimated that approximately 140 million standard cubic feet (MMscf) of natural gas was released from the NPS 36 L2 pipeline. As a precaution, some 125 people near the occurrence location were evacuated, including about 60 from Lheidli T’enneh First Nation,Footnote 5 who self-evacuated at 1743. There were no injuries.

At the time of the occurrence, the sky was cloudy and the temperature was approximately 0 °C.

1.4 Response to the pipeline rupture

The initial emergency response focused on preventing further ignition, controlling the fire, and ensuring public safety. The NPS 36 L2 pipeline was shut down to control and prevent further fire damage. The NPS 30 L1 pipeline was proactively shut down and monitored to evaluate its condition as a result of the rupture.

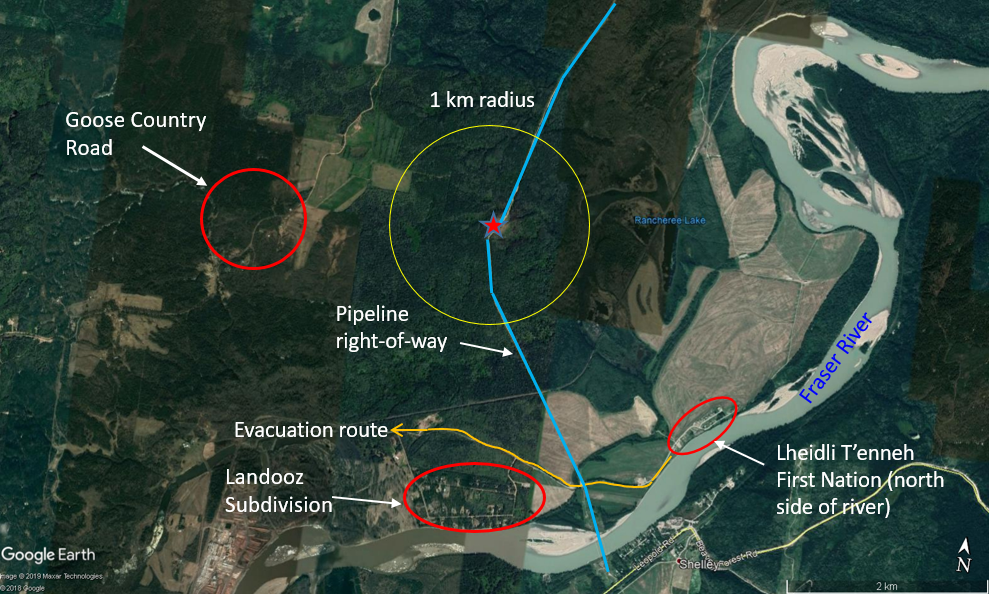

Areas around the occurrence, from which the public and first responders had to be protected, were identified and isolated with roadblocks, with the assistance of the Prince George RCMP, who had been dispatched to the site. An emergency planning zone of 1 km around the occurrence location had initially been established, but it was determined that there were no residents in this zone.

Firefighters from Prince George Fire Rescue were also dispatched to the location, but they did not approach the occurrence site itself because fuel continued to flow through the pipeline as the pressure in the isolated section bled off. The potential for wildfires was assessed and determined to be low, as the ground was determined to be too wet for the fire to spread.

Overall, 6 Westcoast employees responded to the site to help isolate the pipeline. Enbridge Calgary Gas Control employees also worked remotely to safely shut down the pipeline.

At around 1745, shortly after the Lheidli T’enneh First Nation community became aware of the fire, they informed Westcoast that they had decided to evacuate their homes (22 residences and 1 facility), located on the north side of the Fraser River about 2.5 km from the occurrence site, as a precaution. The residents evacuated using the single road leading into and out of the community. Shortly after, the evacuation zone was extended to include the Landooz Subdivision (33 residences) and Goose Country Road (3 residences) (Figure 3).

Most residents from the Landooz Subdivision and Goose Country Road returned later that night (about 4 hours after the evacuation), when it was determined by the responding parties that it was safe to do so. Most of the evacuated residents from the Lheidli T’enneh First Nation returned to their residences the next day.

The fire extinguished itself once the pipeline was isolated and vented. At approximately 0815 on 10 October 2018, an aerial visual assessment of the occurrence site was conducted, and Westcoast employees confirmed that the pipeline and surrounding fires were extinguished; some residual spot fires and smoke remained.

1.5 Site examination

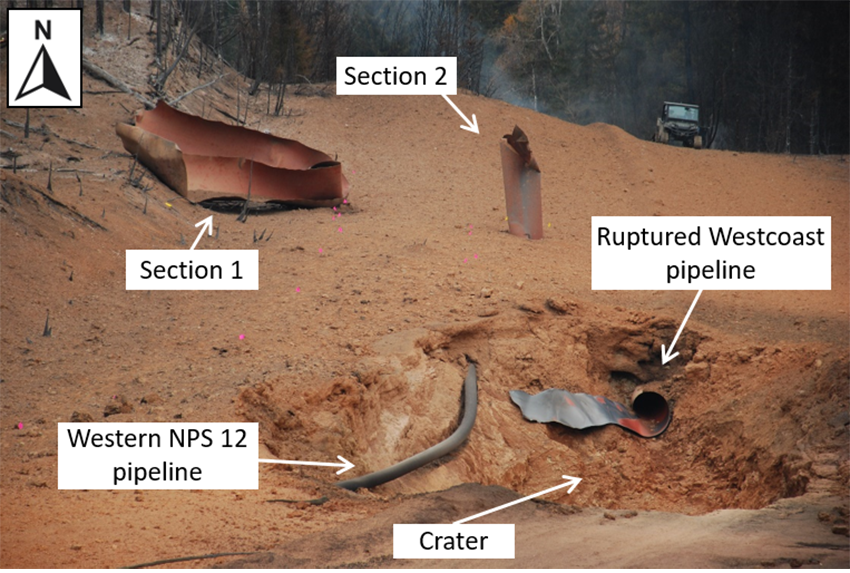

The area affected by the fire that resulted from the pipeline rupture covered about 52 000 m2 (Figure 4).

The crater that was created during the rupture and ejection of the pipeline from the ground was about 35 m long, 13 m wide and had a peak depth of about 9 m (Figure 5).

The ruptured ends of the pipeline in the crater showed signs of tearing and heat exposure. The coating in the area of the 4AL2 segment had been destroyed, and some heat-affected, disbonded coating remained at the edges of exposure. There was a small stream east of the crater. There was no indication of groundwater present in the crater.

To the west of the pipeline, within the crater, about 30 m of the Western NPS 12 pipeline also showed coating damage due to heat exposure. There had been no loss of product from that pipeline.

The Westcoast NPS 30 L1 pipeline was not exposed during the occurrence.

Two large sections of pipe were ejected from the crater (Figure 5).

One section (labelled as section 1 in Figure 5) was split open longitudinally, formed a U shape, and landed about 25 m northwest of the north end of the crater, over the unexposed NPS 30 L1 pipeline. A second section (labelled as section 2 in Figure 5) was cylindrical in shape, slightly compressed, with the appearance of tearing at the end. This section landed upright 18.5 m north of the north end of the crater, east of the Western NPS 12 pipeline. A portion of section 2 was embedded in the ground.

No coating was observed on the ejected sections of pipeline; this was likely due to disintegration resulting from exposure to heat from the fire.

1.6 Consequences of the pipeline rupture

The rupture and subsequent fire damaged the Westcoast NPS 36 L2 pipeline. About 140.72 MMscf of natural gas from the pipeline was combusted as a direct result of the occurrence. An additional 30 MMscf was vented during a controlled blowdown of a parallel section of the Westcoast NPS 30 L1 pipeline.

1.6.1 Westcoast pipelines

Following the occurrence, Westcoast notified its customers that all natural gas flow on the Westcoast T-South system would be cut off until service could be restored.

Once Westcoast received NEB approval, the NPS 30 L1 pipeline was returned to service on 11 October 2018 at a restricted operating pressure of 80% of its previous 60-day high pressure. On 01 November 2018, repairs were complete: the NPS 36 L2 pipeline was returned to service with a restricted operating pressure of 80% of its previous 60-day high pressure, as approved by the NEB.

1.6.2 Western NPS 12 pipeline

The adjacent Western NPS 12 pipeline was not flowing at the time of the occurrence. The pipeline’s coating was damaged due to exposure to heat from the fire during the occurrence—but released no crude oil—and 193 m of the pipeline had to be replaced. The pipeline was returned to service on 13 November 2018.

1.6.3 FortisBC gas supply shortage

As a result of the occurrence, the FortisBC system experienced a gas supply shortage when the Westcoast T-South system was shut down between Compressor Station 4B and the Huntingdon meter station. The largest shortage occurred on 09 and 10 October, with some customers’ supply cut off entirely. Footnote 6 FortisBC worked in collaboration with regional parties, including other local distribution companies, to re-establish a supply-demand balance Footnote 7 for the region. These actions, in conjunction with an overall milder-than-normal winter season, helped avoid sustained service disruptions during the winter period.

As the 2 Westcoast pipelines were brought back online, the service was continually balanced, and slowly the curtailment of service was reduced based on the forecasted demand and available supply. Both pipelines were operating at a reduced rate after 01 November 2018, which continued to affect the supply of gas to the distribution system throughout the winter. Residents receiving gas supplied through the Westcoast T-South system south of Compressor Station 4A were asked to conserve their use of gas during the winter as a result of this occurrence.

1.6.4 Environmental impacts

The occurrence resulted in damage to forest and grass on the provincial Crown land surrounding the site.

Trace amounts of soil and silt ejected during the occurrence settled on stationary objects such as vehicles, sheds, and decks at 2 residential properties located 2 to 3 km away from the accident site. Soil and water tests for contaminants in the surrounding area in the week after the occurrence did not indicate any immediate adverse consequences of the release of natural gas and the fire that followed. Westcoast has begun to develop a soil- and water-monitoring plan to perform longer-term testing and monitoring. Westcoast carried out a soil and water monitoring program in 2018 and 2019 that confirmed there were no lingering contamination sources and no offsite risk.Westcoast will continue to monitor for erosion and sediment control in 2020.

1.6.5 Property impacts

There was no damage to private property as a result of the rupture and fire. After the occurrence site was assessed, it was determined that an access road had to be built through private property so that the Westcoast NPS 36 L2 and Western NPS 12 pipelines could be repaired.

1.7 Pipeline operating history

From Compressor Station 2 to the Huntingdon Meter Station, the combined capacity of the 2 Westcoast natural gas pipelines (NPS 36 L2 and NPS 30 L1), at the original maximum operating pressure of 6453 kPa, is 2 billion cubic feet per day (Bcf/d).

The 4AL2 segment, which includes the occurrence site, is approved by the NEB at a maximum operating pressure of 6453 kPa.

In the 24 hours prior to the occurrence, the pipeline was being operated at steady pressures and flow rates within the allowable operating parameters that the NEB had approved.

At the time of the occurrence, the flow rate at the discharge of Compressor Station 4A was 1171 million cubic feet per day (MMcf/d). The maximum operating pressure was 6364 kPa.

1.8 Pipeline coating and cathodic protection

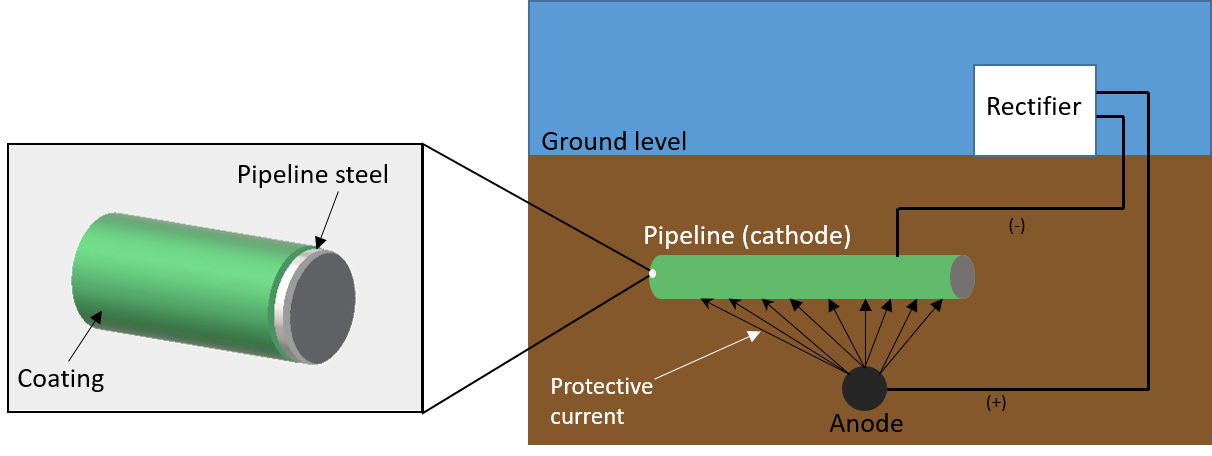

Controlling the external corrosion of a buried pipeline system is normally done using a dual system of external coating and cathodic protection (CP). The primary purpose of the external coating is to protect the pipe surface from its external environment. If the external coating degrades or otherwise fails, the CP system is designed to protect the pipe from corrosion (Figure 6).

Corrosion occurs when electrical current leaves the surface of the pipeline (anode) via the surrounding soil. To reverse this natural process, an impressed current CP system applies a voltage to the pipeline through the soil, giving the pipeline a cathodic potential.

To ensure that CP systems remain effective at preventing corrosion, regular monitoring is done by measuring the pipe-to-soil potential using a reference electrode and a CP test station that is electrically connected to the pipe. Measured potential values are then analyzed and compared to criteria specified in the regulatory requirements.

1.8.1 NPS 36 L2 pipeline

The CP system on the NPS 36 L2 pipeline provides current for all 3 of the pipelines in the shared right-of-way because they are electrically bonded together. The most recent annual pipe-to-soil CP survey on the 4AL2 segment of pipe was conducted on 19 September 2018. For 2017 and 2018, between KP 29.48 and KP 31.07 on the 4AL2 pipeline segment,Footnote 8 the “on” potential values were in the range of −906 mV to −1079 mV, and the “off” potential values were in the range of −861 mV to −989 mV. All negative polarized potential readings in the vicinity of the occurrence site exceeded 850 mV, meeting Westcoast’s standard operating practice requirements for CP surveys.Footnote 9 The data from these surveys are used to support or prioritize in-line inspections.

1.8.2 Examination of the coating following the occurrence

The coating on the pipeline adjacent to the rupture location was exposed and examined during repair activities. There was tenting and wrinkling of the polyethylene tape coating along the longitudinal seam and girth weld in sections of pipe downstream of the rupture location. There was also electrolyte and corrosion product under the disbonded coating. The coating of the exposed upstream pipe had minor tenting and wrinkling, and there was very little electrolyte under it.

The coating on the upstream and downstream joints in the pipe at the failure location is a field-applied polyethylene tape anti-corrosion coating with a fibreglass outer wrap. Covering both the body and weld areas of the pipe, it is about 1 m wide and is spiral-wrapped with an overlap of about 10 cm.

1.9 Laboratory examination of failed pipe

The two sections of pipe that were ejected from the crater and the two fracture ends were transported to the Acuren laboratory in Richmond, BC. The Westcoast 4AL2 ruptured sections of pipeline were examined to determine the mechanical properties of the pipeline and its mode of failure.

The outside pipe diameter was 914.4 mm (36 inches) with a nominal wall thickness of 9.91 mm. The chemical composition and tensile properties of the occurrence pipe material met the American Petroleum Institute standard API 5LX-1971 for Grade X60 steel that applied at the time the pipe was manufactured. Charpy impact energy values were within the range typical for Grade X60 steel.Footnote 10 The microstructure and microhardness values were within a typical range for Grade X60 pipe steel.

Using magnetic particle inspection, numerous indications consistent with colonies of stress corrosion cracking (SCC) were present on the outside surface of the examined pipe sections (Figure 7).

The rupture originated at stress corrosion cracks on the outside surface of the pipe. The cracks grew over time due to a near-neutral pH environment combined with operating stresses and eventually coalesced into a larger single crack. This reduced the load-bearing capacity of the pipeline steel until the critical crack size was exceeded and an instantaneous overstress fracture of the pipe occurred at normal operating pressures. The crack characteristics were consistent with near-neutral pH SCC (Figure 8).

1.10 Near-neutral pH stress corrosion cracking

Near-neutral pH SCC on pipelines occurs as a result of the combination of a susceptible metallic material, an applied or residual tensile stress, and a suitable environment. This mechanism initiates on the external surface of susceptible pipe and can grow in both depth and length (circumferentially or longitudinally).

The 4 factors associated with the development of a suitable environment for initiating near-neutral pH SCC are

- type and condition of coating,

- soil,

- temperature, and

- cathodic current level.

The type and condition of coating are critical factors in the initiation of near-neutral pH SCC on pipelines. Polyethylene tape coating was widely used in the 1960s and 1970s on new pipeline construction. This type of coating has a tendency to separate (disbond) from the pipeline, allowing moisture present in the soil to contact the pipe surface and shield it from the CP current. The period of time between the installation of the pipeline and the disbondment of the tape coating is referred to as the incubation period. This period varies widely and is difficult to determine accurately. The tape coating may disbond soon after construction if it is not applied correctly, or years later due to other soil or environmental conditions.

The failure of the tape coating will allow the exterior environment—including groundwater, which has a near-neutral pH—to come in contact with the pipe surface while shielding it from the CP current. Colonies of SCC may then randomly initiate. Some of the SCC will continue to grow as a consequence of the near-neutral pH environment and mechanical forces. Colonies of cracks that are long in the longitudinal direction and narrow in the circumferential direction have the potential to coalesce, which accelerates the SCC growth rate and increases the potential of a rupture.

In the 20 years since the NEB’s Public Inquiry Concerning Stress Corrosion Cracking on Canadian Oil and Gas Pipelines: Report of the Inquiry Footnote 11and ensuing recommendations, many measures have been put in place to help address SCC. These measures included developing and publishing industry-recommended practices, and updating federal regulations and pipeline standards. New requirements to develop and implement management systems and integrity management programs were also put in place. This resulted in improvements to the management of near-neutral pH SCC by Canadian pipeline operators.

SCC is addressed through an SCC management program, which requires a systematic approach to managing pipeline sections that have identified near-neutral pH SCC as a hazard. This type of program uses specific knowledge of the pipelines (operating and inspection history) and applies best practices from across the industry.

1.11 Westcoast NPS 36 L2 Integrity Management Program

Enbridge’s Pipeline Integrity Management ProgramFootnote 12 applies to the Westcoast pipeline system.Footnote 13 The program was designed using the guidelines of Canadian Standards Association (CSA) Standard Z662-15, Oil and Gas Pipeline Systems.Footnote 14 It is reviewed once a year and revised as needed; the last revision was April 2018. The aim of the program is to ensure that sweet and sour natural gasFootnote 15 are transported without adverse effects on the public, company employees, and the environment.

1.11.1 Integrity risk assessments

Pipeline integrity risk assessments for the Westcoast system were used to validate the effectiveness of the pipeline integrity program. Deficiencies found through the assessment were prioritized and the mitigation controls assessed to maintain fitness for service.

The integrity risk assessment report of the Westcoast system completed in June 2018 identified that the 4AL2 segment of pipe had been given the 2nd highest risk ranking for SCC. This assessment was based on the previously collected in-line inspection data on each segment of pipe. The assessment also identified that, due to the lapse of time between runs of in-line inspections on the 4AL2 segment, there was greater uncertainty when it came to the actual defect size due to the use of an assumed growth of a potential defect over a longer period of time.

A detailed overall risk assessment of Westcoast’s Canadian Gas Transmission System was completed in October 2018. This risk assessment was used to evaluate specific, local field-observed threats for prioritization. No SCC-related issues were identified by this process.

1.11.2 Westcoast’s Stress Corrosion Cracking Hazard Management Plan

Westcoast’s Stress Corrosion Cracking Hazard Management Plan (SCC Hazard Management Plan) is a sub-component of the integrity management program. This document applies to the Westcoast pipeline system and is designed to address the safety and loss management of near-neutral pH SCC on the Westcoast pipeline system.

The SCC Hazard Management Plan follows the Canadian Energy Pipeline Association (CEPA)’s recommended practices for managing near-neutral pH SCC.Footnote 16 The purpose of the plan is to

- assess the potential risk created by the identified hazard of SCC that exists on the company’s pipeline system;

- provide a risk reduction and corrective action plan for SCC;

- implement the component of the integrity management plan related to SCC; and

- provide the method for monitoring results of the plan for continuous improvement.Footnote 17

The plan uses a 9-step process for evaluating near-neutral pH SCC. The steps are grouped into 3 main categories: susceptibility assessment; condition assessment and mitigation; and condition monitoring.

The susceptibility assessment portion requires the user to determine if the pipeline is subject to near-neutral pH SCC based on primary information such as coating type and quality. An analysis of all available pipeline data is then done to prioritize the susceptibility of pipeline segments to near-neutral pH SCC. To perform this analysis, an initial crack size and a crack growth rate that is representative of the pipeline segment being assessed are required. Usually, the initial crack size is based on data collected by in-line inspection. The crack growth rate can be estimated based on known industry data or calculated based on statistical analysis of inspection data for a particular segment of pipeline.

CEPA’s recommended practices for managing near-neutral pH SCC provides crack growth rates experienced by 2 historical SCC failures that occurred on 36-inch pipelines. The time-averaged growth ratesFootnote 18 for the environmental component of the cracks were 0.3 and 0.63 mm/year respectively.

1.12 SCC management of the NPS 36 L2 pipeline

Westcoast’s integrity management program in effect at the time of the occurrence for the 4AL2 segment recognized near-neutral pH SCC to be an integrity hazard. Westcoast developed and implemented an SCC hazard management plan specific to the NPS 36 L2 pipeline. This plan was updated at a maximum interval of 3 years, or when new inspection data were received and analyzed.

The plan used risk assessment techniques to manage SCC on the Westcoast pipeline system. The risk assessment determined the type of inspection required, the frequency of inspections, and any pipe replacements, repairs, or upgrades required in high-risk scenarios.

The inspection frequency for near-neutral pH SCC using electromagnetic acoustic transducer (EMAT) in-line inspections was based on Westcoast’s risk assessment of the NPS 36 L2 pipeline.Footnote 19 The resulting calculated inspection interval was then compared with Westcoast’s maximum interval of 9 years for monitoring SCC using in-line inspections. The more conservative of the 2 intervals drove the inspection frequency for SCC in-line inspections.

Locations where SCC was either modelled to exist or had been identified by EMAT in-line inspections required further verification by integrity digs. Once a pipeline had been exposed, the surface could be inspected using magnetic particle inspection. For this pipeline, condition monitoring using magnetic particle inspection was also done at all repair locations and in areas where the pipe was exposed for maintenance.

Inspections had revealed near-neutral pH SCC on the Westcoast NPS 30 L1 and the NPS 36 L2 transmission pipelines. The SCC assessments done based on the inspection data collected on the NPS 36 L2 pipeline had indicated that there was a minor to moderateFootnote 20 risk of SCC failure.

SCC remediation of the NPS 36 L2 pipeline was performed at inspection sites by buffing to remove the SCC and recoating the pipe with a non-shielding, high-performance coating,Footnote 21 or applying reinforcing sleeves if required.

In locations where remediation was required on more than 100 m of pipe, a pipeline replacement or recoating was performed. Pipe replacement as a mitigation method for SCC was based on a site-specific engineering analysis that combined aspects of the SCC risk of failure, as well as regulatory and other operational considerations. Before the occurrence, 3 sections of the NPS 36 L2 pipeline had been replaced as part of the SCC remediation process.Footnote 22

1.12.1 Risk assessment of the 4AL2 segment

A risk assessment for the 4AL2 segment was done after an EMAT in-line inspection tool was run in 2003. The data from 2003 had identified 9 cracks that were above the set reporting criteria. These cracks were all identified as toe cracks in the longitudinal seam weld.Footnote 23 There were no longitudinal cracks above the reporting criteria in the pipe body. Data based on the most severe of the 9 cracks was used to calculate an in-line inspection interval of 5 yearsFootnote 24 for the 4AL2 segment.

An EMAT in-line inspection tool was run in 2008, after which a risk assessment was conducted. The assessment indicated that there had been little to no change in the condition of the A4L2 pipeline segment since the in-line inspection conducted in 2003. With this information, it was determined that data originating from the 2003 inspection would be used in calculations to determine the next in-line inspection interval for that segment.

The SCC growth rate was calculated by an algorithm that uses crack dimension data received from the EMAT in-line inspection. The critical crack sizeFootnote 25 was also calculated using the hydrotest pressure, which is defined as 125% of the maximum operating pressure, to determine the maximum allowable crack depth. The calculated crack growth rate and the critical crack size were then analyzed to calculate the reinspection interval for the in-line inspection. The reinspection interval was determined by the time required to reach the critical crack size, up to the maximum inspection interval of 9 years that Westcoast set for the NPS 36 L2 pipeline.

In 2008, the inspection interval was calculated using the largest crack identified in 2003 and a crack growth rate of about 0.15 mm/year, and it was found to be 12 years for a critical crack size calculated at the hydrotest pressure.Footnote 26 However, because Westcoast’s maximum allowable inspection interval for SCC EMAT in-line inspection was 9 years, the next inspection of the 4AL2 pipeline segment was set for 2017.

1.12.2 In-line inspection deferral process

The Westcoast integrity management program contains provisions to allow the deferral by 1 year of an EMAT in-line inspection tool run, as long as a technical assessmentFootnote 27 is done and a deferral request is made and approved. This practice is documented in Westcoast’s standard operating practice for waivers and technical assessments,Footnote 28 and is used when a decision that affects the integrity management program is related to deviations, clarifications, or changes to other programs, plans, or practices is required.

As part of the standard operating practice, a waiver form containing 3 sections that are required for approval, is completed.

- The 1st section is completed by the regional office requesting the deviation (deferral) or waiver. It includes the description of the project, proposed deviation, and rationale for the deviation.

- The 2nd section is completed by the integrity team lead, and includes the analysis of the proposed deviation. This includes the technical assessment of pipeline safety, regulatory compliance, technical feasibility, and the ability to meet the intent of the applicable program, plan, or standard operating practice.

- The 3rd section is the approval from the relevant regional manager or director. The standard operating practice also outlines that all transmittals shall be communicated by email and electronically retained.

This process was well established at Westcoast and had been used appropriately on other occasions.

In 2016, a deferral request was made through Westcoast’s inspection tracking tool without a documented rationale. The inspection tracking tool was used to note the decision to defer the 4AL2 EMAT in-line inspection from 2017 until fall 2018. The waiver form, which includes the required approval signatures, was not used to document the deferral of the EMAT in-line inspection for the 4AL2 segment. Despite the absence of a completed waiver form, the in-line inspection for 4AL2 was deferred until fall 2018. The investigation was unable to determine why the standard operating practices were not followed.

1.13 Stress corrosion cracking inspection program

Based on CEPA’s recommended practices for near-neutral pH SCC, the 3 basic components for SCC management are

- susceptibility assessment,

- characterization and mitigation of SCC, and

- condition monitoring.

Condition monitoring of the NPS 36 L2 pipeline is done using EMAT in-line inspection combined with magnetic particle inspection on the exterior surface of the pipe during subsequent integrity digs.

When an EMAT in-line inspection is performed, an ultrasonic signal is induced in the pipe wall electromagnetically and detected by the tool. EMAT tools do not make direct contact with the pipe surface: they allow the inspection to be performed without using a liquid couplant to transmit and receive ultrasonic signals. Because no liquid couplant is required, EMAT tools are ideal for inspecting gas pipelines. In addition to cracks, EMAT tools can detect coating disbondment. This can be a useful piece of information to correlate with the presence of cracks in the pipeline.

Since its original construction, the 4AL2 segment had been internally inspected multiple times using various types and generations of SCC in-line inspection technologies.

The nearest integrity dig was done 1104 m upstream of the rupture site in 2002. The SCC detected using magnetic particle inspection was determined to be insignificant, and it was remediated by buffing the indications from the pipe and recoating it with a new high-performance coating.

1.13.1 Westcoast’s in-line inspection detection criteria

Westcoast’s SCC Hazard Management Plan focusses on verifying the detection and discrimination ability of the EMAT in-line inspection tool. This allows Westcoast to evaluate the confidence in the tool’s ability to detect a crack. The probability of detection quantifies the probability of the EMAT tool’s capability to detect SCC features of interest within the dimension thresholds specified by the inspection technology.

The EMAT detection threshold Westcoast used is set to detect a crack with dimensions greater than 50 mm long and 2 mm deep. The standard probability of detection for the EMAT technology that the in-line inspection supplier provided and Westcoast used is 90% for detection of cracks greater than the indicated threshold. This value is generally validated by performing excavations where the technology has detected a high number of SCC cracks and any findings from other excavations that were not driven by the in-line inspections. These data must be recorded and compared to the EMAT data for validation. A probability of detection of 90% allowed Westcoast to achieve the confidence required to calculate the reinspection intervals based on the crack size dimensions received from the EMAT in-line inspection tool.

1.14 Emergency management

Emergency management has 4 interdependent components:

- prevention and mitigation,

- preparedness,

- response, and

- recovery.

According to Public Safety Canada,Footnote 29 emergency planning should use a risk-based approach that addresses all potential natural or human-induced hazards. All organizations, governments, communities, and individuals can have an impact in ensuring that, in the case of an emergency, systems and personnel are prepared to respond in a way that ensures their safety.

The NEB requires each pipeline company to have an emergency management program that anticipates, prevents, manages, and mitigates conditions during an emergency. The NEB monitors the effectiveness of each company’s program using audits and compliance verification activities to ensure that pipelines and associated facilities are suitable for continued safe, reliable, and environmentally responsible service.

The NEB works in collaboration with other federal government institutions, provincial and territorial emergency management organizations, first responders, other stakeholders, and communities in support of the overall emergency management system across the country.

The NEB also requires that federally regulated pipeline companies work collaboratively with agencies that could be involved in an emergency response (first responders, city planners, municipalities, local communities, and Indigenous groups). Pipeline companies must also enter into discussions with these agencies to ensure that an emergency response can be appropriately coordinated in case of an incident.

In an emergency, the NEB holds the company responsible for responding appropriately by monitoring, observing, and assessing the overall effectiveness of the company’s emergency response, while taking part in the single or unified command framework.Footnote 30

1.14.1 Emergency management for local communities

Emergency response planning at all levels of government and communities is key to ensuring that a response to an emergency occurs in a way that is organized and safe.

In BC, the emergency management responsibilities of local authorities, provincial ministries, Crown corporations, and on-reserve First Nations communities are outlined in the Emergency Program Act Footnote 31 and related regulations. As part of these provisions, local authorities are required to

- prepare local emergency response plans that reflect the assessment of the relative risk of occurrence of a hazard Footnote 32 and the potential impact on people and property,

- periodically update the local emergency response plans, and

- establish and maintain a training program that includes exercises for all personnel involved in an emergency response.

Local communities need to assess whether they are affected by hazards associated with a pipeline emergency. They must then develop the emergency response plans specific to the needs of each local authority or community to establish the mitigation and response plans for those hazards.

In general, the majority of local emergency response plans are developed independently of the emergency response plans for federally regulated pipeline companies.

1.14.2 Situational awareness in emergency management

Situational awareness can be divided into 3 levels:

- the perception of elements in the environment,

- the comprehension of their meaning, and

- the projection of their future status. Footnote 33

To develop and maintain accurate situational awareness during an emergency, those involved need to perceive the relevant information of the emergency scenario, understand what that information means, and use it to select the correct emergency response. This applies at both the individual and group level. To practise and coordinate an emergency response plan, all participants of that plan need to have the same understanding of the emergency scenario and the same understanding of what each member of the group should or will do in response to that scenario.

Several factors may affect development and maintenance of situational awareness. These include not having sufficient knowledge to understand the emergency scenario, to select the correct emergency response, and to understand each group member’s responsibility in that emergency.

Knowledge-based performance is largely conscious, occurring as an individual learns new situations and outcomes. Over time, an individual learns rules to produce more regulated if–then performance. If individuals do not learn sufficient knowledge and rules, they may not know how to understand or deal with certain scenarios, including emergency scenarios Footnote 34 , Footnote 35

In a similar way, when physically performing a task, an individual learns the associated motor actions for that task. As the individual practises the task, these motor actions develop into skilled-based performance. This skill development process is important for when the individual is required to perform in an emergency while under stress. In such cases, the individual, with limited time and cognitive capacity, will be able to perform the task automatically: that is, rapidly, accurately, and without much thought. Conversely, if an individual does not practise the task, the cognitive effort to plan and execute the novel task may exceed the time and capacity available.

1.15 Westcoast’s emergency response management

Westcoast’s emergency response plan is designed to support an all-hazards approach to emergency response and crisis management. Its aim is to ensure that consequences of emergencies are appropriately mitigated. Westcoast’s emergency planning also includes carrying out effective training drills and exercises.

Westcoast uses the Incident Command System to manage a response to an emergency. The structure of this system is designed to coordinate with other responding agencies and to include those agencies inside the command post to manage a coordinated response.

Westcoast’s emergency response plan has a structured approach to identify hazardous zones of an emergency (emergency planning zones). These are used to clearly identify the high-risk areas and to reduce the hazards to the on-site responders and members of the public.

The emergency planning zones determine the evacuation areas and take into account the location of access routes, power lines, pipelines, and fire and explosion hazards. In this occurrence, there were no residents within the emergency planning zone of 1 km around the occurrence site.

1.15.1 Westcoast emergency response planning near the occurrence location

Westcoast’s emergency response plan involves performing various types of simulated emergencies and may involve mutual aid partners and regulatory agencies. Emergency response exercises allow responders to practise their roles and identify opportunities to improve emergency preparedness. Westcoast holds an emergency response plan training exercise in each geographical area at least once a year. Every 3 years, the training exercise must be a full-scale exercise or an actual event, involving equipment, Westcoast employees, contractors, local first responders, agencies and regulators, and other stakeholders, as appropriate.

The most recent exercise near the occurrence location was conducted on 25 July 2018. It was a tabletop exercise at Compressor Station 3, simulating a significant gas leak and ignition in the city of Prince George. The aim of the exercise was to emphasize the importance of Westcoast employees being able to respond to emergencies at compressor stations that were not part of their regular assignments. This type of activity helps employees develop a level of familiarity with the location of other facilities, access routes, and valve operations. External organizations, regulators, or communities did not participate in this table-top exercise.

The Lheidli T’enneh First Nation reserve, other communities, and operators of other pipelines near the 4AL2 pipeline segment were not included in any of Westcoast’s emergency response exercises between 2014 and 2018. However, on 13 June 2016, a Westcoast representative visited the Lheidli T’enneh First Nation reserve to discuss emergency response planning. The Lheidli T’enneh First Nation south-side residents, located outside the pipeline’s emergency planning zone, were informed of the emergency response process. The Lheidli T’enneh First Nation north-side residents, located within the emergency planning zone, were given information on pipeline emergency response, and resident contact information was collected.

1.16 Regulatory requirements and oversight

The NEB’s Onshore Pipeline Regulations, 1999 require a company to develop, implement, and maintain a management system that includes an integrity management program and an emergency management program. The Regulations further require pipeline operators, through incorporation by reference, to adhere to applicable mandatory provisions of the latest edition of CSA Standard Z662.

While the NEB, in its Guidance Notes for the Regulations, provides direction in developing an integrity management program, regulated companies have flexibility and discretion to develop the content of their plans. Regulated companies develop integrity management programs tailored to their specific operations and take corrective action as required, in compliance with applicable provisions and criteria set out in CSA Standard Z662-15.

The NEB expects companies, as part of their integrity management programs, to proactively identify and continually monitor the specific hazards associated with their pipelines and associated facilities, and to update their program immediately when new hazards are identified.

NEB-regulated companies are held accountable to operate safely during all phases of a pipeline life cycle.Footnote 36 The NEB monitors the effectiveness of each company’s program on an ongoing basis using audits and compliance verification activities to ensure that pipelines and associated facilities are suitable for continued safe, reliable, and environmentally responsible service.

1.16.1 Audits of Westcoast’s integrity management program

The NEB's most recent audit of Westcoast’s regulated activities began in November 2012; the final report was released in March 2013. The audit protocols were based on NEB’s Onshore Pipeline Regulations, 1999.

With respect to the integrity management program, the audit report noted the following:

- Westcoast demonstrated that it has an integrity management programfor its pipeline facilities.

- Westcoast’s integrity management programincludes and mitigates the majority of possible hazards to the pipeline system.

- Westcoast’s integrity management programdid not meet the NEB’s expectations for a complete, robust, and fully implemented program; however, the deficiencies identified did not reflect a complete system failure.

Among the non-compliance findings related to Westcoast’s integrity management program were that Westcoast

- had not demonstrated that it had developed or implemented procedures to analyze incident data to identify trends, systemic issues, and opportunities for improvements;

- had not accurately tracked or reported key performance indicators; and

- had not completed an internal audit of the integrity management program at the time of the audit.

The NEB determined that no enforcement actions were immediately required. However, Westcoast was directed to submit a corrective action plan within 60 days to address all identified non-compliances.

In response to the audit report, Westcoast developed, submitted to the NEB, and implemented a corrective action plan that addressed each of the non-compliances. In March 2017, the NEB notified Westcoast that it had closed the audit because the corrective actions had been implemented.Footnote 37

1.17 Other similar occurrences

Since 2002, the TSB has investigated 3 other occurrences where near-neutral pH SCC was identified as the primary mode of failure.

P11H0011 – On 19 February 2011, TransCanada PipeLines Limited (TransCanada) Line 100-2 experienced a natural gas pipeline rupture, fire, and explosion near Beardmore, Ontario. A large crater was created and 3 pieces of pipe broke from the system, with pipe and other debris being ejected up to 100 m from the rupture site. Six residents near the site evacuated until the fire was extinguished. There were no injuries. The Board determined that failure of this section of Line 100-2 pipe was the result of longitudinally oriented, near-neutral pH SCC, which was trans-granular in nature. Stress corrosion cracking in the pipe body reduced the load bearing capacity of the pipeline steel such that local permanent yielding occurred at normal operating pressures, leading to the rupture, explosion and fire.

P09H0074 – On 12 September 2009, TransCanada Line 100-2 experienced a natural gas pipeline rupture, fire, and explosion south of its Compressor Station 107, located near Swastika, Ontario. A large crater was created and 2 sections of pipe broke from the system, with 1 section being ejected approximately 150 m from the rupture site. There were no injuries. The Board determined that failure of the section of Line 100-2 pipe was the result of near-neutral pH SCC that occurred coincident with the toe of the longitudinal weld seam. The accident occurred when cracks in the steel in the vicinity of the longitudinal seam weld progressed to the depth that local permanent yielding occurred at normal operating pressures, leading to the rupture and explosion.

P02H0017 – On 14 April 2002, TransCanada Line 100-3 experienced a natural gas pipeline rupture and fire approximately 2 km from the village of Brookdale, Manitoba. There were no injuries. As a precautionary measure, approximately 100 people were evacuated from the occurrence area within a 5 km radius, including the village of Brookdale, for a period of one day. The Board determined that the following factors, together with a sustained tensile stress due to the internal operating pressure of the pipeline, permitted a zone of near-neutral SCC to initiate and grow to failure:

- a disbonded exterior coating;

- fluctuations in the environmental conditions surrounding the pipe;

- the presence of anaerobic bacteria;

- a susceptible high-strength steel pipe; and

- the existence of atomic hydrogen, probably from the CP reaction failure.

1.18 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP089/2019 – Survey Data Analysis

- LP101/2019 – Pipeline Failure – Review of pipeline failure analysis

2.0 Analysis

The operation of the pipeline was not considered contributory to this accident. The analysis will focus on the condition of the pipe, the integrity of the pipeline, the integrity management systems used for mitigating stress corrosion cracking (SCC), and emergency response.

2.1 The accident

While operating at normal operating pressures, the Westcoast 4AL2 pipeline segment (the 4AL2 segment) ruptured, and an explosion and fire ensued.

The rupture had originated at stress corrosion cracks on the outside surface of the pipe, consistent with near-neutral pH SCC. The cracks had grown and coalesced over time, reducing the load-bearing capacity of the pipeline steel at normal operating pressures.

Near-neutral pH SCC on pipelines is a result of the combination of a susceptible metallic material, an applied or residual tensile stress, and a suitable environment. It takes place on the external surface of susceptible pipe and can grow in both depth and length (circumferentially or longitudinally).

When the Westcoast nominal pipe size (NPS) 36 L2 pipeline (the pipeline) was built in 1972, its exterior surface was coated with polyethylene tape. The pipeline was further protected from corrosion using an impressed current cathodic protection (CP) system. In response to coating disbondment, the pipeline’s CP system protects the pipeline from corrosion as long as the CP current reaches the pipe surface. Polyethylene tape coatings are prone to disbondment over time due to tenting between the tape coat and the longitudinal weld, or along the tape overlap between successive wraps of tape. When such coatings disbond, they shield the pipe surface from CP current.

Over time, the tape coating on the 4AL2 segment had started to disbond from the pipe surface. Although no free water was observed in the crater, minor water systems in the vicinity of the pipeline right-of-way created a moist environment in the soil. The disbonded coating allowed the moisture in the soil to contact the pipe surface and shield it from the beneficial effects of CP, creating the environment for SCC to initiate. Once initiated, SCC continued to grow over time, assisted by the internal pressure associated with normal pipeline operations. Gradually, the SCC reduced the load-bearing capacity of the pipeline steel.

2.2 Pipeline integrity management program

The overall aim of a pipeline integrity management program is to ensure that hazards and threats affecting the safe operation of the pipeline are effectively identified and mitigated to ensure suitability of the pipeline system for continued service.

Westcoast’s integrity management program for the 4AL2 segment in effect at the time of the occurrence recognized that SCC was an integrity hazard, so Westcoast developed and implemented an SCC hazard management plan. This plan uses risk assessment techniques to manage SCC on Westcoast’s pipeline system and to determine the type of inspection required, the frequency of inspections, and any pipe replacements, repairs, or upgrades required in high-risk scenarios.

2.2.1 Westcoast’s SCC hazard management plan

Westcoast’s SCC hazard management plan identifies the susceptibility, severity, and mitigation methodology (including condition monitoring) of SCC on each pipeline segment. The risk assessment used in the plan relies on several factors, including the data collected during previous SCC assessments. This data can come from SCC in-line inspections using an electromagnetic acoustic transducer (EMAT), as well as magnetic particle inspections of the exterior pipe surface performed in the field each time the pipeline is exposed.

In 2017, Westcoast’s SCC hazard management plan identified near-neutral SCC as a hazard for the 4AL2 segment. The assessment methodology used data based only on cracks found during the previous EMAT in-line inspection, without taking into account the potential for cracks below the EMAT inspection tool’s detection threshold. Because the in-line inspection interval had been set for 9 years, based only on the cracks detected in the previous EMAT inspection, stress corrosion cracks that were below the detectable limits of the EMAT tool continued to grow over time until the failure occurred.

Although Westcoast’s SCC hazard management plan recognized the susceptibility of the pipeline to near-neutral pH SCC, the extent of the existing SCC on this segment of pipe was not identified.

2.2.2 In-line inspection interval

The effectiveness of an in-line inspection program depends on many factors, including data collection and analysis, defect identification, and the selection of an inspection interval.

Westcoast uses a deterministic approach to set the in-line inspection intervals for the inspections and monitoring requirements for near-neutral pH SCC. At the time of the occurrence, the model used to calculate crack growth rates was based primarily on the results of previous inspections. It did not consider stress corrosion cracking that was below the in-line inspection detection threshold, nor the possibility of an increase in crack size due to crack coalescence.

The design of an integrity program is to allow the inspections to detect any defects before they reach a size that could result in a service failure. It can be difficult to predict the point at which a coating will fail and cracks will begin to grow and coalesce due to the environment. Industry data show that the crack growth rates can increase over time. Therefore, as the time period between in-line inspections increases, a level of conservatism is required when assuming that the coating remains in acceptable condition when calculating crack growth.

The inspection data for the 4AL2 segment of pipe identified very few cracks above the in-line inspection tool detection limits, indicating limited SCC activity for this pipeline segment. The 4AL2 segment’s crack growth rates were calculated by Westcoast using the data received from the previous EMAT in-line inspections in 2003 and 2008, which had shown very little SCC activity. Based on a hydrotest pressure of 125% of the maximum operating pressure, an in-line inspection interval of about 12 years was calculated for this segment following analysis of the collected data. As this was greater than the maximum interval of 9 years, the next in-line inspection was scheduled for 2017.

The accuracy of the crack growth rate model depends on the accuracy of the input parameters, including the initial crack size. If any of these parameters have been underestimated, actual crack growth rates will exceed predicted values. Since the time between in-line inspections on the 4AL2 segment was extended to 10 years, the uncertainty in the calculated crack growth of a potential defect increased with time. However, the crack growth model did not sufficiently reflect the uncertainties in the measured values or the increase in crack size as a result of crack coalescence. As such, the predicted growth that was used in the model was less than the actual crack growth.

If the interval for a pipeline’s next in-line inspection does not sufficiently account for uncertainties in the predicted crack growth rate, cracks that were below the detection threshold during the previous inspection can grow to a critical size prior to the next inspection, increasing the risk of an in-service failure.

2.2.3 In-line inspection deferral process

Westcoast, in its integrity management program, has a process that allows an SCC in-line inspection to be deferred by 1 year. The deferral process is described in Westcoast’s standard operating practice for waivers and technical assessments. It requires that a formal deferral request be completed, a technical assessment be performed, and that the relevant manager or director review the request for approval. This process was well established at Westcoast and had been used appropriately on other occasions.

Westcoast had scheduled the next in-line inspection for the NPS 36 L2 pipeline for 2017. In 2016, about 1 year prior to the scheduled EMAT in-line inspection run, a request to defer that inspection by 1 year was noted in Westcoast’s inspection tracking tool. A 1-year extension would bring the in-line inspection interval to 10 years, which would still be below the 12-year interval calculated by the crack growth rate model (which was based on a hydrotest pressure of 125% of the maximum operating pressure).

However, there were no records indicating that a proposed deviation, rationale, or a technical assessment had been done, or that the deferral request had been approved, even though Westcoast’s standard operating practice required these to be documented. Despite the absence of a completed inspection deferral waiver form, the SCC EMAT in-line inspection for the 4AL2 segment, scheduled for 2017, was deferred until fall 2018, resulting in the existing cracks remaining in the pipe undetected until failure.

2.2.4 Emergency response and evacuation

The accident occurred within forested land with hilly topography in a remote area about 13 km northeast of Prince George, British Columbia. The nearest private property is located 500 to 600 m away.

Following the occurrence, Westcoast’s response included isolating and shutting down the affected pipelines, installing roadblocks for public protection, and informing its stakeholders. First responders were dispatched to the scene, and the potential for wildfires was assessed. The fire extinguished by itself once the pipeline was shut down and vented.

Westcoast initially used an emergency planning zone with a 1 km radius from the accident site. It was identified that this zone did not include any residents. However, in the time between the pipeline rupture and official notification by Westcoast, several of the local communities took the precaution of self-evacuating.

The emergency response activities were successful in mitigating the impacts of the occurrence.

2.3 Emergency management

Westcoast’s emergency response plan addresses various emergency response scenarios for the Westcoast pipeline system.

The company’s procedures address the evacuation areas and take into account the location of access routes, other modes of transportation, power lines, other pipelines, and fire and explosion hazards.

Communities are also required to have an emergency plan that covers all types of potential hazards. Hazards that could be present within a community, such as those related to the presence of a pipeline, require an emergency response plan. To achieve a plan that is realistic and can be implemented successfully, communities need to understand the potential emergency and the appropriate response to that emergency situation.

Westcoast had provided the Lheidli T’enneh First Nation, located on the north side of the river, with general information about the emergency response to a pipeline incident for the community to use to develop and implement an appropriate emergency response plan.

In this occurrence, the residents of the Lheidli T’enneh First Nation reserve on the north side of the river self-evacuated using the only road leading out of the community. This road crosses over the pipeline right-of-way approximately 2.5 km from the occurrence site. The safety of the residents was not affected during the evacuation process in this occurrence.

Federally regulated pipeline companies are also required to perform full-scale emergency response exercises every 3 years. Evacuation plans that are practised in regular emergency exercises give all parties potentially involved in a pipeline emergency the knowledge, skills, and confidence they need to manage an evacuation effectively. Such plans are also valuable to identify potential restrictions within the emergency response, including the emergency evacuation routes for communities that could be affected by a pipeline emergency.

Westcoast had performed periodic emergency exercises with government agencies, mutual aid partners, company personnel, and local emergency response personnel. However, the Lheidli T’enneh First Nation reserve, other communities, and operators of other pipelines located near the 4AL2 segment had not been included in any emergency response exercises in the 4 years prior to the occurrence.

Many small local communities, including the Lheidli T’enneh First Nation, rely on mutual aid partners and larger community first response personnel in an emergency. However, when all stakeholders that can be affected by an emergency situation do not participate in periodic emergency response exercises, some stakeholders may not be aware of the actions required of them during an actual pipeline emergency and evacuation.

If pipeline emergency response exercises are not conducted periodically with all potentially affected stakeholders, gaps in emergency response plans for the responders or for the local communities may not be identified, increasing the risk that all parties will not be sufficiently prepared to respond to a pipeline emergency.

3.0 Findings

3.1 Findings as to causes and contributing factors

- While operating at normal operating pressures, the Westcoast 4AL2 pipeline segment (the 4AL2 segment) ruptured, and an explosion and fire ensued.

- The rupture had originated at stress corrosion cracks on the outside surface of the pipe, consistent with near-neutral pH stress corrosion cracking.

- The cracks had grown and coalesced over time, reducing the load-bearing capacity of the pipeline steel at normal operating pressures.

- Over time, the tape coating on the 4AL2 segment had started to disbond from the pipe surface.

- The disbonded coating allowed the moisture in the soil to contact the pipe surface and shield it from the beneficial effects of CP, creating the environment for stress corrosion cracking to initiate.

- Although Westcoast’s Stress Corrosion Cracking Hazard Management Plan recognized the pipeline’s susceptibility to near-neutral pH stress corrosion cracking, the extent of the existing cracking on this segment of pipe was not identified.

- The crack growth model did not sufficiently reflect the uncertainties in the measured values or the increase in crack size as a result of crack coalescence. As such, the predicted growth that was used in the model was less than the actual crack growth.

- The stress corrosion cracking electromagnetic acoustic transducer in-line inspection for the 4AL2 segment, scheduled for 2017, was deferred until fall 2018, resulting in the existing cracks remaining in the pipe undetected until failure.

3.2 Findings as to risk

- If the interval for a pipeline’s next in-line inspection does not sufficiently account for uncertainties in the predicted crack growth rate, cracks that were below the detection threshold during the previous inspection can grow to a critical size before the next inspection, increasing the risk of an in-service failure.

- If pipeline emergency response exercises are not conducted periodically with all potentially affected stakeholders, gaps in emergency response plans for the responders or for the local communities may not be identified, increasing the risk that all parties will not be sufficiently prepared to respond to a pipeline emergency.

3.3 Other findings

- There were no records indicating that a proposed deviation, rationale or technical assessment had been done, or that the deferral request had been approved, even though Westcoast’s standard operating practice required these to be documented.

- The emergency response activities were successful in mitigating the impacts of the occurrence.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

On 26 June 2019, the TSB sent Pipeline Safety Advisory 02/19 to Enbridge Inc. (Enbridge) on the management of stress corrosion cracking (SCC) on susceptible pipelines. The TSB indicated that, based on Enbridge records, there are approximately 500 km of pipe coated with polyethylene tape on the Westcoast nominal pipe size (NPS) 36 transmission south (T‑South) system. The TSB suggested that, given the presence of SCC-susceptible pipe, Westcoast may wish to review its SCC management practices, including in-line inspection intervals, to ensure that the risks associated with polyethylene tape-coated pipe are mitigated.

4.1.2 Westcoast Energy Inc.

Westcoast initiated an engineering assessment of both the NPS 36 L2 and the NPS 30 L1 pipelines, segment by segment, between Compressor Station 2 and Compressor Station 9 to ensure the safety of the pipelines. The engineering assessment for the 4AL2 segment indicated that a 75.81 m replacement section of NPS 36 (914 mm) diameter x 13.1 mm wall thickness X70 (Grade 483) pipe was installed in 2018 between kilometre posts 29.80 and 29.87 as part of the cut-out and repair at this site.

As of January 2020, based on the results of these assessments, the National Energy Board (NEB) had lifted operating pressure restrictions on all 12 segments of the NPS 36 L2 pipeline.

On 11 July 2019, in response to Pipeline Safety Advisory 02/19, Westcoast advised the TSB that it had completed a review of its stress corrosion management practices used on the T‑South natural gas pipeline system in British Columbia in January 2019, and had made several improvements to its SCC management program. Among them, changes were made to how re-inspection intervals for electromagnetic acoustic transducer (EMAT) in-line inspections are established. For example:

- SCC growth rates for all T-South pipeline segments were adjusted to align with industry experiences with pipelines of similar vintage and coating types, and to account for possible crack coalescence.

- Just-missed-flaw (JMF) sizes were adjusted following an analysis of the time-to-failure for a hypothetical JMF, and a safety factor of 2 was applied. This ensures flaws that grow above the detection limit during the re-inspection interval are identified in the next inspection, before they can grow to a critical size.

- The maximum re-inspection interval for EMAT in-line inspections for all L2 pipeline segments was set to 6 years.

Further, Westcoast has implemented a more conservative approach in responding to pipeline inspection data that may identify areas requiring closer monitoring or earlier maintenance work. These changes include

- improvements to the in-line inspection process itself, and verification and validation of tool performance to align with American Petroleum Institute standard API 1163; and

- improvements to how reported in-line inspection anomalies are processed.

In conjunction with changes to SCC management practices and in-line inspections, Westcoast also conducted an inline pipeline inspection program for the 30- and 36-inch natural gas pipeline on the T-South system, which was completed on 09 July 2019.

Westcoast also implemented other program improvements, including workstreams associated with the integrity management program, which were revised and defined to ensure that critical decisions and work processes have explicit review and independent approvals. With respect to the specific workstream related to documenting appropriate technical justification for any in-line inspection deferrals, a formal, independent review and approval, as well as tracking of in-line inspection deferrals, was established as a performance metric to ensure the process is being followed.

Improvements were also made to the emergency response program to clarify expectations for engaging potentially affected stakeholders in emergency response exercises, and to track invitations and participation of potentially affected stakeholders during future full-scale exercises.

4.1.3 National Energy Board

On 10 October 2018, the NEB issued an inspection officer order Footnote 38 allowing Westcoast to return the NPS 30 L1 pipeline to service on 11 October 2018, but at a restricted operating pressure of 80% of its 60-day high pressure. On 23 October 2018, the NEB specified modified and additional measures, including the operation of the NPS 36 L2 (from Station 2 to Huntingdon Meter Station) with a restricted operating pressure of 80% of its 60-day high pressure. On 16 November 2018, NB-001-2018 (Amendment No. 2) was issued to allow Westcoast to increase NPS 36 L2’s restricted operating pressure from 80% to 85% and modify its implementation of the overpressure protection system. The latest amendment to the inspection order was dated 24 December 2018. It restricted the operating pressure of NPS 36 L2 to 88% between Station 2 and Huntingdon Meter Station.

To remove these restrictions, Westcoast was required to submit engineering assessments for NEB review to ensure the safe operation of the relevant segments of NPS 36 L2. An engineering assessment to remove the pressure restriction on segment 4AL1 of the NPS 30 L1 pipeline was also reviewed and approved by the NEB. The NEB issued Notices to Resume Work or of Measures Satisfied after it was demonstrated that the relevant segments of the pipeline were fit for service to safely operate at their respective maximum operating pressures. In addition, field inspections Footnote 39 were performed to verify that regulatory requirements were being met. Technical meetings were held with Westcoast to evaluate crack detection tool reliability and run validation processes. Furthermore, Westcoast’s integrity management practices were examined to verify that regulatory requirements were being met.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .