19 December 2024

Director General, Rail Safety and Security, Transport Canada

Enterprise Building, 14th Floor

427 Laurier Avenue West

Ottawa ON K1A 0N5

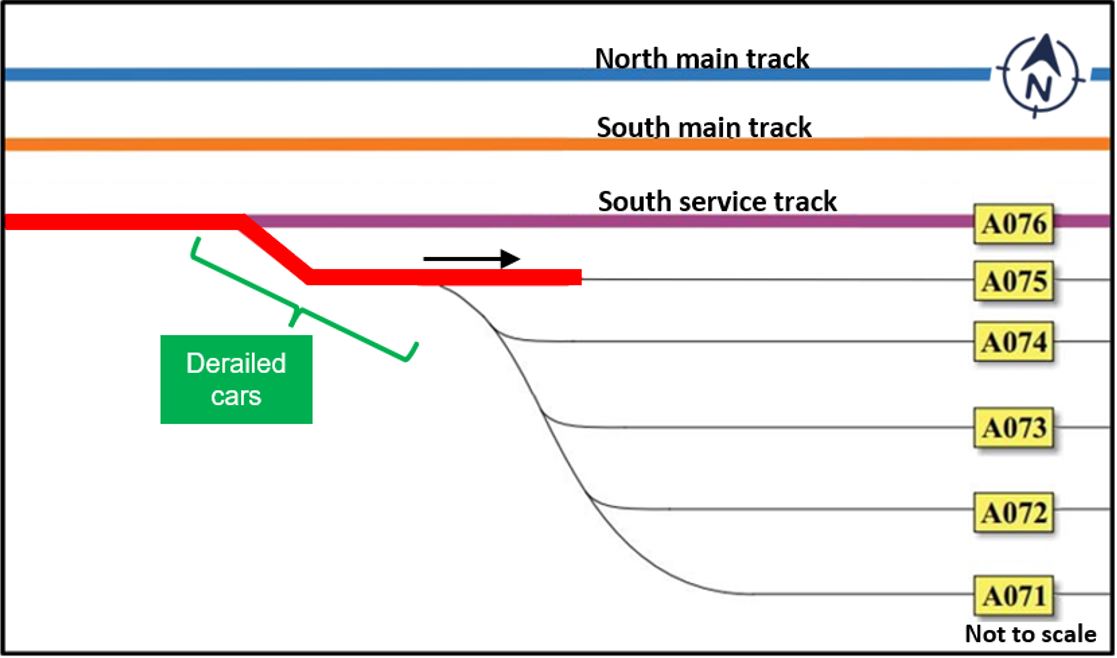

On 14 November 2024, Canadian National Railway Company (CN) freight train M32231-13 (the train) was travelling eastward on the south service track (track A076) of Southwark Yard in Longueuil, Quebec, near Mile 69 of CN’s St-Hyacinthe Subdivision. It consisted of 102 cars: 60 loaded cars, 33 empty cars, and 9 residue cars. It weighed 9156 tons and was 6242 feet long. The crew consisted of a conductor and a locomotive engineer.

The train continued eastward on the lead track toward track A075. At approximately 0827,All times are Eastern Standard Time. when it was travelling at about 9 mph and its leading end was approximately 500 feet beyond switch A075, a train-initiated emergency brake application occurred. Once the train came to a stop, the crew inspected it and found that 8 cars (lines 7 to 14) had derailed in various positions on the lead track between the switches for tracks A076 and A075. The last 2 derailed cars obstructed track A076 and the south main track. No other cars derailed, and no injuries were reported (Figure 1).

Tank car TELX 17064 (line 12 in the train consist), which was loaded with hydrogen peroxide (UN2014), had overturned on its side, resulting in the puncture of its side wall and the partial release of its contents.

At approximately 0911, an initial 800 m lockdown perimeter was established around the derailment site, and Highway 116Highway 116 runs parallel to the tracks located at the south end of the yard. was closed to all vehicular traffic between Highway 134 (Taschereau Boulevard) to the west and Highway 30 to the east. Rail traffic in the area (CN freight trains, VIA Rail Canada Inc. passenger trains, and exo commuter trains) was also interrupted. The lockdown, the perimeter of which had been gradually reduced during the day, was lifted around 0400 on November 15.

Approximately 373 feet of the lead track between the switches for tracks A076 and A075 was destroyed. The damaged rails examined by the TSB were all 100-pound rails and varied considerably in age and degree of wear. Some of the rails dated from 1925 and were marked “OH,” indicating that they had been manufactured using the open-hearth process.Rail manufactured using the open-hearth process has a known propensity for propagating cracks and entrapping inclusions. The open-hearth process is no longer used and has been replaced by more modern steel-refining methods that provide better quality control. The most recent rails were manufactured in 1955.

A section of damaged rail was recovered at the start of the derailment area, in the return curve of switch A076, about 170 feet east of the points of that switch. This section of rail had a head and web separation.Head and web separation is an internal rail defect caused by metal fatigue. Progression of this defect can occur very rapidly with repeated heavy traffic, as the wheel flanges of rail cars exert strong lateral pressure against the inner rail flange, particularly on curves. The fractured surface showed traces of pre-existing corrosion.

That rail was from a 100-pound railIt was not possible to determine either the year of manufacture or the manufacturing process used for the recovered rail, as the corresponding portion showed no embossed inscription on the web. that had 10 mm of wear on the running surface and 6 mm of wear on the inner flange, for a combined wear of 16 mm. This level of wear exceeds the maximum combined wear level of 14 mm prescribed by CN Engineering Track StandardsCanadian National Railway Company, Engineering Track Standards, T.S. 1.0, section 23, table 7D, 23 August 2023. for 100-pound rail.

The top of the head also showed significant deformation (creep) towards the field side (outside) of the rail (Figure 2). Such deformation usually occurs when a rail has been subjected to heavy loads for many years.

According to information gathered by the TSB, the most recent ultrasonic inspection of the track in the vicinity of the derailment was carried out in November 2023. At that time, no defects were detected.

There are many rail yards located close to densely populated urban centres. Every day, a large number of rail cars, some carrying dangerous goods, pass through these yards.

Rails in yards are regularly inspected. Inspection methods generally include visual inspections as well as ultrasonic testing using hi-rail vehicles to detect internal defects. Some track inspection equipment can perform rail wear measurement, but such equipment is generally used on main tracks. As such, in most rail yards, rail wear is not systematically measured as part of the scheduled inspection program.

It is therefore possible that older and/or vintage rails that are near or exceed their established maximum wear standards remain in service in rail yards. Such rails could develop undetected internal defects which increase the likelihood of sudden in-service failure, resulting in a derailment and compromising the safety of the public and nearby infrastructure.

Consequently, Transport Canada may wish to consider reviewing rail inspection and testing requirements for tracks such as those located in rail yards to ensure that they remain fit for continued service.

The TSB would appreciate being informed of what action, if any, will be taken in this regard.

Yours sincerely,

Original signed by

Vincenzo DeAngelis

Director, Investigations (Rail/Pipeline)

cc.

Senior Director, Operations Management, Rail Safety and Security

Transport Canada

Acting Director, Regulatory Affairs, Rail Safety and Security

Transport Canada

Vice President, Safety

Canadian National Railway Company

Senior Manager, Regulatory Affairs, Safety

Canadian National Railway Company

Director, Regulatory Affairs

Railway Association of Canada