Place du Centre, 4th floor

200 Promenade du Portage

Gatineau QC K1A 1K8

19 April 2021

Director General, Civil Aviation

Transport Canada

Re :

Air Safety Information Letter A20C0103-D1-L1

McCauley Propeller Systems blade actuating pin

Dear Sir,

On 27 October 2020, the Wasaya Airways LP (Wasaya) Cessna 208B Grand Caravan aircraft (registration C-FPCC, serial number 208B0840) was conducting flight WSG129 from Pickle Lake Airport (CYPL), Ontario, with only the pilot on board. Shortly after liftoff, there was a loud bang and a loss of thrust, accompanied by severe vibration. The pilot lowered the nose to maintain airspeed and conducted a forced landing, bringing the aircraft to a stop approximately 20 feet from the end of the runway. The pilot was not injured and the aircraft was not damaged; however, a propeller blade was noted to be at an odd angle (Figure 1).

In accordance with the TSB’s Policy on Occurrence Classification, the circumstances of this occurrence were assessed, and the occurrence was classified as a Class 5 occurrence. Consequently, TSB activity was limited to the collection of data, which has been recorded for safety analysis, statistical reporting, and archival purposes. The following paragraphs contain safety-related information derived during the assessment of this occurrence.

The operator conducted a preliminary inspection of the propeller (McCauley Propeller Systems model 3GFR34C703, serial number 911094), which revealed that 1 blade could be rotated freely within the hub. Both the propeller owner and the operator filed service difficulty reports (SDRs) with Transport Canada (SDR No. 202001105014 and No. 20201202006, respectively).

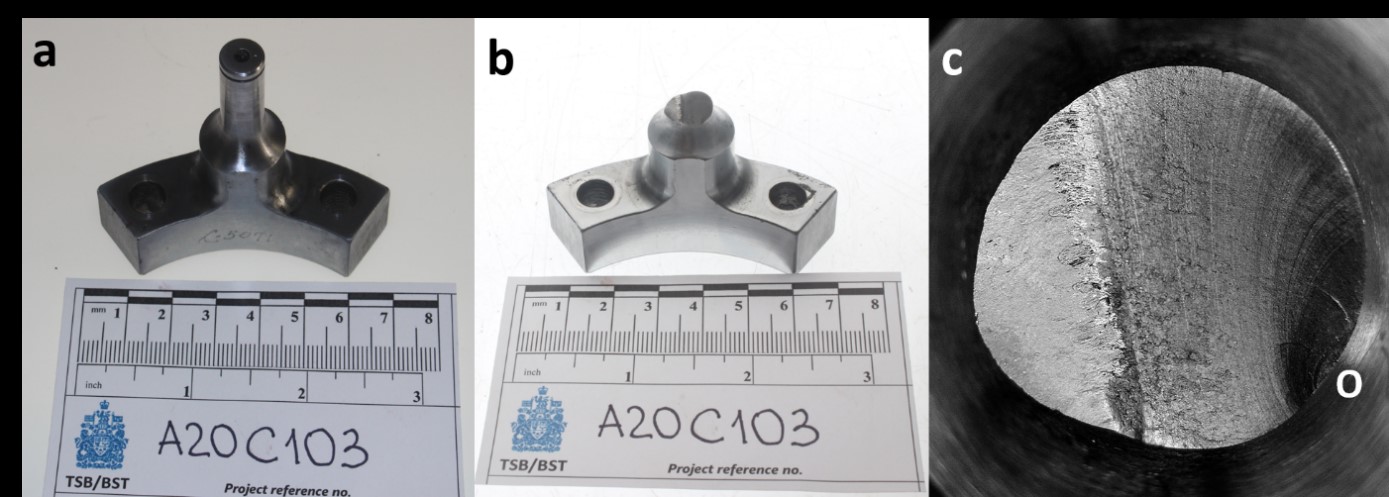

The propeller in this occurrence is a single-acting, reversing, feathering model that utilizes hydraulic pressure to move the blades toward low pitch (high rpm). Springs and counterweights move the blades toward high pitch (low rpm) and, in the absence of hydraulic pressure, to the feather position. Movement of the actuating piston is transferred to each propeller blade through a piston rod and link assembly that drives blade actuating pins (Figure 2a) that are indexed by a roll pin, and bolted to the root of each propeller blade.

Examination by the TSB revealed that the blade actuating pin of the No. 2 propeller blade (Figure 2b) had failed due to a fatigue fracture (Figure 2c). No surface defects or any microstructural irregularities, such as large inclusions or corrosion, were observed at the origin of the fatigue fracture.

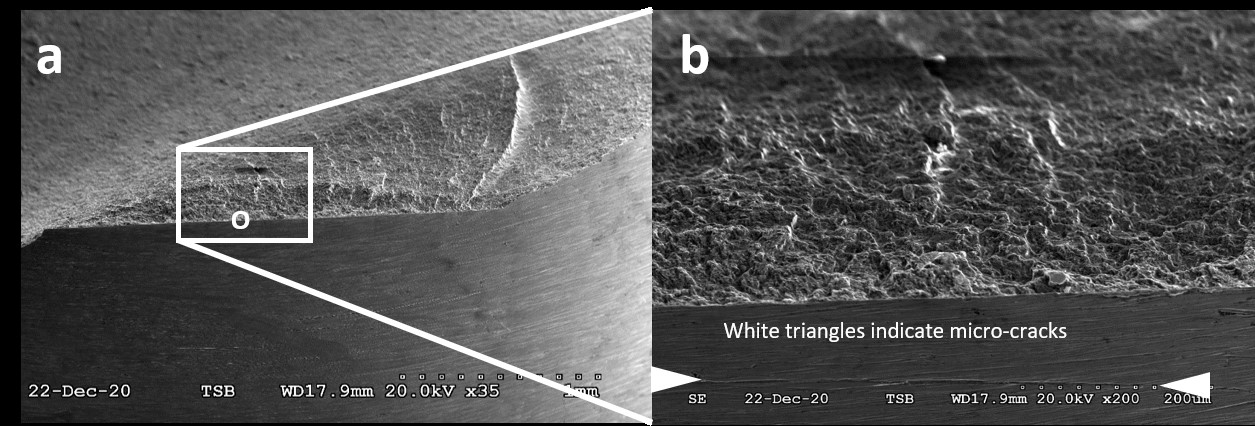

Micrographs of the fatigue origin area taken with a scanning electron microscope revealed that an initial, fingernail-shaped fatigue crack (Figure 3a) started from an almost straight line on the pin surface. Approximately parallel to this line, there were several small, straight micro-cracks (Figure 3b) on the pin surface in the chromium coat. The cracks were likely deep enough to penetrate into the steel core of the pin. The cracks likely developed from bending deformation and served as the fatigue origin that led to the eventual fracture of the blade actuating pin. The micro-cracks were sub-millimetre in length and are too small to be detected by magnetic particle inspection (MPI). No such cracks were found on blade actuating pins of the No. 1 or No. 3 propeller blades.

The propeller was manufactured in 1991. However, the propeller blades were subsequently replaced by blades manufactured in December 2000. It is likely that all 3 propeller blades had been replaced at the same time due to their close range of serial numbers. New propeller blades do not come with new blade actuating pins installed.

The early operational and overhaul history of the propeller is unclear. However, in 2013, while the propeller was installed on a Cessna Grand Caravan (registration N105VE) operating in Europe, a “slight prop strike”Footnote 1 was recorded in the propeller’s technical record. The propeller was removed and sent to an approved repair facility in Linz, Austria. Although the damage was sufficient to warrant the removal of the propeller, the repair facility assessed the damage as minor. The damaged blade was repaired and repainted without disassembling the propeller. At that time, the propeller had accumulated 9398.6 hours since new.

The propeller continued in service on N105VE until it had accumulated 10 357.2 hours since new. It was removed and underwent an overhaul in June 2017 in the United States, during which the blade actuating pins were subjected to MPI. In August 2017, the propeller was sold and shipped to Canada where it was re-assembled. After a period of time in storage, it entered service in August 2018 on another Wasaya aircraft (registration C-FHWA). In September 2019, the propeller was removed and installed on the occurrence aircraft. A year later, it was subjected to a bird strike.Footnote 2 The propeller was inspected in situ, cleaned, and returned to service by the operator.

On the day of the occurrence flight, the propeller had accumulated 2469.6 hours since the 2017 overhaul and 12 826.8 hours since new.

The blade actuating pins (part number C-5071)Footnote 3 are not serialized and have no replacement time limit. They are manufactured from a 4130-steel forging and are heat-treated to specification. During a propeller overhaul,Footnote 4 the blade actuating pins are subjected to dimensional checks, visual inspection, and MPI. There are no directions in the overhaul manual stating that the blade actuating pins must be re-installed on the same blades from which they were removed.

It was not possible to determine the time in service of any of the 3 blade actuating pins. However, the part number on each blade actuating pin had been free-hand vibro-penned in the same handwriting, suggesting that they were from the same manufacturing batch. The fractured blade actuating pin on the No. 2 propeller blade met the alloy and hardness specifications provided by the manufacturer.

McCauley Service Bulletin 176EFootnote 5 (applicable to all McCauley propellers) defines the maintenance action that must be taken if the propeller is subjected to 1 of the following events:

- Object strike of a stationary propeller

- Blade strike of a rotating propeller

- Bird strike

- Sudden engine stoppage

The service bulletin states the criteria for a possible field repair in the case of the first 3 events listed above. If the propeller does not meet the field repair criteria or is subjected to a sudden engine stoppage (the 4th event listed above), the propeller must be overhauled.

This style of blade actuating pinFootnote 6 is in use in a variety of McCauley propeller models installed on a wide range of single- and multi-engine aircraft. As demonstrated in this occurrence, a failure of a blade actuating pin in a single-engine aircraft will result in a loss of thrust and a drastically reduced glide ratio. Fortunately, in this case, there was sufficient runway remaining for the pilot to conduct a forced landing. Had the loss of thrust occurred any later in the flight, the outcome could have been more serious.

This type of failure appears to be a rare event. A search of all blade actuating pin part numbers in Transport Canada’s Canadian Aviation Service Difficulty Reporting system did not reveal any other reported failures.Footnote 7

The detection of damaged blade actuating pins is reliant on an appropriate field assessment of a propeller strike and, if an overhaul is required, by MPI. However, depending on the severity of the propeller strike, the micro-cracks created by the consequent bending moment may not be detectable by the MPI process.

The foregoing is provided for whatever follow-up action is deemed appropriate. The TSB would appreciate being advised of any action taken in this regard.

Yours sincerely,

Original signed by

Natacha Van Themsche

Director of Investigations — Air

Transportation Safety Board of Canada

cc:

- Director, Safety Policy and Intelligence – Transport Canada Civil Aviation

- Accredited Representative, NTSB

- Manager Air Safety Investigations, Textron Aviation

- Manager Technical, McCauley Propeller Systems

- Minister’s observer, Transport Canada

- President/CEO, AMK Aviation

- CEO, Wasaya Airways LP