Striking of berth and shore gantry crane

Container vessel Ever Summit

Vanterm, Port of Vancouver

Vancouver, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 28 January 2019, the container vessel Ever Summit was berthing under the conduct of a pilot at Vanterm in the Port of Vancouver, British Columbia (BC), with 2 tugs assisting when the vessel struck the berth and a nearby shore gantry crane. The vessel, berth, and crane were damaged. There were no injuries or pollution.

1.0 Factual information

1.1 Particulars of the vessels

| Name | Ever Summit | Seaspan Falcon | Seaspan Hawk |

|---|---|---|---|

| International Maritime Organization number | 9300453 | 9072393 | 9072408 |

| Official number | 32786-07 | 816602 | 816601 |

| Flag | Panama | Canada | Canada |

| Classification society | American Bureau of Shipping | N/A | N/A |

| Type | Container vessel | Tug | Tug |

| Gross tonnage | 75 246.00 | 188.77 | 188.77 |

| Length overall | 299.99 m | 25.45 m | 25.45 m |

| Breadth | 42.80 m | 9.14 m | 9.14 m |

| Designed draft | 14.20 m | 3.17 m | 3.17 m |

| Displacement | 107 537 t | 297 t | 297 t |

| Deadweight | 78 612 t | 58 t | 58 t |

| Built | 2007 | 1993 | 1993 |

| Propulsion | 1 diesel engine of 54 942 kW driving 1 fixed-pitch propeller | 2 diesel engines of 2312 kW (total) | 2 diesel engines of 2312 kW (total) |

| Bollard pull | N/A | 40 t | 40 t |

| Cargo | 3462 containers | None | None |

| Crew | 22 | 2 | 2 |

| Operator | Evergreen Marine Corp. | Seaspan ULC | Seaspan ULC |

1.2 Description of the vessel

1.2.1 Ever Summit

The Ever Summit is a 7024 TEUFootnote 1 fully cellularFootnote 2 container vessel (Figure 1). It has a steel hull that is flared at the bow and stern. The bridge front is located approximately 88 m forward of the stern.

The bridge is fully enclosed and is equipped with navigational equipment including a speed log, global positioning system, automatic identification system, and 3 cm and 10 cm radars with automatic radar plotting aid capability. The vessel has an electronic chart display and information system and paper charts. The main steering console is located on the centreline of the vessel. To the starboard of the steering stand is another console with the bridge telegraph and bow thruster controls. There are also consoles on either bridge wing with engine and bow thruster controls for use while berthing.

The vessel has a single 10-cylinder 2-stroke slow speed direct reversing diesel engine that drives a right-hand fixed-pitch propeller. The main engine is remotely controlled from the bridge telegraph via an electronic load management system and provides a service speed of 25.3 knots. Steering is effected by means of a semi-balanced rudder with a maximum angle of 35°, and the vessel has 2 bow thrusters with a combined power of 2300 kW. The vessel is fitted with a voyage data recorder.

The vessel was constructed in 2007 in Japan by Mitsubishi Heavy Industries Ltd. and is a Post-Panamax IIFootnote 3 container vessel. It is one of 10 sister ships built for Evergreen Marine Corp. At the time of the occurrence, the vessel was engaged on Evergreen’s Transpacific Northwest liner serviceFootnote 4 between the Pacific coast (Tacoma, Washington, U.S., and Vancouver, BC, Canada) and various ports in China and Japan.

1.2.1.1 Manoeuvring characteristics

The vessel’s manoeuvring characteristics are displayed on the aft bulkhead of the bridge. The information includes turning circles, stopping characteristics, speeds, and effectiveness of the bow thrusters under test conditions.

The vessel’s pilot cardFootnote 5 also provides manoeuvring characteristics and information on the dimensions of the vessel, drafts, displacement, anchors, steering particulars, and any outstanding defects. The pilot card incorrectly indicated that the vessel’s parallel body lengthFootnote 6 was 285 m; this was actually the length between perpendicularsFootnote 7 for the vessel. The vessel’s parallel body length was approximately 148 m when measured at the level of the apronFootnote 8 and 97 m when measured at the level of the vessel’s mean draft.Footnote 9

The back of the pilot card included brief guidance for approaching and leaving a berth (Figure 2). The guidance indicated that, for berthing, the vessel was to be stopped parallel to the berth at a distance of approximately 1.5 to 2 vessel breadths (64 to 86 m). Tugs were to be made fast as early as possible, and the vessel was to be manoeuvred laterally into the berth at a maximum landing speed of less than 0.3 knots (15.4 cm/s). The guidance also highlighted manoeuvres for berthing and unberthing that were considered dangerous for this particular vessel.

1.3 History of the voyage

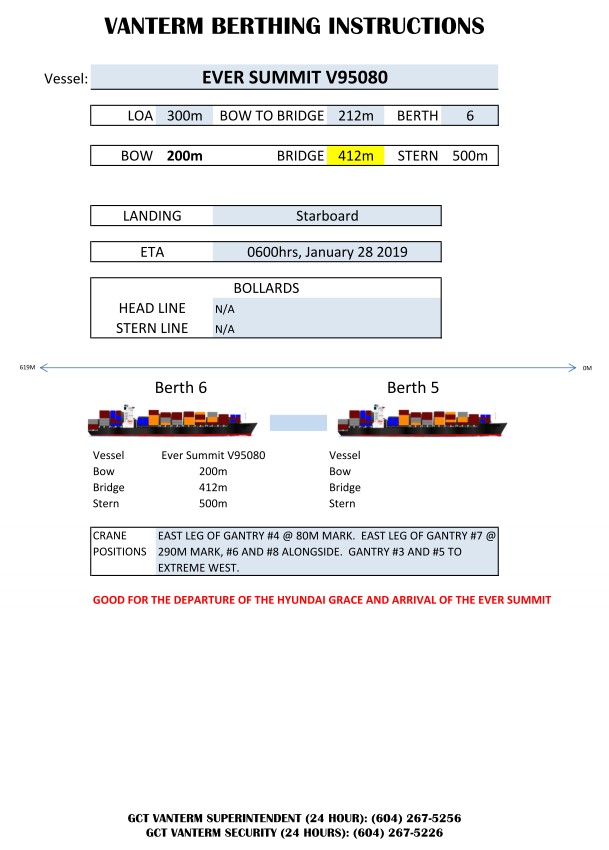

After completing a crossing from Ningbo, China, to Vancouver, the Ever Summit was scheduled to berthFootnote 10 at Vanterm (a container terminal in the Port of Vancouver) on 28 January 2019 at around 0600.Footnote 11 The vessel was carrying 3462 containers spread across 70 bays. The containers were stacked up to 8 high above deck, in accordance with the vessel’s stowage plan. The vessel’s draft was deepest aft, at 13.70 m.

The vessel arrived at the pilot station off Victoria, BC, on 27 January, and the crew tested the navigation equipment, machinery, steering gear, and astern propulsion in preparation for docking. At 2240, a British Columbia Coast Pilots, Ltd. (BCCP) pilot and observing pilotFootnote 12 boarded the vessel. At that time, the master was conning the vessel on the bridge, accompanied by the officer of the watch, a trainee officer, and a helmsman who was manually steering the vessel.

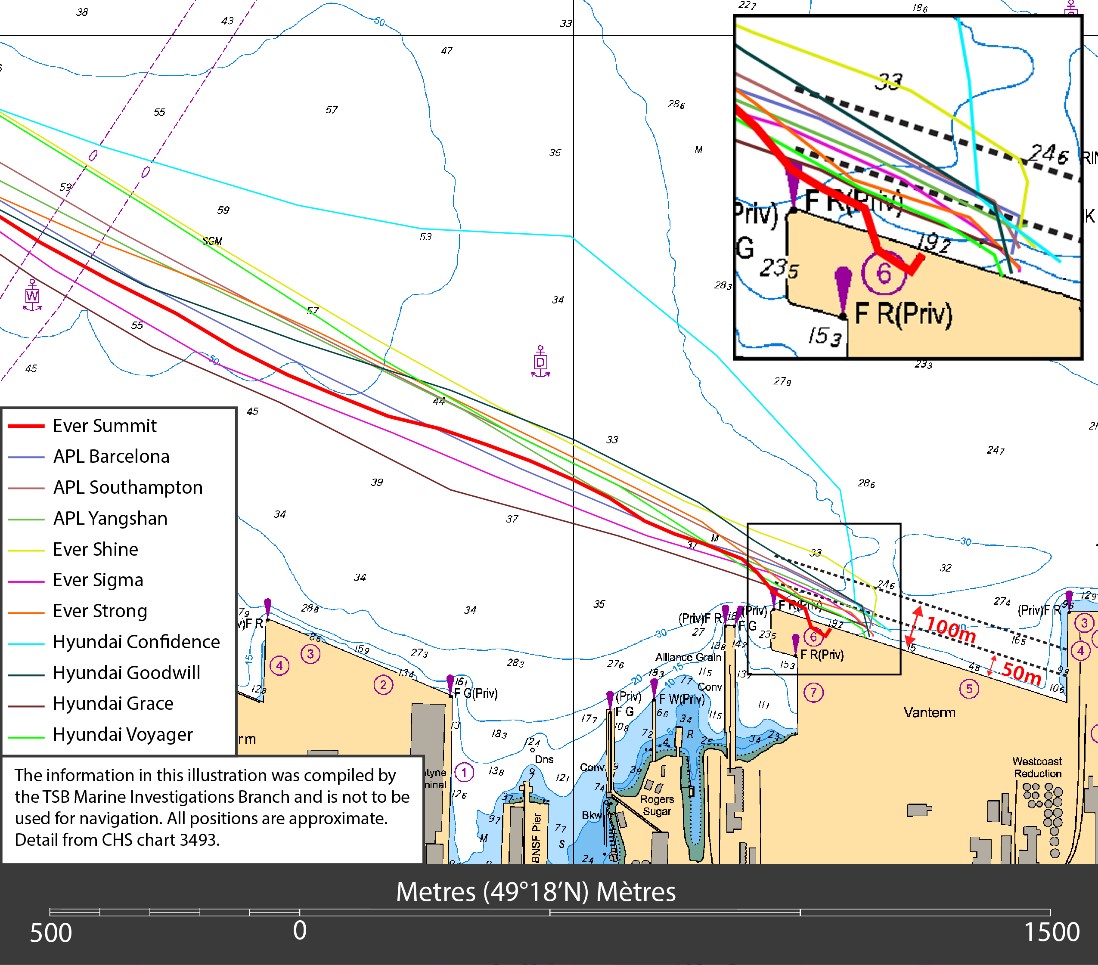

After the pilot boarded, the pilot asked the master about the items on the master-pilot exchange card.Footnote 13 The pilot and the master then exchanged information and details about the vessel. This included verifying the draft and the time required for the vessel to reduce to manoeuvring speed, as well as confirming that there were no machinery deficiencies. The pilot discussed the berthing plan and informed the master that the vessel would be going starboard-side alongside berths 5 and 6 (Figure 3). Two tugs would be used, and the pilot would provide the master with the underkeel clearance before transiting the Lions Gate Bridge. The pilot requested that the master have crew standby the anchors 2 miles before the Lions Gate Bridge and asked the master if he had any questions, which he did not. The vessel’s pilot card was also presented to the pilot. The pilot observed the berthing guidelines on the back of the pilot card. The master and pilot signed the master-pilot exchange card, and the pilot set up his portable pilot unitFootnote 14 (PPU) in order to monitor the vessel’s progress.

As the vessel continued its voyage to Vanterm, the pilot took over the conduct and the master went to his cabin. The master intermittently monitored the vessel’s progress from his cabin, and the 2 pilots discussed pilotage matters on the bridge. At 0230, the master returned to the bridge, and at approximately 0300, the vessel’s crew were put on standby for mooring stations and securing assist tugs fore and aft. The anchors were readied for deployment in case of an emergency.

The vessel transited First Narrows at 0321, at which point the vessel’s speed was approximately 8 knots. At approximately 0323, the pilot contacted the assist tugs, Seaspan Falcon and Seaspan Hawk, using his handheld very high frequency (VHF) radiotelephone on channel 17 (the Pacific Pilotage Authority’s working channel). He indicated to the tugs that he would position them alphabetically along the vessel’s port side, securing the Seaspan Falcon forward and the Seaspan Hawk aft.Footnote 15 The Seaspan Hawk was secured aft at about 0333, and the Seaspan Falcon was secured forward at around 0338 while the vessel continued toward Vanterm at a speed of approximately 5 knots (Appendix A). Propulsion control was transferred from the main steering console to the starboard console, and the pilot continued conning the vessel from the starboard side of the bridge.

With the tugs secured, the Ever Summit continued towards the berth, gradually reducing speed by operating the engines either dead slow ahead or stop. There were no other vessels anchored in the vicinity of Vanterm at either Anchorage D or Anchorage W, allowing a direct approach.

The tug Charles H. Cates V was scheduled to perform the duties of the mooring boatFootnote 16 and was standing by at the berth to assist with the mooring lines. At approximately 0338, the Charles H. Cates V contacted the pilot on VHF channel 17 and informed him of the current near the berth, which was estimated to set slightly to the west.Footnote 17 The Charles H. Cates V was initially unable to locate the bridge markerFootnote 18 due to poor lighting, but identified it a few minutes later at approximately 0342 and relayed to the pilot its position at about the 412 m mark on the berth.Footnote 19

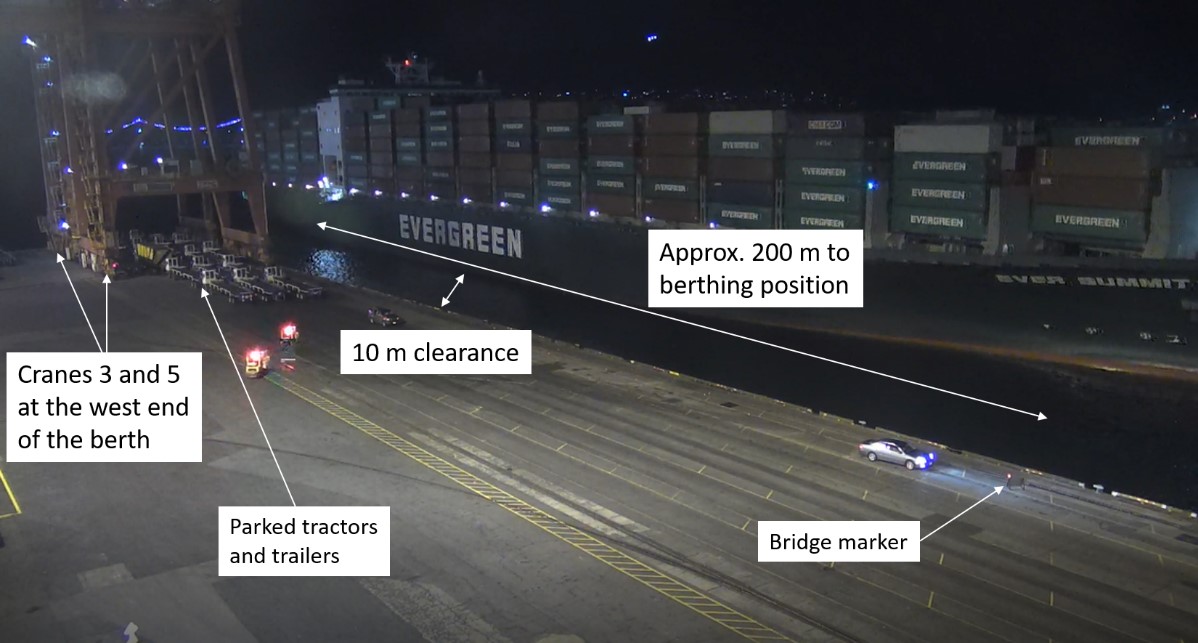

The pilot and tugs were all using VHF channel 17 for communications. At approximately 0343, after experiencing some disturbance on this channel, they switched over to another working channel. At this time, the Ever Summit was approaching the berth on a course that was nearly parallel to it and approximately 10 m off (Figure 4).

Two shore gantry cranes (Cranes 3 and 5) were positioned at the extreme west end of the berth (around the 600 m mark), 3 cranes were positioned mid-berth (around the 300 m mark), and a last crane was positioned at the east end (around the 80 m mark).Footnote 20

The vessel’s speed was approximately 1.3 knots as the bridge passed the west end of the berth, and the bow was in line with the bridge marker on the shore. There were no significant effects from the ebb tide on the vessel.

At 0359, with approximately 200 m to go before the bridge was in line with the bridge marker, the pilot ordered the engines dead slow astern to reduce the vessel’s speed to under 1 knot. To counteract an anticipated sheer of the stern toward the berth as a result of the astern order on the engines, the pilot began communicating instructions to the tugs, which were not visible from his position on the starboard side of the bridge.Footnote 21

The Seaspan Falcon (forward tug) was instructed to back up on the line and take up the strain. As tension came on the line, the vessel’s stern started taking a sheer towards the berth. The Seaspan Falcon was then instructed to increase power up to maximum and the Seaspan Hawk (aft tug) was instructed to push maximum.

This resulted in the vessel’s stern moving rapidly toward the berth, and the master attempted to alert the pilot. The pilot ordered the bow thrusters full to starboard, the engines dead slow ahead, and the helm hard to starboard.

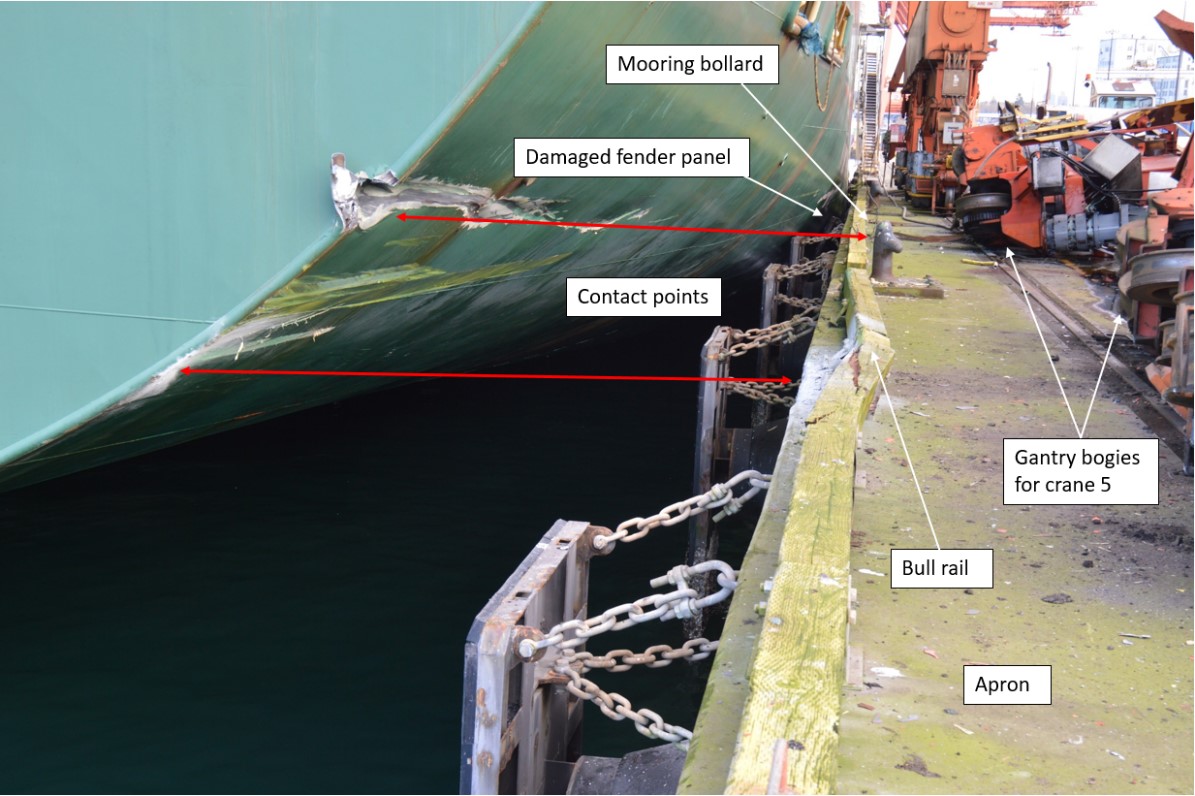

At 0401, with the tugs still operating at maximum power, the flared stern of the Ever Summit struck the berthFootnote 22 and made contact with Crane 5. The shore-side gantry bogiesFootnote 23 for Crane 5 collapsed inwards toward the terminal and the boom fell onto the vessel. At the time of the striking, the vessel was at an angle of approximately 10° from the berth face (Figure 5).

After the striking, the pilot ordered the engines and bow thruster stopped and instructed the tugs to reduce power to full stop. The pilot also ordered the vessel to drop its port anchor and instructed the tugs to hold the vessel in position (Figure 6). Vessel operations at the berth were shut down, and an exclusion zone was set up.

1.4 Damage to the vessel and cargo

Approximately 6 containers stowed in the uppermost bays were damaged when the crane boom fell onto the vessel (Figure 6).

In addition, the vessel sustained the following damage (Figure 7):

- A hole of approximately 30 cm by 40 cm was punctured in the vessel’s starboard aft shell plating where the shell meets the transom.

- The shell plating was also pushed inward and dented by up to 6 cm over a horizontal length of approximately 8 m (between the transom and frame +2, in way of side longitudinals 7 and 8).

- Rub marks, scratches, and paint discoloration were visible where the shell meets the transom and along the starboard-side shell plating.

Before the vessel departed for its next voyage, temporary repairs to the hull were completed on 06 February in Vancouver, BC, to the satisfaction of the attending classification society surveyor.

1.5 Damage to the terminal

As a result of the occurrence, vessel operations at the berth were disrupted for approximately 8 days.

The concrete edge of the berth sustained impact damage, and the wooden bull rail was cracked and pushed back by approximately 8 cm at the point of contact (Figure 7). The mooring bollard showed signs of abrasion (Figure 7), and 2 of the fender panels were bent and had topside damage.

The apron (the horizontal surface forming the topside of the berth) was punctured and some of the concrete pre-cast panels were damaged.

Crane 5 was declared a total loss, and Crane 3 sustained minor damage. In addition, numerous tractor-trailers stowed below Crane 5 were damaged (Figure 6).

1.6 Personnel certification and experience

All of the individuals involved in the occurrence held the required certifications for the intended voyage.

The master held a Class 1 STCWFootnote 24 certificate of competency issued in the Republic of China in 1994. He had 32 years of experience working with Evergreen Marine Corp., and had served as a master for 25 of these years. The master had called at Vancouver approximately 20 times before, and was familiar with the berth at Vanterm.

The officer of the watch held an STCW certificate as officer in charge of a navigational watch issued in the Republic of China in 2015. He had joined Evergreen Marine Corp. as a cadet in 2013.

The master and all deck officers had received bridge resource management (BRM) training in 2015/2016.

The pilot had obtained a Pilot, Class I, Unrestricted licence in 1992. The pilot was familiar with Vanterm and had completed 14 other assignments berthing and unberthing vessels at Vanterm in the previous 3 years. The pilot had completed a BRM course specific to pilots in April 2016 and had last undergone a skills assessmentFootnote 25 in November 2014.

The masters of the Seaspan Falcon and Seaspan Hawk both held Master 500 Gross Tonnage certificates issued by Transport Canada and had operated harbour tugs since 1980 and 1988 respectively. The tugs were each manned with a master and deckhand.

1.7 Vessel certification

The Ever Summit was certified and equipped in accordance with existing flag state and classification society regulations. The vessel was classed by the American Bureau of Shipping.

The vessel operated under a safety management system as required by the International Safety Management (ISM) Code.Footnote 26 The system was certified and audited by the American Bureau of Shipping.

1.8 Environmental conditions

At the time of the occurrence, there were light airs, it was dark, and the visibility was clear. High water was 3.6 m at 2358 on 27 January, and low water was 2.7 m at 0454 on 28 January, making for a tidal range of 0.9 m. The tides were neap, with an observed height of 2.63 m at the time of the occurrence.

On 28 January, the maximum ebb at First Narrows was predicted to be 1.7 knots at 0253, and slack water at First Narrows was predicted at 0530. At the time of the occurrence, the tidal current was ebbing and was approximately 1.2 knots at First Narrows.

1.9 The Port of Vancouver

The Port of Vancouver is Canada’s largest port and the gateway for North American trade with Asia and other parts of the world. The Port of Vancouver is managed by the Vancouver Fraser Port Authority. The port authority has purview over activities within its jurisdiction.Footnote 27 The port authority leads development of common‑use infrastructure both on and off the port (e.g., overpasses and large‑scale terminal reconfigurations), while port tenants lead on‑terminal improvements such as those made to fenders, mooring bollards, and cranes.

The facilities at 2 of the port’s terminals—Vanterm and Deltaport—are described and compared below.

1.9.1 Vanterm

Vanterm is leased by Global Container Terminals (GCT) Canada from the Vancouver Fraser Port Authority. The terminal spans 34.6 hectares in the Burrard Inlet between First Narrows and Second Narrows. The terminal was originally constructed in 1975. It is a gravity‑based structure made of concrete box caissonsFootnote 28 filled with ballast.

For large container vessels, Vanterm has a 619 m berth face made up of berths 5 and 6 combined (Figure 3). The original berth plans for the terminal indicate that the terminal was designed to have 2 separate berths.Footnote 29 However, the increase in length of container vessels currently berthing at Vanterm has effectively reduced the terminal to a one berth operation, with the vessels being docked somewhere between berths 5 and 6. The water depth alongside is approximately 15.5 m. The apron extends 7.08 m above chart datum. At the mean high tide point, the distance between the top of the apron and the water level is approximately 2.2 m.

Vessels berthing at Vanterm must comply with GCT Canada requirements regarding under-keel clearance, berth spacing, and shore crane reach. In order to reach Vanterm, they must also transit under the Lions Gate Bridge in compliance with the First Narrows Traffic Control Zone requirements (Appendix C). As of January 2019, the largest vessel that had berthed at Vanterm had a TEU capacity of approximately 11 000.

GCT Canada has a manual that provides information about berth operations. It includes details about general roles and responsibilities, as well as rules and safe working procedures that are followed at Vanterm. The manual applies to GCT Canada staff as well as stevedores handling the terminal tools, equipment, and machinery. The manual includes a vessel inspection form, which is completed semi-annually by site safety committee representatives. The representatives board a vessel and use the checklist to inspect items such as the gangway, walkways, railings, and lashing equipment.

Operational decisions, such as those relating to the maximum container vessel size that can berth at Vanterm, are made at the discretion of GCT Canada and the liners. The port authority will intervene if a concern is brought to its attention, but it does not typically provide oversight of port operations.

1.9.1.1 Fendering system

As part of an upgrade in 1990, berths 5 and 6 were fitted with hollow rubber cylindrical fenders (Figure 8). The fenders are 120 cm in external diameter and 150 cm long. They are draped along the side of the berths at 18.3 m intervals. Each fender hangs on a steel bar that is anchored to the berth with chains. The energy absorption capacity of the fenders is rated at 243 kilonewton metres (kN-m).

When a vessel’s hull presses on the cylindrical fenders, they will compress up to a maximum of 60 cm, which is equal to the inner diameter of the fender, leaving a clearance of approximately 60 cm between the vessel’s hull and the berth face. Once the fender is fully compressed, it behaves as a solid rubber element. Any further compression past this point causes pressure on the vessel’s hull.

The cylindrical fenders do not have a means of reducing sliding friction. Large friction forces can develop as the rubber fender is compressed between the vessel hull and the concrete berth face, resulting in damage to the anchoring chains or plates. The fenders are known to the pilots as being “sticky,” meaning that the vessel’s hull does not slide easily along the fenders, but rather “sticks” on them, which can make berthing more difficult.

In 2002, berth 6 was extended by approximately 53 m to accommodate larger vessels. The engineering plans for the berth extension indicated the particulars of the maximum and minimum design vessels as follows (Table 2):

| Particular | Largest vessel | Smallest vessel |

|---|---|---|

| Deadweight tonnage | 70 000 t | 25 000 t |

| Length overall | 275 m | 166 m |

| Minimum freeboard | 7.0 m | 4.2 m |

| Maximum draft | 12.70 m | 11.60 m |

| Moulded breadth | 39.40 m | 28.50 m |

The fender system installed on the berth 6 extension differed from the fenders on berth 5 and the original part of berth 6. The fenders on the berth extension are cone fenders fitted with fender panels and support chains (Figure 9). The energy absorption capacity of these fenders is rated at 799 kN-m.

The fendering system for the berth extension was intended to accommodate berthing of design vessels based on the following criteria:

- A maximum velocity perpendicular to the berth face of 15 cm/s

- A maximum angle of approach of 10°

- A maximum hull pressure of 20 t/m2

The fenders are capable of compressing up to a maximum of 83.3 cm. When the fenders are fully compressed, there is a clearance of approximately 36.7 cm between the vessel’s hull and the berth face.

The berthing angle (created by the vessel’s angle of approach to the berth) and the flare angle (created when the flared portion of the vessel’s hull contacts a vertical fender) will have an effect on the capability of the fenders to absorb energy. Berth plans for terminals typically identify the maximum safe approach angle for the design vessel. At larger angles of approach, not only does the vessel’s hull contact fewer fenders, but also the resulting flare angle is larger, reducing the ability of the fenders that are contacted to absorb energy.

1.9.1.2 Review of fendering system

In 2012, GCT Canada and the port authority hired an engineering firm to review the fendering system at Vanterm and make recommendations. The review was initiated after instances of damage to the fendering systems at berths 5 and 6 as well as damage to the incoming container vessels.

The review concluded that the damage was a result of the existing fendering system not having sufficient capacity to absorb the kinetic energy of the large vessels berthing at the terminal. Specifically, when the fenders are compressed to their maximum, large vessels can make contact with the berth face, causing impact damage to both the berth and the vessels.

The review also identified that the existing cylinder fender system was inappropriate for the size of container vessels that dock at the berth. The energy absorption capacity of the fenders was significantly less than the required energy absorption for the maximum design vesselFootnote 30 (1662 kN-m). The fender stand-off distanceFootnote 31 was inadequate, and the fender spacing was too far apart considering the size of the fenders and the heavy loads placed on them.

1.9.1.3 Mooring system

Berths 5 and 6 are fitted with bollards of 100 tonnes safe working load that are located at intervals of approximately 18.3 m. The berth extension is equipped with bollards of 125 tonnes safe working load.

A mooring analysis is typically conducted at the time of a terminal’s construction to determine the maximum forces that the mooring system is capable of withstanding. This helps determine, among other things, the upper limit of wind and current velocity that the design vessels can sustain while berthing or when moored to the dock, as well as the maximum safe angles of elevation and loads for the mooring lines.

The maximum safe angles of elevation for the mooring lines at Vanterm are unknown, and there has been no analysis to determine the maximum forces that the existing mooring system will withstand with respect to the current size of vessels berthing at the terminal.

Additionally, the terminal is not fitted with a docking aid system. A docking aid system consists of laser sensors that measure the distance of a vessel to the outer edge of the fenders while berthing. The docking aid system then computes this information and shows the vessel’s speed, distance, and angle of approach on a display board.

1.9.1.4 Shore gantry cranes

Berths 5 and 6 are fitted with 6 shore gantry cranes, each with a capacity of 50 long tons. The cranes have gantry bogies and can traverse the length of the berth on rail tracks. The distance from the water-side crane rail to the berth lineFootnote 32 is approximately 2.13 m.Footnote 33

Two of the cranes can reach 16 containers across, 1 of the cranes can reach 18 containers across, and 3 of the cranes can reach 22 containers across. Container vessels that are stacked 7 or 8 containers high can only be accessed by the 3 cranes with the largest reach in certain tidal conditions (i.e., not at high tide).

Before a vessel berths at Vanterm, the cranes are positioned with their booms raised to accommodate the vessel’s intended berthing location. Typically, 3 cranes are positioned amidships and the others are positioned approximately 60 m clear of the vessel’s bow and stern. This is done to avoid having the cranes come into contact with a vessel’s bow or stern flare while the vessel is berthing.

1.9.1.5 Vanterm infrastructure upgrade

In 2018, the port authority and GCT Canada renewed the long-term lease agreement for Vanterm. In May 2019, GCT Canada announced a $160 million investment to modernize Vanterm. The upgrade was meant to increase container handling capacity and allow the terminal to handle larger container vessels within its existing footprint.Footnote 34 The investment included upgrading the existing fendering and bollard system as well as 2 shore gantry cranes. In June 2020, the fenders at Vanterm berths 5 and 6 were replaced with larger-capacity fenders. Specifications for the new fenders were passed on to the Pacific Pilotage Authority (PPA).

1.9.2 Deltaport

In addition to Vanterm, GCT Canada also operates Deltaport, a container vessel terminal located at Roberts Bank, BC. The terminal has 3 berths, the largest of which (Deltaport 3) was constructed in 2009 and can accommodate vessels as large as 150 000 deadweight tonnes.

There are some notable differences with respect to the fendering systems, bollards, and position of the shore gantry cranes at Deltaport as compared to Vanterm. The fendering system at Deltaport 3 consists of super-cone fenders paired vertically at intervals of approximately 20 m. The distance between the fenders reduces to approximately 10 m at the ends of the berth where the vessel’s bow and stern would be expected to make contact during berthing. The fenders each provide an energy absorption of 968 kN-m.

Figure 10 and Figure 11 show examples of the fenders at Vanterm and at Deltaport 3, respectively.

Deltaport 3 was designed for a maximum approach angle of 5° at a velocity of 12.5 cm/s. The bollards are rated for 125 tonnes safe working load, with 200 tonnes safe working load bollards at the ends of the berth. The distance from the waterside crane rail to the berth line is approximately 6.96 m at Deltaport 3, whereas the distance from the crane rail to the berth line at Vanterm is 2.13 m (Figure 12 and Figure 13).

1.10 Increase in container vessel size

Container vessels around the world have increased in size over the last decade. The growth rate has been primarily driven by liners in search of economies of scale.Footnote 35 The dimensions of large vessels pose challenges during berthing. For example, large vessels may be limited by infrastructure issues such as the available length of a berth, a berth’s capacity to handle forces exerted by the vessel, the rating of fenders and mooring fittings, and/or the height of the berth above the waterline.

Large vessels have greater freeboards, requiring higher berth walls in order to berth safely. The larger displacement of these vessels means that berth walls are also required to absorb more energy and support larger mooring forces. Large vessels also pose challenges to cranes in terms of outreach and height (overhang). Figure 14 shows the scale of growth in container vessels, including their TEUs, dimensions, and cargo-carrying capacity.

The increasing size of container vessels is evident at Vanterm. Table 3 shows the largest container vessel by summer deadweightFootnote 36 that berthed at Vanterm each year between 2008 and 2018. The table demonstrates that, over 10 years, the overall dimensions of vessels berthing at Vanterm have increased. The most significant increases are a 91% increase in summer deadweight and a 25% increase in vessel length overall. During this 10-year period, there were no major changes to the fenders, mooring bollards, and cranes at Vanterm, although a review of Vanterm’s fendering system was conducted in 2012 and an upgrade plan was announced in 2019.

| Year | Vessel | Summer deadweight (t) | Summer draft (m) | Length overall (m) | Beam (m) |

|---|---|---|---|---|---|

| 2018 | CMA CGM Vela | 131 831 | 15.53 | 347.48 | 45.27 |

| 2017 | APL Southampton | 131 358 | 15.50 | 347.05 | 45.25 |

| 2016 | CMA CGM Tage | 113 800 | 14.80 | 299.95 | 48.20 |

| 2015 | Sofia Express | 104 007 | 14.61 | 335.06 | 42.80 |

| 2014 | Ever Salute | 78 733 | 14.20 | 299.99 | 42.80 |

| 2013 | Ever Ethic | 75 898 | 13.50 | 299.99 | 42.80 |

| 2012 | Ever Elite | 75 898 | 13.50 | 299.99 | 42.80 |

| 2011 | MOL Pace | 71 902 | 14.02 | 293.19 | 40.00 |

| 2010 | Akinada Bridge | 71 366 | 14.02 | 284.71 | 40.00 |

| 2009 | Hanjin Oslo | 68 993 | 14.02 | 279.00 | 40.41 |

| 2008 | Hanjin Oslo | 68 993 | 14.02 | 279.00 | 40.41 |

| Percentage increase over 10 years | 91% | 11% | 25% | 12% | |

1.11 Vessel overhang due to hull shape

When a vessel with a flared hull approaches a berth at an angle, the flared portion of the hull can sometimes overhang the berth because the hull is wider at the top and narrower at the waterline. The extent to which a vessel’s hull can overhang a berth is an important consideration in berthing operations due to the risk of the flared hull making contact with berth structures such as bollards or shore cranes.

Some of the factors that affect the maximum overhang of a vessel are:

- The vessel’s draft

- The tide height

- The height of the apron above the waterline

- The vessel’s characteristics (e.g., the degree of flare on the hull at the bow and stern)

- The angle of approach

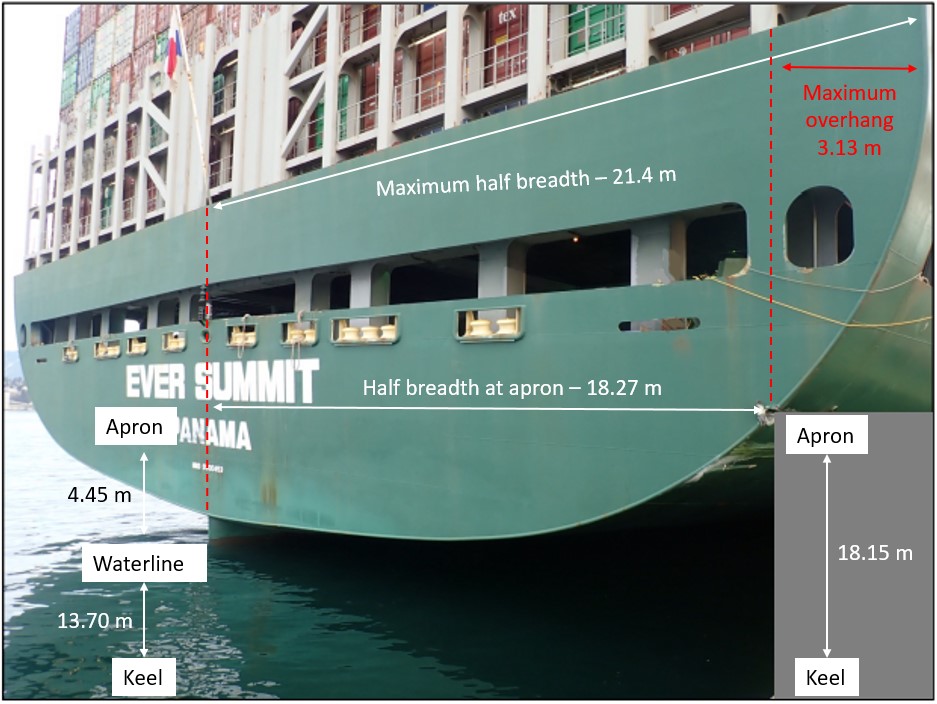

The TSB determined that, at the time of the occurrence, the Ever Summit’s maximum possible overhang at the stern was approximately 3.13 m (Figure 15 and Appendix D).

1.12 Pilotage in the Port of Vancouver

Pilotage in the Port of Vancouver is governed by the Pacific Pilotage Regulations, which make pilotage compulsory for all vessels over 350 gross tonnage (GT). Responsibility for the operation, maintenance, and administration of pilot services for compulsory pilotage areas on the Pacific coast lies with the Pacific Pilotage Authority (PPA), a Crown corporation. The PPA does not directly employ pilots, other than those operating in the Fraser River. Rather, the PPA contracts a private company, the British Columbia Coast Pilots, Ltd. (BCCP), to provide pilotage services for vessels. The PPA sets the hiring and training standards for pilots and requires biennial medical examinations of all active pilots.

The PPA has provided each pilot with a PPU. Pilots do not have standardized approaches to berths. The PPA leaves approaches to the berth to individual pilots, who determine the route using their expertise and local knowledge.

1.12.1 Berthing methods at Vanterm

Berthing methods used at Vanterm by pilots are influenced by various factors including the vessel characteristics, the berth specifications, the prevailing environmental conditions (e.g., wind, current, and visibility), the number and capacity of tugs on hand, and other vessel traffic in the vicinity, including vessels docked at adjacent berths.

Berthing is also affected by the tidal currents in relation to the berth construction, and the direction and speed of wind at the time. Closed berths tend to form a water cushion or bubble between the vessel and the berth as the vessel is manoeuvred in, while open berths allow the water to flow freely. The majority of the berths at Vanterm are of closed construction, with the exception of the berth 6 extension, which is of open construction.

Guidance issued by the terminal focuses on the positioning of cranes for vessels arriving at and departing the berth. The operations superintendent at Vanterm is responsible for planning the vessel’s intended berthing position, taking into consideration the fore and aft clearances with other docked vessels. The superintendent is also responsible for planning the position of the cranes. This information is then sent out to the vessel and the agents for the vessel or liner (Appendix B).Footnote 37

When berthing vessels the size of the Ever Summit, it is customary for the pilots to engage 2 tugs, one at each end of the vessel.Footnote 38 Tugs are secured after the vessel has transited First Narrows and entered Burrard Inlet. Once the tugs are secured, the vessel is typically manoeuvred to a position where it is approximately parallel to the dock at a distance of half to one vessel breadth. A bridge marker on the apron indicates the final berthing position.

The vessel then remains parallel to the berth while manoeuvring towards the berth laterally using the vessel’s engines, rudder, bow thrusters, and assistance from the tugs. The intent is to berth the vessel parallel to the dock (“flat”), as close as possible to the final berthing position, while contacting the fenders with the least momentum possible.

In practice, it is challenging to manoeuvre a large conventional vesselFootnote 39 laterally into a berth while continuously maintaining a near-parallel heading. This requires close attention, monitoring, and continuous adjustment of the vessel’s engines, rudder, thrusters, and any assisting tugs. The presence of another vessel at the berth or at nearby anchorages may require the vessel to execute an alternate route or modify its final approach.

Information about the approaches taken by vesselsFootnote 40 berthing at Vanterm in January 2019 has been compiled in the figure below (Figure 16). All of the vessels were successfully berthed. A total of 4 vessels transited the berth face at a distance of 50 m or less while approaching the berth. On approach, the Ever Summit was the closest of the 4 to the berth.

1.12.2 Risk management of large container vessels by the Pacific Pilotage Authority

The PPA recognizes that there are risks associated with berthing large container vessels. In 2012, prompted by concerns about the capacity of fendering systems, the PPA sent a request to 44 marine terminals in BC asking for updated information about the berths at their terminals: up-to-date bathymetry for all berths, berth plans that indicated the location and safe working load of all mooring equipment and fittings, as well as the terminals’ standard operating procedures for berthing and unberthing vessels. Out of the 44 terminals, 17 responded. Vanterm did not provide an update.

In 2015, extensive discussions took place between the PPA and Vanterm, and the PPA and the Port of Vancouver engaged a consultant to assess the risks of berthing the largest container vessels that call at major container terminals in BC.Footnote 41 The study focused on terminal configuration, fendering, and ship spacing.

The consultant’s report, completed in 2016, concluded that the existing standards of ship spacing on container berths in Vancouver, combined with the capacity of the fenders on these berths, meant that Vancouver was operating at a higher degree of risk than some comparable ports. The report noted that not only is Vancouver’s acceptable spacingFootnote 42 tighter than most, but also the capacity of the fitted fenders requires a higher degree of precision in berthing. The report indicated that these factors have the potential to increase the number of berthing incidents with the arrival of larger vessels unless measures are taken to mitigate the risk.

In March 2016, following instances where arriving or departing vessels were faced with a crane in a boom-down position, or the crane was left in a position where it could contact the flare of a vessel, the PPA issued a Notice to IndustryFootnote 43 reiterating the need for terminals to keep cranes at the midpoint or as far away from arriving or departing vessels as practicable and in the boom-up position.

In December 2018, following a number of near-misses involving very large container vessels (with lengths of 330 m to 366 m), particularly where the assigned tugs were operating at 100% power with no safety reserve, the PPA issued a Notice to IndustryFootnote 44 introducing an interim measure requiring 2 tractor tugs for all vessels over 280 m, and 3 tugs at the pilot’s request, based on the vessel manoeuvrability, weather conditions, and displacement.Footnote 45

The pilots have also raised an issue with respect to the orientation of the container terminal (berths 5 and 6) in relation to berth 4, which is equipped to handle oil tankers. Berths 5 and 6 run along an east-west direction of 108° to 288° true and meet berth 4, which runs in a north-south direction, at a 72° angle. The pilots note that the configuration can create a hazard for berthing and unberthing when 2 vessels are berthed at the container terminal,particularly if berth 4 is occupied.

1.12.3 Safety communications and lessons learned

The PPA has a Safety and Operating Review Committee, whose mandate is to review and assess pilotage practices and areas of concern and to seek solutions that improve safety and efficiency. The committee is chaired by a director of the Board and includes representatives from PPA management, the BCCP, and members of the marine industry. The committee meets 4 times a year.

The PPA communicates with pilots through Notices to Pilots. These notices are disseminated in the form of a list, to which items are continually added. Topics range from operational issues to administrative policies.

In 2016, following instances where container vessels had close calls with shore cranes while berthing or unberthing, the PPA issued a Notice to PilotsFootnote 46 informing pilots of the ideal position of cranes to minimize the likelihood of contact while berthing or unberthing. The notice also asked pilots to

[b]erth the vessel so cranes are as near to the mid-ship point of the vessel as is practical, even if the entire berth face is vacant i.e. do not land the vessel with the cranes at the bow or stern and then shift into position.

The BCCP holds weekly meetings where pilots can drop in and discuss issues. Attendance is not mandatory and, given their work schedules, not all pilots are able to attend at the same time. The BCCP sends information to the pilots by email and by weekly newsletter. The BCCP also holds monthly formal meetings with its members, and the minutes of these meetings are then circulated to all members.

The BCCP is structured so that each pilot is an independent and equal shareholder in the company. BCCP management recognizes the importance of sharing safety-critical information and lessons learned among the pilots and endeavours to disseminate information effectively. However, sharing safety information and lessons learned within the BCCP is restricted by concerns related to the legal implications of doing so.

In 2013, following 4 incidents where vessels made contact with eye pads on Vanterm’s fendering system, the TSB identified an issue whereby vessels approaching Vanterm at or near high tide, which were not coming alongside exactly parallel, could have their bow and/or stern exposed to these eye pads and make contact with them. The BCCP and PPA were aware of these incidents but neither organization had distributed information regarding this hazard to pilots. The TSB issued a safety information letterFootnote 47 to the BCCP and the PPA emphasizing the importance of sharing safety information.

The BCCP also has an accident/incident protocol which states that after an accident, the PPA and BCCP are required to review standard operating procedures for the terminal involved and make changes to BCCP’s standard operating procedures, or consider the need to establish standard operating procedures if none are in place.

1.13 Bridge resource management

BRM is the effective management and use of all available resources, both human and electronic, by a bridge team to ensure the safe navigation of a vessel. The essence of BRM is a safety culture and management approach that supports communication, cooperation, and coordination among the individuals involved in a vessel’s navigation.

The Standards of Training, Certification, and Watchkeeping (STCW) Code requires all officers in charge of a navigational watch on vessels of 500 GT or more to be competent in BRM.Footnote 48 In 2010, the STCW Code was amended to include a further requirement for masters and chief mates on vessels larger than 500 GT to complete Human Element and Leadership Management training.Footnote 49 The amendment came into effect in 2012.

With regard to BRM training for pilots, the International Maritime Organization (IMO) adopted Resolution A.960 on 05 December 2003, which covers recommendations on training, certification, and operational procedures for pilots. This resolution includes a recommendation that every pilot be trained in BRM. In recognition of the above guidance, various institutions and training providers, including some pilotage organizations, provide customized BRM training aimed specifically at the needs of pilots, often called BRM-P.

There are no requirements for BRM or similar training for tug masters. When performing the duties of an assist tug, tug masters are limited to executing the orders provided by the pilot.

The Marine Accident Investigators’ International Forum and the International Maritime Pilots’ Association have jointly published a poster highlighting the importance of sharing information between the bridge team and the pilot, respecting each other’s role, communicating throughout the pilotage, working together, and staying alert.Footnote 50

1.13.1 Bridge resource management and pilotage

BRM concepts extend to situations where a pilot is on board as well. All members of the bridge team, especially the master and the pilot, must have a shared understanding of how a voyage will progress and must take an active role identifying situations where the voyage deviates from the intended plan. To this end, when a pilot embarks, the pilot and master normally conduct a master-pilot exchange to help establish a shared understanding of the voyage, exchanging information on details such as intended courses and route, the speed of the vessel, where and when turns will be made, and how tugs will be used.

Among the duties of the bridge team, the master, bridge officers, and pilot share a responsibility for good communications and understanding each other’s role for the safe conduct of the vessel in pilotage waters.Footnote 51 The STCW Code emphasizes the importance of an ongoing exchange of information between master and pilot and states that

despite the duties and obligations of pilots, their presence on board does not relieve the master or officer in charge of the navigational watch from their duties and obligations for the safety of the ship.Footnote 52

IMO Resolution A.960 also specifies that masters and bridge officers have a duty to support the pilot and to ensure the pilot’s actions are monitored at all times.Footnote 53

In 1995, the TSB completed a safety study on the operational relationship between marine pilots and vessel masters/watchkeeping officers. The objective of this study was to identify safety deficiencies associated with teamwork on the bridge, including communication between marine pilots and masters/officers of the watch. The report noted that a pilot’s decision making

can become the weak link in a system prone to single-point failure; i.e., in the absence of effective monitoring, there is little safety backup for the pilot in the navigation of the vessel.Footnote 54

1.14 Communications with tugs

Tugs are versatile and manoeuvrable and can be positioned at various locations along a vessel (e.g., at the bow, amidships, or at the stern) while assisting with berthing. If tugs are to be secured to the vessel during berthing, the pilot, in conjunction with the master, decides the location at which to secure tugs by taking into consideration factors such as the tugs’ bollard pull and propulsion type, the total number of tugs available, the tugs’ arrival sequence, and the characteristics of the vessel.

In BC, pilots normally use a handheld VHF radiotelephone to issue tug commands. At the time of the occurrence, guidance from the PPA with respect to communication with tugs was limited to emergency signals using the vessel’s whistle in case of loss of VHF communications with the tug.

Tug commands, although not standardized, are typically uniform. Pilots tend to keep the tug commands short and clear. Commands usually include the tug’s name, the order (back/push), and the power (stop/easy/half/full). Commands sometimes specify the location of the tug (bow/amidships/stern), but not always. Following instances where pilots have mistaken the location of a tug while manoeuvring a vessel with multiple tugs, individual pilots have adopted various aide-mémoires to help them remember the tugs’ positions, such as jotting this information down on a piece of paper or on their hand. In this occurrence, the pilot positioned the tugs alphabetically from forward to aft, to serve as a memory aid.

The international language used in maritime operations is English. The bridge team, the pilot, and the tug masters in this occurrence communicated in English. The crew of the Ever Summit were Taiwanese and Chinese, and it was common for the bridge team to converse among themselves in Mandarin.

The language of choice for communication between pilots and tugs, assist vessels, and terminal staff varies depending on region or country, but usually these communications are conducted in the local language. This can make it difficult for the bridge team to monitor the communications between pilots, tugs, and other assist vessels, and may mean that bridge teams are not in the habit of monitoring communications between the pilots and tugs.

At the time of the occurrence, the master and bridge officers on the Ever Summit were focused on monitoring the status of vessel machinery and executing the helm, engine, and bow thruster orders issued by the pilot. They were not aware of the instructions given to the tugs just prior to the occurrence.

1.15 Skill-based performance

There is a model of human performance that can be used to identify types of errors at 3 levels of performance: skill-based, rule-based, and knowledge-based.Footnote 55 Individuals who process information at the skill-based level are those who are experienced with the task. A skill-based error is an action by the operator that is not in accordance with the operator’s intentions. Typical errors that can occur during skill-based processing of information are slips and lapses. Slips are associated with attentional or perceptual failures. Lapses involve failures of memory.

1.16 Similar occurrences

Between January 2009 and July 2020, the TSB received reports of 20 occurrences involving damage to vessels or shore infrastructure during berthing/unberthing at container terminals within the Port of Vancouver (Appendix E).

The TSB also looked specifically at the occurrences at Vanterm in comparison to Deltaport. On average, 196 container vessels berth at Vanterm per year and 291 vessels berth at Deltaport per year.Footnote 56 Between January 2009 and July 2020, the TSB was notified of 13 occurrences involving damage to container vessels or shore infrastructure at Vanterm. In this same time period, the TSB was notified of 2 occurrences involving damage to vessels or shore infrastructure at Deltaport.

1.17 TSB simulation analysis of berthing conditions at Vanterm

The TSB contracted for a simulation analysis to help identify the risks presented by berthing large container vessels at Vanterm. The simulations were performed using a desktop simulator and an existing model vessel.Footnote 57 A 3‑dimensional dynamic tidal stream model was used to replicate tidal conditions similar to those in effect at the time of the occurrence.

The first part of the simulation analysis looked at the forces applied to the fenders during berthing operations for a vessel similar to the Ever Summit. This involved 10 simulations where the vessel was berthing at an angle of 7° to 8° from the berth line. The lateral ground speed at the stern when making contact with the fenders was increased in each simulation by 1 cm/s, from 5 cm/s to 15 cm/s.

The second part of the simulation analysis measured the forces applied on the fenders when berthing a vessel on a parallel heading with a lateral contact speed of 15 cm/s. The vessel size was varied, with generic simulation vessels ranging from 200 m length overall with a 32 972 tonne displacement, to 366 m length overall with a 172 098 tonne displacement.

The third part of the simulation analysis assessed a range of safe berthing heading angles for a vessel similar to the Ever Summit, with consideration of load conditions and tide height.

The results of the simulation concluded that:

- the course over the ground is a critical component in determining energy transfer. The force applied on the fenders increases significantly (by up to 2397 kN) in a situation where a vessel is moving laterally towards the berth and the stern makes contact with the fenders versus a situation where the stern makes contact with the berth when the vessel is stopped or moving away.

- the total force on the fenders when a vessel is approaching the berth laterally at a rate of 15 cm/s exceeds 10 000 kN for a vessel displacing 85 000 tonnes, and exceeds 26 000 kN for a vessel displacing 143 000 tonnes. In the case of a vessel displacing 85 000 tonnes that contacts 9 fenders simultaneously, this would equate to a shared load of 1220 kN per fender. In the case of a vessel displacing 143 000 tonnes that contacts 14 fenders simultaneously, this would equate to a shared load of 1916 kN per fender. With small deviations in the heading angles, as little as 0.5° from parallel, the number of fenders contacted is reduced by half, and the force is effectively doubled.

- at low tide, for a vessel with a hull design and freeboard height similar to the Ever Summit with a moderate-to-full load, heading angles that either converge or diverge from parallel to the berth by more than 3° create a situation where a portion of the vessel’s hull will make contact with the berth face. At high water, these angles are reduced to 1.5°.

2.0 Analysis

The investigation determined that the Ever Summit struck the berth after the vessel made a close approach and that the pilot inadvertently gave the assisting tugs the opposite instructions from what was intended during the berthing manoeuvre. The investigation looked at communications with tugs during berthing, the suitability of the berth infrastructure for large container vessels at Vanterm, and overall risk management of the terminal.

2.1 Factors leading to the striking

Over the last 10 years, there has been an increase in the size of container vessels berthing at Vanterm and no corresponding upgrades to the terminal. As a result, this has introduced new hazards to berthing large container vessels at Vanterm as they are more vulnerable to small deviations from a perfectly lateral landing against the berth face. Such a deviation may result in the vessel’s hull applying too much force on the fendering system and/or, depending on the vessel’s hull shape and freeboard, the vessel’s overhang contacting the berth and/or any shore cranes in proximity. These hazards are increased at times of high water.

In the case of the Ever Summit, the company guidance recommended the vessel be stopped parallel at least 1.5 vessel breadths (64 m) off the berth and then pushed in laterally using tugs. However, the vessel transited the berth approximately 10 m off, an approach which limited the time to respond to any deviations during the berthing manoeuvre. In the master’s experience, it was not uncommon for pilots to approach the berth at Vanterm at distances less than described on the vessel’s pilot card, and he did not express concern during the berthing of the Ever Summit.

As the vessel was transiting close to the berth, the pilot attempted to reduce speed by using astern propulsion. Anticipating the stern to sheer towards the berth due to the interactions of operating the propeller astern in proximity to the berth and the effects of water cushion, the pilot engaged the tugs in order to maintain the vessel parallel to the dock. Intending to have the forward tug push and the aft tug pull, he inadvertently gave the opposite commands. As the tugs carried out the commands, the vessel’s stern rapidly sheered towards the berth. The master expressed concern about the sheer to the pilot, but neither the pilot nor the master identified that the tugs were assisting in the opposite direction than intended. Attempting to correct this, the pilot called for increased power on the tugs, but the sheer increased.

The master and the bridge team were relying on the pilot to safely manoeuvre the vessel into the berth and were focused primarily on monitoring the vessel’s position and carrying out engine, thruster, and helm orders given by the pilot. As a result, they were not monitoring the pilot’s commands to the tugs and were not in a position to help identify the deteriorating situation.

Corrective action using the vessel’s engine, rudder, and thruster had insufficient effect, and the vessel’s stern struck the dock at an angle of 10° with the berth line and a speed of approximately 0.4 knots. The vessel’s large overhang and the proximity of the crane to the berth line resulted in the vessel’s hull striking the berth and the crane, which caused the gantry bogies to collapse and the boom to fall onto the vessel.

2.2 Communications with tugs during berthing

Tugs are commonly used to assist large container vessels with berthing. The use of tugs may be complicated by various factors such as the number of tugs in use, whether or not the tugs are visible to the pilot, and the degree of complexity of the berthing manoeuvre. Procedures around the use of tugs are largely left to the discretion of individual pilots, and there are no standard communication protocols or formal sharing of best practices.

In the case of the Ever Summit, the tugs were obscured from the view of the pilot and the bridge team, and the pilot was relying on his memory and mental model of the manoeuvre to keep track of the location and movements of the tugs. The pilot had lined up the tugs alphabetically to make it easier to remember each tug’s position; however, during the manoeuvre itself, which is a time of high information processing workload, he inadvertently mixed up their positions and gave them the opposite instructions. This memory lapse occurred during skill-based processing of information. The pilot had previously berthed vessels at Deltaport using the Seaspan Hawk forward, which may have contributed to the error.

This is not the first instance of a pilot in BC waters mixing up tug names while manoeuvring. In most circumstances, such errors are identified and corrected without much delay or damage, resulting in these errors going unrecognized and unreported. However, the investigation determined that there are no written procedures or guidance to standardize communications between pilots and tug masters in BC and the commands provided to tugs are not always comprehensive. Although they do include the direction (pull/push) and power (full /half/easy), they do not always include the location where the action is required (e.g. bow/amidships/stern).

If standardized communications are not used between pilots and tug masters, errors in tug commands will continue, increasing the risk of accidents.

Gaps in bridge resource management (BRM) may allow a communication error such as this one to go undetected. All members of a bridge team have a responsibility to not only perform their own duties, but to also monitor the actions of others to help identify potential errors. The TSB has identified a number of factors that may make BRM more challenging when a vessel has a pilot on board and is manoeuvring with the assistance of tugs:

- Commands are often relayed through the pilot’s handheld very high frequency radiotelephone and therefore may not be clearly audible to the bridge team, and as a result they may not be able to help identify possible errors.

- Tug commands are not standardized and differ from port to port, which can make it more challenging for bridge teams to follow them.

- Language barriers may make it difficult for foreign bridge teams to understand the communications between the tugs and the pilot.

- Foreign bridge teams may not be in the habit of monitoring a pilot’s communications with tugs because the commands are often issued in the local language.

During the berthing manoeuvre, the Ever Summit bridge team was monitoring the vessel’s position and carrying out manoeuvring orders issued by the pilot, but they were not closely monitoring the pilot’s commands to the tugs. This meant that the bridge team was not in a position to identify the erroneous tug command. Crews who work together regularly tend to develop shared understandings and familiarity with one another's practices, but maintaining good BRM practices is especially important when working with pilots and tugs.

Tug masters are not typically in a position to monitor the pilot’s actions. The responsibility of tug masters is limited to safely executing instructions received from the pilot. The tug masters’ visibility is often obscured by the size and proximity of the vessel they are assisting, so they are not in a position to question a pilot’s command. In the case of the Ever Summit, the tugs correctly executed the commands that were communicated to them. Without any indication of the location where the assistance was required (e.g., “Falcon push easy on the bow” or “Hawk pull easy on the stern”), there was no way for the tug masters to identify the error and alert the pilot.

It is important that bridge teams employ all measures and tools available to them to ensure the safe navigation of the vessel. This includes closely monitoring the actions of the pilot, other crew members, and any tugs assisting during manoeuvring.

If effective BRM is not maintained by bridge teams, including pilots and tug masters, there is a risk that errors will go undetected.

2.3 Suitability of berth infrastructure

An important consideration in safely berthing a vessel is ensuring that the berth’s structure, dimensions, and associated fittings (e.g., bollards and fenders) are appropriate for the characteristics and size of the vessel. The berth must be capable of withstanding the typical forces exerted during berthing and while a vessel is moored, taking into consideration the maximum environmental forces that can be expected.

As the size of vessels at Vanterm has increased, the tolerance for error while berthing has decreased. The investigation identified concerns related to the fendering system and the clearance between the crane rail and the berth line when berthing large vessels such as the Ever Summit at Vanterm.

2.3.1 Fendering system

Fenders must be adequately sized and spaced to absorb the kinetic energy of an incoming vessel without resulting in damage to the vessel or the berth. The study of the fendering system conducted in 2012 concluded that, at that time, the existing fender systems had insufficient capacity to properly absorb the kinetic energy of the large vessels berthing at the terminal, which was resulting in damage to both vessels and the berth. Since the study took place in 2012, there has been a further increase in the size of vessels berthing at Vanterm.

2.3.2 Clearance between the crane rail and the berth line

Shore gantry cranes must be of sufficient height and reach to be able to service the highest stacked container, as well as those stowed on the outboard end of the vessel at various tidal and draft conditions. The distance between the waterside crane rail line and the berth line will affect the outreach for a particular crane (i.e., the closer the crane rail to the berth line, the greater the reach). However, there must also be sufficient distance between the berth line and the waterside crane rail to reduce the chance of a vessel’s flare striking the crane legs.

Although there are no regulations stipulating the minimum clearance between the crane rail and the berth line in relation to the size of vessels, The Port Designer’s Handbook identifies that with most shore gantry cranes, the distance between the berth line and the waterside crane rail should not be less than 3 m. For large container vessels, this distance should be around 7.5 m due to the shape of the bow and the berthing angle of the vessel.

The distance from the crane rail to the berth line at Vanterm is only 2.13 m, which means that even a slight angle on a vessel while berthing could cause the flare of its bow or stern to come into contact with a crane if one is in the vicinity. At Deltaport, by comparison, the distance from the crane rail to the berth line is 6.96 m.

If a berth’s infrastructure is not appropriate for the size of vessels berthing at a terminal, additional hazards may be introduced into berthing operations, increasing the risk of accidents.

2.4 Risk management

Managing risk involves identifying what might cause harm to assets, workers, and the environment and determining whether reasonable steps are being taken to prevent that harm from happening. Broadly, risk management is a process that involves identifying hazards and assessing and controlling risks.

At Vanterm, the hazards posed by the existing infrastructure when berthing large container vessels have persisted for a number of years. With the exception of the berth extension in 2002, no other significant berth upgrades or modifications had been conducted since 1990 to accommodate the growing size of vessels berthing at the terminal. However, following a review of the fendering system in 2012 and a study on the risks of berthing large container ships in 2016, an infrastructure upgrade plan was announced in 2019.

At the Port of Vancouver, decisions pertaining to suitability of the berths at Vanterm are solely at the discretion of the terminal operators. GCT Canada does not have a formal process at Vanterm to determine the suitability of the vessels berthing at the terminal, and thereby eliminate hazards relating to an increase in vessel size. The frequency of occurrences during berthing at Vanterm (13 since 2009) suggests shortcomings in risk management.

Currently, vessels berthing at Vanterm are limited in size by the transit under Lions Gate Bridge through First Narrows, as well as restrictions around the reach of the cranes, overall length of the vessel, and the available depth of water at the berth. GCT Canada does not set restrictions on maximum vessel displacement and freeboard. Displacement influences the total energy that is transferred during the berthing process, and freeboard in relation to the tidal height limits the maximum possible overhang for the vessel. Large vessels with high freeboards also create greater angles of elevation for mooring lines, reducing the holding capacity of the mooring system.

There are currently no requirements in place for any independent body, such as a port authority or Transport Canada, to periodically examine or audit the suitability of a berth in relation to the maximum size of vessels berthing at a terminal and the berthing process. This has resulted in the burden of managing this risk being shifted to the master and pilot, who are left with the challenge of berthing large container vessels with a tolerance for error that continues to decrease. Additionally, Vanterm is not fitted with a berthing aid system that can provide valuable real-time information during the critical stages of berthing.

In 2012, the Pacific Pilotage Authority (PPA) requested information from GCT Canada to facilitate safe berthing, but the berth plans for the terminal were not provided. These plans would have provided important information such as maximum displacement and dimensions of the design vessel, maximum safe angle of approach, and maximum fender forces and mooring loads.

The PPA has made attempts to mitigate such risks by using additional tugs, by incorporating the use of portable pilot units, and by conducting risk assessments and simulator trials. However, the PPA is limited in the extent to which it can mitigate risks associated with berth infrastructure. If these risks persist, additional defences may need to be considered, including limitations on acceptable parameters for berthing large vessels (e.g., weather, daylight, or tidal restrictions) or the use of a second pilot.

If terminal limitations on maximum vessel size are not comprehensive, berthing vessels and infrastructure may be placed at risk.

If hazards associated with the increase in size of container vessels in relation to existing terminal infrastructure are not adequately mitigated, there is an increased risk of accidents while berthing these vessels.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- Over the last 10 years, there has been an increase in the size of container vessels berthing at Vanterm and no corresponding upgrades to the terminal.

- The vessel transited the berth approximately 10 m off, an approach which limited the time to respond to any deviations during the berthing manoeuvre.

- The pilot engaged the tugs in order to maintain the vessel parallel to the dock. Intending to have the forward tug push and the aft tug pull, he inadvertently gave the opposite commands.

- As the tugs carried out the commands, the vessel’s stern rapidly sheered towards the berth. Attempting to correct this, the pilot called for increased power on the tugs, but the sheer increased.

- The master and the bridge team were relying on the pilot to safely manoeuvre the vessel into the berth and were focused primarily on monitoring the vessel’s position and carrying out orders given by the pilot. As a result, they were not monitoring the pilot’s commands to the tugs and were not in a position to help identify the deteriorating situation.

- Corrective action using the vessel’s engine, rudder, and thruster had insufficient effect, and the vessel’s stern struck the dock at an angle of 10° with the berth line and a speed of approximately 0.4 knots.

- The vessel’s large overhang and the proximity of the crane to the berth line resulted in the vessel’s hull striking the berth and the crane, which caused the crane’s gantry bogies to collapse and the boom to fall onto the vessel.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If standardized communications are not used between pilots and tug masters, errors in tug commands will continue, increasing the risk of accidents.

- If effective bridge resource management is not maintained by bridge teams, including pilots and tug masters, there is a risk that errors will go undetected.

- If a berth’s infrastructure is not appropriate for the size of vessels berthing at a terminal, additional hazards may be introduced into berthing operations, increasing the risk of accidents.

- If terminal limitations on maximum vessel size are not comprehensive, berthing vessels and infrastructure may be placed at risk.

- If hazards associated with the increase in size of container vessels in relation to existing terminal infrastructure are not adequately mitigated, there is an increased risk of accidents while berthing these vessels.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- The pilot card incorrectly indicated that the vessel’s parallel body length was 285 m; this was actually the length between perpendiculars for the vessel.

- Sharing of safety information and lessons learned within British Columbia Coast Pilots Ltd. is restricted by concerns related to the legal implications of doing so.

- There are currently no requirements in place for any independent body, such as a port authority or Transport Canada, to periodically examine or audit the suitability of a berth in relation to the maximum size of vessels berthing at a terminal and the berthing process.

4.0 Safety action

4.1 Safety action taken

4.1.1 Pacific Pilotage Authority

Following the occurrence, the Pacific Pilotage Authority (PPA) took the following actions:

- Reviewed the incident to identify findings and make recommendations. These were promulgated to British Columbia Coast Pilots Ltd.

- In April 2019, requested that all terminals provide general arrangement plans and berthing and fender information for their berths. The PPA has since received the requested information for most of the terminal berths. This information has been promulgated to industry and the pilots via the PPA website. Footnote 58 Berthing and fender information for Vanterm 5 and 6 was provided to the PPA in May 2020, while upgrades to the terminal were underway.

4.1.2 British Columbia Coast Pilots Ltd.

Following the occurrence, British Columbia Coast Pilots Ltd. took the following actions:

- Developed a standard operating procedure regarding tug communications to be used between pilots and tugs for berthing and unberthing operations. Among other things, the procedure requires pilots to determine a backup very high frequency (VHF) channel, discuss the planned manoeuvre with the tug masters, and include the tug’s position with reference to the vessel with every command.

- Issued an email to pilots with safety-related information about the occurrence.

- In discussion with the PPA, issued a letter to the Port of Vancouver stating that a third tug would be required for berthing all vessels that are 280 m in length overall and over at Vanterm until properly engineered fendering with the appropriate fender factor for high freeboard vessels is provided.

- Met with GCT Canada to discuss safety, crane spacing, berthing spacing, and fendering.

- Created standard operating procedures for major container terminals on the west coast of BC.

- Conducted a post-incident fitness for duty and simulation assessment with the pilot involved in the occurrence.

4.1.3 GCT Canada

GCT Canada reviewed its practice of storing shore gantry cranes during berthing and unberthing operations and concluded that the best option was to disperse the cranes along the berth, boom up and unmanned during these operations.

4.1.4 Port of Vancouver

The Port Information Guide was amended in June 2020 to reflect crane positioning requirements at Port of Vancouver container terminals for arriving and departing vessels.

4.2 Safety concern

4.2.1 Impact of the growth of container vessel size on the safety of berthing operations

Over the past decade, there has been a substantial increase in the size of container vessels worldwide, as well as those calling at container terminals in the Port of Vancouver. Larger container vessels have greater scantlings, deeper drafts, heavier displacements, and higher freeboards. As well, the hull at the waterline of newer container vessels tends to be more sculpted and finer form compared to traditional designs. This creates larger flares at the bow and stern, which necessitate approaches to the berth that are near parallel or “flat”, with very little tolerance for error.

The report on the TSB simulation analysis of berthing conditions at Vanterm identified that a vessel of the Ever Summit’s size and design approaching the berth at Vanterm at an angle greater than 3° can result in the vessel contacting the berth, its fittings, or shore cranes, particularly at high tide. The investigation also determined that the energy absorption capacity of the fendering systems, the clearance between the waterside crane rail and the berth line posed hazards. These factors, as well as the suitability and location of mooring bollards and vessel spacing at the berth, need to be carefully evaluated, particularly in light of the greater displacements, length overall, and higher freeboards of large container vessels.

All terminals have a maximum design vessel size and most have built-in safety margins to minimize the consequences of error. However, there are currently no requirements in place for any independent body, such as a port authority or Transport Canada (TC), to periodically examine or audit the suitability of a berth in relation to the maximum size of vessels berthing at a terminal and the berthing process. Decisions about the maximum size of vessels that are accepted are left to the discretion of individual terminals. This can lead to situations where vessels are calling at terminals that were not designed to accommodate them. At Vanterm, for example, there are no defined limitations on a vessel calling at the terminal, other than the First Narrows transit restrictions and limitations around a vessel’s draft. The original berth plans for the terminal dated back to 1972 and did not contain information on maximum vessel size, berthing velocities, or approach angles. It was only after the occurrence, in May 2020, while upgrading the fenders, that the terminal obtained this information and made it available to pilots.

Those involved in berthing operations at Vanterm have made attempts to mitigate the risks for large container vessels by using additional tugs, revising procedures, planning terminal upgrades, and completing a risk analysis of the berthing process. However, as demonstrated by the Ever Summit occurrence, and another similar occurrence that happened shortly afterwards involving one of the Ever Summit’s sister ships,Footnote 59 certain risks associated with Vanterm’s capacity to safely accommodate large container vessels have persisted.

As the size of container vessels calling at the Port of Vancouver continues to increase and, given the absence of any oversight as to the suitability of the berths by TC or the Vancouver Fraser Port Authority, the Board is concerned that the size of vessels may exceed the Port of Vancouver’s terminal infrastructure capacity to accommodate them safely.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – The Ever Summit’s track from First Narrows to Vanterm

Source: Canadian Hydrographic Service, with TSB annotations

Appendix B – Vanterm berthing instructions for the Ever Summit

Source: Vanterm

Appendix C – First Narrows Traffic Control Zone requirements

The Port of Vancouver Information GuideFootnote 60 sets out the requirements of the First Narrows Traffic Control Zone. Vessels are required to have

- a minimum overhead clearance of 2 m under the Lions Gate Bridge

- an underkeel clearance of 10% for First Narrows and 5% alongside the berth

- a maximum allowable moulded breadth of 60 m

- a maximum unrestricted draft for transit of 13.6 m at chart datum

The guide also specifies that vessels with a draft in excess of 13.6 m may transit subject to tidal windows. Container vessels greater than 340 m length overall have additional restrictions relating to tide.

Finally, the guide notes that vessels having a length overall of 366 m and above and/or a moulded breadth of 51.25 m and above are restricted from entering Burrard Inlet without the prior approval of the port authority.

Appendix D – Overhang calculations for the Ever Summit

Given the damage sustained at the transom, the below calculation provides an estimate of the maximum possible overhang under the prevailing conditions at the time of the occurrence.

To determine the maximum overhang at the transom, the difference between the half-breadth of the vessel at the apron level and the maximum half-breadth of the vessel was calculated. The maximum possible overhang at the transom was determined to be 3.13 m (Figure D1).

Prevailing conditions at the time of the occurrence:

- Aft draft: 13.70 m

- Height of tide: 2.63 m

Apron measurements:

- Height of apron above chart datum: 7.08 m

- Height of apron above waterline: 4.45 m (obtained by subtracting the height of the tide from the height of the apron above chart datum)

- Height of apron above the keel: 18.15 m (obtained by adding the aft draft to the height of the apron above the waterline)

Measurements at the transom, from the vessel’s Lines and Offsets plan:

- Maximum half-breadth: 21.40 m

- Half-breadth at the apron level: 18.27 m

Appendix E – Berthing occurrences involving container vessels at Port of Vancouver terminals, January 2009 to July 2020

| Date | Vessel | Length overall | Terminal | Summary |

|---|---|---|---|---|

| 05 Apr 2020 | Ever Shine | 300 m | Vanterm 6 | Contact with shore crane while berthing. |

| 28 Jan 2019 | Ever Summit | 300 m | Vanterm 6 | Striking of berth and shore crane while berthing. |