Main-track derailment

Canadian Pacific Railway

CP freight train 113-26

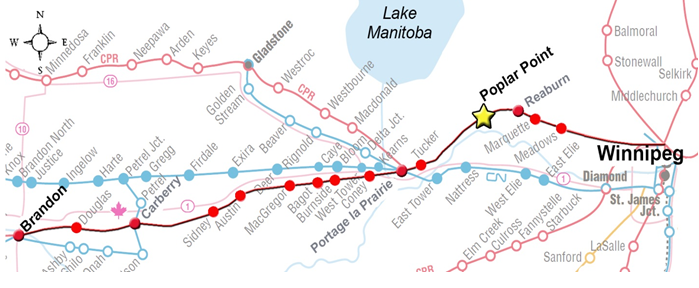

Mile 34.3, Carberry Subdivision

Poplar Point, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 29 July 2012, at approximately 1810 Central Daylight Time, Canadian Pacific Railway intermodal freight train 113-26, en route to Brandon, Manitoba, from Winnipeg, Manitoba, was proceeding westward on Canadian Pacific Railway's Carberry Subdivision when it derailed 12 intermodal cars (16 car bodies) loaded with empty double-stacked containers. There were no injuries; no dangerous goods were involved.

Factual information

On 29 July 2012, Canadian Pacific Railway (CP) freight train 113-26 (train 113) departed Winnipeg, Manitoba, travelling westward en route to Brandon, Manitoba, on CP's Carberry Subdivision. The train consisted of 2 locomotives and 56 well-type intermodal container cars, loaded with empty double-stacked containers. The train was approximately 6300 feet long and weighed about 5500 tons. The train crew comprised a conductor and a locomotive engineer. Both were familiar with the territory, qualified for their respective positions and met fitness and rest requirements.

At approximately 1810,Footnote 1 while travelling at about 27 mph through severe weather, the train 113 crew received a radio call from the CP rail traffic controller (RTC). The RTC warned the crew of high winds in the area and advised it to take the necessary precautions. Almost simultaneously, a train-initiated emergency brake application occurred and the head-end of train 113 came to a stop at Mile 35.0 near Poplar Point, Manitoba (Figure 1).

Subsequent inspection by the conductor determined that 12 cars (16 car bodies in total), the 26th to the 37th cars behind the head-end locomotive, had derailed. There were no injuries and no dangerous goods were involved.

At the time of the occurrence, there were high winds and heavy rain in the area. Before the accident, the high winds had impeded the train's ability to achieve track speed, but otherwise, the crew did not experience any unusual train handling.

Site examination

In the vicinity of the accident, the track was situated on flat, open prairie land. There was little to no surrounding foliage (e.g., trees or large brushes).

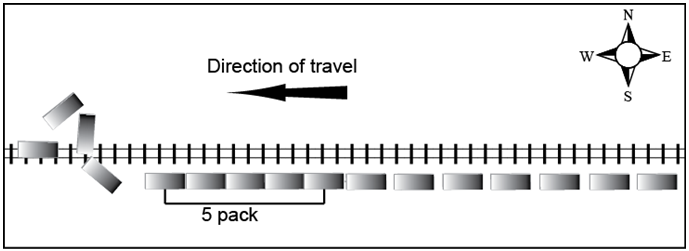

The first car to derail was a single well container (single well) car. This was followed by 3 more single well cars, a "5-pack" (5 car bodies) articulated multi-well container (multi-well) car and 7 single well cars. Each of the 16 car bodies were loaded with 2 empty double-stacked containers (2 containers stacked one on top of one another). Thirteen of the car bodies derailed to the south side of the track (see Figure 2).

Most of the cars remained in line connected together and derailed onto their sides with the double-stacked containers still locked in place. The corresponding trucks remained relatively intact, but strewn about the track (see Photo 1).

Wheel flange marks were observed on the ties starting at about Mile 34.3. There were no marks observed on the rail heads.

Subdivision and track information

CP's Carberry Subdivision extends from Winnipeg (Mile 0.0) to Brandon (Mile 133.1). Train movements are governed by Centralized Traffic Control (CTC), as authorized by the Transport Canada (TC) approved Canadian Rail Operating Rules (CROR) and supervised by an RTC located in Calgary, Alberta. The maximum authorized timetable speed for trains in the area of the accident is 60 mph. Train traffic consists of about 15 freight trains per day.

In the area of the derailment, the track was tangent. The rail was 115-pound continuous welded rail (CWR) secured to tie plates and hardwood ties with track spikes. Rail wear was determined to be within specified limits. Track geometry inspection and ultrasonic rail flaw detection were last conducted in the vicinity of the derailment on 27 June 2012 and 28 July 2012, respectively. In both cases, no defects were observed. The track was in good condition.

Weather

On 29 July 2012, Environment Canada issued a severe thunderstorm warning. At 1720, weather radar identified a cluster of intense thunderstorms, just east of Carberry, that was moving in the east-southeast direction. The local weather office determined that these thunderstorms could produce damaging wind gusts in excess of 100 km/h (62 mph), large hail and torrential rain. At about the same time, local news stations reported wind gusts of up to 150 km/h (93 mph) near St. Laurent, Manitoba, about 40 km north of the derailment area.

Based on past Environment Canada weather data (1995 to 2013), the strongest wind reported in the area of the occurrence was 150 km/h (93 mph) in 2000. A review of these high wind events determined that winds of 100 km/h (62 mph) and stronger had been primarily associated with the presence of thunderstorms.

Canadian Pacific Railway operating protocols

General operating instructions

Instructions for the marshalling of loaded intermodal trains are contained in CP's General Operating Instructions (GOI):

- Section 7 presents an overview of CP's Train Area Marshalling (TrAM) system.

- Section 10 covers dimensional traffic and outlines speed restrictions at specific locations for trains handling articulated multi-well cars loaded with double-stacked containers.

In this occurrence, the train was marshalled in accordance with CP's GOI, and there were no speed restrictions listed for the Carberry Subdivision.

Protocols for high wind conditions

CP has an arrangement with Environment Canada for the provision of a weather monitoring service to its Network Management Centre (NMC)/Operations Centre (OC). As part of this service, Environment Canada communicates the forecast or presence of severe winds to CP electronically through the Rail Weather Information System (RailWIS).

RailWIS is a web-based tool that acquires and analyses multiple weather and hazard information on a real-time basis. It is specifically designed to identify and report potential weather-related threats to CP. The system's weather data, alerts and warnings are CP region specific. This system also produces historical rainfall information, which enhances CP's ability to predict possible landslide and erosion events.

When a RailWIS wind warning is generated, an e-mail notification, which is normally labelled "Wind Warning", is sent to CP's NMC/OC emergency line. Upon notification of a wind warning, the NMC Supervisor relays the information to the RTC, who in turn instructs the train crews involved in accordance with Section 3.5 of the RTC Manual.

In this occurrence, at 1734, Environment Canada issued a "Severe Thunderstorm Warning" to NMC/OC. A wind alert message was embedded within the text description of this warning. However, no separate e-mail notification labeled as "Wind Warning" was sent. Consequently, the wind warning information was not immediately recognized by the NMC Supervisor. This information was only recognized shortly after 1800, just before the occurrence.

CP RTC Manual - Section 3.5 – Severe Weather Warning Procedure

When advised by the Supervisor that a severe weather warning is in effect, the RTC must:

- Not perform any other non-emergency task until they have:

- advised all movement(s) within, or immediately approaching the affected area of the weather alert information [item 2(i)];

- placed a general bulletin order (GBO) block (CTC or OCS) as applicable over the affected area; and

- recorded in Train Information and on RTC Planning sheet the details and location of the weather warning.

- Contact all movement(s) that will encounter the weather warning area(s) and:

- advise them of the weather alert information; and

- determine from the operating crew(s) the local conditions.

- Communicate the local conditions [item 2(ii)] to the Supervisor for determination of operating plan.

- Verbally advise movement(s), as per the Supervisor's request, to:

- stop;

- proceed prepared to stop short of any condition which may affect safe passage and in no case exceeding 25 mph; or

- proceed at authorized track speed.

- Not remove any restrictions placed on movement(s) until advised that:

- the weather warning alert is cancelled;

- the track has been inspected and reported as safe for movement(s); or

- the weather within the area is clearing as determined by crew(s) on movement(s) and the Supervisor advises that it is safe to do so.Footnote 2

CP Wind Warning Response - Action Guide for Canada

When a "Wind Warning" e-mail notification is received, CP's NMC/OC personnel follow the protocol outlined in the "Wind Warning Response - Action Guide for Canada". The guide specifies (in part) that:

- When expected or actual wind gusts of over 90 km/h (56 mph) are reported, the RTC will issue a GBO indicating that all trains handling empty bulkhead flat cars or double stack intermodal cars must not exceed 25 mph.

- When expected or actual wind gusts of over 100 km/h (62 mph) are reported, the RTC will:

- Issue a GBO for the wind affected area.

- Record the details and location of the weather warning.

- Advise any Engineering Services employees that are in the vicinity.

- Stop wind affected trains containing empty bulkhead flat cars or Double Stack intermodal cars on the leeward side of track when possible.

- Hold wind affected trains out of wind affected area on leeward side of track when possible.

- Wind warning alert is cancelled;

- Weather within the area is clearing as determined by crew(s) on movement(s)Footnote 3

Operating protocols for high wind conditions at other railways

The operating protocols for high wind conditions at other railways include:

Canadian National (CN)

- There are no current systems in place for disseminating weather warnings to crews operating on track other than bridges. At bridge locations that have been identified as being in a wind affected area, wind monitoring equipment has been installed.

Burlington Northern and Sante Fe (BNSF)

- BNSF has identified high wind locations at bridges and in the prairies. At these locations, fencing has been installed to reduce the effect of wind on trains. BNSF has also installed wind monitoring equipment at bridges where a wind related derailment had occurred. There are no specific processes in place to warn train crews of high wind conditions.

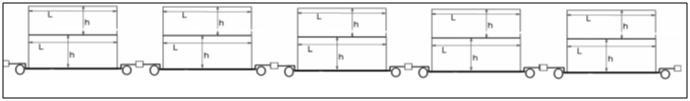

Single well and multi-well container cars

Single well cars are equipped with a freight car truck at each end. When connected together, 5 single well cars would be equipped with 10 trucks total. With each single well car carrying similar-sized containers double-stacked on top, the distance between containers on adjacent cars would be approximately 23 feet. The 5 single well cars would have the configuration displayed in Figure 3.

Multi-well cars are equipped with a freight car truck at each end of the first and last platform while the platforms within the car share common trucks at each end (see Figure 4). A 5-pack multi-well car would be equipped with 6 trucks. With the multi wells full and similar-sized containers double-stacked on top, the distance between containers on adjacent car bodies would be approximately 11 feet.

Transportation Safety Board wind load calculations

The TSB Engineering Laboratory performed a theoretical static analysis (LP225/2012) to determine the wind speed required to initiate wheel lift or car rollover for single well and multi-well container cars loaded with double-stacked containers. With the calculations configured for a wind direction that is perpendicular to the car and container surface, it was determined that:

- The wind speed required to tip a single well container car with double-stacked empty containers is 84 mph (135 km/h).

- The wind speed required to tip a 5-pack multi-well container car with double-stacked empty containers is 74 mph (119 km/h).

- In comparison to a series of single well cars, the lower wind speed required to tip a multi-well car is primarily due to:

- the reduced distance between the containers on adjacent car bodies, and

- the reduced number of trucks and corresponding weight of the car.

- The wind speed required to tip a single well car with double-stacked loaded containers is 125 mph (201 km/h).

Dynamic simulation of occurrence train

Using normal wear and clearance values, CP conducted a NUCARSFootnote 4 dynamic simulation of the occurrence train. The following inputs and assumptions were used:

- normal wear and clearance values for a typical single well car,

- track profile and geometry information recorded between Mile 33 and Mile 35 of the Carberry Subdivision during the 27 July 2012 geometry inspection,

- a constant speed of 27 mph,

- wind direction perpendicular to the car surface, and

- wind loads were applied to the center of the car body at 63.2 inches above the top of the rail.

The dynamic simulation determined that wind speeds in excess of 90 mph (145 km/h) were required to initiate a wheel lift derailment.

Other similar occurrences

On 1 November 1999, at approximately 0735 Central Standard Time, CP intermodal freight train 471-30 (train 471), travelling westward on the north main track of the Carberry Subdivision near Poplar Point, Manitoba, derailed 2 cars loaded with empty double-stacked containers near Mile 42.4. The derailed cars remained upright, but were leaning towards the south main track. At about the same time, eastward CP intermodal freight train 472-30 (train 472) was passing on the south main track and collided with the top containers of the derailed cars from train 471. The 3 locomotives and 1 container on train 472 were damaged while 6 of 8 containers that were on the 2 derailed cars from train 471 were also damaged. There were no injuries, and no dangerous goods were involved. It was determined that high winds from severe weather in the area had exaggerated the natural oscillation of the intermodal cars, causing wheel lift and the subsequent derailment (TSB Occurrence Number R99W0231).

Between 1999 and 2012, there were 4 other derailments (TSB Class 5 Occurrences) where cars had been affected by high winds:

- R05W0018 - On 22 January 2005, CP freight train 104-21 reported going into emergency at Mile 13.8 of the Maple Creek Subdivision when 20 non-regulated intermodal cars derailed (18 loads and 2 empties). At the time of the occurrence, there were high cross winds in the range of 80 to 100 km/h in the area.

- R06D0017 - On 23 February 2006, CP reported that the last 6 cars of CP train C901-16 had derailed on a bridge over the St. Lawrence River at Mile 42.4 of the Adirondack Subdivision. Five of the derailed cars were single well cars loaded with empty double-stacked containers. High cross winds in excess of 100 km/h had been reported in the area at the time.

- R07W0145 - On 30 June 2007, CN Train Q11451-29 reported that 20 intermodal cars loaded with empty containers had derailed while exiting the bridge near Code, Saskatchewan at Mile 233.5 of the Rivers Subdivision. Strong winds had blown the containers off the car platforms into a valley below.

- R12W0137 - On 27 June 2012, CP reported that a cut of 17 empty covered hopper cars at Mile 47.0 of the main track on the Gravelbourg Subdivision were derailed. At the time of the occurrence, there had been extreme high wind conditions in the vicinity.

Transportation Safety Board laboratory reports

The following TSB Engineering Laboratory report was completed:

- LP225/2012 – Wind Load Calculations

Analysis

The train was being operated in accordance with company and regulatory requirements and there were no unusual train handling events leading up to the derailment. The track was in good condition and there were no equipment related defects that were considered as causal. The analysis will focus on the severe weather conditions and the related safety protocols in place.

The accident

Starting at about Mile 34.3, wheel flange marks were observed on the ties but there were no marks observed on the rail head. The absence of any definitive marks on the rail head indicates that wheel lift had likely occurred, leading to the derailment. Most of the derailed cars had remained connected and in-line on their sides while most of the freight car trucks from the derailed cars had remained intact near the track. The positioning of the derailed equipment was consistent with the cars having been rolled or pushed over off their trucks.

The track in the area of the accident was primarily tangent on flat, open prairie with little to no surrounding foliage. The westbound train was hauling 56 well-type intermodal container cars loaded with empty double-stacked containers. The north side of the train was directly exposed to cross winds that were gusting up to 150 km/h (93 mph). The first car to derail was a single well container car loaded with empty double-stacked containers.

Transportation Safety Board static calculations and a Canadian Pacific Railway (CP) dynamic NUCARS simulation determined that wind speeds in the range of 135 km/h to 145 km/h (84 mph to 90 mph) would be sufficient to induce wheel lift on a single well car loaded with empty double-stacked containers. On the day of the occurrence, with wind gusts in the range of 150 km/h (93 mph), it is likely that the derailment occurred when high winds resulting from severe weather in the area blew over the cars.

Wind warning notifications

Environment Canada issues "wind warnings" to CP through the RailWIS Web Portal and e-mail notification process. Upon reception of a "Wind Warning" notification, CP Network Management Centre (NMC)/Operations Centre (OC) personnel follow the required protocols, including advising the rail traffic controller (RTC). In this occurrence, Environment Canada did not label the e-mail notification with "Wind Warning". Instead, the wind warning information was contained within the text description of a "Severe Thunderstorm Warning". Consequently, the NMC/OC was not immediately aware of the high wind conditions. Once the oversight was recognized, the high wind condition information was immediately relayed to the RTC and to the train crew. However, the information was received just as the accident occurred. While CP had protocols in place to deal with severe weather conditions, a lapse in posting "Wind Warning" information delayed notification of the train crew which allowed the train to continue and contributed to the derailment. When wind condition information is not immediately communicated during severe weather, train crews may not be aware of high cross wind conditions in a timely manner, increasing the risk of wheel lift derailments, especially for intermodal freight trains transporting empty double-stacked containers.

Wind effect on multi-well container cars

The estimated wind speed required to tip a 5-pack articulated multi-well car loaded with empty double-stacked containers was 119 km/h (74 mph) while the estimated wind speed required to tip a single well car loaded with empty double-stacked containers was 135 km/h (84 mph). When comparing a 5-pack articulated multi-well car loaded with double-stacked empty containers to a similarly loaded single well car, the area affected by wind is directly related to the number and size of the containers. However, for the 5-pack articulated multi-well car, the space between the containers, the overall number of trucks and the weight of the car are reduced. When compared with a similarly equipped single well car, a 5-pack articulated multi-well car loaded with empty double-stacked containers has a higher potential for wheel lift during high wind conditions.

Findings

Findings as to causes and contributing factors

- The derailment occurred when high winds resulting from severe weather in the area blew over the intermodal container cars loaded with empty double-stacked containers.

- While Canadian Pacific Railway had protocols in place to deal with severe weather conditions, a lapse in posting "Wind Warning" information delayed notification of the train crew. This resulted in the train continuing without mitigating action being taken, and likely contributed to the derailment.

Findings as to risk

- When wind condition information is not immediately communicated during severe weather, train crews may not be aware of high cross-wind conditions in a timely manner, increasing the risk of wheel lift derailments, especially for intermodal freight trains transporting empty double-stacked containers.

Other findings

- Compared with a similarly equipped single well car, a 5-pack articulated multi-well car loaded with empty double-stacked containers has a higher potential for wheel lift during high wind conditions.

Safety action

Canadian Pacific Railway's Severe Weather Warning Procedure was amended in September 2012. The new procedure includes the following steps:

- The RailWIS duty meteorologist will review the details of all "Severe Thunderstorm Warnings".

- If there is any mention of a high wind threat (i.e., greater than 90 km/h), the duty meteorologist will resend the e-mail warning, labelled as "Wind Warning" in the advisory header.

- The duty meteorologist will call the CP NMC/OC emergency line to provide a verbal update.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on . It was officially released on 29 August 2013.