Main-track train derailment

Canadian National Railway Company

Freight train L59411-30

Mile 32.7, Sussex Subdivision

Near Dunsinane, New Brunswick

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

1.0 Factual information

1.1 The accident

On 30 October 2023, Canadian National Railway Company (CN) freight train L59411-30 left CN’s Gordon Yard in Moncton,All locations are in the province of New Brunswick, unless otherwise indicated. destined for Saint John. The mixed freight train consisted of 2 head-end locomotives (CN 3306 and CN 2932) and 46 cars, including 10 tank cars carrying dangerous goods. It weighed about 5115 tons and was approximately 2832 feet long. The train crew consisted of 1 locomotive engineer, 1 conductor, and 1 locomotive engineer trainee. All the crew members were qualified for their positions, met fitness and rest requirements, and were familiar with the territory.

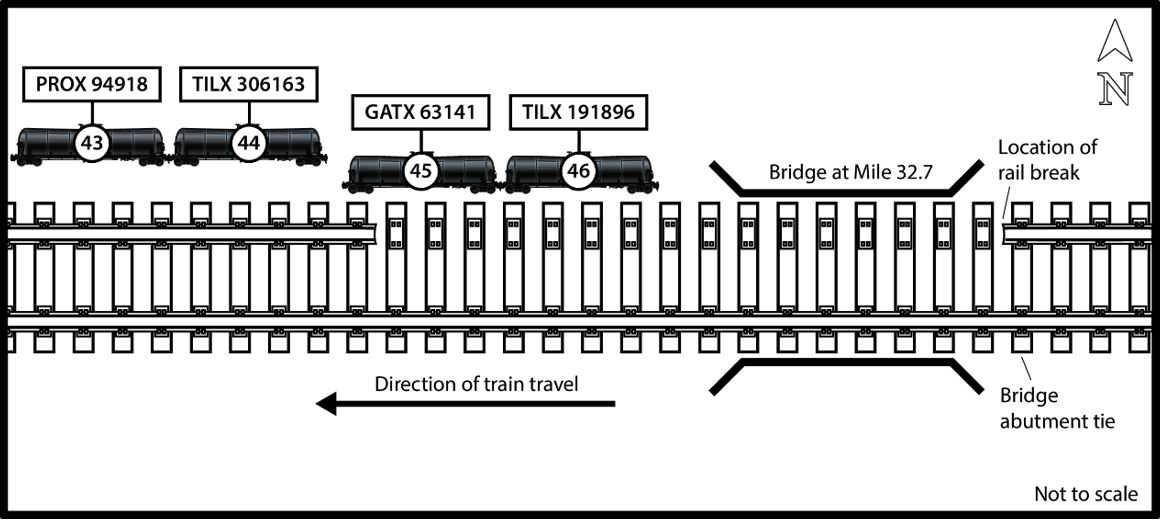

The train was travelling westward on CN’s Sussex Subdivision at about 38 mph when a train-initiated emergency brake application occurred at approximately 1310.All times are Atlantic Daylight Time. Once the train had stopped, the conductor inspected it and discovered that the last 4 cars had derailed around Mile 32.7, near Dunsinane (Figure 1). There were no injuries or fires.

1.2 Site examination

The 4 cars that derailed, in positions 43 to 46,Cars PROX 94918, TILX 306163, GATX 63141, and TILX 191869, respectively. were tank cars carrying dangerous goods.The cars in positions 43, 44, and 45 were DOT-112J tank cars carrying butane (UN1075) and the car in position 46 was a DOT-111 tank car carrying methanol (UN1230). They had derailed on the north side of the track, west of a small bridge (Figure 2). Cars in positions 43 and 44 had remained coupled together and were on their side, while cars in positions 45 and 46 had remained coupled together and had overturned. Visual examination of the tank cars showed that there were no breaches to the tank shells.

On-site examination also noted that a section of the north rail had broken into multiple pieces at the eastern side of the bridge, beginning around the bridge abutment tie where the rail transitioned from roadbed to bridge structure and extending over the first 3 ties of the bridge. The bridge abutment tie and the last 2 wooden ties of the roadbed east of the section of the rail break were split and the tie plates had cut into the wooden ties.

The recovered pieces of the north rail were sent to the TSB Engineering Laboratory in Ottawa, Ontario, for further examination.

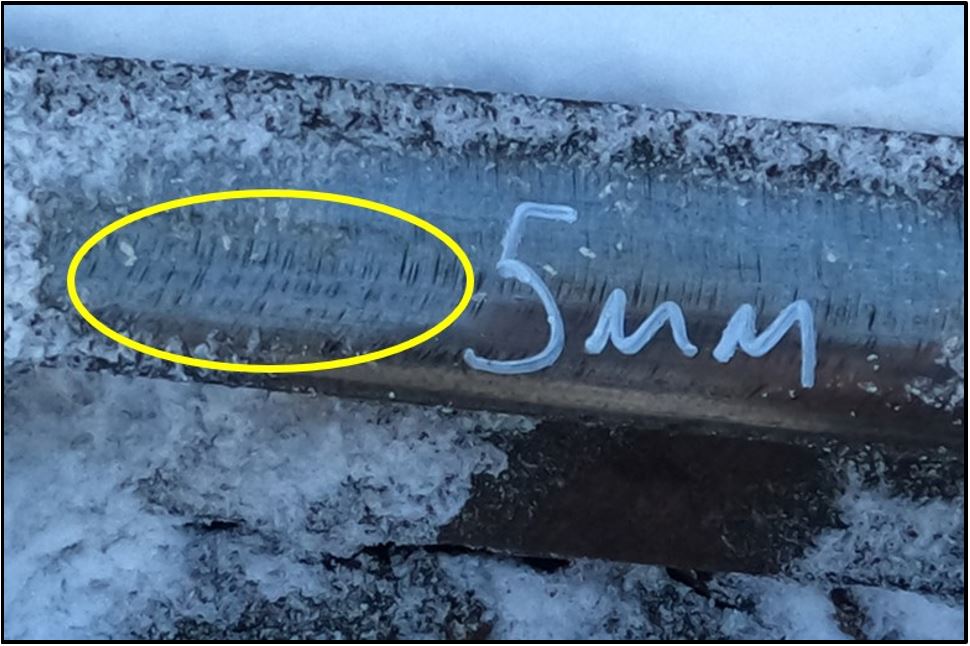

The condition of the rail observed on site showed that the north rail on the bridge had extensive head checking along its rolling surface (Figure 3).

In contrast, the undamaged north rail on the roadbed approaching the bridge showed a smooth rolling surface with marks consistent with recent grinding activity (Figure 4).

During the post-derailment cleanup, when the last derailed tank car (car in position 46, containing methanol) was moved for transloading, it was discovered that approximately 2000 litres of methanol had leaked from the car’s pressure relief device, which had been damaged during the derailment. The leaked methanol was contained in the area surrounding the tank car and was subsequently recovered, along with any contaminated soil.

Finding: Other

Tank car TILX 191869 overturned during the derailment and approximately 2000 litres of methanol leaked from the car’s damaged pressure relief device.

1.3 Recorded information

Forward-facing camera and locomotive voice and video recorder footage from the lead locomotive was retrieved and reviewed by the TSB. A noise can be heard on the forward-facing camera audio as the locomotive crossed the bridge at Mile 32.7; however, the track appeared intact as the locomotive traversed this section of rail.

Readouts from the last wheel impact load detector that the consist passed (at Mile 29.0 of CN’s Napadogan Subdivision) were reviewed by the TSB. The readings were below condemnable limits.

1.3.1 Weather

At the time of the occurrence, it was −1 °C and snowing, with a visibility of about 2 km.Environment and Climate Change Canada historical data. Hourly temperature measured at the closest station to the occurrence site: Sussex Four Corners (15 km from the site). There were several centimetres of snow on the ground and covering the rail.

1.4 Subdivision information

The CN Sussex Subdivision is a Class 3 track under the Rules Respecting Track Safety, also known as the Track Safety Rules (TSR), and has an average annual tonnage of approximately 4.8 million gross tons. The single main track extends from Marsh Junction (Mile 0.0) in Moncton to Coldbrook Station (Mile 83.5) near Saint John.

From Mile 2.9 to Mile 83.5, train movements on the subdivision are governed by the occupancy control system as authorized by the Canadian Rail Operating Rules and dispatched by a rail traffic controller located in Edmonton, Alberta. The speed limit for freight trains is 40 mph.

1.5 Track information

At the location of the derailment, the track consisted of continuous welded rail made of carbon steel (100-pound rail, manufactured in 1951, on the north side, and 115-pound rail, manufactured in 1958, on the south side), which was secured to 8-foot hardwood ties. The installation date of the north rail could not be confirmed by CN. The north rail had 12-inch tie plates with alternating spike pattern (2 or 3 spikes per plate), and the south rail had 14‑inch tie plates and the same spike pattern. The ties were box-anchored every second tie through a left-hand curve leading to a bridge at Mile 32.7. The crushed rock ballast was in good condition with full cribs and shoulders.

The bridge at Mile 32.7 was a single span open deck bridge, approximately 18 feet long, and traversed a small unnamed watercourse. It consisted of concrete abutments and a steel structure with 19 wooden ties (three 16-foot ties and sixteen 12-foot ties). There were also five 12-foot ties on each side of the bridge, making the transition to 8-foot ties in the roadbed. It had been reported that there was rough track in the area of the occurrence at Mile 32.7.

1.6 Track inspections

In accordance with the TSR, the Sussex Subdivision receives a minimum of 2 visual inspections by hi-rail vehicle per week as well as an ultrasonic rail flaw detection (RFD) test and a geometry test twice per year. CN’s track standards allow for more frequent inspections than prescribed under the TSR. The following inspections were performed in the area of the derailment:

- A visual inspection of the track was performed by a qualified CN track supervisor by hi-rail vehicle several hours before the derailment, and no defects were identified.

- An ultrasonic RFD test was conducted on behalf of CN by an operator working for a third-party service provider on 16 October 2023, 31 August 2023, and 07 June 2023. In each of these tests, the test vehicle encountered interference in the area of Mile 32.7, which required the operator to run a second test with the vehicle. The second test also had interference, which resulted in the operator having to scan the rail with an ultrasonic hand tool.Ultrasonic rail flaw detection vehicle tests are continuously recorded and analyzed by computer software as well as the operator. Ultrasonic hand tool tests are not recorded; the output screen of the tool is monitored by the operator and analyzed during testing. A report is generated by the third party and sent to the railway, which includes what mileages were tested and what defects were found. However, the report does not specify if a hand tool was used during the tests. There were no anomalies or defects reported to CN for the area of Mile 32.7.

- A CN geometry test car was operated over the track in the area on 25 September 2023.Track geometry inspections are automated inspections using instrumented vehicles to measure and assess track geometry under load. These inspections test parameters such as cross-level of the track surface, curvature, track gauge, and elevation differentials. The results showed a small dip in the track on the lead-up to the bridge, but no urgent or near-urgent defects were identified.

1.7 Laboratory examination of the recovered rail

The recovered pieces of the broken north rail that were sent to the TSB Engineering Laboratory are shown in Figure 5. The piece labelled Rail #1 corresponds to the eastern section of the north rail around the bridge abutment tie. The piece labelled Rail #2 corresponds to the western section of the north rail on the bridge. The smaller fragments were found between Rail #1 and Rail #2.

The examination of the recovered pieces of the broken north rail determined the following:

- The rail was manufactured by Dominion Steel and Coal Corporation in 1951.

- The rail showed extensive head checking along the gauge side of the rolling surface (Figure 6).

- The head of the rail had approximately 6 mm of wear and was within CN acceptable wear limits.

- Rail #1 contained a type of transverse detail defect (TDD) on its broken end initiating from the upper gauge side for approximately 0.5 inch through the head of the rail (Figure 7). The defect was approximately 15% of the total cross-sectional head area, likely initiating from the head checking condition.

- Rail #2 also contained a smaller detail fracture on one of its broken ends in the upper gauge side corner of the head (Figure 8).

- Both defects had the features and appearances associated with fatigue cracking.

1.8 Rail grinding

Rail grinding is a preventive maintenance procedure that is normally based on the traffic volume, the rate of the growth of defects, and the rail surface condition. Rail grinding is used to control surface damage on the rail from rolling contact fatigue, which includes corrugations,Corrugations are small repeating variations or waves worn into the surface of the rail head which are typically attributed to repetitious wheel sliding from passing trains. shelling,Shelling is a progressive horizontal separation of the steel that may crack out, typically at the upper gauge corner. Shelling develops from minute inclusions in the rail head or on worn rail where the gauge corner has been subject to concentrated loading (surface fatigue). head checking,Head checking is a longitudinal separation of material close to the rolling surface. Head checking results from stresses on the rail surface caused by sliding friction from non-conformal wheel-rail contact geometry. and spalling.Spalling is localized degradation of the rail surface with shallow microcracks, which typically correspond to the direction of traffic. It is a surface fatigue condition related to high shear stresses as well as normal contact stresses. Rail grinding is also used to restore the contact geometry between the rolling stock wheel and the rail by ensuring the correct rail head profile. In doing so, the wheel/rail contact position can be moved across the rail head to a location that minimizes contact stresses. By adjusting the contact geometry, the initiation of deep-seated shell defects such as TDDs at the upper gauge corner can be prevented. Rail grinding can slow down the initiation and growth of small, deep-seated shell defects and can therefore extend the rail’s service life. An additional benefit of rail grinding is that the resulting smooth rail surface can minimize interferences on ultrasonic testing equipment and enable it to perform as designed.

The last rail grinding program for the Sussex Subdivision was completed on 18 June 2023. According to CN’s track standards,Canadian National Railway Company, Engineering Track Standards (June 2021), TS 1.4: Rail Grinding with Self-Propelled Grinding Machines, Fire Prevention, p. 1.4-2. some bridges may not undergo grinding as a precaution due to the risk of fire to a bridge’s wooden ties.Rail grinders are equipped with spark protective systems and are followed by rail-bound, water-carrying vehicles that are specifically designed to prevent fires. Additionally, fire suppressants are sometimes added to the water to enhance the capability of fire control. However, when the risk of fire is high, grinding programs are adjusted to ensure that fire-sensitive areas, such as bridges, are avoided. In this occurrence, CN indicated that, due to the risk of fire, the rail on the bridge at Mile 32.7 had not been ground during the last rail grinding program; at the time of the occurrence, this grinding had not been rescheduled.

1.9 Transverse detail defects

A TDD is a category of fatigue defect in which the plane of the crack or fracture is perpendicular to the running direction of the rail. The size of the defect is commonly recorded as the percentage of the cross-sectional head area of the rail.

Detail fractures from head checking are a type of TDD that are progressive, initiating at the gauge corner of the rail head and developing transversely in the head. Growth can be very rapid after the fracture reaches a size of 5 to 10% of the cross-sectional area of the rail head.

The combination of various in-service forces and resulting stresses that affect rail over its service life can lead to the growth of fatigue defects. These stresses include:

- rolling-contact stresses from rolling stock wheels that generate stresses near the running line and internally in the rail head.

- cyclic loading and unloading stresses (i.e., the flexing or bending of the rail) due to the passing of rolling stock. These stresses are amplified by poor rail support conditions.

TDDs cannot be identified visually and require ultrasonic testing to be detected. TDDs generally result in a complete break in the rail as the fracture grows in size such that the defect-free head area can no longer support the load.

1.10 Internal rail flaw detection

Railways rely on RFD testing performed by third-party service providers to identify internal rail defects. RFD hi-rail vehicles are equipped with an undercarriage test platform that contains electromagnetic (induction) technology and ultrasonics to detect rail flaws. The ultrasonic testing equipment consists of 3 fluid-filled roller search unit wheels for each rail. Each roller search unit contains transducers that generate high-frequency sound energy through the rail in the form of waves to detect vertical and transverse defects within the rail. The data collected are analyzed by the vehicle operator and submitted to the railway for appropriate action.

As with all non-destructive test methods, ultrasonic testing has limitations; the detectability of defects depends on their type, size, and orientation, and can be influenced by environmental conditions as well as rail surface conditions such as head checking, shelling, spalling, and head wear. Such conditions can inhibit the transmission of sound energy into the rail head, masking any internal defects. Rail surfaces must be smooth and clean to optimize the detection and identification of defects. When there is interference during the vehicle tests, a hand test can be performed to verify the rail condition. A hand test is performed by the operator with an ultrasonic hand tool typically consisting of a single transducer that is placed over the head of the rail. The operator can choose different transducer settings and angles to scan the rail for defects. The transducer readings are interpreted by the operator at the time of testing and any identified defect is recorded.

CN’s Engineering Track Standards dictate that, when valid ultrasonic test results cannot be obtained, the location must be noted as a “no test” location and another test must be performed within 60 days.

The 3 vehicle tests performed on the occurrence rail were not able to obtain valid results and, in each instance, the rail was tested by the third-party service provider using an ultrasonic hand tool. The results of the vehicle tests are recorded.

1.11 Previous TSB reports

In the past 10 years, the TSB has investigated 6 other occurrences where TDDs were determined to be a factor.TSB rail transportation safety investigation reports R21S0048, R19C0094, R19E0147, R19W0329, R14C0114, and R14W0256.

1.12 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP159/2023 – Rail Examination

2.0 Analysis

Canadian National Railway Company (CN) freight train L59411-30, a mixed freight train, was operated in accordance with regulatory requirements. Neither the condition of the rolling stock nor the manner in which the train was operated is considered a contributing factor to this accident. Pieces of the broken north rail section containing defects were recovered from the derailment site. The analysis will therefore focus on the condition, inspection, and maintenance of the rail section that failed.

2.1 The accident

On 30 October 2023 at about 1310, CN freight train L59411-30 was travelling westward on CN’s Sussex Subdivision at approximately 38 mph over a small bridge at Mile 32.7 when the last 4 cars of the train derailed.

Post-occurrence site examination noted that a section of the north rail had broken between the eastern side of the bridge, where the rail transitioned from roadbed to bridge structure, and a portion of the bridge.

Finding as to causes and contributing factors

The last 4 cars on CN freight train L59411-30 derailed when a section of the north rail broke as the train was travelling over a small bridge at Mile 32.7 of the CN Sussex Subdivision.

2.2 Condition of the rail

The section of the north rail that broke was 100-pound continuous welded rail. It was manufactured by Dominion Steel and Coal Corporation in 1951. This section of rail had extensive head checking and did not have any recent grinding marks. In contrast, the undamaged roadbed rail located east of the broken section had a smooth rolling surface with marks indicative of recent rail grinding having been performed.

2.2.1 Rail grinding

Rail grinding is critical for maintaining a rail surface in good condition and is considered the primary defence against the initiation and propagation of rail defects. Rail grinding schedules are normally based on the traffic volume, the evolution of the rail surface condition, and the need to maintain the preferred rail profile.

According to CN records, the last rail grinding program for the Sussex Subdivision was completed on 18 June 2023, approximately 4 months before the derailment. However, due to the risk of fire, grinding on the bridge at Mile 32.7 had not been completed and nor had it been rescheduled prior to the occurrence.

According to TSB laboratory analysis, a type of transverse detail defect (TDD), likely a detail fracture from head checking, was present in the rail head of Rail #1 (the eastern section of rail around the bridge abutment tie) and Rail #2 (the western section of rail on the bridge).

Finding as to causes and contributing factors

Although rail grinding was performed on the Sussex Subdivision 4 months before the derailment, the rail on the bridge at Mile 32.7 had not been subjected to grinding. This resulted in extensive head checking not being removed on the rail that broke.

The extensive head checking on the rail that broke likely contributed to the initiation of the TDDs.

2.3 Transverse detail defect growth

A TDD is a type of fatigue defect that grows due to in-service forces and resulting stresses such as rolling-contact stresses from rolling stock wheels, and cyclic loading and unloading stresses due to the passing of rolling stock. These stresses are amplified by poor rail support conditions.

The bridge structure appeared to be in good condition and the bridge ties were all solid, with no signs of splitting. However, the 2 wooden ties at the bridge’s east approach showed signs of splitting. The steel tie plates had cut into the wooden ties, indicating that the rail may not have been fully supported by these ties. Examination of the track geometry readings taken before the derailment showed a small dip in elevation at this location. While the amount of change in track elevation did not reach a condemnable level, this elevation differential would have allowed the rail to flex vertically while the bridge structure would have remained fixed. This difference in support from softer roadbed ties to solid bridge structure likely contributed to increasing the cyclic loading and unloading stresses due to the passing of rolling stock.

In this occurrence, the combination of all these stresses likely resulted in fatigue of the occurrence rail and the propagation of internal defects such as the TDD in each of the 2 recovered rail pieces.

The TDDs in the broken north rail section likely originated from head checking and then transitioned into transverse fatigue cracks. The north rail then failed in sudden overstress once the reduced cross-sectional area of the defect-free rail head was reduced to the point it could no longer handle the applied load.

Finding as to causes and contributing factors

The TDDs originated at the rail head and propagated over time by way of fatigue due to stresses from in-service forces.

The TDDs in the north rail grew to a point such that the rail failed in overstress, under normal service conditions.

2.4 Internal rail flaw detection

A TDD may not be visually identified until the rail breaks because the longitudinal separation or seam in a detail fracture is rarely exposed. Thus, failure can occur before the defect becomes visible.

Railways rely on rail flaw detection (RFD) testing as a reliable and economical method of identifying rail defects. For example, a regularly scheduled ultrasonic testing program can help prevent rail breaks that occur during train operations by identifying defects before they progress to failure. The technology for ultrasonic inspection (i.e., hardware, software, and flaw detection algorithms) is continuously evolving, resulting in improved capabilities to identify defects of interest.

A smooth rolling surface, such as found after a rail grinding program, improves the effectiveness of ultrasonic RFD.

The rail section that broke in the area of Mile 32.7 had undergone ultrasonic testing with a hi-rail vehicle 3 times within the 5 months preceding the derailment. During each of the tests, the third-party service provider was unable to obtain valid results. An ultrasonic hand tool was then used; however, the internal defect was not identified.

Finding as to causes and contributing factors

The extensive head checking on the surface of the rail likely affected the reliability of the ultrasonic RFD testing in identifying the existing TDDs within the broken rail such that the internal defect was not identified.

Finding as to risk

If rail surface conditions that affect the reliability of the ultrasonic RFD testing are not required to be reported to a railway operator, internal rail defects can remain undetected and mitigation measures may not be implemented, increasing the risk of a derailment due to an in-service rail failure.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The last 4 cars on Canadian National Railway Company (CN) freight train L59411-30 derailed when a section of the north rail broke as the train was travelling over a small bridge at Mile 32.7 of the CN Sussex Subdivision.

- Although rail grinding was performed on the Sussex Subdivision 4 months before the derailment, the rail on the bridge at Mile 32.7 had not been subjected to grinding. This resulted in extensive head checking not being removed on the rail that broke.

- The extensive head checking on the rail that broke likely contributed to the initiation of the transverse detail defects.

- The transverse detail defects originated at the rail head and propagated over time by way of fatigue due to stresses from in-service forces.

- The transverse detail defects in the north rail grew to a point such that the rail failed in overstress, under normal service conditions.

- The extensive head checking on the surface of the rail likely affected the reliability of the ultrasonic rail flaw detection testing in identifying the existing transverse detail defects within the broken rail such that the internal defect was not identified.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If rail surface conditions that affect the reliability of the ultrasonic rail flaw detection testing are not required to be reported to a railway operator, internal rail defects can remain undetected and mitigation measures may not be implemented, increasing the risk of a derailment due to an in-service rail failure.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

4.0 Safety action

4.1 Safety action taken

The Board is not aware of any safety action taken following this occurrence.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 14 November 2024. It was officially released on 17 December 2024.