Incorrect type of fuel

2080061 Ontario Inc. (dba SkyCare Air Ambulance)

Piper PA-31-350, C-GQXD

Pickle Lake Airport, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the flight

At approximately 1420Footnote 1 on 14 October 2023, the 2080061 Ontario Inc. (doing business as SkyCare Air Ambulance [SkyCare]) Piper PA-31-350 aircraft (registration C-GQXD, serial number 31-8052063) landed at Pickle Lake Airport (CYPL), Ontario, with 2 flight crew members—a captain and a first officer (FO)—on board. The aircraft had been conducting flights in the area of Pickle Lake, Ontario, since 10 October 2023, and the pilots had made arrangements with North Star Air Ltd. (North Star Air) to be supplied with aviation gasoline (AVGAS).

At CYPL, fuel is stored in above-ground fixed storage tanks (Figure 1), which are placarded according to the type of fuel. Aircraft must taxi or be towed to the designated refuelling area.

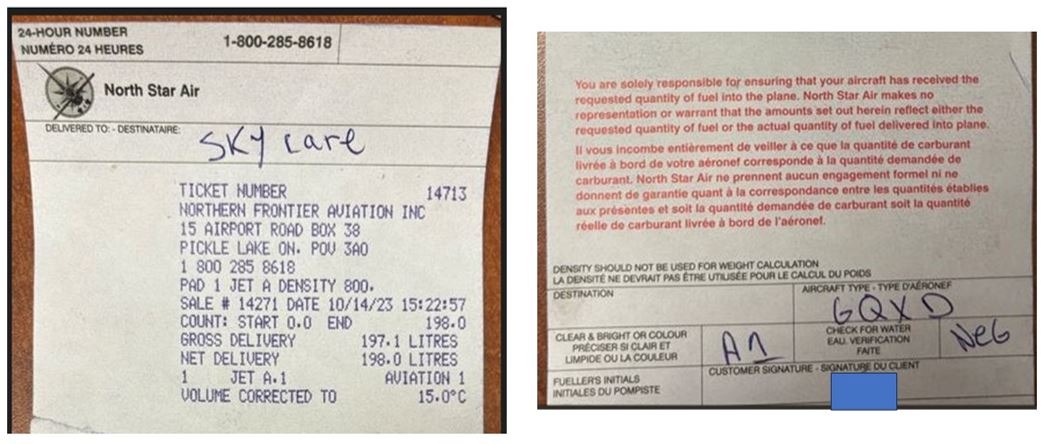

At approximately 1500, the occurrence aircraft taxied to the refuelling pad, where it had been refuelled over the course of the previous 4 days. The captain then left the refuelling area to work on flight planning while the FO stayed with the aircraft. The FO requested that the refuelling agent add fuel to the aircraft, and the refuelling agent proceeded to refuel the aircraft with Jet A-1. Video footage obtained from North Star Air shows the refuelling agent and the FO communicating before, during, and after the refuelling event, though it does not show the whole aircraft or the refuelling process. Once fuelling was completed, the refuelling agent handed the FO a fuel receipt (Figure 2), and the FO signed it and retained a copy. The FO then handed the receipt to the captain, who did not review it. At approximately 1700, the refuelled aircraft departed CYPL for Winnipeg/St. Andrews Airport (CYAV), Manitoba, with the flight crew on board.

Just before takeoff, take-off power was applied to both engines. During the application of power, the FO, who was the pilot flying, heard an abnormal sound and perceived a fluctuating manifold pressure indication on both engines. The captain, who was the pilot monitoring, observed that all engine parameters were normal.

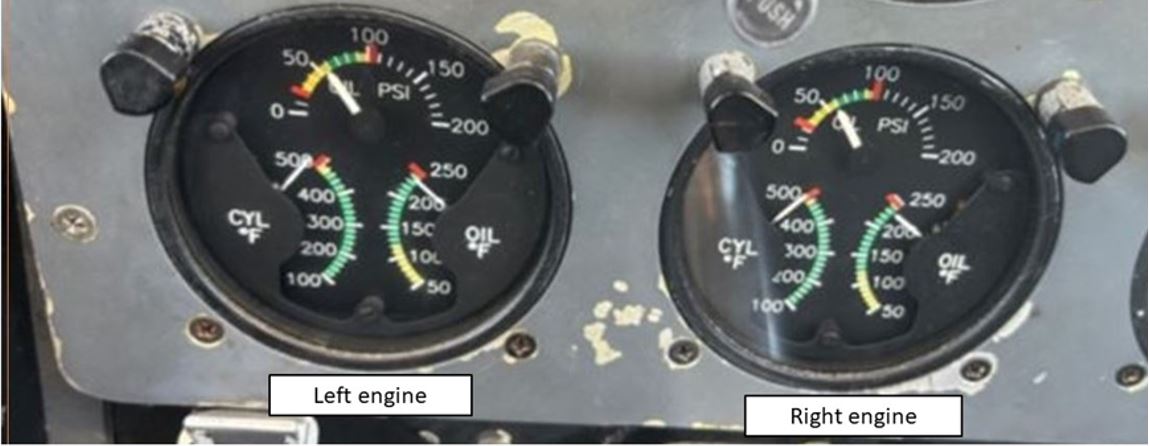

In the climb through 200 feet above ground level, the flight crew noticed that cylinder head temperatures for both engines were above 500 °F, oil temperatures were approximately 250 °F, and oil pressures indicated 50 to 60 psi (Figure 3).

A co-worker of the refuelling agent noticed unusual emissions trailing from the aircraft on departure and contacted the refuelling agent, who was leaving work after his shift. During the ensuing conversation, they decided that the emissions had likely been caused by fuel venting due to full auxiliary fuel tanks. Shortly after, the refuelling agent consulted the internet and realized that PA-31-350 aircraft normally take AVGAS and that the occurrence aircraft had instead been fuelled with Jet A-1 fuel. He subsequently reported this incident to his manager at North Star Air, who then contacted SkyCare dispatch and the London Flight Information Centre (FIC) to inform them that the occurrence aircraft had been fuelled with Jet A-1, the wrong type of fuel.

Approximately 15 minutes after departure, the flight crew received a radio call from the London FIC informing them that their aircraft had been fuelled with Jet A-1. SkyCare dispatch also informed the crew of the incorrect fuel type directly, via text message. Due to the fact that Jet A-1 had been added to the inboard tanks and there was no additional fuel available in the outboard tanks, the flight crew decided to divert to Sioux Lookout Airport (CYXL), Ontario, and notified air traffic control. The aircraft landed at CYXL without incident.

Aircraft information

The PA-31-350 is a twin-engine aircraft certifiedFootnote 2 for day and night visual flight rules and instrument flight rules operations. It is equipped with reciprocating engines (Lycoming Engines TIO-540-J2BD) that require AVGAS with a minimum 100 octane rating. The occurrence aircraft had complied with Federal Aviation Administration (FAA) Airworthiness Directive (AD) 87-21-01,Footnote 3 which narrowed the fuel filler opening to 58 mm in accordance with Piper Aircraft, Inc. Service Bulletin No. 797B, dated 01 September 1987.Footnote 4

The occurrence aircraft’s fuel filler opening had a placard (Figure 4) that indicated the type and grade of fuel and conformed to the FAA’s certification regulations, which state, in part:

(c) Fuel, oil, and coolant filler openings. The following apply:

- Fuel filler openings must be marked at or near the filler cover with—

- For reciprocating engine-powered airplanes—

- (A) The word "Avgas"; and

- (B) The minimum fuel grade.Footnote 5

Personnel information

The captain had been employed by SkyCare since 10 October 2022. From that date until 07 December 2022, he was an FO on the PA-31-350. On 07 December 2022, he completed the Fairchild Aircraft Corporation SA227 pilot proficiency check and became an FO on this aircraft type. On 17 September 2023, he was assigned to the PA-31-350 as a captain and was based out of CYAV.

Before the occurrence, he had accumulated 1275 total flight hours, including 116 hours as captain and about 40 hours as FO on the PA-31-350.

The FO had been employed by SkyCare since 25 October 2022 and was a PA-31-350 FO with 277.3 hours on type.

The refuelling agent had been employed by North Star Air since 11 September 2023 and had received company training that consisted of procedures for fuelling aircraft from stationary tanks.

Aircraft refuelling

In a discussion of operational engine failures caused by misfuelling accidents, FAA Advisory Circular (AC) 20-105C explains that

[r]eciprocating engines that burn jet fuel at high-power settings may suffer detonations, rapid loss of power, and high Cylinder Head Temperatures (CHT). A complete engine failure can quickly follow these conditions.Footnote 6

Transport Canada (TC) does not regulate or perform oversight of fuel dealers. However, TC AC 300-012 provides information and guidance to those involved with the fuelling of aircraft at aerodromes and states TC’s position regarding the storage, handling, and dispensing of aviation fuels. Referring to the Canadian Standards Association (CSA) Standard B836, the TC AC states that

[it] is Transport Canada’s view that [the CSA standard] provides industry the best practices. Since the introduction of this standard, Transport Canada also recommended that all aerodrome operators adopt the standard for their individual operations.Footnote 7

CSA Standard B836:22 outlines requirements for aviation fuel at Canadian aerodromes. In particular, section 8 states the qualifications and training requirements for all personnel involved in fuelling aircraft. According to the CSA standard,

[f]acility and fuelling equipment operators shall have a documented training program and are responsible for ensuring that all personnel under their direction and control are properly trained or performing tasks assigned to them as specified in this Standard.Footnote 8

In addition, section 4.3.14 explains the required features of overwing fuel nozzles, which are designed to prevent aircraft from being filled with the wrong type of fuel. It states:

Overwing fuel nozzle spouts for aviation turbine fuel shall meet the requirements of SAE AS1852D.Footnote 9 Overwing fuelling nozzles shall be grade-marked and colour-coded (black handle or body for jet fuel and red or blue handle or body for avgas). Nozzle spouts shall not be painted or coated.

- For avgas fuelling, nozzle spouts with a maximum external diameter of 49 mm, fitted with a dust cap, shall be used.

- Selective spout: For jet fuel overwing fuelling, a nozzle with a selective spout having a major axis of 67 to 70 mm shall be fitted.

Notches, latches, and hold-open devices shall not be used on overwing fuel nozzles.

In cases where the fuel nozzle spout does not fit the aircraft fuel tank opening and aviation turbine fuel is required, a documented procedure may be followed to temporarily change the SAE AS1852D nozzle spout for that aircraft only. […]

Note: This Clause is intended to prevent piston-engine aircraft from being refuelled with aviation turbine fuel.Footnote 10

At the time of the occurrence, North Star Air was aware of the CSA Standard B836.

Fuel nozzle sizes

A physical defence against the incorrect selection of fuel type exists in the form of the Jet A-1 flared spout (67 to 70 mm in width), which, as mentioned in the CSA Standard, is identified with a black handleFootnote 11 (Figure 5). This spout will not normally fit into the AVGAS fuel filler opening. However, for various reasons, the use of the Jet A-1 flared spout is impossible, or impractical, on some turbine-powered aircraft. Aircraft that were manufactured before 1993, when the airworthiness standards were amended to include fuel filler opening requirements,Footnote 12 or that have been modified by the installation of turbine engines may have fuel filler openings that do not meet the dimension requirements and, therefore, require a reduced-diameter spout (maximum external diameter of 49 mm) (Figure 6). The airworthiness standards for rotorcraft do not specify the size of fuel filler openings.Footnote 13

As a result, fuelling equipment commonly includes a reduced-diameter spout identified with a red handle (AVGAS). The spout can be removed and installed on the jet fuel handle for use with non-standard fuel filler openings. However, when a reduced-diameter spout is available to accommodate non-standard fuel filler openings, there is an increased risk that Jet A-1 fuel will be dispensed into an aircraft that requires AVGAS. Another defence available, in addition to the black and red handles, is a coloured wraparound hose sleeve (figures 7 and 8) that can be installed near the nozzle to identify the type of fuel when the refuelling agent is at the aircraft refuelling point.

The fuel nozzle for the Jet A-1 hose at CYPL had been fitted with the reduced-diameter (1 inch) spout before the occurrence aircraft requested fuel, given that there was frequent helicopter activity that required its use. North Star Air does not have a documented procedure for removing or replacing the reduced-diameter nozzles after use. North Star Air had a flared spout available (2.6 inches), but it was not installed. The wraparound hose sleeves were not in use at CYPL.

Similar occurrences

A similar fuelling error occurred in 2015 near Thompson, Manitoba,Footnote 14 causing another PA-31-350 aircraft on a scheduled flight to conduct a forced landing shortly after takeoff. All 8 occupants, including the pilots, survived but sustained various serious injuries. In that occurrence, the flight crew did not receive a copy of the fuel receipt, nor did they supervise the fuelling operation.

A review of the TSB database has found 3 additional occurrences since 2015 involving piston-powered aircraft for which jet fuel was uplifted.Footnote 15

Safety action taken

In response to this occurrence, SkyCare issued on 01 December 2023 an operational bulletin outlining the event and the hazards associated with refuelling, and highlighting the need for flight crews to supervise the fuelling of their aircraft.

Safety message

It is important that the refuelling procedures of air operators and fuel dealers incorporate defences, such as appropriate equipment, communication, and flight-crew monitoring, to ensure that aircraft are fuelled with the correct type of fuel.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .