Capsize on water landing

Simpson Air (1981) Limited

Cessna U206G, C-FNEQ

Little Doctor Lake, Northwest Territories

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 16 August 2018, a Simpson Air (1981) Limited float-equipped Cessna U206G aircraft (registration C-FNEQ, serial number U20605036) was conducting a sightseeing flight from Fort Simpson Island Water Aerodrome, Northwest Territories, with stops at Virginia Falls and Little Doctor Lake, Northwest Territories. The pilot and 4 passengers were on board. At approximately 1830 Mountain Daylight Time, while the pilot was conducting a water landing at Little Doctor Lake, control of the aircraft was lost and the aircraft nosed over, coming to rest inverted and partially submerged. The pilot and 1 passenger were able to escape the submerged fuselage and climb up onto the floats; they were rescued by a nearby boater within 15 minutes. The 3 remaining occupants were unable to escape the fuselage and drowned. The emergency locator transmitter activated on impact; however, the signal was not received by the Joint Rescue Coordination Centre because the emergency locator transmitter was submerged.

1.0 Factual information

1.1 History of the flight

On 16 August 2018, a Simpson Air (1981) Limited (Simpson Air) float-equipped Cessna U206G aircraft (registration C-FNEQ, serial number U20605036) was conducting a sightseeing flight from Fort Simpson Island Water Aerodrome (CEZ7), Northwest Territories, with stops at Virginia Falls Water Aerodrome (CFV5), Northwest Territories, and Little Doctor Lake, Northwest Territories.

In accordance with Canadian Aviation Regulations (CARs) section 703.39, which requires a safety briefing before takeoff, the pilot gave the 4 passengers a safety briefing based on the company’s script (Appendix A) before they boarded the aircraft at CEZ7. Simpson Air’s policyFootnote 1 is to demonstrate the operation of the exits as part of the safety briefing. In this case, the passenger seated in the last row, who occupied that seat for all flights, was required to manually open and close the rear double cargo doors on the right side (the flaps were in the up position at the time). No passenger operated the pilot’s door.

The pilot and passengers then boarded the aircraft, which departed CEZ7 on the Mackenzie River at 1355.Footnote 2 The flight to CFV5 was uneventful, other than encountering light-to-moderate turbulence. After a hiking tour to Virginia Falls, the group returned to the aircraft. This time, no pre-flight briefing was given, and the emergency procedures were not reiterated, nor are they required to be, according to the Company Operations ManualFootnote 3 and the Commercial Air Services Standards in the CARs.Footnote 4

The destination for the next flight, Little Doctor Lake, is susceptible to unpredictable winds, resulting in significant wave action, due to a gap in the mountain range on the west side of the lake. This well-known phenomenon is called “gap wind.” When it occurs, the preferred landing area is the bay in the northern corner of the lake.

The flight was noticeably smoother than the earlier flight. The aircraft flew through a gap in the Mackenzie Mountains, which surround part of Little Doctor Lake, without experiencing any turbulence. The pilot then flew the aircraft around the southern edge of the lake to assess the wind (Figure 1). The prevailing wind had been reported as coming from the south, but the pilot was concerned that there might be wind coming through the gap in the mountains, as was often the case. The pilot decided to continue flying around the lake, to conduct the final descent from the east along Sibbeston River, which flows into the lake, and to land in a sheltered bay in the northern corner of the lake.

The pilot set the flaps to 20° and flew the approach, planning to land in the bay.Footnote 5 The approach was uneventful until approximately 300 feet above the surface of the water, when the rate of descent began to increase. The pilot increased power to compensate, resulting in the aircraft landing beyond the desired touchdown point.

At approximately 1830, the aircraft touched down along the north shore of the main body of the lake in a nose-high attitude, with the rear of the floats contacting the water first. The stall warning horn was sounding at the time. The aircraft then bounced and became airborne momentarily. The stall warning horn silenced briefly and then began sounding again. The aircraft bounced once more, this time on the rear of the left float, and then pitched forward and banked to the right. During the bouncing sequence, directional control was attempted with the use of left rudder. The right wing contacted the surface of the lake and the aircraft nosed over, coming to rest inverted and partially submerged.

The pilot and 1 passenger were able to exit through the window in the pilot’s door and climbed up onto the floats. The pilot dove down to attempt to rescue the other passengers but was unable to open any doors. The pilot and surviving passenger were rescued by a nearby boater within 15 minutes. The 3 remaining occupants were unable to exit the aircraft and drowned; they were found inside the cabin with their seat belts undone.

1.2 Injuries to persons

The aircraft was configured with 3 rows of seating; the first 2 rows had 2 seats, and the last row had a single seat on the right side of the cabin (Figure 2). The pilot, who had been seated in the front-left seat, received no injuries and was mobile and conscious during the entire event. The passenger who survived had been seated in the left seat of the middle row, behind the pilot. She also received no injuries and was mobile and conscious during the entire event.

The remaining passengers had been seated in the front-right seat, the right seat of the middle row, and the right seat of the last row. These passengers drowned; they had no other injuries.

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | 0 | 3 | – | 3 |

| Serious | 0 | 0 | – | 0 |

| Minor/None | 1 | 1 | – | 2 |

| Total | 1 | 4 | – | 5 |

1.3 Damage to aircraft

The force of the water on impact and as the aircraft nosed over resulted in damage to the lower nose bowl area, windshield, and right wing. The vertical stabilizer received minor damage; however, the investigation could not determine whether the damage occurred during the accident sequence or after the accident, when the vertical stabilizer touched the bottom of the lake as the aircraft drifted with the wind.

1.4 Other damage

Not applicable.

1.5 Personnel information

Records indicate that the pilot was certified and qualified for the flight in accordance with existing regulations. She held a Canadian commercial pilot licence – aeroplane with a seaplane rating. The pilot had begun working at Simpson Air in June 2017, and, at that time, had 7 hours of float time—the minimum required by regulation to obtain and hold a seaplane rating.

The pilot’s first season working for Simpson Air was spent flying a Cessna U206G on wheels. In June 2018, the pilot began training on the Cessna U206G on floats. This training was provided by both a contract pilot and the owner of Simpson Air, and it was completed on 05 July 2018.

The Simpson Air pilot training manualFootnote 6 describes the elements required by section 703.98 of the CARs for flight crew training. Section 3.5.7 of the training manual states the following:

Where the aircraft undergoes a seasonal change in the gear configuration, the pilot shall compete [sic] a minimum conversion training program of three take-off and landings in each alternate configuration. This training shall cover those items from the flight training syllabus, as applicable to the gear configuration.Footnote 7

During the initial training, it was noted that the pilot had difficulty carrying out water landings in the manner preferred by the company. The pilot had a tendency to fly level near the surface of the water and then cut the power and drop onto the water. The company’s preferred method was to set a pitch attitude, controlling the descent with power, and land with power on. As the training continued, the pilot’s performance improved, and she was cleared for duty.

After the pilot’s training was completed, 2 flights were carried out under the supervision of the company owner. The 2 flights totalled 6.4 hours and involved 6 water takeoffs and landings on floats. Two weeks after those flights, on 03 August 2018, the owner scheduled another training flight for the pilot, which he supervised, to practice takeoffs and landings.

The pilot successfully conducted 6 flights on the occurrence aircraft between 08 and 11 August 2018, which involved 6 water takeoffs and landings. Earlier in the day on 16 August 2018, the pilot had landed successfully at Virginia Falls; the accident took place during the second landing of the day.

| Pilot licence | Commercial pilot licence – aeroplane |

|---|---|

| Medical expiry date | 01 December 2018 |

| Total flying hours | 1018.6 |

| Flight hours on type | 732.1 |

| Flight hours on floats | 32.0 |

| Flight hours in the last 7 days | 19.8 |

| Flight hours in the last 30 days | 53.9 |

| Flight hours in the last 90 days | 147.0 |

| Flight hours on type in the last 90 days | 147.0 |

| Hours on duty before the occurrence | 9.5 |

| Hours off duty before the work period | 10.5 |

The pilot’s flight duty times were reviewed, and it was determined that fatigue was not a factor in this occurrence.

1.6 Aircraft information

1.6.1 General

The Cessna U206G was designed and manufactured by the Cessna Aircraft Company. It has a maximum take-off weight of 1636 kg (3600 pounds). When the aircraft is equipped with Aerocet floats, its gross weight remains the same, as specified in the supplemental type certificate.Footnote 8 It has a maximum cruising speed of 149 knots indicated airspeed. The “U” (utility) designation on this model of the Cessna 206 indicates that the aircraft design was modified to improve its utility in loading and unloading cargo by adding a rear double cargo door on the right side of the aircraft.

The occurrence aircraft was equipped for instrument flight rules and single-pilot operations. It was registered to Simpson Air (1981) Limited as a commercial airplane on 19 February 2013. At the time of the occurrence, the aircraft had accumulated 6945.1 hours of airtime. It had no known deficiencies before the occurrence flight and was being operated within its weight-and-balance and centre-of-gravity limits. Nothing was found to indicate that the aircraft had encountered any type of system malfunction during the flight.

| Manufacturer | Cessna Aircraft Company |

|---|---|

| Type,* model and registration | C206, U206G, C-FNEQ |

| Year of manufacture | 1979 |

| Serial number | U20605036 |

| Certificate of airworthiness/flight permit issue date | 12 April 2007 |

| Total airframe time | 6945.1 hours |

| Engine type (number of engines) | Teledyne Continental Motors IO-550-F (1) |

| Propeller/Rotor type (number of propellers) | Hartzell PHC-J3YF-1RF/F7691 (1) |

| Maximum allowable takeoff weight | Float Plane 1636 kg (3600 lb) |

| Recommended fuel type(s) | 100LL |

| Fuel type used | 100LL |

* Federal Aviation Administration, Type Certificate Data Sheet no. A4CE, Revision 49 (29 July 2015).

1.6.2 Floor coverings

As part of the certification process, aircraft manufacturers are requiredFootnote 9 to publish an illustrated parts manual, which describes in detail all of the parts that make up a certified aircraft. The purpose of the illustrated parts manual is to provide operators with specific information on each part so that they can maintain their aircraft to the standards to which the aircraft was certified when designed and produced, using parts that have been tested and approved. Maintaining an aircraft in accordance with the maintenance manual and with the illustrated parts manual also ensures that the aircraft and its systems will function as designed in an emergency. If part of an aircraft is modified, or a new part is added to the aircraft, it can only be used if a supplemental type certificate is obtained from the regulatory body responsible for the type certificate.

The floor covering approved for the occurrence aircraft was a carpet assembly, as specified in the illustrated parts manual.Footnote 10 It is a 1-piece assembly held in place by 11 retaining devices. Each seat leg also retains the carpet around the seat tracks. The carpet had been removed and replaced with rubber matting. This rubber matting was cut into strips, fitted between the seat rails. Most of the strips were about 4 feet long and fixed to the floor on one end to prevent them from sliding as passengers moved in the cabin. The aircraft technical records did not have a supplemental type certificate for this modification.

1.6.3 Aircraft cabin doors

The Cessna U206G is equipped with 2 exits: a pilot door on the left, next to the pilot’s seat, and double cargo doors on the right, in the rear of the cabin. The forward door of the double cargo doors is in line with the middle row of seats, and the aft door is in line with the rear seat. All seats face forward.

1.6.3.1 Pilot door operation

The pilot door has a locking mechanism with a recessed lever-type exterior door handle that remains flush with the door when closed. On the interior, the door has a conventional L-shaped door handle in the armrest. The handle has 3 positions: OPEN, CLOSE, and LOCK. The handle is spring-loaded to the CLOSE (up) position (Figure 3). When the door has been pulled shut and latched, it is locked by rotating the door handle forward to the LOCK position (flush with the armrest). An over-centre action holds the handle in that position while locked.

As stated in TSB Aviation Investigation Report A05O0147, by design, when the door is locked from the inside, it cannot be opened from the outside. In the context of that investigation, Cessna indicated the following:Footnote 11

as part of the aircraft design, testing and certification processes, safety issues relating to egress from the aircraft were considered at various stages. A variety of competing risks, safety factors and scenarios are evaluated through these processes. For example, risks associated with unexpected and/or unwanted opening of the doors are balanced against countervailing concerns such as access from outside the aircraft, with the goal being the development of a design that provides the best overall safety for the public.

1.6.3.2 Operation of the right double cargo doors

The right double cargo doors are opened from outside the aircraft using a recessed door handle near the aft edge of the forward door. The forward end of the handle is depressed to rotate it out of its recess and then pulled outward.

After the forward door is open, the aft door may be opened by grasping a red handle on the forward edge of the door and pulling downward to release the locking pawls (Figure 4).

When closing the doors, the aft door must be closed first and must be held in the frame until the handle is manipulated to engage both locking pawls. Once the aft door is secured, the forward door can then be closed. Inside the door, there is a placard above the door handle with OPEN, CLOSE, and LOCK shown on it (Figure 5). Once the forward door has been closed and latched, the door handle must then be rotated forward to the LOCK position.

1.6.3.3 Operation of the right double cargo doors as an emergency exit

The Cessna U206G pilot’s operating handbookFootnote 12 provides the following instructions for the operation of the rear double cargo doors as an emergency exit:

If it is necessary to use the cargo doors as an emergency exit and the wing flaps are not extended, open the forward door and exit. If the wing flaps are extended, open the doors in accordance with the instructions shown on the placard which is mounted on the forward cargo door.Footnote 13

When the wing flaps are extended, the forward door can only be opened approximately 8 cm before coming into contact with the flap (Figure 6).

The procedure to open the door from the inside with the flaps down, which is listed on a placard above the handle on the forward cargo door (Figure 7), is the following:

- Rotate forward cargo door handle full forward then full aft.

- Open forward cargo door as far as possible.

- Rotate red lever in rear cargo door forward.

- Force rear cargo door full open.

1.6.3.4 Certification history

Cessna produced various models of the 206 aircraft from 1964 until the single-engine production line was shut down in 1986. The 206 was first certified in 1963, on the basis of U.S. Civil Air Regulations, Part 3, as amended by amendments 3-1 through 3-8. All models of the Cessna 206 manufactured up to 1986, including the occurrence aircraft, were certified based on this certification standard.

Section 3.387 of the U.S. Civil Air Regulations states the following:

Exits. (a) Closed cabins on airplanes carrying more than 5 persons shall be provided with emergency exits consisting of movable windows or panels or of additional external doors which provide a clear and unobstructed opening, the minimum dimensions of which shall be such that a 19-by-26-inch ellipse may be completely inscribed therein. The exits shall be readily accessible, shall not require exceptional agility of a person using them, and shall be distributed so as to facilitate egress without crowding in all probable attitudes resulting from a crash. The method of opening shall be simple and obvious, and the exits shall be so arranged and marked as to be readily located and operated even in darkness […].

Several amendments have been made to the original emergency exit certification standard since 1963 (Table 4).

| Date | Regulatory reference | Seating capacity | Number of emergency exits required (in addition to the main door) |

|---|---|---|---|

| 1963 | U.S. Civil Air Regulations, Part 3 | More than 5, but not more than 15 | At least 1 emergency exit on opposite side of the cabin from the main door |

| 1965 | U.S. Federal Aviation Regulations 23.807 Amendment 23-0 | More than 5, but less than 16 | At least 1 emergency exit on opposite side of the cabin from the main door |

| 1969 | U.S. Federal Aviation Regulations 23.807 Amendment 23-7 | More than 5, but less than 16 | For aircraft with 1 or more engines mounted on the approximate centreline of the fuselage, at least 1 emergency exit on opposite side of the cabin from the main door |

| 1971 | U.S. Federal Aviation Regulations 23.807 Amendment 23-10* | 5 or less | At least 1 emergency exit on opposite side of the cabin from the main door |

| 1988 | U.S. Federal Aviation Regulations 23.807 Amendment 23-36 | 2 or more | At least 1 emergency exit on opposite side of the cabin from the main door |

* In 1997, the U.S. Federal Aviation Administration certified the Cessna 206H based on this amendment of U.S. Federal Aviation Regulation 23.807, and in 1999, Transport Canada certified the Cessna 206H based on this amendment of the regulation.

There is no requirement to change the design of the aircraft to meet the most current certification standard. In the case of the occurrence aircraft, which was manufactured in 1979, it had to meet only the requirements set out in 1963, not the subsequent amendments in 1965, 1969, or 1971. The U.S. Federal Aviation Administration (FAA) had approved the design of the rear double cargo doors as meeting the certification standard for an emergency exit

1.6.3.5 Previous efforts to address the risk associated with the design of the rear double cargo doors

The rear double cargo doors have been identified as a risk to passengers in emergency situations for many years. As a result, the TSB and other investigative agencies have been advocating for changes to the door design.

On 22 March 1991, Cessna issued Service Bulletin SEB91-4,Footnote 14 providing a service kit and asking owners to incorporate a spring assembly that would automatically retract the handle on the aft door to allow the aft door to pass the forward door. The service kit also included luminescent placards to indicate the location of the door handle and to provide instructions on how to operate it. On 16 October 1997, Transport Canada (TC) issued Service Difficulty Alert AL-97-04,Footnote 15 which strongly recommended that owners and operators incorporate Service Bulletin SEB91-4 if they had not already done so. Although incorporating the service bulletin simplifies the procedure to open the double cargo doors, it does not eliminate another problem: the jamming of the forward cargo door against the flaps.

Service Bulletin SEB91-4 had not been incorporated on the occurrence aircraft, nor was such action mandatory under the CARs.

In 1998, after a 12-year hiatus in the production of Cessna 206, the Cessna Aircraft Company began producing the Cessna 206H, which was certified based on Part 23 of the U.S. Federal Aviation Regulations.Footnote 16 The new model was essentially the same airframe as the U206G, which had been produced up until 1986. The difference between the 2 models lay mainly in the power plant and avionics.

Shortly after production resumed, the Cessna Aircraft Company submitted an application to TC for a Canadian type certificate. The previous Cessna 206 had been accepted by TC based on the U.S. Federal Aviation Administration’s (FAA’s) type certificate. However, by 1998, TC’s policy had changed and it no longer accepted applications for Canadian type certificates simply based on FAA type certificates.

During the certification process, TC determined that the new Cessna 206H did not meet the requirements of section 23.807 of the U.S. Federal Aviation Regulations and that the rear double cargo doors could not be considered an emergency exit because they were not readily accessible and because the opening was not simple and obvious.

Between 1999 and 2003, TC, the FAA, and Cessna worked together to come up with a design change that could be applied to the 206H and used to retrofit the previous Cessna 206 fleet. However, no acceptable solution was found, and the matter was dropped. This left the Cessna 206H with a 5-occupant limit and the Cessna U206G and previous Cessna 206 aircraft with a 6-occupant limit.

By 2005, TC determined that some form of action was warranted to address the discrepancy in the number of certified seats in the various models of Cessna 206 aircraft—if only for floatplane operations—given the similarity of the rear double cargo door design. TC proposed an Airworthiness Directive to limit the seating capacity to 5 on all models of Cessna 206 aircraft on floats. After consultation with industry, TC decided in June 2006 to put the Airworthiness Directive on hold until the results of an evaluation of egress from submerged floatplanes became available, which was in August 2006. Ultimately, TC decided to leave the 5-occupant limit on the 206H model. No further action was taken in regard to earlier Cessna 206 series aircraft or to modifying the rear double cargo door. Results of the evaluation indicated there were no suitable design changes that could feasibly be applied to the entire Cessna 206 fleet. By May 2008, TC decided to put the file on hold because of other priorities and the absence of a clear way forward.

There are currently 190 Cessna U206 aircraft, 50 Cessna TU206 aircraft, and 11 Cessna 206H aircraft being operated in Canada, in private or commercial service.

1.6.4 Cabin windows

The pilot door on the left is equipped with a window that can open. It is held in the closed position by a detent-equipped latch on the lower edge of the window frame. To open the window, the latch is rotated upward. The window has a spring-loaded retaining arm, which helps rotate the window outward and hold it there. The window-retaining arm had been removed from the occurrence aircraft.

An option is available to add a window that can open on the front right side of the aircraft, which functions in the same manner as the window in the pilot door. The occurrence aircraft was not fitted with this option.

None of the other cabin windows in the Cessna 206 can open.

1.7 Meteorological information

At the request of the TSB, Environment and Climate Change Canada produced a meteorological assessmentFootnote 17 that examined the actual and forecast meteorological conditions over southwestern Northwest Territories and northeastern British Columbia around the time of the accident.

The report showed that, on the afternoon of 16 August 2018, light southerly to southwesterly surface winds were likely present over most of southwestern Northwest Territories, with westerly winds near 15 knots at 6000 feet. A surface trough of low pressure, combined with daytime heating, would have contributed to an unstable air mass; however, dry air in the westerly flow across the Mackenzie Mountains led to mainly clear skies for the region that day. Lightning maps from that day confirmed that there were no thunderstorms over the area. The weather would not have been conducive to the development of lee waves across the Mackenzie Mountains, as these usually require winds greater than 30 knots perpendicular to the mountain top level and a layer of stable air near the mountaintop, neither of which was present that day.

The main body of Little Doctor Lake lies just east of a small mountain range, and the lake cuts through the range. When there is higher atmospheric pressure to the west of the range and relatively lower atmospheric pressure to the east, there can be significant airflow through the gap. This gap wind phenomenon is well known on Little Doctor Lake, and it causes significant wave action with very little warning. On the day of the accident, the area was dominated by low pressure, so it is unlikely that there was gap wind of any significance.

1.8 Aids to navigation

There was no indication of any issues with the available aids to navigation.

1.9 Communications

There was no indication of any issues with the available communication systems.

1.10 Aerodrome information

Not applicable.

1.11 Flight recorders

The occurrence aircraft was not equipped with a flight data recorder or a cockpit voice recorder, and neither was required by regulation.

The aircraft was equipped with a Garmin Aera 500 global positioning system and SPOT portable tracking device. The TSB Engineering Laboratory in Ottawa, Ontario, downloaded tracking and waypoint information from both units.

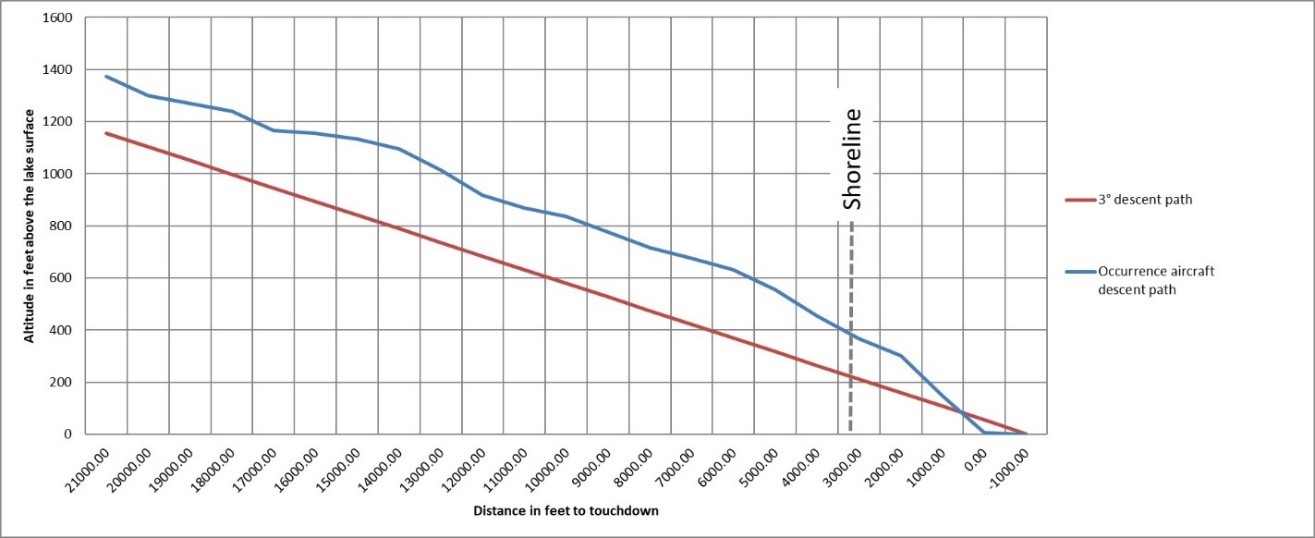

The data obtained were used to determine the approach route and profile of the accident flight (Figure 8). Once the occurrence aircraft crossed the shoreline, the descent angle increased from an average of 2.7° to 4.28°, to a peak descent angle of 6.17°.

1.12 Wreckage and impact information

All flight control surfaces were accounted for. The right-wing leading edge was crushed approximately 24 inches inboard from the wing tip. The right-wing aileron and flap were distorted. The forward lower fixed engine cowling panels and rudder leading edges were damaged, and the windshield was shattered. The left wing and engine did not show any signs of damage. The floats and wing struts remained intact and undamaged.

During recovery of the wreckage, it was noted that the rubber floor mats had been secured to the floor at one end only. When the aircraft was floating inverted in the water, supported by the floats, these rubber floor mats hung down into the cabin.

Following recovery of the wreckage, the pilot door and rear double cargo doors could all be operated with no binding. The propeller and spinner were undamaged. The wing flaps were found in the 20° position, and the cowl flaps were open. The fuel selector was in the right-fuel-tank position. The elevator trim was set to full nose up, and the rudder trim was set to about 1/3 right of neutral. The throttle was fully forward, the propeller pitch control was set full forward, and the mixture control was set to full rich.

1.13 Medical and pathological information

The pilot and surviving passenger received minor scrapes and bruises. The autopsy results showed that the remaining passengers were uninjured in the crash but had subsequently drowned.

1.14 Fire

Not applicable.

1.15 Survival aspects

1.15.1 Evacuation and rescue

Based on the lack of overall damage to the airframe, the investigation determined that the aircraft rollover was relatively gentle.

As the aircraft tumbled, the top of the windshield broke, which allowed lake water to fill the cabin very quickly. The pilot, who was immediately immersed in water, was unable to find the door handle to open the pilot door. Once free of her seat belt, she began to kick the pilot door’s window. Her foot caught the window latch and the window opened outward. The pilot immediately swam out through the window. The passenger in the front right seat grabbed the passenger who had been seated immediately behind the pilot and propelled her through the window. No other passengers exited the aircraft.

The accident sequence was observed from the east beach of the lake. A boater arrived on the scene within 15 minutes and brought the pilot and passenger back to the beach. During the rescue, an eyewitness on the beach used a SPOT portable tracking device to raise the alarm and request assistance.

1.15.2 Seat belts

None of the occupants’ seat belts failed. It was common for the pilot to forego the available shoulder harness because she had to have the seat as far forward as possible, sat on a pillow, and had a pillow behind her back. As a result, the shoulder harness would have crossed the pilot’s forearm instead of passing over the shoulder. On the occurrence flight, the pilot was not using a shoulder harness; the passenger in the front-right seat was using one. The passengers who were unable to exit the aircraft were found in the cabin, with their shoulder harness (front seat passenger) and lap belts undone.

1.15.3 Emergency locator transmitter

The aircraft’s 406 MHz emergency locator transmitter (ELT) activated upon impact. The ELT was secured to the occurrence aircraft by a hook-and-loop fastener. It stayed intact and secured to the mounting tray during the impact sequence and remained serviceable; however, it was ineffective in transmitting the distress signal to the Joint Rescue Coordination Centre once the aircraft was submerged. When the aircraft was recovered and right side up, the ELT continued to transmit a distress signal until it was manually selected OFF.

1.15.4 Personal flotation devices

Subsection 602.62(1) of the CARs states the following:

No person shall conduct a take-off or a landing on water in an aircraft or operate an aircraft over water beyond a point where the aircraft could reach shore in the event of an engine failure, unless a life preserver, individual flotation device or personal flotation device is carried for each person on board.Footnote 18

Simpson Air provided personal flotation devices (PFDs) in sealed plastic pouches, which were stored in the seat pocket ahead of each passenger. The pilot and front-right passenger’s PFDs were stored in the side pockets beside their seats. The company’s emergency egress briefing (Appendix A) included instructions for the passengers to first obtain and don the PFD, then locate the nearest emergency exit and open it. Passengers were instructed to keep a hand on the exit, release the seat belt, exit the aircraft, and, once free of the aircraft, inflate the PFD. Neither survivor used their PFD as they exited the aircraft.

1.15.5 Survival kit

Subsection 602.61(1) of the CARs specifies that

[…] no person shall operate an aircraft over land unless there is carried on board survival equipment, sufficient for the survival on the ground of each person on board, given the geographical area, the season of the year and anticipated seasonal climatic variations, that provides the means for

- starting a fire;

- providing shelter;

- providing or purifying water; and

- visually signalling distress.Footnote 19

Further, section 703.82 of the CARs states that

No air operator shall operate an aircraft unless the emergency equipment carried on board the aircraft pursuant to Division II of Subpart 2 of Part VI meets the Commercial Air Service Standards and is inspected regularly in accordance with the inspection schedule set out in the air operator’s company operations manual.Footnote 20

Simpson Air had equipped the aircraft with a suitable survival kit as required by subsection 602.61(1) of the CARs, but the survival kit was located in the cargo bay in the rear of the aircraft. Therefore, it was not accessible to the pilot after the aircraft had submerged.

1.15.6 Emergency underwater egress training

Emergency underwater egress training has been available in Canada for several years, but was not required by regulation at the time of the accident. The occurrence pilot had not received underwater egress training; however, she had discussed the procedure with other pilots who had received the training.

1.16 Tests and research

Not applicable.

1.17 Organizational and management information

1.17.1 General

Simpson Air is a TC-approved commercial air operator that has been in operation since 1981, conducting flight operations under CARs subparts 702 (Aerial Work) and 703 (Air Taxi Operations). It is based in Fort Simpson, Northwest Territories.

At the time of the occurrence, Simpson Air operated 2 Cessna U206Gs aircraft (including the occurrence aircraft), 1 Cessna A185F aircraft, 1 de Havilland DHC-2 aircraft, and 1 Piper PA-23-250 aircraft. Maintenance is performed on the aircraft by contracted TC-approved maintenance organizations.

1.17.2 Safety management at Simpson Air

When implemented properly, a safety management system provides a framework for companies to manage risk effectively and make operations safer. Because Simpson Air is a CARs subparts 702 and 703 operator, the company was not required to have a safety management system and did not have one.

1.18 Additional information

1.18.1 Stable approaches

As described in the FAA’s Airplane Flying Handbook, “The objective of a good, stabilized final approach is to descend at an angle and airspeed that permits the airplane to reach the desired touchdown point at an airspeed that results in minimum floating just before touchdown; in essence, a semi-stalled condition.”Footnote 21

The Transport Canada Flight Test Guide—Commercial Pilot Licence—AeroplaneFootnote 22 provides a generic description of a stable visual flight rules approach as the following:

On the correct final approach flight path:

- Briefings and checklists complete;

- Aircraft must be in the proper landing configuration appropriate for wind and runway conditions;

- Appropriate power settings applied;

- Maximum sink rate of 1,000 feet per minute;

- Speed within +10/−5 knots of the reference speed;

- Only small heading and pitch changes required;

- Stable by 200 feet AGL [above ground level].

Note: If stability is not established by 200 feet AGL, an overshoot will be executed.

Simpson Air’s preferred method of approach and landing is to conduct a stabilized approach and land with power on; power is required to control the rate of descent during the landing while maintaining a constant pitch attitude in the flare.

1.18.2 Bounced landing and recovery

As described in TC’s Aeroplane Flight Training Manual, “A normal landing is a slow transition from the normal glide attitude to the landing attitude. This transition is referred to as the flare […] and is progressively increased and continued as altitude is lost” Footnote 23 and the aircraft settles on the landing surface. There are many factors that can contribute to a bounced landing, including an unstable approach, wind gust, over-controlling, and touching down with excessive speed or rate of descent. When the descent rate is high, the landing surface gives back the energy imparted to it in the hard landing, resulting in the aircraft lofting back into the air. Footnote 24 A pilot has 2 choices to recover from the bounced landing: either execute a go-around or continue the landing. “[This] choice will be dictated to some extent by the airspeed, landing distance available, height above ground and [the pilot’s] skill.” Footnote 25

1.18.3 TSB recommendations for seaplanes

The Board has issued several recommendations for seaplane operations to eliminate or reduce safety deficiencies that pose significant risks. The following sections provide highlights of some of those recommendations.

1.18.3.1 Recommendation on rapid egress exits

During a TSB investigationFootnote 26 into an accident involving a DHC-2 aircraft departing Lyall Harbour, British Columbia, in 2009, the TSB recognized the importance of having exits available to escape from a sinking aircraft. The Board recommended that

the Department of Transport require that all new and existing commercial seaplanes be fitted with regular and emergency exits that allow rapid egress following a survivable collision with water.

Transportation Safety Recommendation A11-05

In January 2017, TC responded to Recommendation A11-05 by indicating that, in 2006, it had conducted an evaluation of egress from submerged seaplanes, which included suggestions to enhance safety but concluded that there was no readily identifiable design solution that would have a major impact on the existing level of floatplane safety. TC stated that it would therefore focus on regulatory requirements for egress training and other enhancements on floatplane safety, and would not devote further activity to Recommendation A11-05.

The TSB’s March 2017 reassessment of TC’s response states that the intent of the TSB recommendation is to reduce the risk of occupants being trapped when some or all exits are jammed as a result of an accident.

Emergency door-release mechanisms, better door handles, and push-out windows have been developed for certain types of floatplanes. Although some floatplane operators have installed these modifications, many have not.

Regulatory requirements for mandatory egress training for commercial floatplane pilots may result in some improvement in emergency egress from commercial seaplanes. However, if the regulator does not mandate or promote voluntary modifications to normal exits, seaplanes will continue to operate with exits that could become unusable following an impact, diminishing the occupants’ chance to exit the aircraft following a survivable accident. The response to Recommendation A11-05 was last assessed by the TSB as Satisfactory in Part. This deficiency file is currently Dormant.Footnote 27

1.18.3.2 Recommendations on personal flotation devices and egress training

Following the Lyall Harbour accident in 2009, the TSB also recognized that, if a PFD is not worn, and in the absence of other rescue capabilities, there is a higher risk that survivors of water impact will drown. Therefore, the TSB recommended that

the Department of Transport require that occupants of commercial seaplanes wear a device that provides personal flotation following emergency egress.

Transportation Safety Recommendation A11-06

On 06 March 2019, amendments to the CARs for seaplane operations were published in the Canada Gazette, Part II. These amendments include

- a requirement for seaplane operators to have procedures in their company operations manual to ensure that crew members and passengers wear a flotation device when the seaplane is operated on or above water;

- a requirement for the pilot-in-command to instruct crew members and passengers to wear a flotation device when the seaplane is operated on or above water; and

- requirements prescribing how the flotation device must be worn, as well as exemptions to the regulation for a person carried on a stretcher, incubator, or other similar devices.

These amendments are applicable to all seaplanes operated under CARs subparts 703 and 704 and will come into effect in September 2020.

In addition, the TSB has recognized, after many seaplane accidents, that pilots who receive underwater egress training have a greater chance of escaping the aircraft and surviving an accident. Those pilots can then help passengers to safety. In 2013, following a DHC-2 floatplane accident in Lillabelle Lake, Ontario,Footnote 28 the TSB recommended that

the Department of Transport require underwater egress training for all flight crews engaged in commercial seaplane operations.

Transportation Safety Recommendation A13-02

The amendments to the CARs for seaplane operations published in the Canada Gazette, Part II, on 06 March 2019 also require mandatory initial and recurrent training, every 3 years thereafter, on underwater egress for flight crews operating under CARs subparts 703 and 704. These regulations will come into effect in March 2022.

The Board believes that these amendments have substantially reduced the risk associated with the safety deficiencies identified in recommendations A11-06 and A13-02.

Therefore, the Board considers the responses to recommendations A11-06 and A13-02 to be Fully Satisfactory. These deficiency files are Closed.

1.19 Useful or effective investigation techniques

Not applicable

2.0 Analysis

2.1 General

The investigation determined that there were no system malfunctions that would have contributed to the crash. The weather did not contribute to the accident, nor was there any indication that physiological factors, including fatigue, played a role. Therefore, the analysis will focus on the operational and organizational factors that contributed to the accident.

2.2 Approach

The destination of the occurrence flight, Little Doctor Lake, is susceptible to unpredictable winds, resulting in significant wave action, due to a gap in the mountain range on the west side of the lake. With this in mind, the pilot chose to fly through the gap in the mountains, circle to the south, and then around the eastern shore to get a good look at the surface of the lake. The intention was to land in a bay in the northern corner of the lake. This allowed a descent over the Sibbeston River, leading to a touchdown in the bay, which generally had calmer conditions than the main body of the lake and was not affected by strong airflows out of the gap in the mountain range.

The majority of the approach path was stable until approximately 300 feet above ground, when the descent rate increased significantly. The pilot attempted to reduce the rate of descent by adding power. Just before touchdown, the aircraft entered into a nose-high attitude, and the stall horn activated. The nose-high landing attitude resulted in the aircraft touching down on the very rear of the floats with considerable force.

Thus, for the last 300 feet of the descent, a stable approach profile was not maintained. The increased rate of descent before touchdown resulted in a hard landing and subsequent bounce.

2.3 Bounced landing

One of the possible results of an unstable approach is a bounced landing. This happens when the aircraft contacts the landing surface at a high rate of descent.

In this occurrence, the rate of descent was high at the end of the approach, leading to a hard landing on the very rear of the floats in a near full-stall condition, with the stall warning horn sounding. The hard landing led to a bounce. No power was added to reduce the rate of descent for a subsequent touchdown. As the second attempt to land was made, the stall warning horn sounded again. As the aircraft settled, it touched down hard on the rear of the left float. There was enough energy to pitch the aircraft forward and to the right. The right wing contacted the surface of the lake, and the aircraft nosed over.

Recovery techniques for a bounced landing were not applied, which resulted in a loss of control, the right wing contacting the water, and the aircraft nosing over.

2.4 Egress

When the aircraft came to rest inverted in the water, the cabin filled with water relatively quickly. The pilot and surviving passenger escaped through the window of the pilot door. All of the doors were functional but were found in the closed and locked position. The 3 passengers who did not survive had removed their seat belts but were unable to exit the aircraft and drowned.

2.5 Passenger safety briefing

Before boarding the aircraft for the first flight of the day to Virginia Falls Water Aerodrome (CFV5) on 16 August 2018, the passenger seated in the last row was shown how to manipulate the handles for the rear double cargo doors and was required to operate the doors himself. However, there was no mention in the briefing that flap deployment would block the forward rear double cargo door, and no instructions were provided on how to overcome that situation to open the aft rear double cargo door.

If the passenger safety briefing is incomplete, passengers may not know the process required to escape the aircraft in an emergency.

2.6 Floor coverings

In the occurrence aircraft, the original carpet floor coverings had been removed and replaced with thin rubber matting that did not comply with Cessna’s illustrated parts manualFootnote 29. Furthermore, the aircraft technical records did not have an approved supplemental type certificate for this modification.

Because the matting was fixed only at one end, once the aircraft overturned and was floating upside down, the strips hung down, blocking the spaces between the seats. This could have made navigating those spaces difficult and could have added to the confusion as passengers tried to make their way to emergency exits.

If unapproved parts are installed in an aircraft, they may interfere with safe operation during normal and emergency situations.

2.7 Certification

The Cessna U206 was designed with a rear double cargo door on the right side of the aircraft. In accordance with section 3.387 of the U.S. Civil Air Regulations, the aircraft’s emergency exits were required to be clear and unobstructed, easy to use, and simple and obvious to operate. The regulations also stipulated that, if an aircraft carried 5 to 15 occupants, there must be an emergency exit on the opposite side of the aircraft from the main door. When the flaps are retracted, the rear double cargo doors are relatively simple to operate and meet the criteria for an emergency exit. However, when the flaps are deployed, which is typically the case in a landing accident, they block the forward door, which can open only approximately 8 cm before coming into contact with the flap. There is a procedure to open the aft rear cargo door, but it is not easy to use, or simple and obvious to operate. In addition, the requirement for emergency exits to be unobstructed is not met because the flaps can block the door.

If the design of an aircraft’s emergency exit does not meet the basis of certification, then it may not be adequate for safe egress in an emergency.

2.8 Survival gear

Simpson Air had equipped the aircraft with a suitable survival kit and had stowed it in the aft cargo area of the cabin. Once the aircraft overturned and was partially submerged in the lake, the survival kit was no longer accessible to the survivors. Stowing the survival kit in a float compartment may increase the likelihood that it can be reached in an emergency.

If survival equipment is stowed in an inaccessible place on the aircraft, survivors risk not being able to reach and use it after an accident, consequently reducing their chances of survival.

3.0 Findings

3.1 Findings as to causes and contributing factors

- For the last 300 feet of the descent, as the pilot attempted to land at the intended touchdown point, a stable approach profile was not maintained. The increased rate of descent before touchdown resulted in a hard landing and subsequent bounce.

- Recovery techniques for a bounced landing were not applied, which resulted in a loss of control, the right wing contacting the water, and the aircraft nosing over.

- The 3 passengers who did not survive had removed their seat belts but were unable to exit the aircraft and drowned.

3.2 Findings as to risk

- If the passenger safety briefing is incomplete, passengers may not know the process required to escape the aircraft in an emergency.

- If unapproved parts are installed in an aircraft, they may interfere with safe operation during normal and emergency situations.

- If the design of an aircraft’s emergency exit does not meet the basis of certification, then it may not be adequate for safe egress in an emergency.

- If survival equipment is stowed in an inaccessible place on the aircraft, survivors risk not being able to reach and use it after an accident, consequently reducing their chances of survival.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

On 18 February 2019, the TSB issued Aviation Safety Advisory A18W0129-D1-A1 to highlight the significant safety issues involving Cessna 206 aircraft that are fitted with rear double cargo doors.

On 31 May 2019, Transport Canada responded to the TSB Safety Advisory and, after a preliminary risk assessment, has planned to m ake a formal safety recommendation to the U.S. Federal Aviation Administration

- informing it of the results of National Aircraft Certification’s risk assessment (when finalized);

- asking it to require Cessna to develop, deploy, and mandate improvements to the cargo door design to ensure successful egress if an accident terminates in the water; and

- informing it that, in the absence of a positive response, Transport Canada Civil Aviation plans to proceed with unilateral action: specifically, issuing Airworthiness Directives mandating occupant restrictions similar to those contained in Type Certificate Sheets A-212 and cargo door latch improvements contained in Cessna Service Bulletin SEB91-4.

4.1.2 Simpson Air (1981) Limited

Following this accident, Simpson Air (1981) Limited has made the following decisions:

- It will no longer operate the Cessna 206 on floats.

- All seasonal floatplane flight crew will receive underwater egress training—2 employees have already completed this training.

- New floatplane flight crew will be required to undertake a 50-hour bush float course or have 500 hours of previous float experience.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on

Appendices

Appendix A – Simpson Air (1981) Limited’s Scripted Safety Briefing

Safety Briefing – All Aircraft

- Okay folks, just a quick safety briefing before we get going here, you will find a safety feature card in the seat pocket in front of you and I invite you to follow along.

- Seatbelts work via inserting the metal tab into the silver buckle in the middle, pull on the strap to ensure a snug fit. Pull the silver buckle to release the belt, please keep your seatbelts fastened for the duration of the flight.

- Smoking is prohibited at all times during the flight and around the aircraft.

- Portable electronics devices may only be used in flight mode and should be stowed during taxi, takeoff and landing.

- We do carry first aid, survival gear and an emergency locator beacon in the very rear baggage compartment and a fire extinguisher under the front seat

- Additionally, Simpson Air has the spot tracking system (point to it) which sends a signal back to base every 10 minutes letting them know where we’re at.

- And a quick reminder on your exits...

[…]

- The Cessna 206 has 2 exits, 1 up front left by me and the other on the back right. Both are similar, pull the big silver lever towards the rear of the plane and that will open the door. To open the second part of the rear door, once the front portion is open, pull the red leaver located halfway down towards the front of the plane, push open, stow the lever then open the door fully. […]

- If there are any questions, please feel free to ask.

Safety Briefing – Egress (Floatplanes)

Okay folks, as we are on a floatplane today, I am required to give you the following emergency egress briefing. In the unlikely event that we have to evacuate the aircraft on or under the water, please remember the following 4 key points!

- Stay calm and keep your seatbelt fasted.

- Grab your life jacket (from the seat pocket in front of you/from overhead left and or right/or if you’re upfront with me, from the front right door pocket). Remove it from the pouch, place over your head and secure with the waist strap.

- Locate your nearest exit, open the exit with one hand, then open your seatbelt with the other and pull yourself free from the aircraft.

- And lastly, only inflate your life jackets AFTER EXITING THE AIRCRAFT. Life jackets can be inflated by pulling sharply on the red tabs at the bottom of the vest or manually using the mouth piece