Loss of control on takeoff

Privately registered

Van’s Aircraft, Inc. RV-14A (amateur-built aircraft), C-GXIV

Calgary/Springbank Airport (CYBW), Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the flight

On 16 May 2025, the pilot of the privately registered Van’s Aircraft, Inc. RV-14A amateur-built aircraft (registration C-GXIV, serial number 140988) intended to conduct the aircraft’s maiden flight. At 0714,All times are Mountain Daylight Time (Coordinated Universal Time minus 6 hours), unless otherwise stated. the pilot made an initial take-off attempt from Runway 17 at Calgary/Springbank Airport (CYBW), Alberta. After the aircraft had reached a maximum speed of 85.2 knots indicated airspeed (KIAS) during the take-off roll, the pilot perceived the aircraft performance to be lower than anticipated and aborted the takeoff.The airspeed data was retrieved from the aircraft’s electronic flight instrument system. The pilot then taxied back to the threshold of Runway 17 and made a 2nd take-off attempt at 0724.

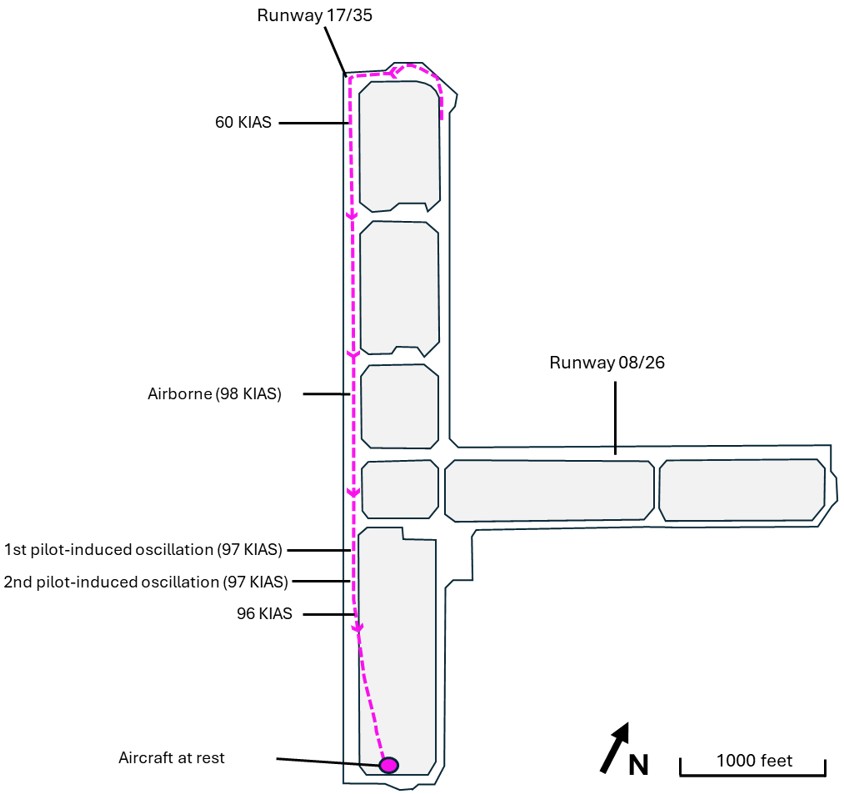

During the 2nd attempt, the aircraft gained approximately 10 to 20 feet of height and reached a maximum speed of 98.4 KIAS. When the aircraft passed the threshold for Runway 08, and at an airspeed of 97 KIAS, the pilot aborted the takeoff because he again perceived the aircraft performance to be lower than anticipated. The aircraft descended and contacted Runway 17, nose landing gear first. The aircraft subsequently bounced, became airborne again, entered a pilot-induced oscillation (PIO),See the section titled Pilot-induced oscillation in this report for a description of this phenomenon. and drifted to the left of the paved runway surface. The aircraft descended and impacted the grass area on the left (east) side of Runway 17 (Figure 1).

The right main landing gear broke free from the aircraft and impacted the right horizontal stabilizer. The left main landing gear collapsed and folded aft under the fuselage, and the nose landing gear collapsed aft. The propeller contacted the ground, and all 3 propeller blades broke off (Figure 2). The firewall area of the forward fuselage also sustained significant damage.

The pilot received serious injuries but was able to extract himself from the cockpit. There was no post-impact fire, and the emergency locator transmitter (ELT) activated.

Weather information

The weather was suitable for visual flight rules flight and was not considered to be a factor in this occurrence.

Pilot information

The pilot held the appropriate licence for the flight in accordance with existing regulations: a private pilot licence - aeroplane for single-engine landplanes. The pilot began flight training toward this licence in September 2012 and took the flight test in June 2014. At the time of completion of all requirements to hold the private pilot licence, the pilot had accrued 169.6 hours total time.

The pilot then flew regularly until 2018. No flight time was accrued in 2019 or 2020. In 2021, the pilot accrued 1.2 flight hours, and in 2022, he flew 5.9 hours. In 2023, the pilot began training in a Van’s Aircraft, Inc. RV-7AA Van’s Aircraft RV-14A is similar in design and construction to an RV-7A. The key differences are that the RV-14A is approximately 10% larger and utilizes a different airfoil on the wing. and performed 3 flights, totalling 7.5 flight hours. In 2024, the pilot completed 3 more flights in an RV-7A, totalling 8.5 hours. In April 2025, in preparation for the 1st flight in his RV-14A, the pilot once again completed 3 familiarization flights in an RV-7A, totalling 7.2 flight hours.

At the time of the occurrence, the pilot had accumulated 380.5 total flight hours.

Aircraft information

The Van’s Aircraft, Inc. model RV-14A is a 2-seat (side-by-side), all-aluminum, amateur-built aircraft. The aircraft was equipped with a 215 hp, Lycoming YIO-390 4-cylinder engine, and a 3-blade, constant-speed MT-Propeller. The aircraft has a stall speed (VS) of approximately 47 KIAS.Van’s Aircraft Total Performance, https://www.vansaircraft.com/rv-14/#aircraft-details-2 (last accessed on 06 November 2025). Given the universally accepted practice of using a landing approach reference speed (VREF) of 1.3 times VS, this results in an approximate speed of 61 KIAS on final approach to landing.

The aircraft was within the envelope for weight and centre of gravity.

Electronic flight instrument system

The aircraft was equipped with a Garmin G3X Touch electronic flight instrument system. The builder is required to set up and calibrate all of the installed components. In this instance, the builder was required to set up and calibrate the elevator trim position indicator on the primary flight display and the direction of travel for the elevator trim actuator itself to ensure the correct operation of the elevator trim system.

Elevator trim system

The aircraft was equipped with an electric elevator trim system. The system consists primarily of 4 components:

- Elevator trim switch (located on the pilot’s control stick grip)

- Elevator trim position indicator (located on the pilot’s primary flight display)

- Electric elevator trim actuator and elevator trim tab assembly (located in the left elevator assembly)

- Control box

The initial post-accident examination of the aircraft found the elevator trim position indicator indicating full nose-up deflection and the elevator trim tab in the full nose-down deflection. Subsequent inspection and testing found that what the elevator trim position indicator showed was consistent with the position and actuation of the elevator trim switch, but that the elevator trim actuator itself was working in reverse and actually moving the elevator trim tab in the opposite direction.

The investigation was unable to determine what, if any, role the reversed elevator trim system had played in the occurrence. The checklist that the pilot was using for the occurrence flight included a “flight controls-free/correct” item but did not specifically identify a verification of the trim system. The aircraft kit manufacturer indicated that with the elevator trim tab at full nose-down deflection, and at a typical cruise airspeed, approximately 40 pounds of force would be required on the control stick to maintain level flight. The pilot did not recall any unusual control forces during either take-off attempts.

Engine

Although the builder of the occurrence aircraft had performed several ground runs of the engine before the 1st take-off attempt, the engine had never been operated at full power on the ground to confirm satisfactory engine performance. A review of the engine data recorded in the Garmin G3X Touch system and the airspeed attained during the 2 take-off attempts indicates that engine performance did not likely contribute to the occurrence.

Minister’s Delegate - Recreational Aviation

The Minister’s Delegate - Recreational Aviation (MD-RA) is a person delegated by Transport Canada (TC)Government of Canada, Aeronautics Act (R.S.C., 1985, c. A-2), subsection 4.3(1). who is authorized to inspect amateur-built aircraft in Canada and issue the initial Special Certificate of Airworthiness - Amateur-built when an aircraft is completed. This delegated authority is granted to individuals who meet the applicable experience and training requirements, and is valid for a 3-year period. Transport Canada Civil Aviation (TCCA) performs oversight as required on individuals who hold the MD-RA delegated authority. MD-RA Inspection Service, a commercial entity, provides, by agreement with TC, administrative support services to MD-RAs who inspect and certify amateur-built aircraft on behalf of the Minister of Transport; it performs no regulatory function. TC periodically audits the completed aircraft files that MD-RA Inspection Service submits.

MD-RAs also perform inspections of aircraft projects at various stages of assembly, as well as a final inspection when an aircraft is complete, before the 1st flight. The occurrence aircraft had received all inspections, including its final inspection on 18 April 2025. As part of that inspection, the elevator trim system was signed off, and no issues were noted. The engine was also signed off as having been inspected and ground run. The data collected over the course of the investigation indicates that no engine ground run was performed under the observation of the MD-RA during the final inspection process.

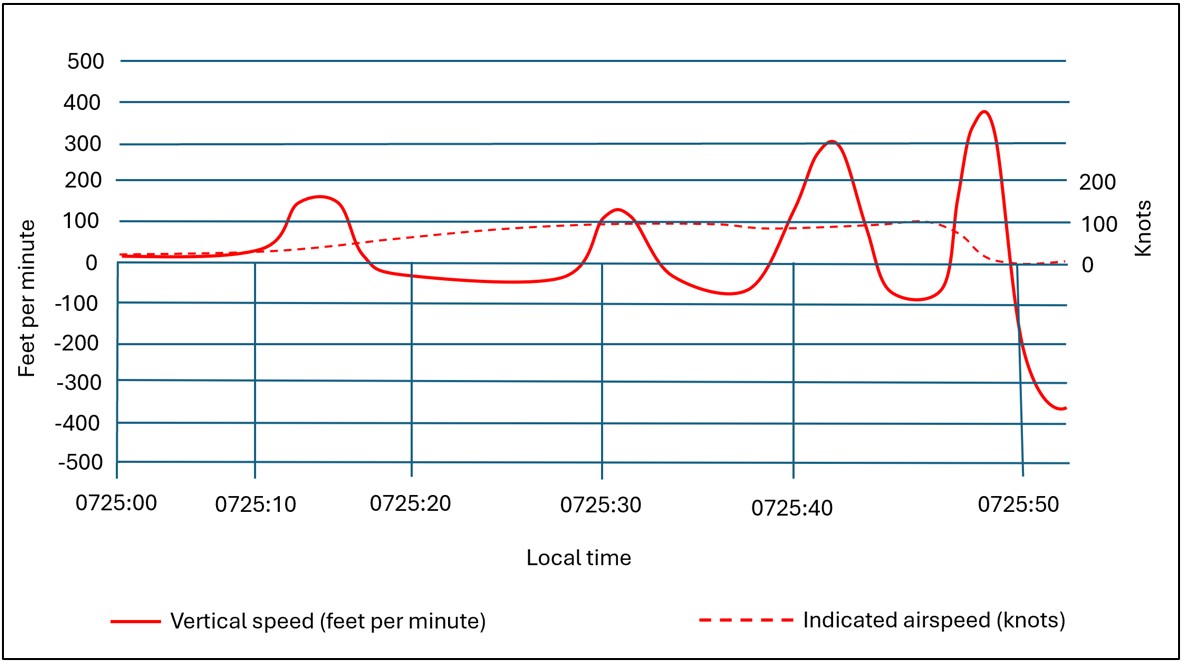

Pilot-induced oscillation

PIO, also known as porpoising, can present a notable challenge to pilots during the landing phase of a flight. As explained by the U.S. Federal Aviation Administration (FAA) in its Airplane Flying Handbook, “[i]n a bounced landing that is improperly recovered, the airplane comes in nose first, initiating a series of motions imitating the jumps and dives of a porpoise.”Federal Aviation Administration (FAA), FAA-H-8083-3C, Airplane Flying Handbook (2021), Chapter 9: Approaches and Landings, p. 9-34. As was the case in the occurrence flight (Figure 3), the series of oscillations involves an increase in amplitude.

Several factors can contribute to PIO during landing. These include the inherent handling characteristics of the aircraft, pilot technique, and environmental conditions such as turbulence or wind shear. General aviation aircraft typically rely on direct mechanical controls, which may be more sensitive to abrupt inputs. Consequently, pilots must develop a strong sense of timing and control finesse, especially during the critical low-speed phase of final approach.

TrainingTransport Canada, TP1102E, Aeroplane Flight Training Manual, 4th Edition (revised August 2004), Exercise 18: Approach and Landing, Recovering from Bad Landings, p. 112. focused on recognizing the onset of PIO and practising smooth, measured control inputs can help pilots reduce oscillations and improve overall landing safety. If there is not enough elevator or stabilator trim applied, the aircraft may touch down nose-wheel first, causing a PIO motion.

PIO can also result from improper airspeed management. For example, when an approach is too fast, an aircraft tends to float above the runway, and the pilot may attempt to force it down before it is ready to settle. This can lead to several different results, the 1st being that the aircraft is briefly lifted back into the air by wind gusts, runway bumps, or even small control inputs. The 2nd is that the nose wheel makes initial contact with the runway surface and bounces upward. This is quickly followed by the pilot overcorrecting, pushing forward on the controls, and mistiming the next flare, resulting in the nose wheel once again contacting the runway surface first and the sequence repeating itself with oscillations of increasing amplitude. A PIO can also be produced without runway contact when the pilot overcorrects or mistimes control inputs during the flare in the landing phase of flight. If the PIO is severe and the pilot applies control and power inputs too late or improperly, the pilot may unintentionally worsen the oscillations, potentially causing the nose gear to be damaged or even collapse on impact with the ground.

Safety pilot

Although TC does not provide any specific guidance to builders and pilots on conducting 1st flights in amateur-built aircraft with an additional pilot (also known as a safety pilot), the FAA has published Advisory Circular (AC) 90-116: Additional Pilot Program for Phase I Flight Test.Federal Aviation Administration (FAA), Advisory Circular (AC) 90-116: Additional Pilot Program for Phase I Flight Test (2014).,Phase I flight testing is the flight testing required to be performed for the aircraft’s first 25 hours of operation, during which passengers cannot be carried on board and flight operations must be conducted within 25 nautical miles (NM) of the designated airport listed in the operating conditions as part of the Special Certificate of Airworthiness.

This AC furnishes detailed information and guidance concerning the Additional Pilot Program (APP) for the flight testing of experimental aircraft. The APP was established to enhance safety by advancing the competencies of builders and pilots and by mitigating, through the engagement of qualified additional pilots, the risks associated with Phase I flight testing.Federal Aviation Administration (FAA), Advisory Circular (AC) 90-116: Additional Pilot Program for Phase I Flight Test (2014), p. 1. Participation in the APP is entirely optional and offers an alternative avenue for conducting Phase I flight testing. The conventional method, whereby a pilot performs solo flight testing during Phase I, is neither addressed nor modified by this AC and remains a viable option for those who elect to proceed in accordance with the aircraft’s operating limitations.

Although AC 90-116 is not wholly applicable to Canadian builders/pilots, it does highlight the FAA’s review of over 10 years of historical data from accidents involving experimental amateur-built aircraft. Most notably, the AC states that “utilizing a qualified additional pilot to mitigate risks associated with LOC [loss of control] in Phase I flight, under controlled circumstances, is appropriate.”Ibid., p. 2.

Safety messages

Builders and maintainers of amateur-built aircraft are reminded of the requirement to verify that all flight controls are operating in the correct direction and within the correct travel limits before the 1st flight is attempted and after any maintenance on flight controls has been performed on the aircraft.

It is critical that MD-RAs ensure that all inspection items are completed and checked before signing off the relevant documentation.

Pilots are reminded of the importance of recognizing the onset of a PIO and executing the correct recovery technique.

For the safety of flight, it may be advantageous for pilots of amateur-built aircraft to engage an experienced and qualified pilot when performing Phase I flight testing.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 19 November 2025. It was officially released on 26 November 2025.