Train derailment

Canadian National Railway Company (CN)

Mile 69, St-Hyacinthe Subdivision

Longueuil, Quebec

The occurrence

On 14 November 2024, Canadian National Railway Company (CN) freight train M32231-13 (the train) was travelling eastward on the south service track of Southwark Yard in Longueuil, Quebec, near Mile 69 of CN’s St-Hyacinthe Subdivision. It consisted of 102 cars: 60 loaded cars, 33 empty cars, and 9 residue cars. It weighed 9156 tons and was 6242 feet long.

At approximately 0827, after the train had switched over to track A075 and was travelling at about 9 mph, a train-initiated emergency brake application occurred. Once the train came to a stop, the crew inspected it and found that 8 cars had derailed. The last 2 derailed cars fouled a service track and the south main track (Figure 1).

No other cars derailed, and no injuries were reported. Two of the derailed cars were tank cars containing dangerous goods. The first tank car was loaded with propane (UN1075) but did not leak. The second car was loaded with hydrogen peroxide (UN2014). It remained upright, but its side wall was punctured, resulting in the partial release of its contents.

Initial response

An emergency call was made to the 9-1-1 call centre at approximately 0845. Between 0855 and 0910,

- the first emergency vehicles from police and firefighting services arrived on site;

- a mobile command post was established in the rail yard;

- Highway 116 was closed to all vehicular traffic between Highway 134 (Taschereau Boulevard) to the west and Highway 30 to the east;

- the decision was made to establish a safety perimeter of 800 m around the derailment site, in consultation with the Canadian Transport Emergency Centre (CANUTEC) (Figure 2);

- the firefighters started to hose the tank car that was releasing hydrogen peroxide.

Site examination by TSB investigators

A total of about 373 feet of railway track was destroyed. A section of damaged rail from the start of the derailment area was recovered and examined by the TSB (Figure 3).

This section came from a 100-pound rail that had sustained a head-web separation, because of an internal rail defect related to metal fatigue. Progression of this type of defect can occur very rapidly with repeated heavy traffic.

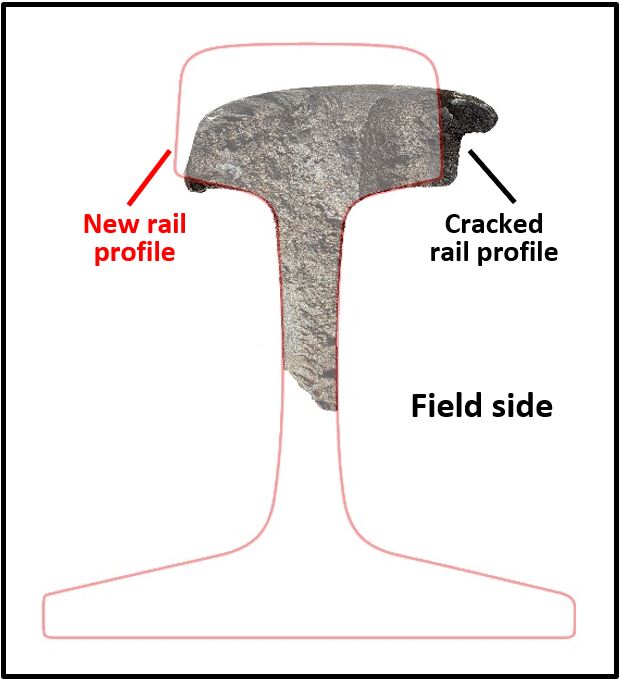

The upper portion of the rail head also showed significant deformation (creep) toward the field side of the rail. This kind of deformation usually occurs when a section of rail has been subjected to heavy loads for many years (Figure 4).

According to information gathered by the TSB, the most recent ultrasonic testing of the rails in the vicinity of the derailment was carried out on 22 November 2023 to identify possible internal defects.

Conclusion and safety communication

Following the assessment of the occurrence on site and the examination of the recovered parts, TSB investigators found safety deficiencies and identified corrective measures that could reduce safety risks.

On 19 December 2024, the TSB issued Rail Transportation Safety Advisory Letter 06/24 to Transport Canada on inspection requirements of tracks such as those located in rail yards to ensure that they remain fit for continued service. This advisory provides the regulator, who has the ability to make the required changes, with relevant information and TSB investigators’ conclusions. As a result, this puts an end to the TSB’s investigation activities related to this occurrence.

Safety communications

Download high-resolution photos from the TSB Flickr page.

Class of investigation

This is a class 5 investigation. Class 5 investigations are limited to collecting data, which are then stored in the modal database. If TSB investigators deployed to the occurrence site, a short description of the occurrence is posted to the TSB website once the investigation has been completed. These investigations are generally completed within 90 days. For more information, see the Policy on Occurrence Classification.

TSB investigation process

There are 3 phases to a TSB investigation

- Field phase: a team of investigators examines the occurrence site and wreckage, interviews witnesses and collects pertinent information.

- Examination and analysis phase: the TSB reviews pertinent records, tests components of the wreckage in the lab, determines the sequence of events and identifies safety deficiencies. When safety deficiencies are suspected or confirmed, the TSB advises the appropriate authority without waiting until publication of the final report.

- Report phase: a confidential draft report is approved by the Board and sent to persons and corporations who are directly concerned by the report. They then have the opportunity to dispute or correct information they believe to be incorrect. The Board considers all representations before approving the final report, which is subsequently released to the public.

For more information, see our Investigation process page.

The TSB is an independent agency that investigates air, marine, pipeline, and rail transportation occurrences. Its sole aim is the advancement of transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability.