In flight breakup

Blue Water Aviation

de Havilland DHC-3, C-GBTU

Little Grand Rapids, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

At approximately 0745 Central Daylight Time on 26 October 2019, the Blue Water Aviation float-equipped de Havilland DHC-3 Otter aircraft (registration C-GBTU, serial number 209) departed Bissett Water Aerodrome, Manitoba, with the pilot, 2 passengers, and approximately 800 pounds of freight on board. The destination was Little Grand Rapids, Manitoba, on the eastern shore of Family Lake. At approximately 0845, while on approach to Family Lake, the aircraft’s right wing separated from the fuselage. The aircraft then entered a nose-down attitude and struck the water surface of the lake. The pilot and the 2 passengers were fatally injured. The aircraft was destroyed by impact forces. The emergency locator transmitter activated momentarily.

1.0 Factual information

1.1 History of the flight

At approximately 0745Footnote 1 on 26 October 2019, the Blue Water Aviation float-equipped de Havilland DHC-3 Otter aircraft (registration C-GBTU, serial number 209) departed Bissett Water Aerodrome (CJY6), Manitoba, on a visual flight rules (VFR) flight to the community of Little Grand Rapids, Manitoba, on the eastern shore of Family Lake. On board the aircraft were the pilot, 2 passengers, and approximately 800 poundsFootnote 2 of freight. The purpose of the flight was to transport 2 contractors, their tools, and some roofing materials. It was the first of a series of flights planned for that day.

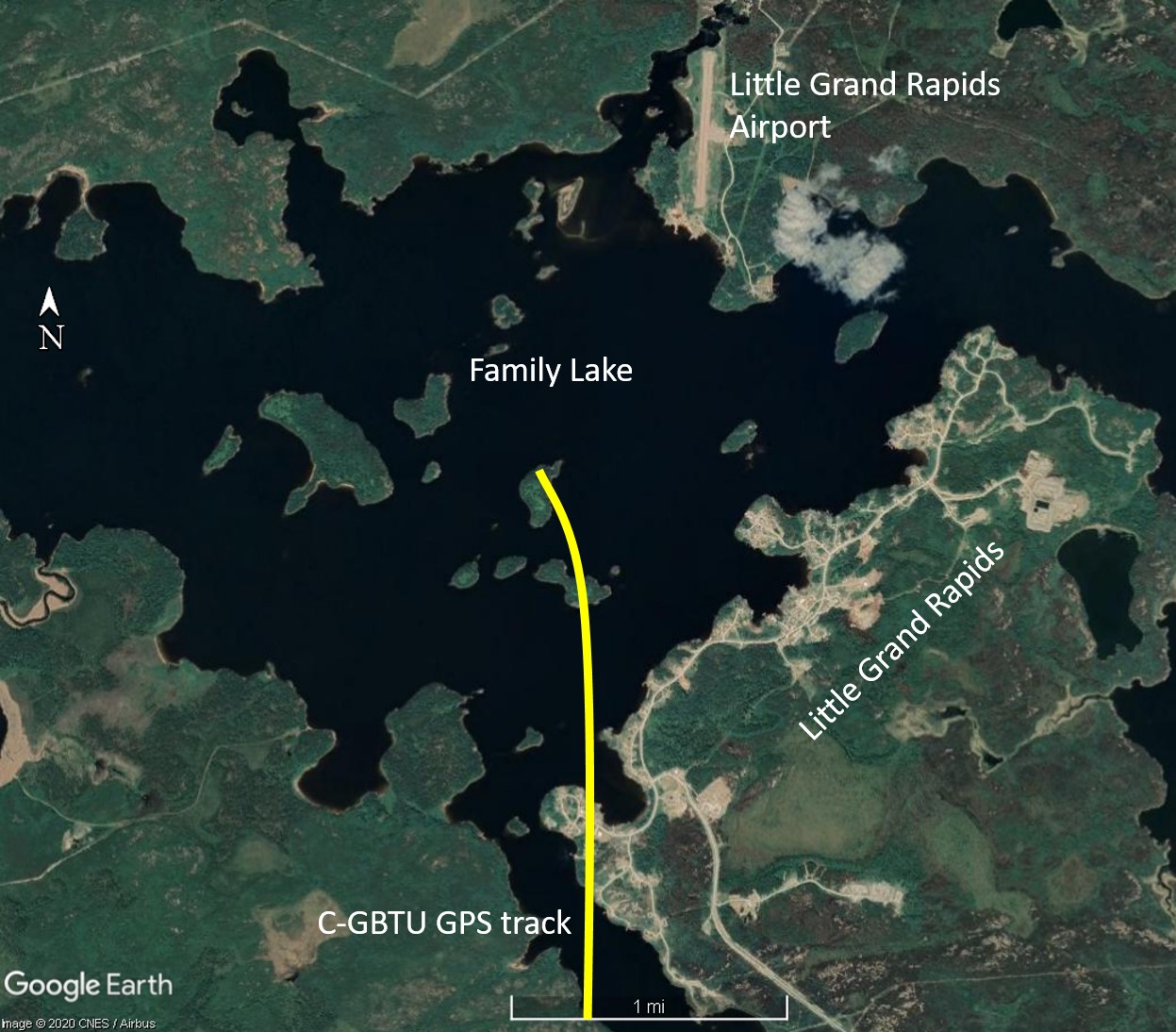

At approximately 0845, when the aircraft was at about 400 feet above ground level (AGL) and making the left turn prior to the final approach for Family Lake, its right wing separated from the fuselage. The aircraft then entered a nose-down attitude and struck the surface of the lake (Figure 1). The pilot and the 2 passengers were fatally injured. The aircraft was destroyed. The emergency locator transmitter (ELT) activated momentarily.

1.2 Injuries to persons

| Injuries | Crew | Passengers | Total in the aircraft | Others |

|---|---|---|---|---|

| Fatal | 1 | 2 | 3 | – |

| Serious | 0 | 0 | 0 | – |

| Minor | 0 | 0 | 0 | – |

| None | 0 | 0 | 0 | – |

| Total | 1 | 2 | 3 | – |

1.3 Damage to aircraft

The aircraft was destroyed by impact forces.

1.4 Other damage

There was no environmental damage reported.

1.5 Personnel information

The pilot was seated in the left seat. He held a commercial pilot licence and was certified for single- and multi-engine airplanes for land and sea operations. A review of his company training and medical information indicated that the pilot was certified and qualified for the flight in accordance with existing regulations.

| Pilot licence | Commercial pilot licence (CPL) |

|---|---|

| Category 1 medical expiry date | 01 May 2020 |

| Total flying hours | Approximately 9500 |

| Flight hours on type | Approximately 5800 |

| Flight hours in the 7 days before the occurrence | 8.2 |

| Flight hours in the 30 days before the occurrence | 58 |

| Flight hours in the 90 days before the occurrence | 127.5 |

| Flight hours on type in the 90 days before the occurrence | 127.5 |

| Hours on duty before the occurrence | 2 |

| Hours off duty before the work period | 13 |

1.6 Aircraft information

1.6.1 General

The de Havilland DHC-3 Otter is a single-engine, high-wing, all-metal monoplane. The occurrence aircraft was originally built in 1957 by de Havilland Aircraft of Canada. In 2006, Viking Air Ltd. acquired ownership of the type certificate for the DHC-3.

The occurrence aircraft was purchased by Blue Water Aviation in 1996 and underwent several major structural inspections and modifications before returning to service.

At the time of the occurrence, modifications had been installed on the aircraft in accordance with several Stolairus Aviation Inc.Footnote 3 supplemental type certificates (STCs), including the following:

- STC No. SA94-114: installation of a Baron short takeoff and landing (STOL) kit.Footnote 4 This modification was made in January 2005.

- STC No. SA95-32: increase of the maximum takeoff weight from 8000 pounds to 8367 pounds.Footnote 5,Footnote 6 This modification was made in June 1999.

- STC No. SA01-111: replacement of the engine with a General Electric (GE) Aviation Czech H75-200.Footnote 7 This modification was made in May 2018.

The aircraft was modified in accordance with STCs No. SA94-114 and No. SA95-32 before Viking Air Ltd. acquired ownership of the DHC- 3 type certificate. All of the above-mentioned work and subsequent maintenance was performed by Winnipeg River Air Service, which is a subsidiary of Blue Water Aviation and a Transport Canada (TC)–approved maintenance organization.

| Manufacturer | de Havilland Aircraft of Canada / Viking Air Ltd. (type certificate holder) |

|---|---|

| Type, model and registration | DHC-3 Otter, C-GBTU |

| Year of manufacture | 1957 |

| Serial number | 209 |

| Certificate of airworthiness/flight permit issue date | 2015-05-26 |

| Total airframe time | 16 474 hours |

| Engine type (number of engines) | General Electric (GE) Aviation Czech H75-200 Turbine (1) |

| Engine total time | 683.8 |

| Propeller type (number of propellers) | Avia V508E/106/A (1) |

| Maximum allowable takeoff weight | 8367 lb |

| Recommended fuel type(s) | Jet A, Jet A-1, or JP 5 |

| Fuel type used | Jet A |

The most recent maintenance inspection of the occurrence aircraft was a 100-hour inspection carried out on 03 September 2019. At that time, the aircraft had accumulated 16 396.6 hours total airframe time. The inspection consisted of a visual inspection of both the airframe and the engine for condition and security.

A review of available records indicate that the occurrence aircraft was certified, equipped, and maintained in accordance with existing regulations and approved procedures, and that there were no outstanding recorded defects with the aircraft on the day of the occurrence.

The investigation did not identify any issues with regards to exceeding aircraft limitations, such as weight and balance and airspeed restrictions.

1.6.2 Aircraft wing and lift strut assembly

The DHC-3 Otter wing structure consists of an aluminum main spar and several aluminum rib assemblies, and is covered with aluminum skin fastened using aluminum rivets. The wings are attached to the top of the fuselage structure and supported approximately mid-span on each wing by a wing lift strut assembly. The wing lift strut assembly is attached to the lower fuselage and to the main spar assembly on each wing. The wing lift strut assemblies transfer flight loads to the wings. The wing lift strut assemblies are in tension during flight and in compression when the aircraft is on the ground or on water.

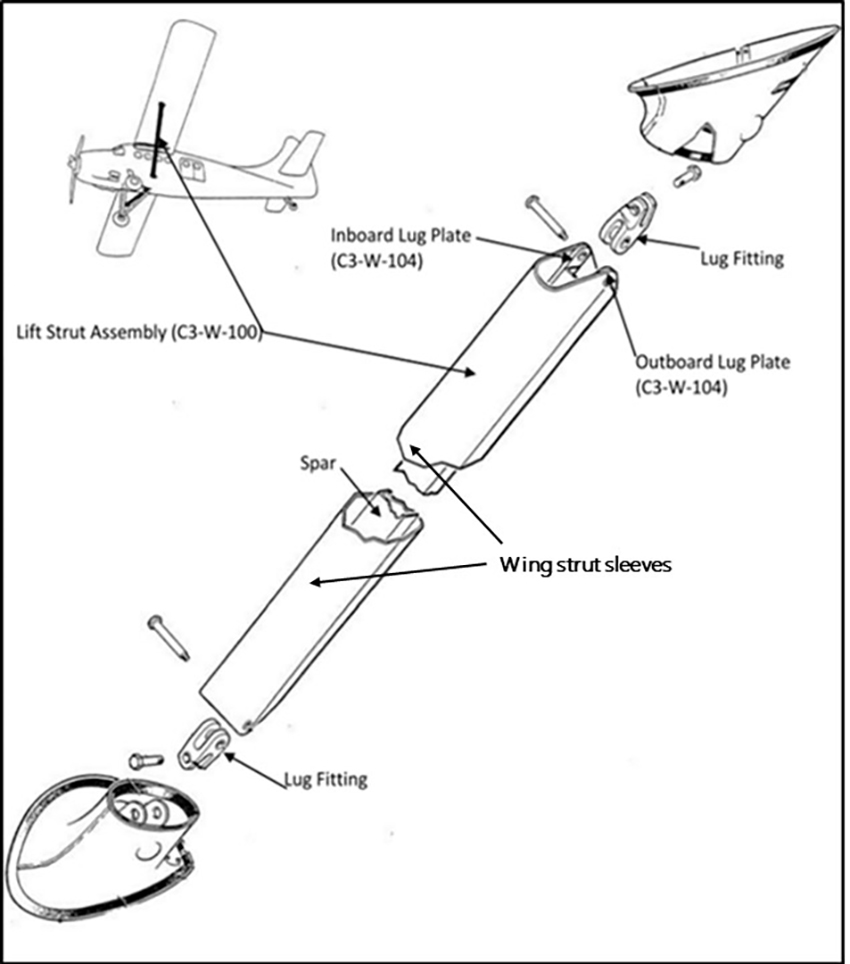

The de Havilland wing lift strut assembly (part number: C3-W-100) consists of an aluminum hollow airfoil with an aluminum spar installed length-wise internally. There are 2 aluminum lug plates (part number: C3-W-104) riveted to each end: 1 on the outboard side and 1 on the inboard side. The 2 lug plates are then attached to a lug fitting at either end of the wing lift strut (Figure 2).

The right-hand wing lift strut assembly was manufactured in 1954, but was stored as a spare part until it was installed on the occurrence aircraft in 1998. When it was installed, it had 0 hours time since new.

The manufacturer’s specified service life for the wing lift struts is 20 000 hours.Footnote 8 When STC No. SA95-32 was incorporated on the occurrence aircraft, the right-hand wing lift strut assembly had accumulated approximately 200 hours since new, and the STC required that the service life limit be reduced to a prorated 17 325 hours remaining. At the time of the occurrence, the right-hand wing lift strut assembly had accumulated 8578 hours since installation of STC No. SA95-32; therefore, it had a remaining service life of 8747 hours.

The occurrence aircraft was maintained using a periodic inspection program that contained the following inspection requirements for the wings and lift strut assemblies:

- At 100-hour intervals, the wing structures were visually inspected for condition and security;

- At 400-hour intervals, the wing lift struts’ upper and lower attach bolts and attachment fittings were visually inspected for condition and security;

- At 100-hour intervals, because the aircraft had been modified in accordance with STC No. SA95-32, the wing lift strut sleeves were visually inspected for condition and security; and

- Annually or at 1200-hour intervals, whichever came first, the wing lift strut sleeves were removed for inspection of the wing lift struts (as specified in STC No. SA95-32 maintenance manual supplement).

The occurrence aircraft was subject to and had complied with the following airworthiness directives (AD) relating to the wing lift struts:

- CF-60-3 – Inspection and repairs of wing lift strut spars;

- CF-82-26R1 – Inspection of wing lift strut to fuselage attachment tie bar assembly for corrosion;

- CF-2017-11 – Inspection of wing lift strut attach bolts for pitting corrosion;

- CF-2017-29 – Determination of equivalent air time hours and replacement of wing strut lug fittings; and

- CF-2018-04 – Inspection for corrosion and cracking.

On 10 March 2018, the occurrence aircraft’s wing lift strut bolt holes were visually inspected in accordance with AD CF-2017-11. During the inspection, trace amounts of surface corrosion were found on the surface of the upper inboard lug plate on the right-hand wing lift strut. The corrosion was removed and new wing lift strut upper attachment bolts were installed. There were no signs of fatigue cracking observed at that time.

1.6.3 DHC-3 wing lift strut corrosion visual inspections

A number of aging aircraft types are currently operating in Canada, including the DHC-3 Otter. Manufactured in 1957, the occurrence aircraft had been in service for more than 60 years. Service experience indicates that aging aircraft are more likely to be adversely affected by corrosion, wear, and fatigue cracking than those with less airframe time or cycles. In addition, parts made of aluminum alloys are known to be susceptible to fatigue cracking. Fatigue cracks can be the result of many factors, such as corrosion, overstress, and high airframe cycles or flight hours. Fatigue cracks produce a very high concentration of stress (stress risers) at their ends. If a growing crack goes undetected, the affected component will eventually fracture or fail.

In response to this phenomenon, Viking Air Ltd., the type certificate holder for the de Havilland DHC-3 aircraft, developed a Supplementary Inspection and Corrosion Control Manual (SICCM). The manual lists components of the aircraft (including wing lift strut assemblies) that require inspection for corrosion-, wear-, and fatigue-related degradation. The inspection requires removing the upper and lower wing lift strut fairings to accommodate a detailed visual inspection (DVI). A borescope with a strong light source is required to inspect the internal surfaces of the wing lift strut. This inspection is required to be carried out every 12 months. TC issued AD CF-2018-04 in February 2018 making this inspection mandatory.

The objective of the DVI is to inspect the wing lift struts for the following:

- Surface finish degradation, cracking, blistering, flaking;

- Surface pitting and corrosion, paying particular attention to the lug plate at the upper and lower ends of the strut;

- Excessive free play at bushings; and for

- Cracks and damage, paying particular attention to the seams, rivets, and lug plates.Footnote 9

The DVI does not require the lift strut assembly to be removed from the aircraft and does not allow for inspection of the lug plate inner surface and bore area.

Visual inspections may be less reliable than other inspection methods, such as non-destructive testing. Fractures can appear as very fine lines that are not visible to the eye and may require enhanced inspection techniques such as non-destructive testing to help reveal any anomalies.

Except for the use of a borescope inspection, non-destructive testing methods were not required in the inspection procedure listed in the SICCM.

Blue Water Aviation last carried out the detailed visual inspection in compliance with AD CF-2018-04 in November 2018. No signs of fatigue cracking were observed at that time.

1.7 Meteorological information

There is no recorded weather information for Little Grand Rapids. The investigation determined that, at the time of the occurrence, the ceiling was variable between 1500 and 2500 feet AGL, with visibility of approximately 10 statute miles. The wind was estimated to be from the south-southeast at approximately 20 knots. The Environment and Climate Change Canada area forecast was predicting ceilings of 1000 to 1500 feet AGL with winds from the south.

Weather was not considered to be a factor in this occurrence.

1.8 Aids to navigation

Not applicable.

1.9 Communications

Not applicable.

1.10 Aerodrome information

Not applicable.

1.11 Flight recorders

The aircraft was not equipped with flight recorders, nor were they required by regulation.

A Garmin GPSmap695 GPS unit was installed on the aircraft. The GPS unit was recovered from the accident site and its data were extracted. The investigation reviewed the available GPS data, including that of the occurrence flight, and it did not reveal any anomalies during the occurrence flight.

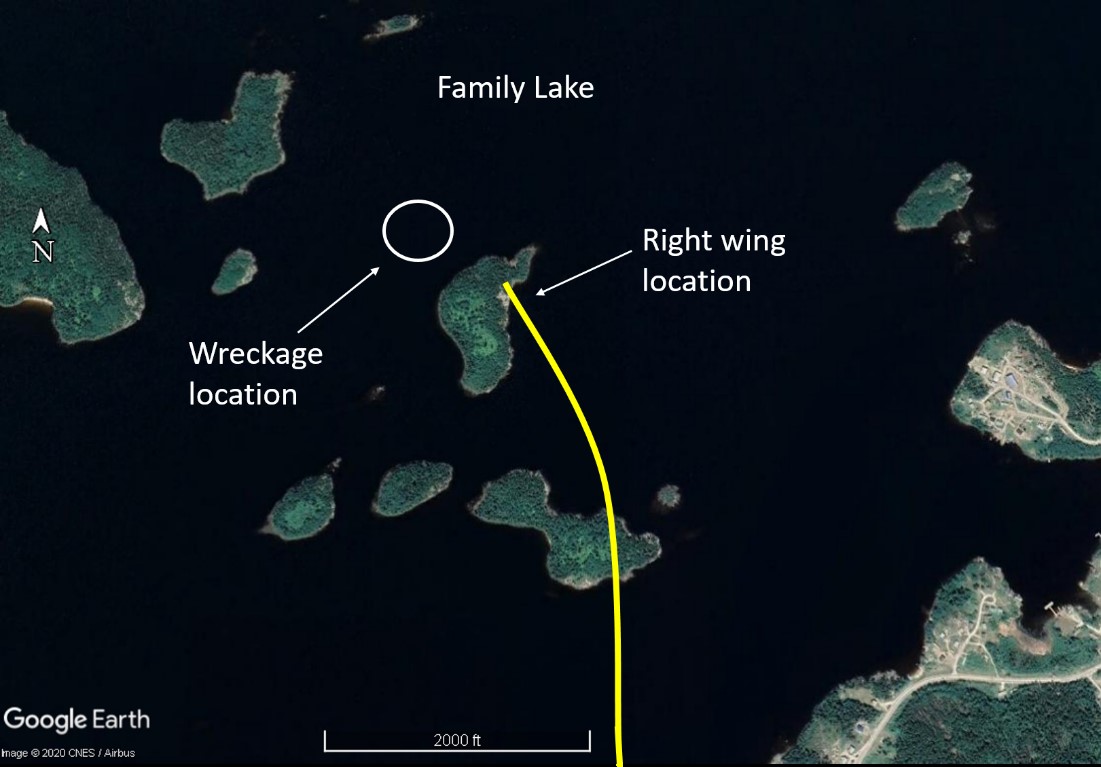

1.12 Wreckage and impact information

There was no visible wreckage when TSB investigators initially arrived at the accident site. Most of the wreckage sank shortly after impact with the water surface. The detached right wing was found floating by a nearby island (Figure 3). However, it could not be determined if this was the wing’s initial resting point, or if it had drifted there due to fairly strong winds that were present at the time. Royal Canadian Mounted Police divers found the underwater debris field, which was mostly localized over an area of approximately 15 m by 15 m (Figure 3; not to scale).

The debris field indicated that the aircraft had struck the water at a steep flight path angle with very little horizontal speed, and that it sank almost immediately after impact with the surface of the water. The right wing was transported to a secure location. There was noticeable damage to the wing lift strut upper attachment.

The remaining wreckage was recovered from the lake floor. It was estimated that 95% of the aircraft (by weight) was recovered. An inspection of the engine and recovered airframe pieces, with the exception of the right-hand wing lift strut’s upper lug plates, did not reveal any pre-impact anomalies. The propeller deformation and twisting were consistent with substantial power being produced by the engine at the time of impact with the water surface.

No flight documentation, such as logbooks or operational flight plans (OFPs), was recovered from the site.

1.13 Medical and pathological information

The investigation did not reveal any pre-existing physiological conditions or events that might have precluded the pilot from safely controlling the aircraft.

1.14 Fire

The were no signs of a pre- or post-impact fire.

1.15 Survival aspects

The accident was not survivable due to the severity of impact forces. The ELT was not recovered from the wreckage site. As a result, the investigation could not determine why it activated only momentarily.

1.16 Tests and research

1.16.1 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP258-2019 – Wing strut fracture examination

1.16.2 Wing lift strut lug plates fracture examination

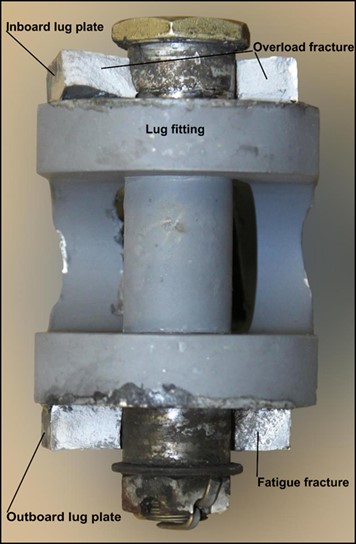

The right-hand wing lift strut’s upper inboard and outboard lug plates (part number C3-W-104) were initially examined at the TSB facility in Winnipeg, Manitoba. It was noted that these parts had separated and they were shipped to the TSB Engineering Laboratory in Ottawa, Ontario, for further analysis.

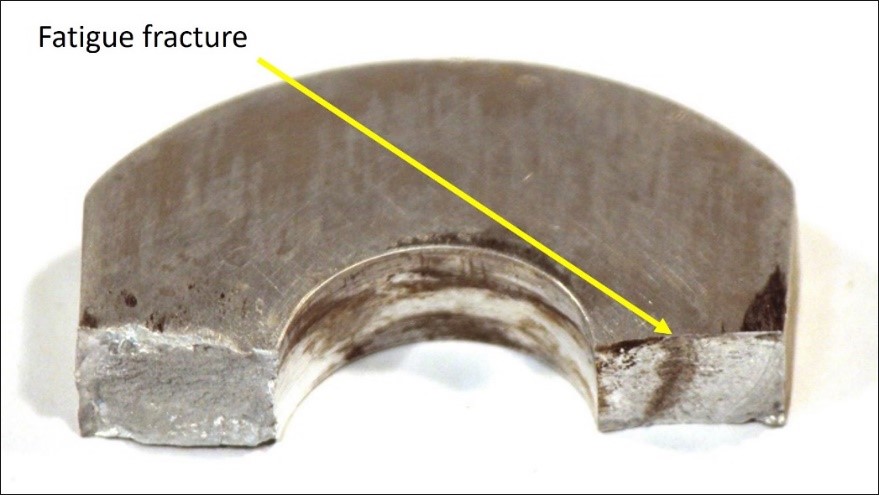

The failed pieces of the right-hand wing lift strut’s upper lug plates were examined using a macroscopeFootnote 10 and a scanning electron microscope (SEM).Footnote 11 The examination revealed a progressive fatigue fractureFootnote 12 inside the bolt hole bore of the right-hand wing lift strut’s upper outboard lug plate, at the strut-to-wing attachment end (Figure 4). A slight fatigue crack was also noted on the opposite (inboard) side of the bolt hole bore (Figure 5). The TSB Engineering Laboratory’s examination indicated that the bore surface was rather rough with circumferential and some longitudinal scoring, though nothing particular was observed on the bore near the fatigue origin.

Testing also confirmed that the material of the part was consistent with aluminum alloy 2024, which was the manufacturer’s specified material for this part. No anomalies were found in the lug plate material.

Surface imperfections, such as scratches, nicks, or corrosion, are known to act as a stress riser for fatigue initiation. It could not be determined what had initiated the fatigue fracture.

The TSB Engineering Laboratory’s inspection of the left-hand wing strut lug plates did not reveal any pre-impact anomalies in the material.

1.17 Organizational and management information

Blue Water Aviation records and stores the aircraft’s manifest and loading information, as well as OFPs, on a tablet device. When the tablet is at a company base, the electronic OFP data and load calculations are uploaded to a cloud data file via the company base’s wireless network. This data contains information about the aircraft, including the number of occupants on board, its route, contents (e.g., cargo), and weight and balance information.

In this occurrence, the tablet containing the occurrence flight’s OFP data and load calculations was not recovered from the wreckage site. Additionally, even though the flight originated at a company base, a review of the cloud data file revealed that the OFP data and load calculations had not been uploaded prior to the occurrence flight. Therefore, no accurate aircraft loading data were available to investigators. The investigation did not determine why the data were not uploaded. The practice of storing flight plan and manifest information electronically is not uncommon in Canada.

1.18 Additional information

Not applicable.

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

The occurrence aircraft was certified, equipped, and maintained in accordance with existing regulations and approved procedures. This analysis will focus on the conditions and events that led to a structural failure and subsequent inflight breakup, as well as the issues discovered regarding the retrieval of operational flight plan (OFP) data.

2.1 Structural failure

Laboratory analysis revealed that a fatigue fracture in the right-hand wing lift strut’s upper outboard lug plate initiated the failure of the wing lift strut assembly, which, at the time of the occurrence, had 8747 hours remaining in its service life. The exact cause of fatigue initiation could not be determined; however, the most likely fatigue origin location would have been a surface imperfection, such as a scratch or nick.

The fatigue fracture originated in the bolt hole bore of the right-hand wing lift strut’s upper outboard lug plate, and eventually led to an overstress fracture of the right-hand wing lift strut’s upper outboard and inboard lug plates during the left turn prior to the final approach.

The failure of the outboard and inboard lug plates led to the separation of the right-hand wing lift strut from the wing and, subsequently, the separation of the right wing from the aircraft.

None of the visual corrosion inspections that were carried out in accordance with the Viking Air Ltd. Supplementary Inspection and Corrosion Control Manual (SICCM), and Transport Canada’s Airworthiness Directive (AD) CF‑2018‑4, had identified a fatigue crack that had developed inside the bolt hole bore of the right-hand wing lift strut’s outboard lug plate. Visual inspections can be an unreliable technique for detecting fatigue cracks, which can appear as very fine lines that are not visible to the eye. Visual inspection of the lift strut lug plates, while installed on the aircraft, is limited to the outer surface and does not allow for inspection of the inner surface and bore area. Non-destructive testing methods, such as the use of eddy current, or dye penetrant inspection, could detect these cracks, but they were not required in the inspection procedure listed in the SICCM. The detailed visual inspection prescribed in the Viking Air Ltd. SICCM, and required by AD CF-2018-4, did not identify cracks that could form in the right-hand wing strut’s upper outboard lug plate.

2.2 Electronically stored operational flight plans

In many cases, electronic OFP data is not uploaded until the tablet is within an operator’s wireless network range. In this occurrence, investigators were not able to accurately determine the weight of the aircraft’s load at the time of the accident as the data had not been uploaded to the cloud data file prior to the flight and the tablet was not recovered from the wreckage site. If OFP data and load calculations are not available, there is a risk that, in the event of a missing aircraft or accident, aircraft information, including its number of occupants, route, cargo, and weight and balance information, will not be available for search and rescue operations or accident investigation.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- A fatigue fracture originated in the bolt hole bore of the right-hand wing lift strut’s upper outboard lug plate, and eventually led to an overstress fracture of the right-hand wing lift strut’s upper outboard and inboard lug plates during the left turn prior to the final approach.

- The failure of the outboard and inboard lug plates led to the separation of the right-hand wing lift strut from the wing and, subsequently, the separation of the right wing from the aircraft.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If operational flight plans data and load calculations are not available, there is a risk that, in the event of a missing aircraft or accident, aircraft information, including its number of occupants, route, cargo, and weight and balance information, will not be available for search and rescue operations or accident investigation.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- The detailed visual inspection prescribed in the Viking Air Ltd. Supplementary Inspection and Corrosion Control Manual, and required by Airworthiness Directive CF-2018-4, did not identify cracks that could form in the right-hand wing strut’s upper outboard lug plate.

4.0 Safety action

4.1 Safety action taken

4.1.1 Viking Air Ltd.

In response to this occurrence, Viking Air Ltd. issued Alert Service Bulletin (ASB) V3/0011 on 26 November 2019. This service bulletin calls for operators to perform more detailed testing on DHC-3 wing lift strut fittings and lug plates.

4.1.2 Transportation Safety Board of Canada

In response to ASB V3/0011, the Transportation Safety Board of Canada issued Aviation Safety Advisory A19C0138-D1-A1, which requested that Transport Canada (TC) work with Viking Air Ltd. to amend the Supplementary Inspection and Corrosion Control Manual (SICCM) or issue a new airworthiness directive (AD) to include the inspection requirements outlined in Viking Air Ltd. ASB V3/0011.

4.1.3 Blue Water Aviation

In response to this occurrence, Blue Water Aviation has removed the complete wing lift strut assemblies on 2 of the aircraft that it operates, and on 4 for which it provides contract maintenance. All have been replaced with new or overhauled wing lift strut assemblies.

4.1.4 Transport Canada

Following the accident, TC conducted a process inspection on 25 November 2019. The process inspection identified some discrepancies in the operator’s quality assurance program. These findings were not related to this occurrence.

Also in response to this occurrence, TC has issued AD CF‑2020-20, which came into effect on 10 June 2020. The AD requires that the following corrective actions be taken:

From the effective date of this AD, P/N [part number] C3W100 wing strut assemblies, all dash numbers, must be removed from service before they accumulate more than 20 000 hours air time.

Note: AWLs [airworthiness limitations] that are associated with increased maximum weight operations, such as those associated with STC [supplemental type certificate] SA95-32, require the strut to be removed from service earlier than the limit specified in Corrective Action A. The reduced AWLs associated with operations at increased maximum weight are mandatory and, if applicable, take precedence over the AWL established by corrective action A.

For aeroplanes with P/N C3W100 wing strut assembly, all dash numbers, that have accumulated more than 2500 hours air time in service as of the effective date of this AD, within thirty (30) days from the effective date of this AD, inspect the wing strut assembly and attachment hardware in accordance with the Accomplishment Instructions of ASB V3/0011, Revision NC, dated 26 November 2019. For wing strut assemblies with fewer than 5000 hours air time, Corrective Action C is an alternative to this corrective action.

Note: Corrective Actions B and C do not apply to wing struts that reach the threshold for the corrective actions (2500 hours air time) after the effective date of this AD. These corrective actions are intended to provide a one-time assessment of the condition of in-service parts. The information gathered from this assessment will be used by Viking and Transport Canada to determine if there is a requirement for further action.

For aeroplanes with P/N C3W100 wing strut assembly, all dash numbers, that have accumulated more than 2500 hours air time but less than 5000 hours air time as of the effective date of this AD, as an alternative to Corrective Action B, operators can contact Viking for visual inspection instructions within thirty (30) days from the effective date of this AD. Operators who select this alternative must inspect the wing strut assembly and attachment hardware in accordance with the written instructions from Viking within five (5) months from the effective date of this AD.

Note: Viking will require details about the source of the strut assemblies and the maintenance and operating history.

If, during the inspection required by Corrective Action B or C of this AD, any failure/discrepancy is detected, as defined in Viking ASB V3/0011, Revision NC, dated 26 November 2019, or in written instructions provided by Viking during the accomplishment of Corrective Action C, before further flight, repair or replace the affected parts in accordance with the ASB.

Within seven (7) days after completing the Corrective Action B or C inspection, report the results to Viking in accordance with the instructions in ASB V3/0011, Revision NC, dated 26 November 2019. Footnote 13

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .