West Wind Aviation L.P.

Avions de Transport Régional ATR 42-320, C-GWEA

Fond-du-Lac, Saskatchewan

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

On 13 december 2017, an Avions de Transport Régional ATR 42-320 aircraft (registration C-GWEA, serial number 240), operated by West Wind Aviation L.P. (West Wind), was scheduled for a series of instrument flight rules flights from Saskatoon through northern Saskatchewan as flight WEW282.

When the flight crew and dispatcher held a briefing for the day’s flights, they became aware of forecast icing along the route of flight. Although both the flight crew and the dispatcher were aware of the forecast ground icing, the decision was made to continue with the day’s planned route to several remote airports that had insufficient de-icing facilities.

The aircraft flew from Saskatoon/John G. Diefenbaker International (CYXE) to Prince Albert (Glass Field) Airport (CYPA) without difficulty, and, after a stop of about 1 hour, proceeded on toward Fond-du-Lac Airport (CZFD). On approach to Fond-du-Lac Airport, the aircraft encountered some in-flight icing, and the crew activated the aircraft’s anti-icing and de-icing systems.

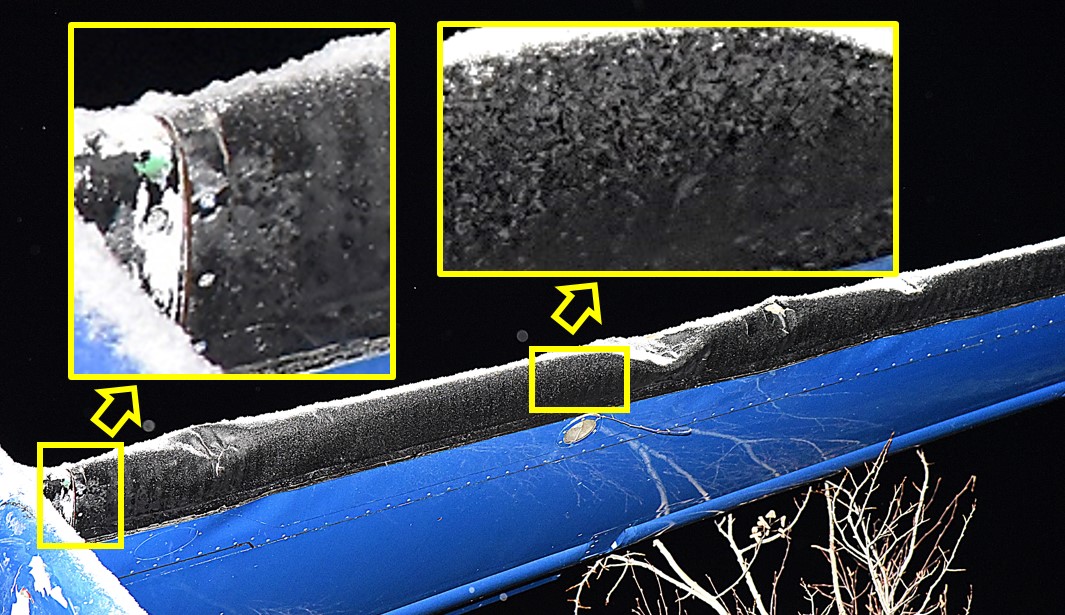

Although the aircraft’s ice protection systems were activated, the aircraft’s de-icing boots were not designed to shed all of the ice that can accumulate, and the anti-icing systems did not prevent ice accumulation on unprotected surfaces. As a result, some residual ice began to accumulate on the aircraft.

The flight crew were aware of the ice; however, there were no handling anomalies noted during the approach. Consequently, they likely did not assess that the residual ice was severe enough to have a significant effect on aircraft performance. The crew continued the approach and landed at Fond-du-Lac Airport at 1724 Central Standard Time.

According to post-accident analysis of the data from the flight data recorder, the aircraft’s drag and lift performance was degraded by 28% and 10%, respectively, shortly before landing at Fond-du-Lac Airport. This indicated that the aircraft had significant residual ice adhering to its structure upon arrival. However, this data was not available to the flight crew at the time of landing.

The aircraft was on the ground at Fond-du-Lac Airport for approximately 48 minutes. The next flight was destined for Stony Rapids Airport (CYSF), Saskatchewan, with 3 crew members (2 pilots and 1 flight attendant) and 22 passengers on board.

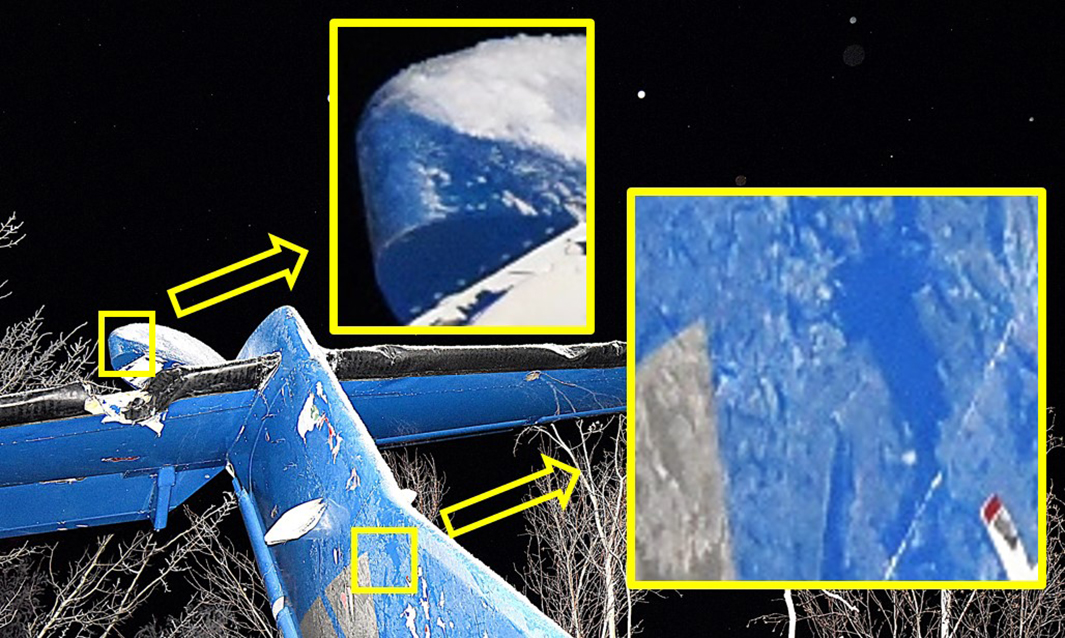

Although there was no observable precipitation or fog while the aircraft was on the ground, weather conditions were conducive to ice or frost formation. This, combined with the residual mixed ice on the aircraft, which acted as nucleation sites that allowed the formation of ice crystals, resulted in the formation of additional ice or frost on the aircraft’s critical surfaces.

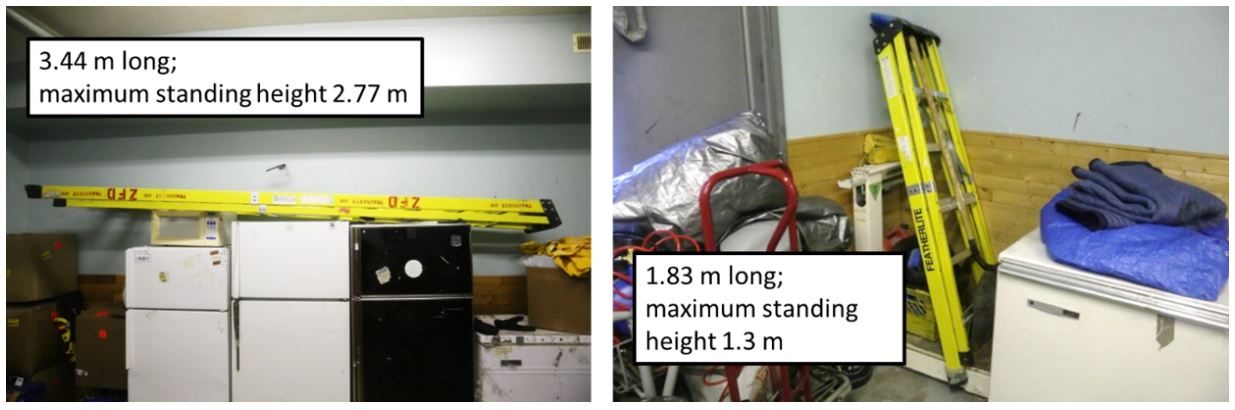

Once the passengers had boarded the aircraft, the First officer completed an external inspection of the aircraft. However, because the available inspection equipment was inadequate, the First officer’s ice inspection consisted only of walking around the aircraft and looking at the left wing from the top of the stairs at the left rear door, without the use of a flashlight on the dimly lit apron.

Although he was unaware of the full extent of the ice and the ongoing accretion, the First officer did inform the captain that there was some ice on the aircraft. The captain did not inspect the aircraft himself, nor did he attempt to have it de-iced; rather, he and the First officer continued with departure preparations.

Company departures from remote airports, such as Fond-du-Lac, with some amount of surface contamination on the aircraft’s critical surfaces had become common practice, in part due to the inadequacy of de-icing equipment or services at these locations. The past success of these adaptations resulted in this unsafe practice becoming normalized and this normalization influenced the flight crew’s decision to depart.

Although the flight crew were aware of icing on the aircraft’s critical surfaces, they decided that the occurrence departure could be accomplished safely. Their decision to continue with the original plan to depart was influenced by continuation bias, as they perceived the initial and sustained cues that supported their plan as more compelling than the later cues that suggested another course of action. At 1812 Central Standard Time, in the hours of darkness, the aircraft began its take-off roll on Runway 28, and, 30 seconds later, it was airborne.

As a result of the ice that remained on the aircraft following the approach and the additional ice that had accreted during the ground stop, the aircraft’s drag was increased by 58% and its lift was decreased by 25% during the takeoff.

Despite this degraded performance, the aircraft initially climbed; however, immediately after liftoff, the aircraft began to roll to the left without any pilot input. This roll was as a result of asymmetric lift distribution due to uneven ice contamination on the aircraft.

Following the uncommanded roll, the captain reacted as if the aircraft was an uncontaminated ATR 42, with the expectation of normal handling qualities and dynamic response characteristics; however, due to the contamination, the aircraft had diminished roll damping resulting in unexpected handling qualities and dynamic response. Although the investigation determined that the ailerons had sufficient roll control authority to counteract the asymmetric lift, due to the unexpected handling qualities and dynamic response, the roll disturbance developed into an oscillation with growing magnitude and control in the roll axis was lost.

This loss of control in the roll axis, which corresponds with the known risks associated with taking off with ice contamination, ultimately led to the aircraft colliding with terrain 17 seconds after takeoff.

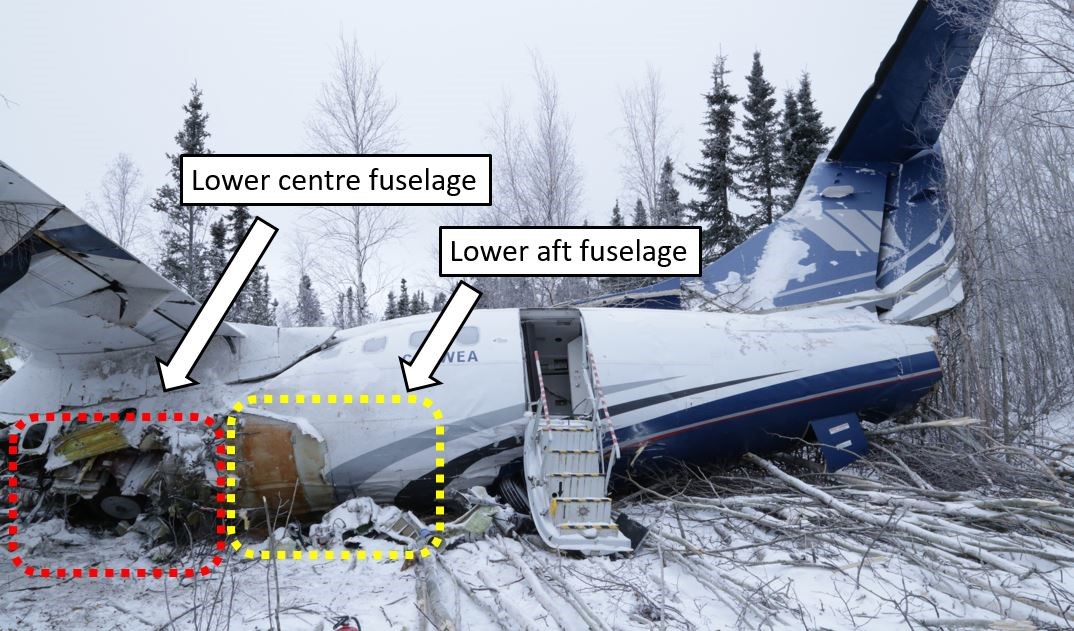

The aircraft collided with the ground in a relatively level pitch, with a bank angle of 30° left. As a result of the sudden vertical deceleration upon contact with the ground, the aircraft suffered significant damage, which varied in severity at different locations on the aircraft due to impact angle and variability in structural design.

Neither current design standards for transport category aircraft, nor those in effect at the time the ATR 42 was certified, specify minimum loads that a fuselage structure must be able to tolerate and remain survivable, or minimum loads for fuselage impact energy absorption. As a result, the ATR 42 was not designed with such crashworthiness parameters in mind.

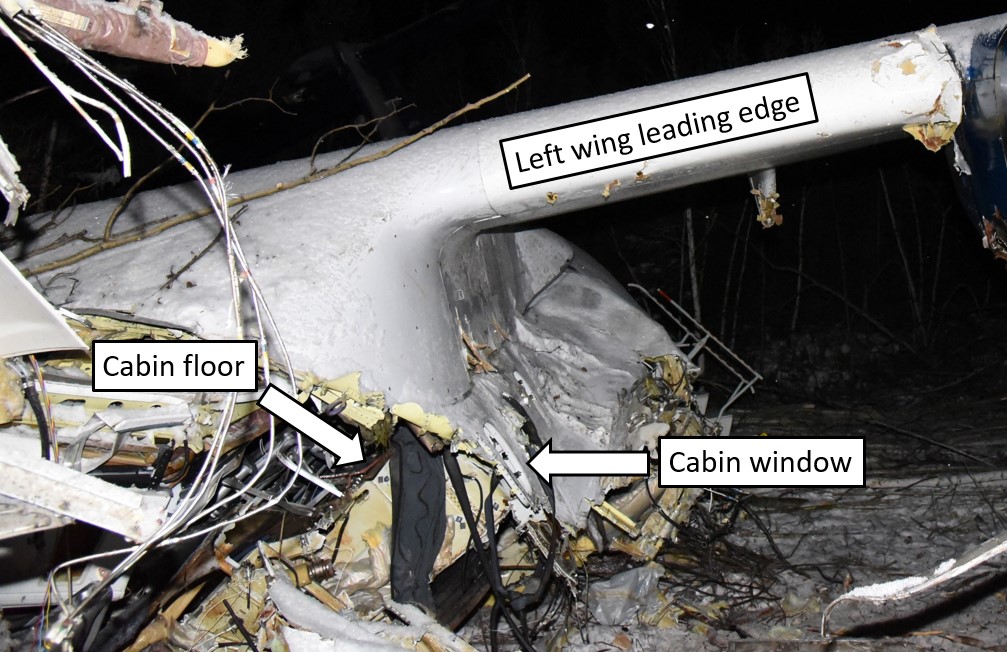

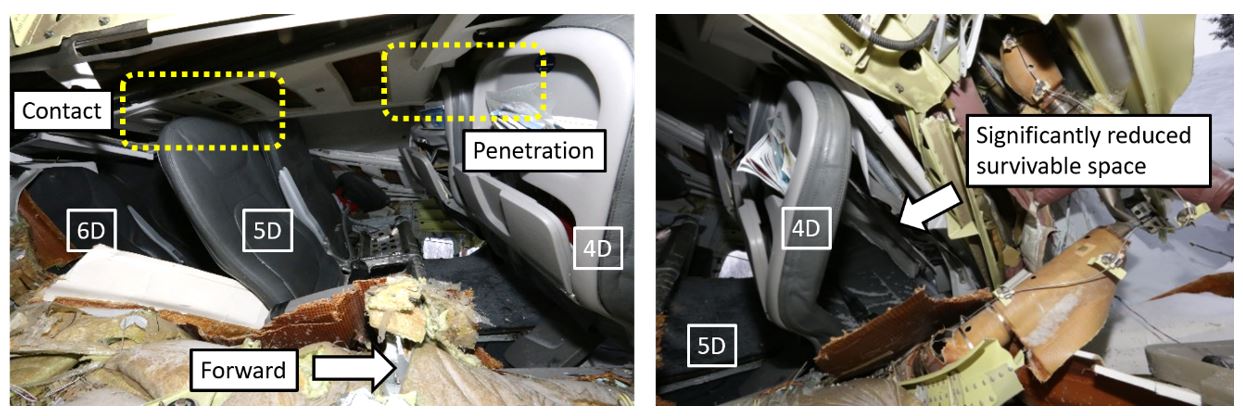

The main landing gear at the bottom of the centre fuselage section was rigid, and, on impact, did not absorb or attenuate much of the load. The impact-induced acceleration was not attenuated because the landing gear housing did not deform. This unattenuated acceleration resulted in a large inertial load from the wing, causing the wing support structure to fail and the wing to collapse into the cabin.

The reduced survivable space between the floor above the main landing gear and the collapsed upper fuselage caused crushing injuries, such as major head, body, and leg trauma, to passengers in the middle-forward left section of the aircraft. Of the 3 passengers in this area, 2 experienced, serious life-changing injuries, and 1 passenger subsequently died.

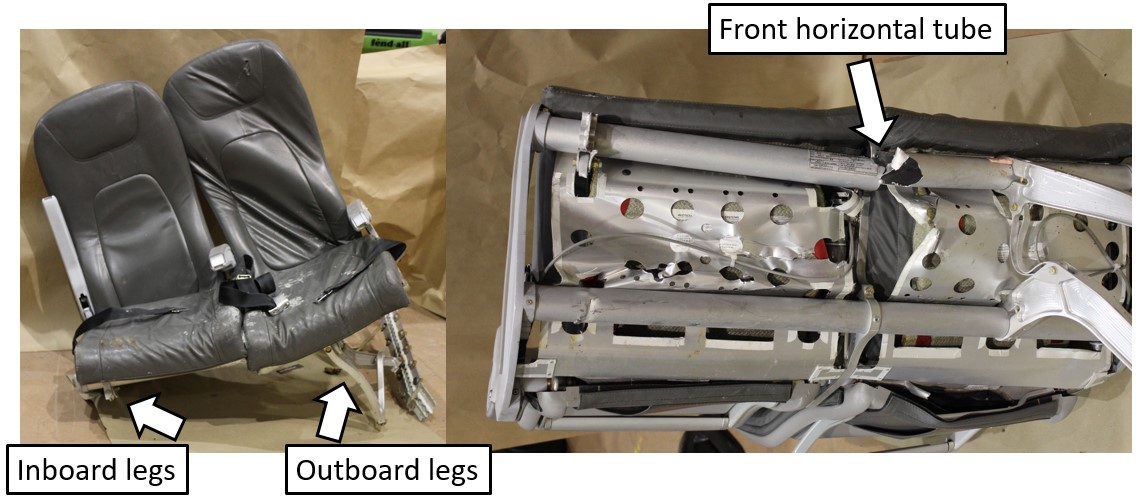

The collapse of part of the floor structure compromised the restraint systems, limiting the protection afforded to the aircraft occupants when they were experiencing vertical, longitudinal, and lateral forces. This resulted in serious velocity-related injuries and impeded their ability to take post-crash survival actions in a timely manner. Unaware of the danger, most passengers in this occurrence did not brace for impact. Because their torsos were unrestrained, they received injuries consistent with jackknifing and flailing, such as hitting the seat in front of them.

As a result of unapproved repairs, the flight attendant seat failed on impact, resulting in injuries that impeded her ability to perform evacuation and survival actions in a timely manner.

Although the TSB has previously recommended the development and use of child restraints aboard commercial aircraft, planned regulations have yet to be implemented by Transport Canada. As a result, the occurrence aircraft was not equipped with these devices, and an infant passenger who was unrestrained received flailing and crushing injuries during the accident sequence.

By the time the aircraft came to a rest, all occupants had received injuries. Passengers began to call for help within minutes of the impact, using their cell phones. Numerous people from the nearby community received the messages and quickly set out to help.

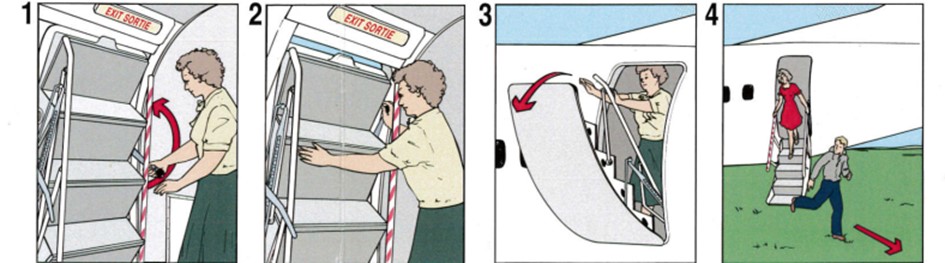

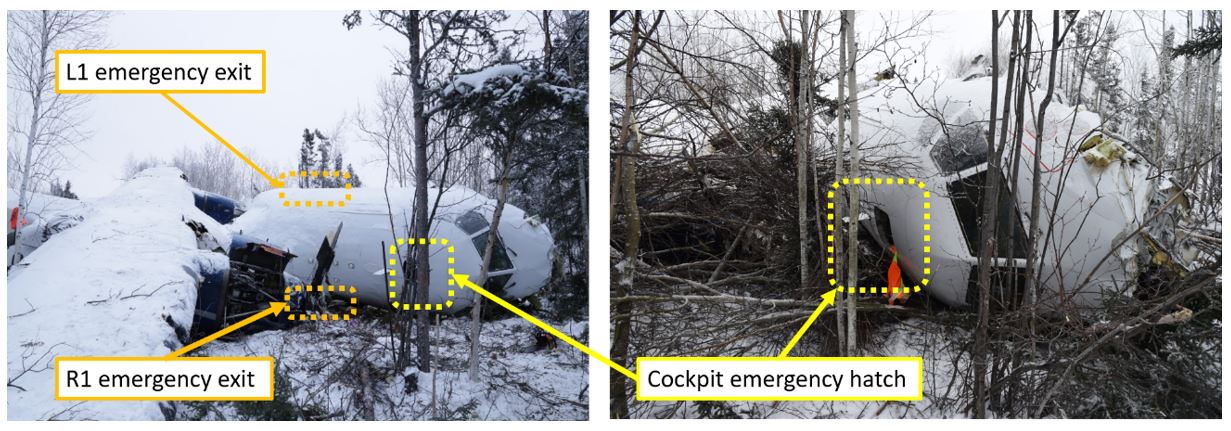

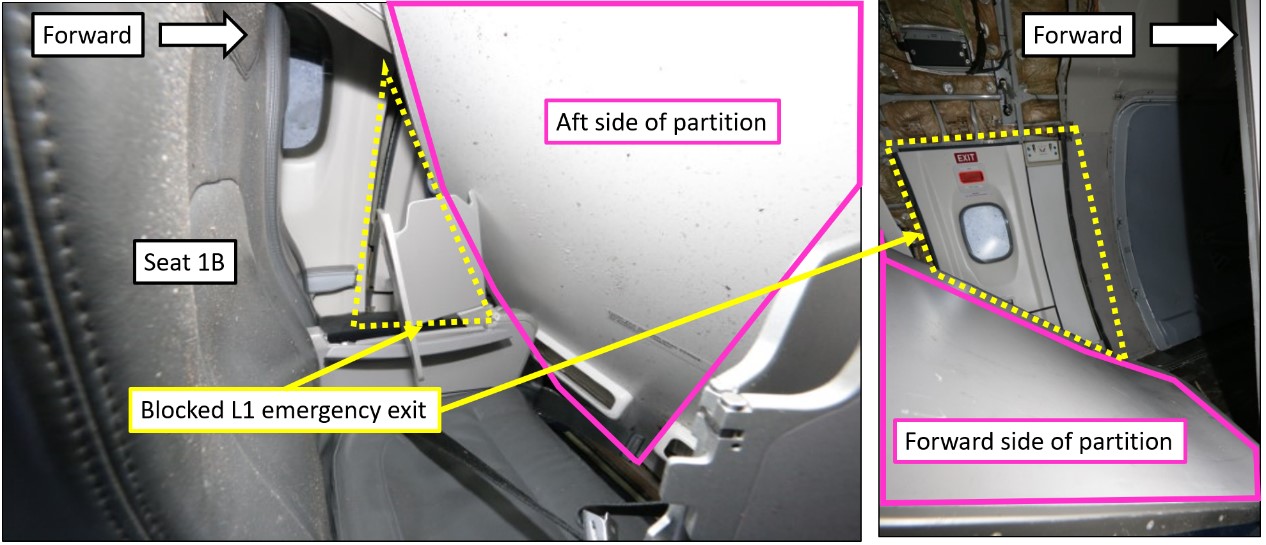

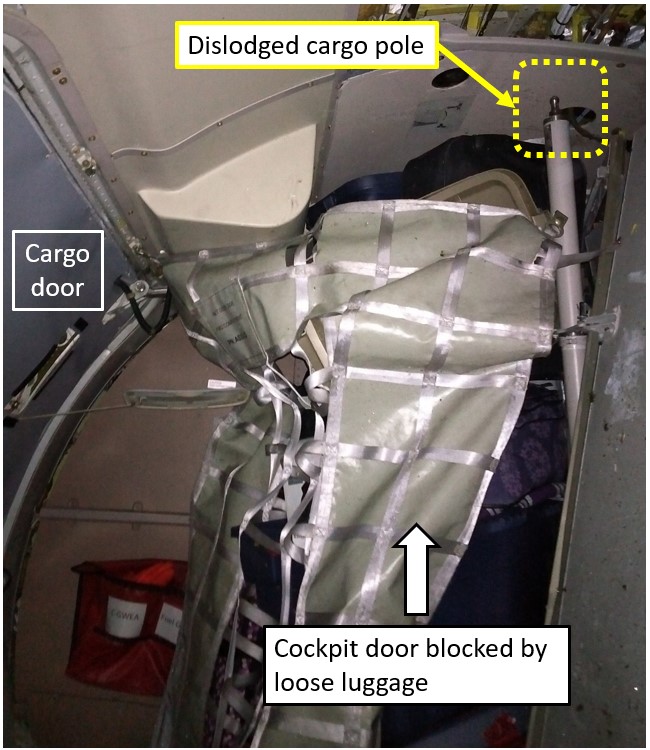

The passengers and crew began to evacuate, but they experienced significant difficulties as a result of the aircraft damage. It took approximately 20 minutes for the first 17 passengers to evacuate, and the remaining passengers much longer; it took as long as 3 hours to extricate 1 passenger, who required rescuer assistance.

As a result of the accident, 9 passengers and 1 crew member received serious injuries, and the remaining 13 passengers and 2 crew members received minor injuries. One of the passengers who had received serious injuries died 12 days after the accident.

There was no post-impact fire, and the emergency locator activated on impact.

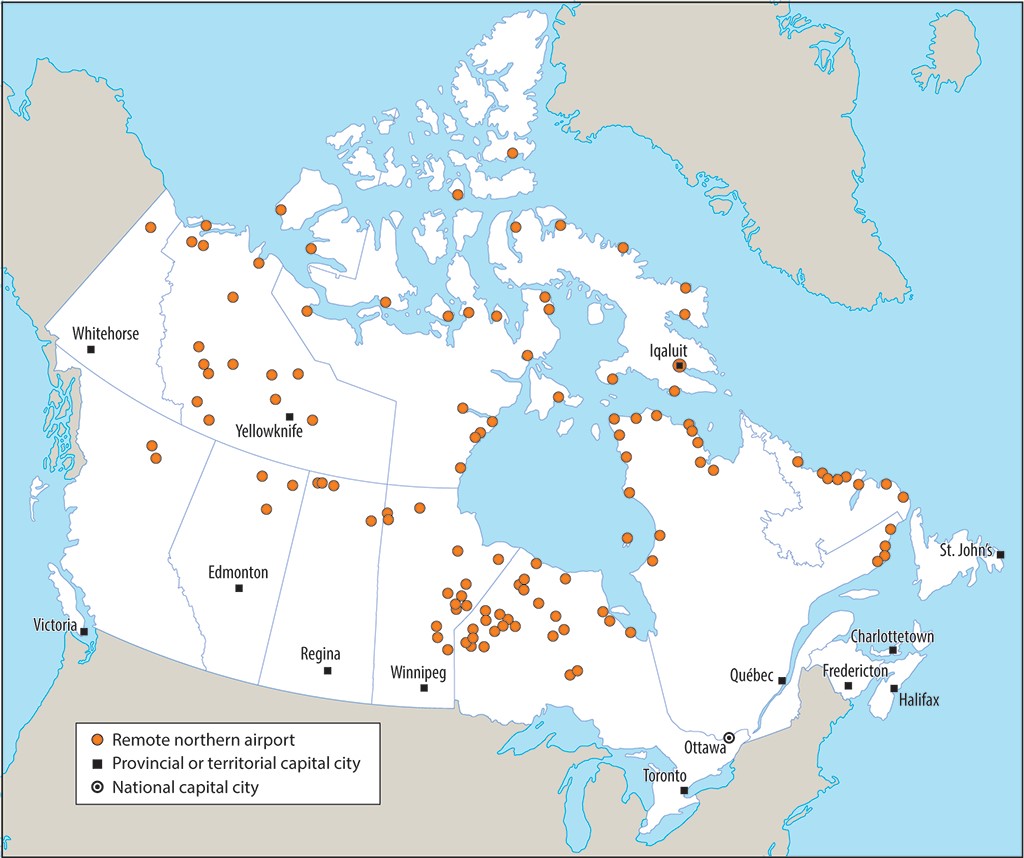

Early in this investigation, it became clear that more information was needed to determine whether the underlying factors identified in this occurrence were present elsewhere in the Canadian commercial aviation industry.

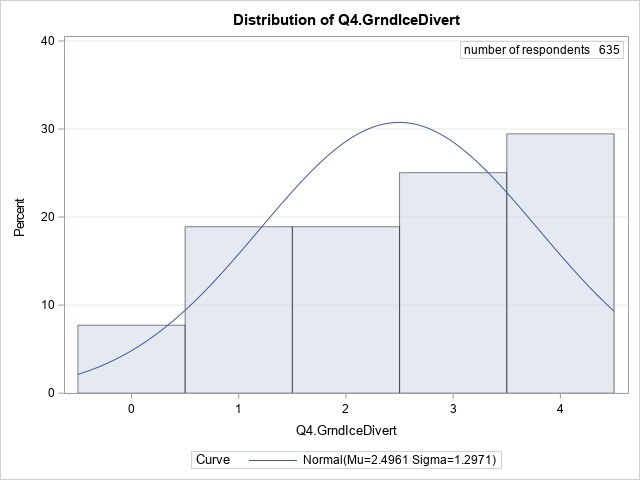

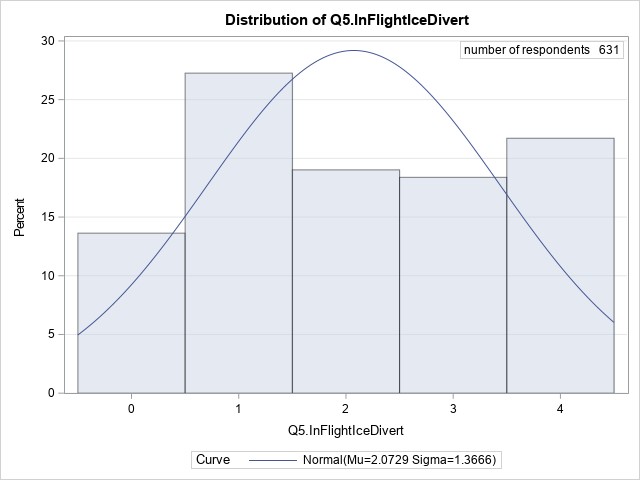

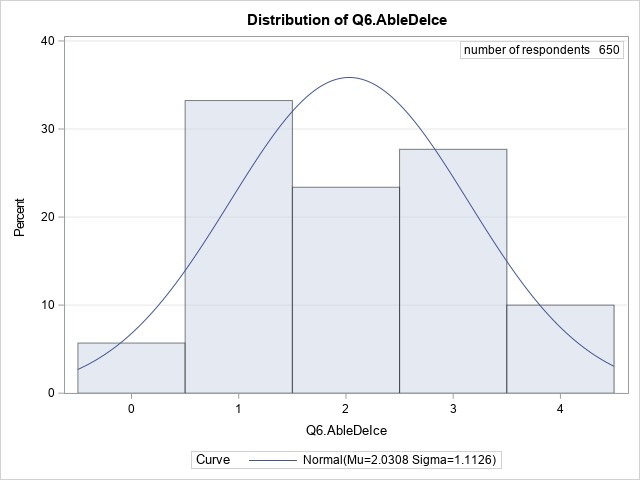

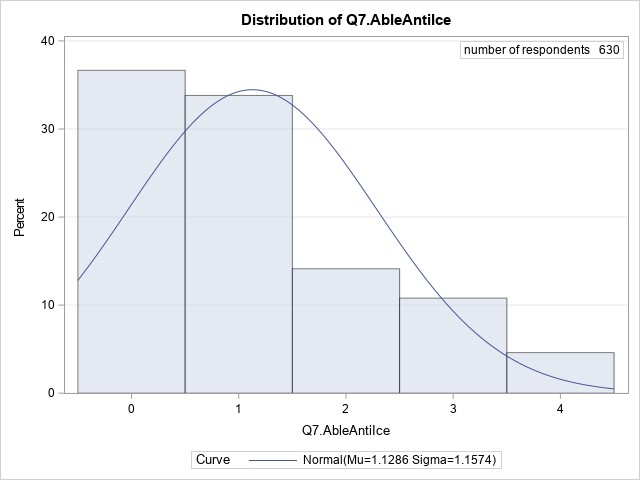

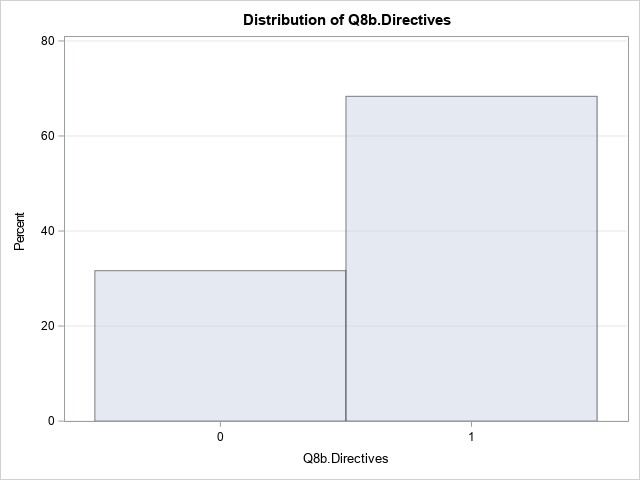

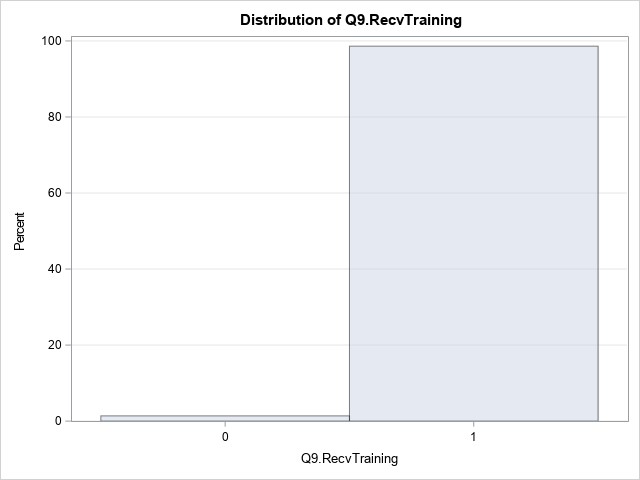

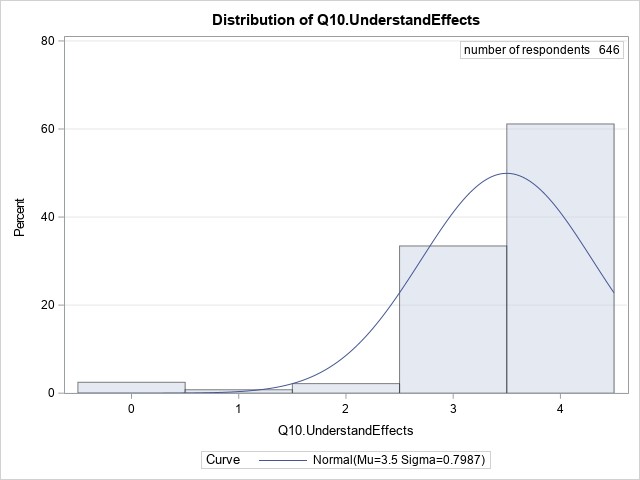

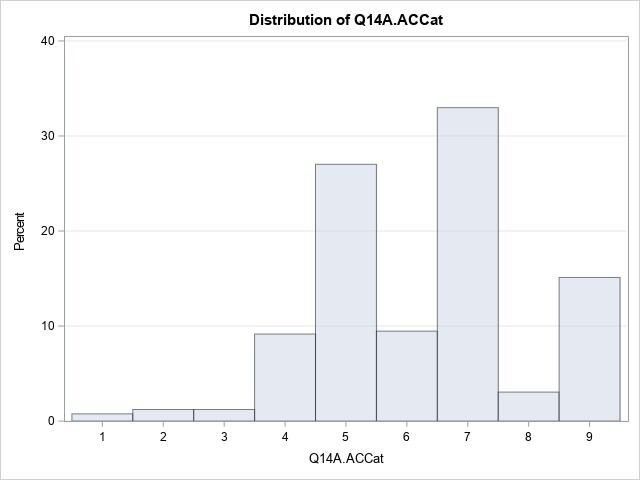

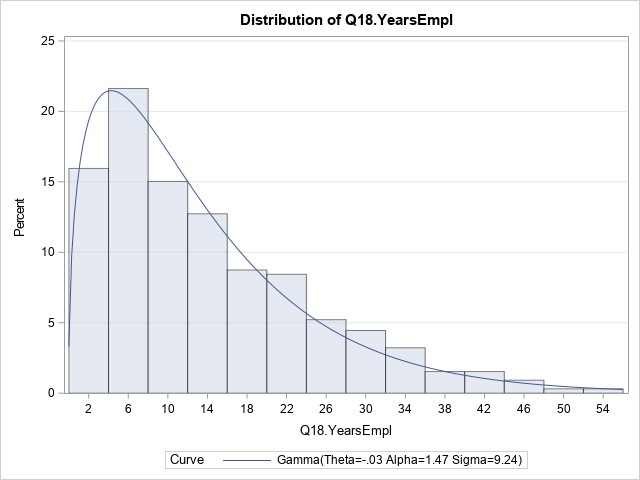

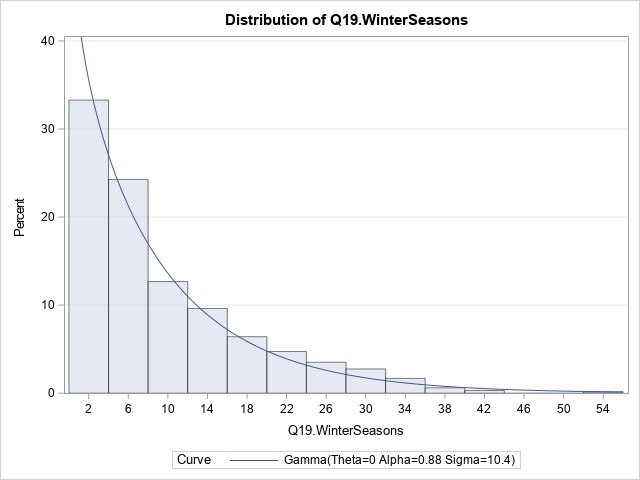

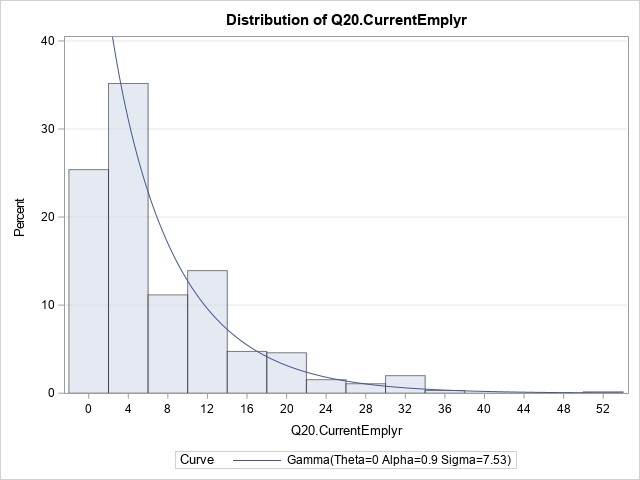

To assess the risks involved with winter operations at remote northern airports, and specifically the risk posed by aircraft taking off with frost, ice, or snow adhering to critical surfaces, the TSB conducted an online survey of pilots who were directly exposed to operations at remote airports throughout Canada.

The responses received to several questions showed that operations at these remote airports were routinely affected by the unavailability and inadequacy of equipment to inspect, de-ice, or anti-ice aircraft.

The combined probability and severity of this safety deficiency poses a high risk to transportation safety. The risk likely varies from airport to airport, depending somewhat on the frequency of operations; however, identifying high-risk locations for immediate mitigation can quickly reduce the likelihood of aircraft taking off with frost, ice, or snow adhering to any critical surface at those locations.

Transport Canada, air operators, and airport authorities have the capacity to identify high‑risk locations, analyze them for hazards and risks, and take mitigating action.

Therefore, in December 2018, the Board recommended that

the Department of Transport collaborate with air operators and airport authorities to identify locations where there is inadequate de-icing and anti-icing equipment and take urgent action to ensure that the proper equipment is available to reduce the likelihood of aircraft taking off with contaminated critical surfaces.

TSB Recommendation A18-02

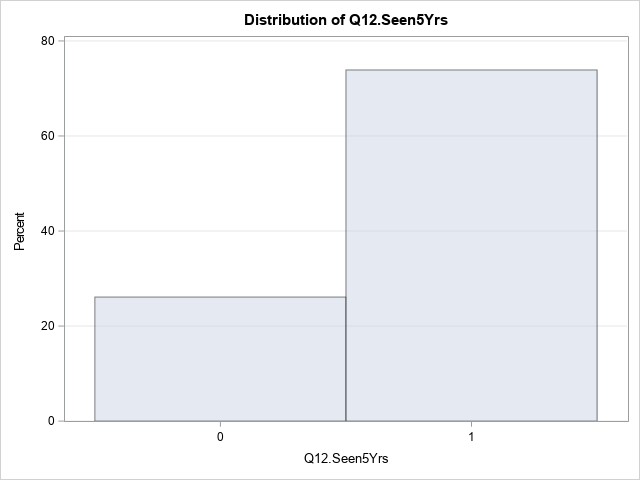

The most notable information received from the survey showed that, in the past 5 years, 74% of pilots had seen aircraft take off with contaminated surfaces, in contravention of regulations and the clean aircraft concept. This majority indicates that the issue is systemic, rather than isolated to a small number of operators or a select few locations.

There are many defences in place to ensure the clean aircraft concept is followed, such as regulations, company operating manuals, and standard operating procedures. However, all of these defences rely singularly on flight crew compliance. As seen in this occurrence, when a single-point compliance adaptation is made, aircraft may depart with contaminated surfaces, despite several adequate administrative defences in place.

To mitigate this hazard, Transport Canada and air operators must take urgent action to ensure better compliance.

Accidents related to contaminated aircraft will continue to occur until the industry and the regulator approach the issue as systemic and take action to eliminate underlying factors that can negatively affect pilot compliance.

Therefore, in December 2018, the Board recommended that

the Department of Transport and air operators take action to increase compliance with Canadian Aviation Regulations subsection 602.11(2) and reduce the likelihood of aircraft taking off with contaminated critical surfaces.

TSB Recommendation A18-03

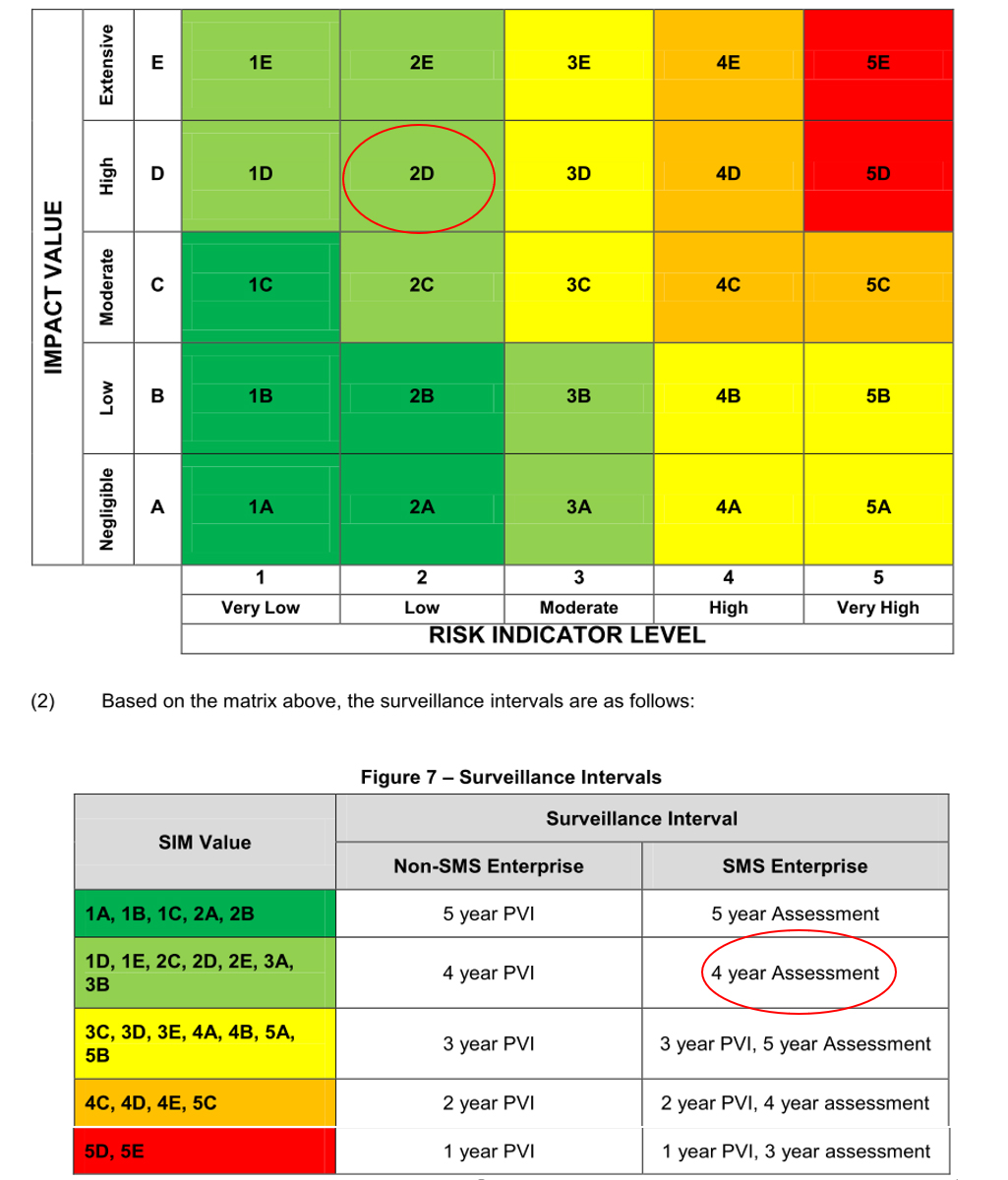

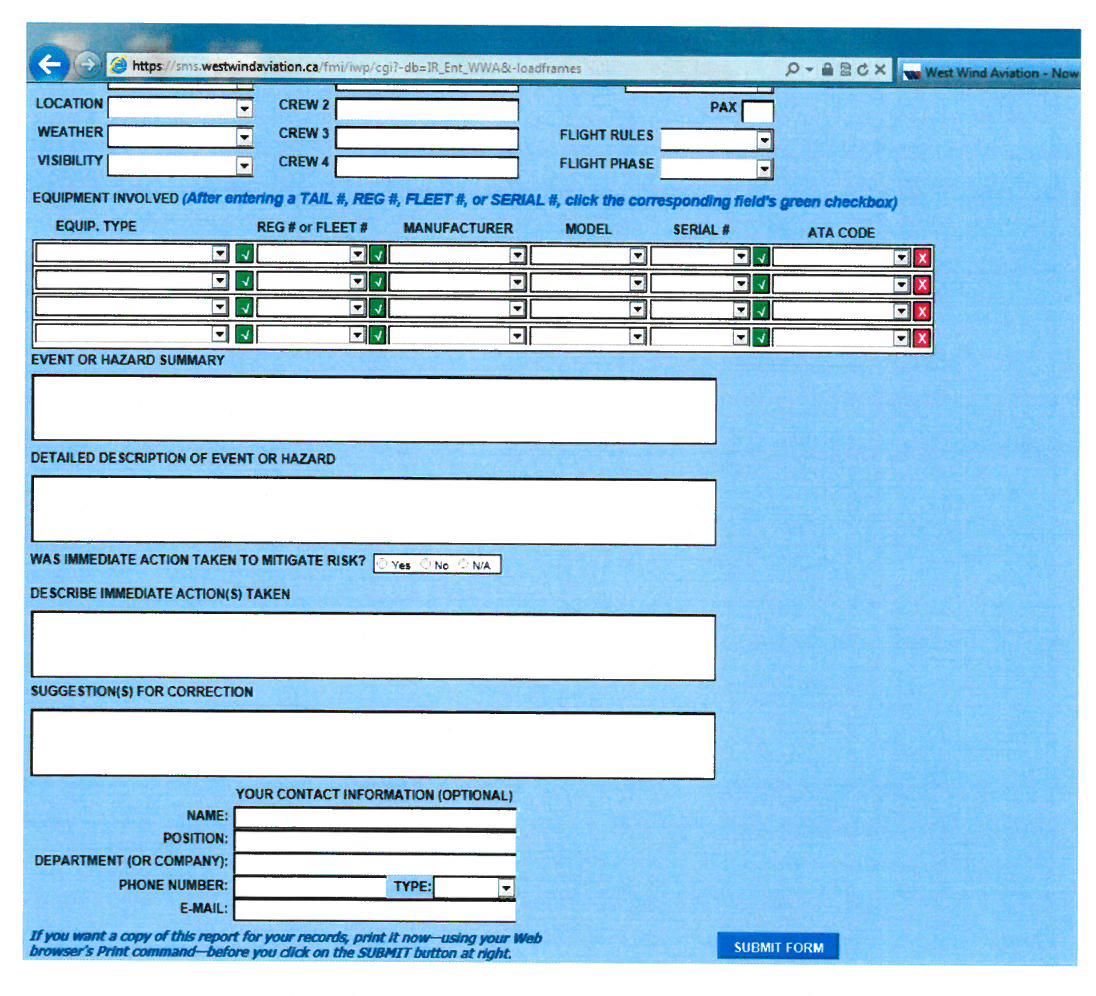

When West Wind commenced operations into CZFD in 2014, no effective risk controls were in place to mitigate the potential hazard of ground icing. Transportation companies have a responsibility to manage safety risks in their operations; however, compliance with regulations can provide only a baseline level of safety. When implemented properly, SMS enables companies to manage risk effectively and make operations safer. For SMS to be effective, it must be supported by a positive safety culture. If a company’s safety culture tolerates unsafe practices, there is a risk that these practices will continue and become a company norm.

Safety management is an issue on the TSB’s Watchlist 2020, which identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

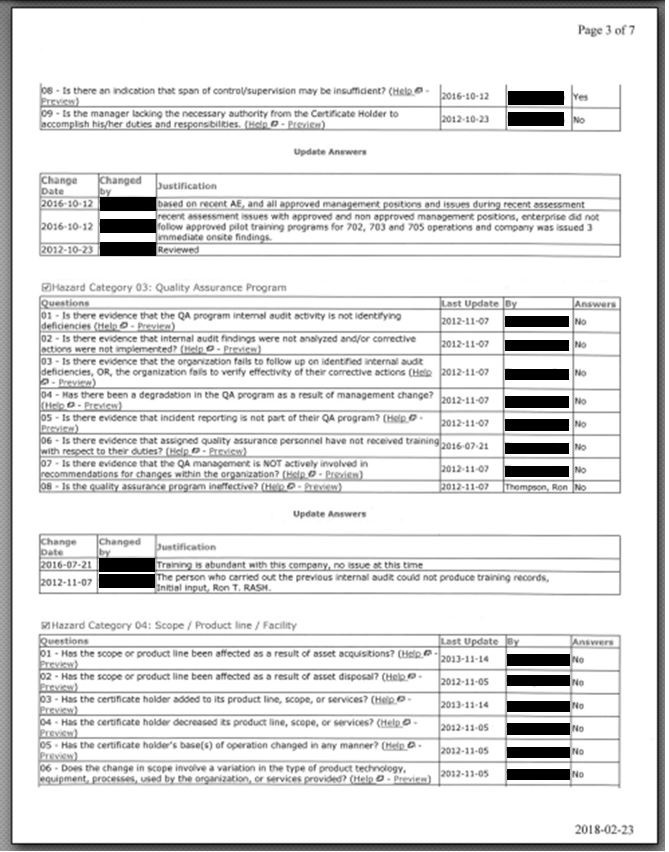

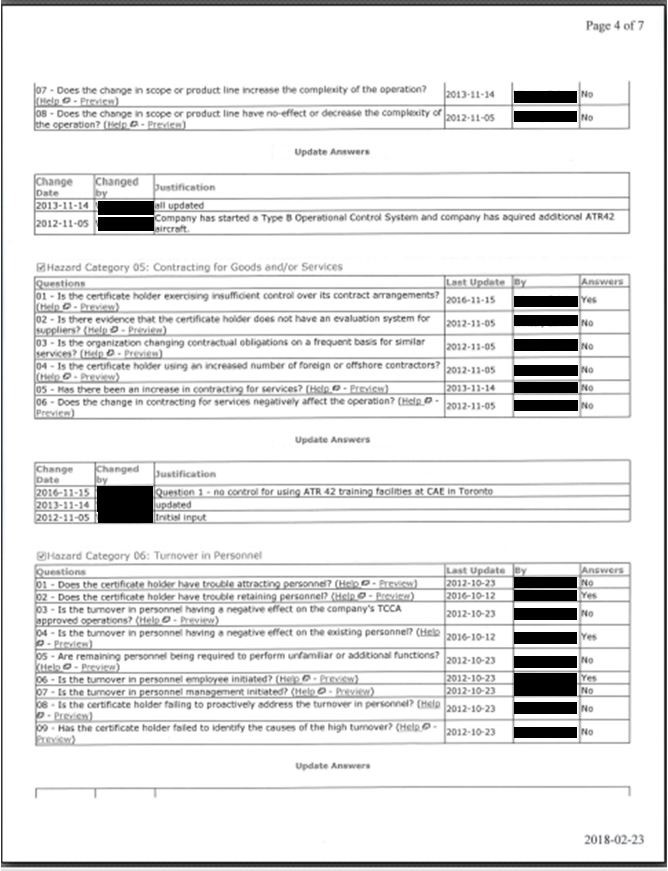

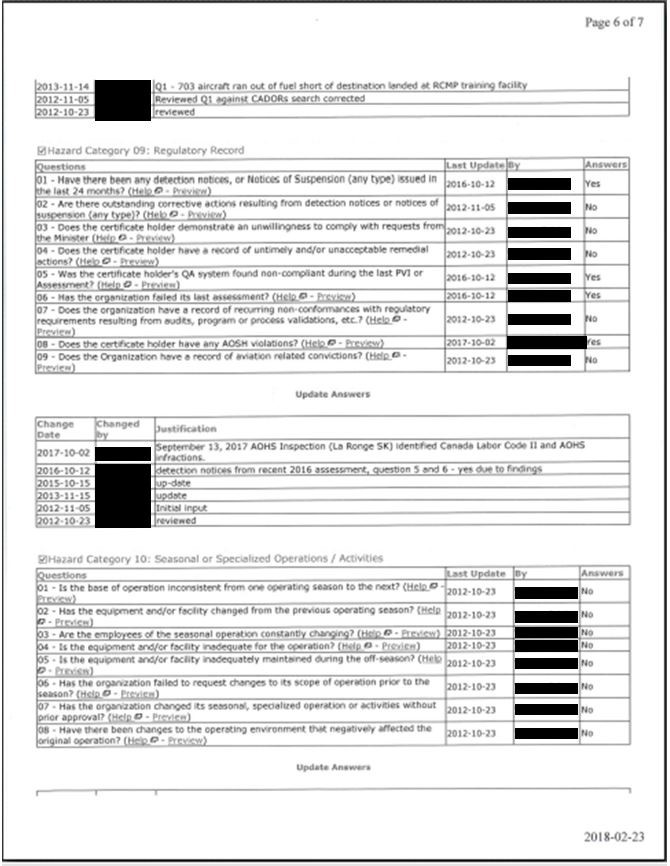

The investigation also revealed a number of instances in which Transport Canada’s surveillance policies and procedures were inconsistently applied to the oversight of West Wind. This is not the first time that such inconsistencies in Transport Canada’s oversight of commercial aviation in Canada have been identified. As detailed in the findings of several TSB investigations, there have been a number of past examples where Transport Canada has been slow to either identify or to rectify unsafe conditions at an operator. Transport Canada’s inconsistent application of its own policies and procedures for the 2016 assessment of West Wind and subsequent post-assessment corrective action plan verifications, as well as the ad hoc approach to enhanced monitoring, resulted in ineffective oversight of an operator that had a history of system-level (i.e., safety management system [SMS]) and systemic (e.g., operational control) non-compliance issues.

If the application of Transport Canada’s surveillance policies and procedures is inconsistent, there is a risk that resulting oversight will be ineffective at ensuring that operators are able to effectively manage the safety of their operations.

Regulatory surveillance is also an item on the TSB’s Watchlist 2020.

1.0 Factual information

1.1 History of the flight

1.1.1 General

On 13 December 2017, the West Wind Aviation L.P. (West Wind) Avions de Transport Régional (ATR) 42-320 aircraft (registration C-GWEA, serial number 240), was conducting West Wind flight 282 (WEW282), which consisted of a series of instrument flight rules flights through northern Saskatchewan.

WEW282 originated from Saskatoon/John G. Diefenbaker International Airport (CYXE), and was scheduled to make stops at Prince Albert (Glass Field) Airport (CYPA), Fond-du-Lac Airport (CZFD), Stony Rapids Airport (CYSF), Wollaston Lake Airport (CZWL), Points North Landing Airport (CYNL), and back to CYPA before terminating at CYXE.

WEW282 was being operated under Subpart 705 of the Canadian Aviation Regulations (CARs).Footnote 2 The flight was chartered by Transwest Air, a West Wind subsidiary, to transport overflow passengers and cargo from a scheduled flight operated by Transwest Air that was flying the same route ahead of WEW282.

1.1.2 Pre-flight planning and dispatch

At 1215,Footnote 3 a West Wind dispatcher began organizing the WEW282 operational flight plans (OFPs) for all 7 segments of the planned flight. WEW282 was planned to depart from CYXE at 1430 with no passengers on board and a fuel load of 8200 pounds. The plan was for WEW282 to complete the scheduled route without taking on additional fuel at any stops en route. At 1225, the OFP for the occurrence flight was completed.

The WEW282 crew, which comprised 2 pilots and 1 flight attendant (FA), reported for duty at the West Wind hangar at CYXE at approximately 1330. The FA proceeded with her duties to get the aircraft cabin ready for the flight, while the captain and First officer (FO) met with the dispatcher for a pre-flight briefing.

The briefing consisted of all of the items required for the flight,Footnote 4 including the current weather; aerodrome and area forecasts for takeoff, en route, destination, alternate and the return trip segments; and the forecast icing in the area of operations.

1.1.3 Saskatoon to Fond-du-Lac

For the departure from CYXE, the captain was seated in the left seat and was the pilot flying (PF). The FO, who was also captain-qualified, was seated in the right seat and was the pilot not flying (PNF). The pilots were planning to switch seats and flying duties for the rest of the day after landing at CYSF.

WEW282 departed CYXE at 1406 and, following an uneventful flight, arrived at CYPA at 1442. WEW282 departed CYPA at 1532, with 15 passengers on board, and was cleared by air traffic control (ATC) to fly direct to CZFD at flight level (FL) 220.Footnote 5 The takeoff, climb, and cruise segments of the flight were uneventful.

At 1657, WEW282 was in cruise flight approximately 86 nautical miles (NM) south of CZFD when ATC issued a clearance to depart controlled airspace and provided the crew with the 1654 automated weather observation system (AWOS) aerodrome routine meteorological report (METAR) for CYSF (see section 1.7.2.1 Aerodrome routine meteorological reports).

At 1658, the crew of a Saab 340 operating as Transwest Air flight 280 (TW280) informed WEW282 that TW280 was also inbound to CZFD and was approximately 6 minutes ahead. Shortly thereafter, the crew of another aircraft, a Beechcraft 1900 operating as WEW660, announced that they were also inbound to CZFD and were ahead of TW280.

At 1702 civil twilight ended, and night began. Four minutes later, the WEW282 flight crew briefed for the RNAV (GNSS)Footnote 6 instrument approach procedure for landing on Runway 28. At 1710, the crew of TW280 broadcasted that they were 6 miles to the south of the airport and had the runway in sight.

At 1713:15, while WEW282 was descending through 8100 feet,Footnote 7 it began to encounter in-flight icing. The captain instructed the FO to increase ice protection from Level 1 to Level 2 (see section 1.6.2 Aircraft ice protection systems), and the aircraft’s torque was increased from less than 5% to 50%.

Thirty seconds later, while the aircraft was descending through 7600 feet, the master caution single chime sounded and the CAUTION and ICINGFootnote 8 alert lights illuminated, indicating that ice accretion was detected on the ice probe. Five seconds after icing conditions were detected by the ice detector, the captain instructed the FO to engage Level 3 ice protection (pneumatic airframe de-icing systems).

Three minutes after the probe initially detected icing conditions, as the aircraft was descending through 4700 feet, the torque was reduced to 35% and the aircraft performance monitoring (APM)Footnote 9 system’s DEG PERF light illuminated.Footnote 10 The ICING light remained illuminated.

At 1719:50, as the aircraft was established on the extended runway centreline, the APM’s INC SPD (increase speed) flashing light illuminated.Footnote 11 The airspeed was 156 knots indicated airspeed (KIAS), and the descent rate was approximately 250 fpm. Shortly thereafter, the torque increased to 55% and airspeed increased to 167 KIAS. Fourteen seconds after the initial illumination, the INC SPD light extinguished; however, the APM’s DEG PERF light remained illuminated.

At 1720:43, while the aircraft was descending through 3000 feet, the flaps were set to 15° and the landing gear was extended. At the same time, the APM’s DEG PERF light extinguished.Footnote 12 The descent rate increased to 750 fpm.

Forty seconds later, while the aircraft was descending through 2900 feet, the ICING light also extinguished and remained off for the remainder of the flight, indicating that ice was no longer accreting on the probe. Flaps were extended to 30° at 1721:57.

At 1722:23, while the aircraft was descending through 2100 feet, both pilots acquired visual reference with the runway, and 1 minute later, after letting the de-icing system run through 1 more cycle, the crew returned ice protection to Level 1. Following this selection, the crew briefly discussed the presence of residual ice on the aircraft.

While the aircraft was descending through 1450 feet, the captain disengaged the autopilot. No anomalies were noted during the remainder of the approach, and the aircraft landed on Runway 28 at 1724:44.

1.1.4 On the ground at Fond-du-Lac

At 1726:19, WEW282 cleared the runway and taxied to the apron. WEW660 already had its engines running and was ready to start taxiing for departure, which it did immediately after WEW282 taxied past, and subsequently departed from Runway 10.

At 1727:42, once the aircraft was stopped on the apron, the flight crew of WEW282 engaged the parking brake, shut down the left engine, and activated the propeller brakeFootnote 13 for the right engine. Eight of the 15 passengers on board were destined for Fond-du-Lac and disembarked; the other 7 were destined for later stops and remained on board.

The flight crew then left the cockpit to assist with loading. At about 1745, loading was completed, and the captain returned to the cockpit and began programming the next flight into the flight management system (FMS) and calculating the weight and balance. The FO proceeded to the airport terminal building to escort passengers to the aircraft.

At 1754, TW280 taxied away from the apron and subsequently departed from Runway 28. The FO of WEW282 then escorted 15 passengers to the aircraft; these passengers included 1 child and 1 passenger in a wheelchair.

Once the passengers had boarded the aircraft, the FO walked around the aircraft to conduct a visual external inspection. Although this inspection was accomplished during the hours of darkness on the dimly lit apron and without the use of a flashlight, the FO observed contamination on the nose of the aircraft and some residual ice on the leading edges of the wings, engine intakes, and the vertical stabilizer. The FO completed the external inspection by visually examining the left wing from the top of the airstair door on the left side of the rear cabin.

By 1803:40, the FO had returned to the cockpit. He told the captain that he noticed that there was more ice outside than he had originally thought. The captain, who was working on departure calculations, acknowledged, and then the FO pointed out that ice was also sticking to the power lines. The captain again acknowledged, and, referring to the ice on the power lines, the FO said that the ice was on the aircraft as well. The captain responded in a way that indicated he was not concerned. The discussion lasted for 9 seconds before the captain returned to his calculations.

Within 15 seconds from the beginning of the icing discussion, the captain told the FO that they had 7 more passengers than anticipated, and instructed the FO to begin the before-start checklist.

1.1.5 Taxiing for departure from Fond-du-Lac

The proposed flight plan for WEW282 for the 42 NM eastbound flight from CZFD to CYSF was to fly direct at an altitude of 7000 feet.

At 1805, while the before-start check was being conducted, the captain briefed the normal speeds on the 35 000-pound take-off card (Figure 1) because the aircraft was heavier than originally planned. The crew then set the speed bugs as per the normal (non-icing) numbers on the card: V1/VR 100 KIAS,Footnote 14 V2 106 KIAS,Footnote 15 VLO 127 KIAS,Footnote 16 and VLO icing 147 KIAS.Footnote 17

By 1806:35, the right engine propeller brake was released, the left engine was started, and the aircraft began to taxi for Runway 28.

The taxi and backtrack for Runway 28 was slightly longer than that for Runway 10, and the takeoff was in the opposite direction of the planned flight. However, the captain discussed that although the winds were light, they were favouring Runway 28, and because the aircraft was heavier than originally planned, it would be better to use the into-wind runway.

The FO responded that he agreed and that, with the amount of ice that was on the aircraft, he would rather have a couple of knots of headwind.

As part of the taxi checks, at 1807:45 the captain conducted the take-off briefing. During this briefing, the captain mentioned the known potential threat of departing toward an area of darkness, and how they would mitigate this.

The captain called for before-takeoff checks at 1809:07. In response to the checklist item regarding anti-ice, the captain decided that Level 1 icing protection was sufficient for takeoff.

At 1810:48, the aircraft was stopped on the threshold of Runway 28, in position for takeoff. Ten seconds later, while completing the before-takeoff checks, the captain visually observed the left spoiler from the cockpit window and acknowledged having it in sight. Shortly afterward, the FO visually observed the right spoiler from the cockpit window and reported that he had it in sight, but just barely. This spoiler check is considered the last-chance inspection to check for surface contamination before takeoff.

Between 1811:33 and 1811:58, the crew completed the line-up checks and then made a traffic advisory broadcast on the aerodrome traffic frequency to report that they were rolling for departure from Runway 28. This was the last radio transmission from the WEW282 flight crew before the occurrence.

1.1.6 Takeoff from Fond-du-Lac

At 1812:01, the captain began to increase power, and WEW282 commenced the take-off roll. As instructed by the captain, the FO set the power to the appropriate take-off setting and, at 1812:18, announced that the airspeed was increasing through 70 KIAS.

As the aircraft reached a speed of 100 KIAS at 18:12:29, the FO announced that the speed had reached V1 and VR, and the captain began to rotate the aircraft to 10° of nose-up pitch.

The aircraft lifted off the runway at 1812:31, and, within a second, the FO announced a positive rate of climb, which was immediately followed by the captain instructing the FO to raise the gear and engage the yaw damper. The airspeed was 108 KIAS, and the FO raised the landing gear selector. At that same moment, the aircraft began an uncommanded roll to the left.

The captain immediately applied control inputs to stop the roll, which increased to full right aileron, and the aircraft quickly went from a left bank to right bank. The captain responded to the right bank with partial left aileron input, and the aircraft quickly went into a left bank.

At 1812:37, while applying correction for the second roll to the left, which again increased to full right aileron, the captain asked if this was being caused by the ice. These oscillations continued, and their severity began to increase.

At 1812:39, while the aircraft was reaching a peak left bank of 32.7°, the aircraft’s pitch increased through 20.7°, the angle of attack (AOA) vane angle increased through 18.4°, and the stall warning sounded for 1.6 seconds. The FO announced the stall, and the captain moved the elevator from 9.5° nose up to 14.5° nose down.

At 1812:42, with the aircraft now in a 24.0° right bank, it reached its peak height of 142 feet above ground at 107 KIAS. The captain called for maximum power, and the FO pushed both power levers to the maximum. Airspeed began to increase.

At 1812:46, the stall warning sounded again, and the aircraft’s enhanced ground proximity warning system (EGPWS) announced a BANK ANGLE warning. The aircraft was rolling left, through 40.0° of left bank, with full right aileron applied, at 122 KIAS, and beginning to descend.

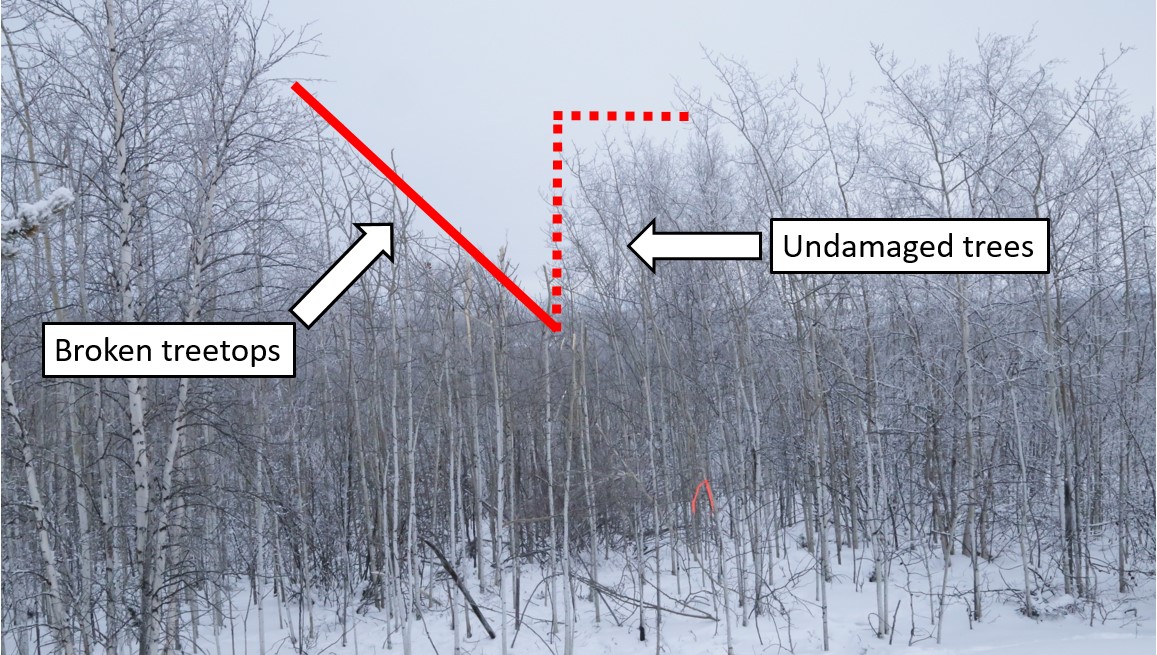

One second later, the aircraft’s left bank reached its peak of 63.3°, and the aircraft began to contact trees. The stall warning sounded briefly.

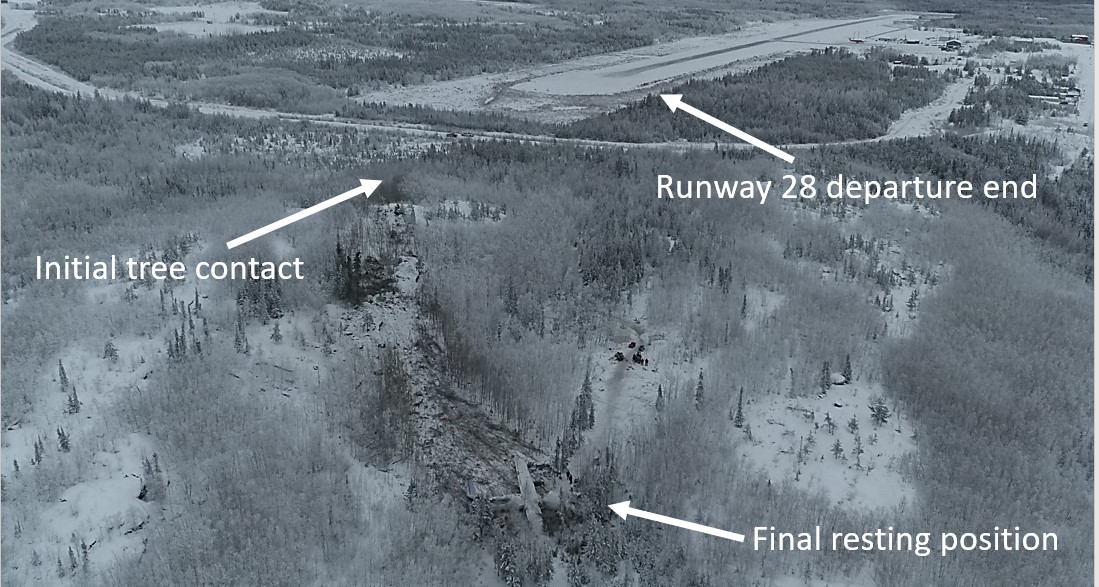

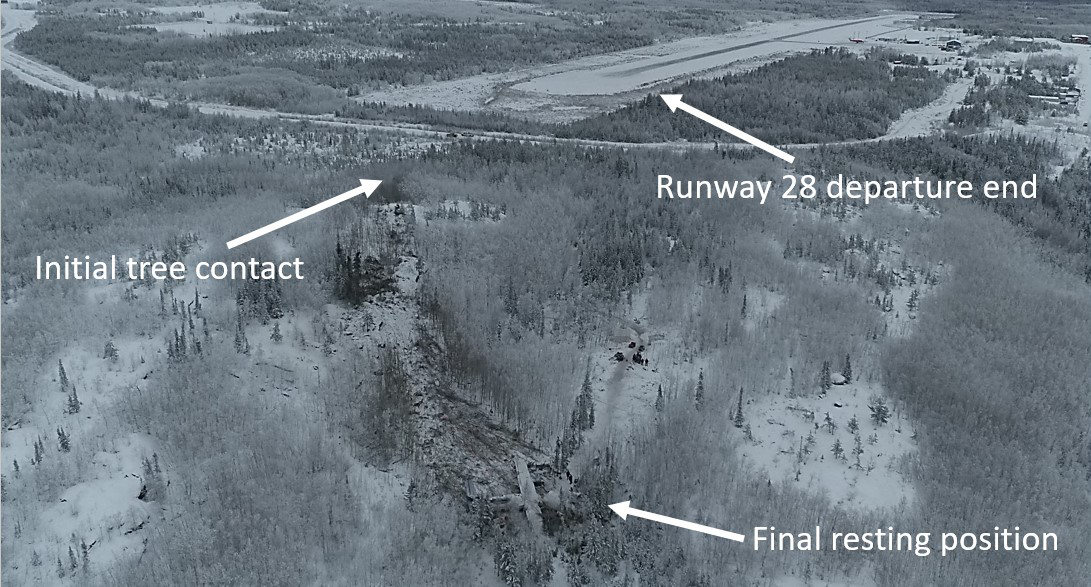

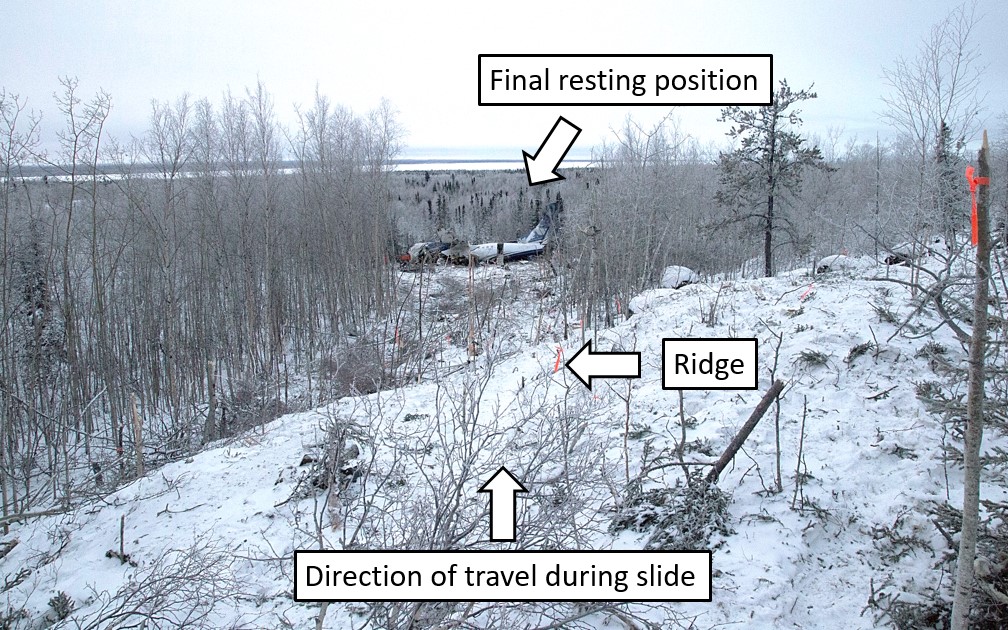

At 1812:48 the aircraft collided with the ground in a 32.0° left bank with approximately 4° of nose-up pitch. The aircraft slid along the ground for about 9 seconds and came to a rest at 1812:57 (Figure 2).

1.1.7 Post-accident events

At 1812:57, the captain and FO, still strapped into their seats with the cockpit section sitting on its right side, began to carry out emergency procedures. To ensure the engines were shut down, the FO pulled the right engine fire handle at 1813:25 and the left fire handle shortly afterward.

At 1814:39, the flight crew carried out the checklist for ON GROUND ENG FIRE OR SEVERE MECHANICAL DAMAGE and set the emergency locator transmitter to ON. After completing that checklist, the pilots determined there was no communication between the cabin and the flight deck, and chose not to carry out the ON GROUND EMERGENCY EVACUATION checklist.

At 1817, the FO called West Wind dispatch on his cellphone to let them know about the accident and to request assistance. A West Wind flight follower who received the phone call activated the company emergency response plan.

1.2 Injuries to persons

All 22 passengers and 3 crew members were injured (Table 1). Many were rendered temporarily unconscious. The captain and 9 passengers were seriously injured, and 1 of the seriously injured passengers died 12 days after the accident as a result of the injuries received.

| Degree of injury | Crew | Passengers | Persons not on board the aircraft | Total by injury |

|---|---|---|---|---|

| Fatal | 0 | 1 | – | 1 |

| Serious | 1 | 8 | – | 9 |

| Minor | 2 | 13 | – | 15 |

| Total injured | 3 | 22 | – | 25 |

For more detailed information on injuries, see section 1.15.4 Direct effect on occupants.

1.3 Damage to aircraft

The aircraft was destroyed.

Further detailed description of damage to specific structures and components is provided in section 1.12 Wreckage and impact information.

1.4 Other damage

The aircraft collided with trees and the ground in a forested area, causing localized disruption to the forest in the impact zone and debris field.

The aircraft departed CZFD with approximately 3068 L of Jet A fuel on board; however, only 1200 L were recovered following the accident. The remaining 1800 L were spilled on the forest floor during the accident sequence.

1.5 Personnel information

1.5.1 General

Records indicate that the captain, FO, FA, and dispatcher were all certified and qualified with respect to their active roles, in accordance with existing regulations.

| Captain | First officer | |

|---|---|---|

| Pilot licence | Airline transport pilot licence (ATPL) | Airline transport pilot licence (ATPL) |

| Medical expiry date | 01 June 2018 | 01 April 2018 |

| Total flying hours | 5990 | 15 769 |

| Flight hours on type | 1500 | 7930 |

| Flight hours in the 7 days before the occurrence | 18.5 | 7.0 |

| Flight hours in the 30 days before the occurrence | 94.3 | 77.6 |

| Flight hours in the 90 days before the occurrence | 212.3 | 200.5 |

| Flight hours on type in the 90 days before the occurrence | 212.3 | 200.5 |

| Hours on duty before the occurrence | 4.7 | 4.7 |

| Hours off duty before the work period | 19.5 | 19.5 |

1.5.2 Captain

The captain was hired by West Wind on 25 June 2010. In November 2015, he began operating the ATR 42 as an FO and, by July 2017, he was promoted to captain. He had approximately 400 hours as pilot-in-command (PIC)Footnote 18 on the ATR 42.

The captain was on reserve duty the day before the occurrence but did not fly. On 13 December 2017, he began duty at 1330 and reported feeling rested. The planned duty period was about 9 hours. Fatigue was not considered a contributing factor in this occurrence.

A review of training records determined that the captain had completed all required company initial and recurrent training, including:

- Emergency/Fire Evacuation Procedures – 07 May 2016

- SMS [Safety Management Systems] for Employees – 23 January 2017

- Ground and In-Flight Icing Training – 26 September 2017

- ATR 42 Recurrent Ground School – 04 June 2017

- Crew Resource Management (CRM) – 06 June 2017

1.5.3 First officer

The FO was hired by West Wind on 15 June 2000 as an FO on the British Aerospace BAE-31 Jetstream. In November 2005, he began flying the ATR 42 as an FO. In May 2011, he was promoted to a captain position on the ATR 42. On the day of the occurrence, the FO, who usually flew as a captain, was scheduled to fly as an FO due to the unavailability of FOs.

The FO was on reserve duty the day before the occurrence but did not fly. On 13 December 2017, he began duty at 1330 and reported feeling rested. The planned duty period was about 9 hours. Fatigue was not considered a contributing factor in this occurrence.

A review of training records determined that the FO had completed all required company initial and recurrent training, including:

- Emergency/Fire Evacuation Procedures – 01 June 2016

- SMS for Employees – 29 January 2017

- Ground Icing Training – 23 September 2017

- In-Flight Icing Training – 30 September 2017

- ATR 42 Recurrent Ground School – 04 June 2017

- Crew Resource Management – 17 June 2017

1.5.4 Flight attendant

The FA was hired by West Wind on 09 February 2015 and completed initial FA training on 16 March 2015. She then completed line indoctrination on the ATR 42 on 26 March 2015. In March 2017, the FA completed annual FA recurrent training, which included CRM training.

The FA had been on leave for 5 weeks before the accident. West Wind required the FA to review emergency procedures before returning to work. The FA was on reserve duty the day before the occurrence but did not fly. The occurrence flight was the second day back to work for the FA.

On 13 december 2017, the FA began duty at 1330 and reported feeling rested. The planned duty period was about 9 hours. Fatigue was not considered a contributing factor in this occurrence.

1.5.5 Flight dispatcher

The dispatcher was hired by West Wind in 2012 in another role and completed initial dispatch training in November 2017.

On 13 december 2017, the dispatcher began duty at 1200 and reported feeling rested. The planned duty period was about 8 hours. Fatigue was not considered a contributing factor in this occurrence.

1.6 Aircraft information

1.6.1 General

The ATR 42-320 is a pressurized twin-engine turboprop produced by ATR and type-certified in the transport category.

The occurrence aircraft was manufactured in 1991 and acquired by West Wind in 2012. It was configured with 44 passenger seats.

| Manufacturer | ATR-GIE Avions de Transport Régional (ATR) (formerly Aerospatiale) |

|---|---|

| Type, model, and registration | ATR 42-320, C-GWEA |

| Year of manufacture | 1991 |

| Serial number | 240 |

| Certificate of airworthiness / flight permit issue date | 04 March 1988 |

| Total airframe time | 26 481.3 hours, 32 051 cycles |

| Engine type (number of engines) | Pratt & Whitney Canada PW121 (2) |

| Propeller/rotor type (number of propellers) | Hamilton Sundstrand Model 14SF-5 (2) |

| Maximum allowable take-off weight | 37 258 pounds |

| Recommended fuel type(s) | MIL-T-5624, Grade JP5, AST-MD-1655 Grades JET A, Jet A1 |

| Fuel type used | Jet A |

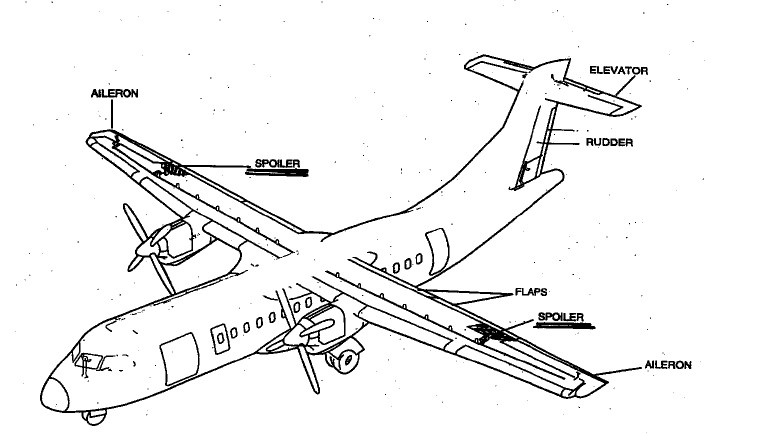

The ATR 42-320 is built with the wing mounted at the top of the fuselage. The empennage is configured with the horizontal tail surface mounted on the top portion of the vertical stabilizer, also known as a T-tail. The height above ground of the wings is 3.76 m and of the horizontal tail surface is 7.75 m. These horizontal surfaces have a combined surface area of approximately 66.2 m2 (Figure 3).

1.6.2 Aircraft ice protection systems

The ATR 42 is equipped with an icing advisory system. This system includes an ice detector located on the left wing, an icing evidence probe located on the lower frame of the left cockpit side window and visible to both pilots, and an indicator light located on the central annunciator panel.

The ATR 42 ice protection system permits the aircraft to operate in icing conditions. Ice protection is provided to critical areas of the aircraft by 2 aircraft systems: an electrical system that provides heat to the pitot and static ports, AOA vanes, windshields, propellers, and flight control horns; and a pneumatic system that provides bleed air from the engines to the outboard leading-edge wing de-icing boots, horizontal stabilizer leading-edge boots, engine air intakes, and engine gas path (Figure 4).

The ice protection system is controlled by an overhead panel in the cockpit. The panel is divided into 3 segments that allow the flight crew to select the desired level of protection. Level 1, 2, and 3 are terms used by West Wind to describe the icing protection that has been selected on the aircraft. Level 1, or “permanent protection,” includes the probes, ports, and front windows. Level 2, or “anti-icing” adds propellers, horns, side windows, and engine intakes. Level 3 or “de-icing” adds all remaining protection, including wings and stabilizer.

1.6.3 Procedures for atmospheric icing conditions

When atmospheric icing conditions are present, aircraft performance can be degraded. To account for this, specific procedures must be followed. These procedures normally include engaging icing protection and adjusting speeds to ensure that margins of safety are maintained. The change to these speeds can also have an effect on take-off and landing distances.

The limitations section in the ATR 42 Airplane Flight Manual (AFM) states that

Atmospheric icing conditions exist when :

– OAT [outside air temperature] on the ground and for take-off is at or below 10° C or when TAT [total air temperature] in flight is at or below 10°C,

– and visible moisture in any form is present (such as clouds, fog with visibility of less than one mile, rain, snow, sleet and ice crystals). Footnote 19

The normal procedures section describes what must be done when these conditions are present:

Procedure for operation in atmospheric icing conditions :

- As soon as and as long as atmospheric icing conditions exist, the following procedures must be applied :

ANTI–ICING (propellers, horns, side–windows, engines)………………………………ON

PROP MODE SEL................................................................................................ According to SAT

NP set.................................................................................................................................... set ≥ 86 %

Minimum maneuver / operating icing speed...................... BUGGED AND OBSERVED

ICE ACCRETION............................................................................................................... MONITOR

NOTE : horns anti-icing selection triggers the illumination of the ”ICING AOA” green light and lowers the AOA stall warning threshold.Footnote 20

1.6.4 Take-off performance calculations

When determining take-off performance calculations, numerous factors must be considered, including take-off weight, wind, temperature, pressure altitude, equipment in use, icing conditions, runway length available, runway surface and slope, and runway surface contamination. Because most of these factors cannot be changed, take-off performance calculations normally result in adjustments to the take-off weight to accommodate for the other factors. For example, procedures require increased take-off speeds in atmospheric icing conditions, which result in longer take-off distances and greater accelerate-stop distances.

Similarly, runways that are softer, such as those made of gravel or those that are contaminated, result in performance degradation, requiring greater take-off distances than those with dry, hard surfaces. At locations where runways are relatively short, the calculated take-off distances can be greater than the distances available, necessitating a reduction in take-off weight to accommodate. The specific details of how to calculate this performance, and the resulting accommodations, are published in the AFM.

1.6.4.1 Selection of icing speeds

When aircraft are designed, they must meet airworthiness standards in order to receive type certification. Many of those standards are related to take-off performance and include ensuring that obstacle clearance is maintained throughout the take-off path, even in the event of an engine failure while operating in icing conditions.

The standards contained in Chapter 525 – Transport Category Aeroplanes of the Airworthiness Manual, define the limits of this take-off path:

The take-off path extends from a standing start to a point in the take-off at which the aeroplane is 1,500 feet above the take-off surface […]Footnote 21

Thus, when determining whether icing procedures should be used on departure, flight crews must consider that the take-off path continues from the ground up to 1500 feet AGL. This flight path duration is also part of the certification standards,Footnote 22 which ensure that aircraft are designed to meet obstacle clearance requirements when the aircraft enters icing conditions during takeoff.

Even though the standards and regulations state that the take-off path continues to 1500 feet, there is no specific guidance in the manufacturer’s official documents (AFM, Flight Crew Operating Manual [FCOM]), West Wind manuals, or in the Transport Canada Aeronautical Information Manual (TC AIM) with respect to the use of icing procedures if icing conditions are perceived to exist at any point below this altitude.

The only reference identified during the investigation that suggested the take-off path extended up to the 1500 feet limit for the purposes of icing procedures was found in the Cold Weather Operations brochure published by ATR, which states the following:

Take-off in atmospheric icing conditions

According to FCOM 2.02.08 the crew must select “anti-icing” ON to prevent ice accretion on airframe. As soon as “anti-icing” is ON, what [sic] is confirmed by the “ICING AOA” light ON, the crew must monitor speed to stay in the flight envelope.

Furthermore takeoff speeds are increased while “ICING AOA” light is ON, leading to performance reduction.

NOTE: The take-off is assumed to last until the aircraft has reached 1500ft AGL or when 10 minutes elapsed from brakes release, whichever occurs first.Footnote 23

Although there were a few clouds reported below 1500 feet at the time of departure from CZFD, there was no active precipitation observed while the aircraft was on the ground. As a result, the crew determined that icing procedures were not required, chose to leave anti-icing off (although Level 1 was active), and selected non-icing speeds for the takeoff. Additionally, because the crew determined that atmospheric icing conditions did not exist, and non-icing speeds were used, the calculated take-off distance required was not increased, and take-off weights were not decreased to accommodate.

1.6.4.2 Unpaved runways

To provide guidance to those operating on unpaved surfaces, Transport Canada (TC) published Advisory Circular (AC) 700-011 in 2012. With regard to operations in winter, the advisory states:

(1) During periods of extended and deep frost, unpaved surfaces such as gravel runways can have strength characteristics similar to those of runways with paved hard surfaces. Operational experience has indicated that two weeks of ambient temperatures of −20°C or lower may be necessary for an unpaved runway to achieve strength similar to a paved hard surfaced runway. Once frozen solid, the runway will remain in this state, until ambient temperatures increase to above freezing.

[…]

(3) All applicable AFM (Aircraft Flight Manual) performance factors should be applied for frozen unpaved runway operations. The performance factors for operations contained in CASS (Commercial Air Services Standard) 724.44(3) should be applied when operating in accordance with this standard.Footnote 24

The runway surface at CZFD is treated gravel (see specific details in section 1.10 Aerodrome information). The ATR 42 AFM contains performance supplements for operations on dry unpaved runways, but not for operations on frozen unpaved surfaces.

Without specific performance penalties published by the manufacturer, and with guidance stating that frozen unpaved surfaces had qualities similar to paved surfaces, the operator and flight crew determined that a performance penalty was not required for the departure.

1.6.4.3 Runway surface contamination

Similar to the performance degradation that results from unpaved runways, surface contamination such as water, ice, or snow, can affect aircraft take-off performance.

At 0700 on the morning of the occurrence, CZFD issued a runway surface condition report for Runway 10/28 that recorded the conditions as 60% bare and dry and 40% compacted snow patches. A similar report was issued the following morning, after the accident; however, this report recorded that the compacted snow patches were no longer present.

The ATR 42 AFM states that, if more than 25% of the runway is covered by compacted snow, it should be considered contaminated, and this condition is to be used when determining aircraft performance.Footnote 25

Given that the most recent runway surface condition report had been issued 11 hours before the time of departure from CZFD, and the restricting contamination was not present 13 hours later, it could not be determined what the actual surface conditions were at the time of departure. However, surface contamination was not considered when calculating the take-off weight of the occurrence flight.

1.7 Meteorological information

This accident involved critical surfaces of an aircraft that became contaminated with ice as a result of in-flight ice accretion on approach and further ice accretion on the ground. This ice accretion was a result of the weather conditions at the time.

This section will focus on the forecast weather conditions, the actual conditions, and how the ice formed on the aircraft.

1.7.1 Forecast conditions

1.7.1.1 Flight planning

There are no recorded weather observations for CZFD, and no METARsFootnote 26 or aerodrome forecasts (TAFs)Footnote 27 are issued for the airport. The nearest airport for which METARs and TAFs are issued is CYSF, 42 NM east of CZFD. However, personnel at CZFD are available to provide a general description of local weather conditions on request.

Because there are no formal weather products for CZFD, pilots and dispatchers use the graphic area forecasts (GFAs)Footnote 28 for the area, as well as the METAR and TAF for CYSF, in planning flights to CZFD.

At 1330, after the flight crew of WEW282 arrived for their flight and approximately 1 hour before the flight’s scheduled departure time from CYXE, a company dispatcher briefed the flight crew on the weather conditions for the route.

The briefing included information about the conditions at CZFD, as observed by local personnel, and a review of the GFA for northern Saskatchewan, including the clouds and weather chart, and the icing, turbulence, and freezing level chart.

The crew were given a printed weather package, which included copies of the GFAs, METARs, and TAFs for the intended route of the flight. At the time of the briefing, there were no recent pilot weather reportsFootnote 29 and no significant meteorological information (SIGMET)Footnote 30 or aviation weather advisories (AIRMET).Footnote 31

1.7.1.2 Aerodrome forecasts

The most recent TAFFootnote 32 for CYSF available at the time of briefing had been issued at 1143. The forecast was based on automatic observations and predicted that, at the time of WEW282’s arrival at CZFD, the conditions at CYSF would be

- variable winds at 3 knots,

- visibility greater than 6 SM,

- no precipitation, and

- overcast ceiling at 1500 feet AGL.

The forecast also predicted a temporary change in weather between 1200 and 2400, for an hour or less, that involved a decrease to 4 SM visibility in light snow and mist, and an overcast ceiling at 700 feet AGL.

This aerodrome forecast was updated throughout the day, and the most recent forecast available at the time of WEW282’s departure from CZFD had been issued at 1739. This forecast predicted the conditions would be

- winds from 280°T at 5 knots,

- visibility greater than 6 SM in light snow,

- scattered clouds at 1000 feet AGL, and

- an overcast ceiling at 2000 feet AGL.

The forecast also predicted a temporary change in weather between 1800 and 0600, for an hour or less, that involved a decrease to 2 SM visibility in light snow and mist, scattered cloud at 700 feet AGL, and an overcast ceiling at 1000 feet AGL.

The guidelines for reporting TAFs in Canada are found in the Manual of Standards and Procedures for Aviation Forecasts.Footnote 33 In the manual, the only provisions for the forecast of icing in a TAF is freezing rain (FZRA), freezing drizzle (FZDZ), or freezing fog (FZFG). Fog and FZFG is to be forecast only if visibility is expected to be below ⅝ SM. There is no provision for forecasting freezing mist (FZBR) for conditions in which icing is expected to occur on surfaces, with visibility of ⅝ SM or greater, in the absence of precipitation.

Similar guidance is found in the International Civil Aviation Organization’s (ICAO’s) Manual of Aeronautical Meteorological PracticeFootnote 34 and the U.S. Federal Aviation Administration (FAA) Advisory Circular (AC) 00-45H.Footnote 35 The FAA circular specifically states, “FZBR is not a valid significant weather combination and will not be used in TAFs.”

1.7.1.3 Graphic area forecasts

GFAs are issued 4 times daily, with a validity period of 12 hours. Each issue is a collection of 6 charts: 2 charts valid at the beginning of the forecast period, 2 charts valid 6 hours into the forecast period, and the final 2 charts valid 12 hours into the forecast period. Each specified time has a chart depicting clouds and weather conditions, and a second chart depicting icing, turbulence, and freezing level conditions.

The most recent GFAs for the Prairies region at the time of briefing had been issued at approximately 1130 and were valid for 1200 and 1800. The information in the GFAs relevant to CZFD is provided in Table 4.

| Valid time | Clouds and weather | Icing, turbulence, and freezing level |

|---|---|---|

| 1200 | Overcast clouds based at 2000 to 3000 feet above sea level (ASL), topped at 8000 feet ASL, and visibility more than 6 SM | Moderate mixed icing in clouds based at 2000 to 3000 feet ASL and topped at 8000 feet ASL |

| Patchy areas of visibility 4 SM to greater than 6 SM in light snow and mist, ceilings between 800 to 1500 feet AGL | Moderate mixed icing in clouds based at 2000 to 3000 feet ASL and topped at 8000 feet ASL | |

| 1800 | Broken layer of clouds based at 2000 to 3000 feet ASL, topped at 7000 feet ASL; visibility more than 6 SM | Patchy areas of moderate rime icing in clouds based at 2000 feet ASL and topped at 7000 feet ASL |

| Patchy areas of visibility 3 to 6 SM in light snow; ceilings between 600 and 1200 feet AGL | Local areas of moderate mixed icing from the surface to 2000 feet ASL due to local freezing drizzle |

The GFA did not predict any icing outside of clouds or precipitation, such as FZFG.

The next GFA was issued at 1731 (clouds and weather) and 1732 (icing, turbulence, and freezing level) and forecast similar conditions for the CZFD area at 1800; however, the crew did not receive this new chart before their departure at 1812.

1.7.2 Actual conditions

1.7.2.1 Stony Rapids Airport aerodrome routine meteorological reports

At the time of initial briefing, the latest METAR for CYSF had been issued at 1300 and indicated calm winds, visibility 9 SM in light snow, an overcast ceiling at 900 feet AGL, temperature −11 °C, dew point −12 °C, and an altimeter setting of 30.00 inHg.

Conditions at CYSF stayed relatively consistent throughout the day. The winds remained light; however, the ceiling tended to rise toward 2000 feet AGL, and the visibility varied between 9 SM and 2 SM in light snow and occasionally mist.

While on descent into CZFD, the flight crew received the latest CYSF weather, which recorded the conditions at 1654 as winds from 260°T at 3 knots, visibility 2½ SM in light snow, a few clouds at 1400 feet AGL with a broken ceiling at 2300 feet AGL and an overcast layer at 3700 feet AGL, temperature −10 °C, dew point −10 °C, and an altimeter setting of 30.00 inHg. The crew also used this weather report for CYSF during preparation for departure out of CZFD.

Between 1654 and WEW282’s taxi for departure from CZFD at 1807, there were 13 updates to the weather at CYSF. By 1722, the automatic system at CYSF started to record icing (ICG) on its ground-based sensor, and it reported icing in each of the 7 updates between 1722 and 1800.

The 1800 METAR for CYSF recorded the conditions as winds from 270°T at 4 knots, visibility 9 SM with no precipitation, an overcast ceiling of 1900 feet AGL, temperature −10 °C, dew point −10 °C, an altimeter setting of 30.06 inHg, with a remark of icing during the past hour.

The conditions at CZFD at the time of departure were determined to be similar to those at CYSF, although visibility was uncertain, and ceilings were slightly lower, at around 1000 to 1500 feet AGL.

Guidelines for the reporting of METAR weather observations in Canada are found in the Manual of Surface Weather Observation Standards (MANOBS). Observations at some locations, such as CYSF, are taken by an AWOS, and these METARs are annotated with “AUTO.”

There are a few differences between AUTO stations and those with human observers. AUTO stations do not report drizzle (DZ) or FZDZ, but rather will normally report these conditions as rain (RA), FZRA, or freezing – unknown precipitation (FZUP).

If icing occurs that does not involve precipitation or fog, METARs produced by human observers report this icing in the remarks section at the end of the METAR.Footnote 36 In contrast, AUTO METARs report icing (ICG) in the remarksFootnote 37 section, regardless of the source of the icing.

There is no provision in MANOBS for METARs (whether AUTO or human-observed) to report FZBR, similar to TAF reporting.

The icing recorded by the CYSF AWOS at the time of WEW282’s ground stop at CZFD coincided with the presence of light snow; however, a review of reports from earlier in the day showed that icing was occasionally recorded during mist conditions, in the absence of fog or precipitation, therefore indicating FZBR was occurring.

1.7.2.2 Fort Smith Airport aerodrome routine meteorological report

The nearest METAR to CZFD based on human observations is from the Fort Smith Airport (CYSM), Northwest Territories, located 151 NM west of CZFD. From 1500 to 1700, the CYSM METAR reported the presence of light freezing drizzle. From 1719 to 2110, CYSM was reporting light snow.

1.7.2.3 Flight crew observations

On the day of the occurrence, 2 other flights (WEW660 and TW280) were also being operated to and from CZFD.

WEW660 was operating all day in the Lake Athabasca region and mine sites; it arrived at CZFD from CYSF approximately 12 minutes before WEW282. Because of the short distance between CYSF and CZFD, WEW660 maintained an altitude of 4000 feet, which put the aircraft between 2 layers of cloud.

On descent into CZFD, WEW660 picked up a trace of icing, which the crew was able to shed before landing at CZFD. The crew reported that there was no precipitation between when they established visual contact with the runway while on approach and when they departed from CZFD. The aircraft was on the ground for approximately 15 minutes and did not de-ice while there.

TW280, was a scheduled flight from CYXE operating the same route as WEW282. TW280 was also inbound to CZFD from the south and was approximately 6 minutes ahead of WEW282.

The crew of TW280 reported a significant amount of icing, which accumulated quickly on the descent from its cruise altitude of 20 000 feet. The crew expedited the descent to minimize exposure to the icing conditions and reported that the worst of the icing was in the latter part of the descent, while below 10 000 feet. After the crew established visual contact with the runway, the aircraft did not encounter any precipitation on approach.

After landing at CZFD, the crew determined that the aircraft’s de-icing systems were effective at keeping ice off the critical surfaces, although some ice remained on unprotected surfaces. The aircraft was not de-iced while on the ground at CZFD and departed after approximately 35 minutes.

WEW282 encountered icing conditions for approximately 8 minutes between 8100 feet and 2900 feet while on descent and approach. The crew of WEW282 did not observe precipitation between when they established visual contact on approach and when the flight departed. The aircraft was on the ground for approximately 48 minutes.

1.7.3 Aircraft icing conditions

1.7.3.1 General

Atmospheric conditions can lead to the formation of ice on the leading-edge surfaces of an aircraft when in flight and on the whole aircraft when it is on the ground. These conditions are referred to as “atmospheric icing conditions” or “aircraft icing conditions.”

1.7.3.2 Hazards of icing

The hazards of aircraft icing are well known to the flying community; however, the fact that small amounts of ice on an aircraft can have a detrimental effect is often misunderstood and underestimated.

TC’s Guidelines for Aircraft Ground Icing Operations state the following:

A very small amount of roughness, in thickness as low as 0.40 mm (1/64 in.), caused by ice, snow or frost, disrupts the air flow over the lift and control surfaces of an aircraft. The consequence of this roughness is severe lift loss, increased drag and impaired manoeuvrability, particularly during the take off and initial climb phases of flight. Ice can also interfere with the movement of control surfaces or add significantly to aircraft weight. There is no such thing as an insignificant amount of ice. Footnote 38

Aircraft manufacturers take the hazard of icing into consideration when designing an aircraft and its lifting and control surfaces. ATR’s Cold Weather Operations brochure states:

In order to ensure a satisfactory behaviour, aircraft are carefully designed so that stall will occur initially at the inner portion of the wing and spread toward the tip as angle of attack increases. Roll moments and abruptness of lift drop are then minimised.

This stall behaviour can be completely jeopardized by ice accretions that have no particular reason to be symmetrical or regular along the entire span of the wing. Footnote 39

1.7.3.3 In-flight icing

Ice can form on aircraft in flight, mainly as a result of 3 processes: supercooled water droplets, freezing of liquid water, or the transition of vapour directly to ice. Depending on the process involved and the conditions, these accretions are normally classified into 4 categories: clear ice, rime ice, mixed ice, and hoarfrost. All of these types degrade performance, although to varying degrees.

All aircraft are affected negatively when accumulating ice in flight. However, many aircraft types are certified for flight in icing conditions and are equipped with systems to shed the ice or prevent it from forming on the aircraft’s critical surfaces when in flight.

Aircraft anti-icing systems are designed to prevent accumulation, and de-icing systems, to remove it. These systems are designed in general for in-flight icing, and, as a result, protect only the leading edges of the control surfaces where ice normally begins to adhere.

As a result of this incomplete coverage and normal limitations of the de-icing system, any ice that accumulates on areas outside of the protected areas, or ice that is not entirely shed by the de-icing system, will remain on the aircraft following an icing encounter unless removed by airflow, vibration, contact with warmer or drier air, or ground de-icing equipment.

The FCOM describes the hazard of this residual ice.

Even with airframe de-icers used according to procedure (i.e. as soon as and as long as ice accretion develops on airframe), the leading edges cannot be completely cleared of ice accretion because of existence of “unprotected” elements on the leading edges and continued accretion between two consecutive boots [sic] cycles.

This residual ice on leading edges changes noticeably the characteristics of flight BELOW the minimum operating speeds defined for ice accretion, as follows:

– Control effectiveness remains good, but forces to manoeuver in roll and to a lesser degree in pitch, may increase somewhat.

– Above the reduced angle of attack:

- An aerodynamic buffeting maybe [sic] felt which will increase with the amount of ice accumulated and angle of attack increase.

- Stability may be slightly affected in roll, but stick pusher should prevent angle of attack increase before wing rocking tend [sic] to develop [...]Footnote 40

1.7.3.4 Ground icing

1.7.3.4.1 Ground icing in the absence of precipitation

Most commonly, ground icing occurs as a result of freezing precipitation, such as freezing rain, freezing drizzle, or snow. However, ground icing can also occur in the absence of visible precipitation. Moisture in the air in liquid form (water droplets) or gaseous form (water vapour) can transition into ice or frost on contact with any aircraft surface that is below freezing temperature (0 °C).

Ice and frost affect aircraft performance by disrupting airflow around the critical surfaces, thereby reducing lift, increasing drag, and increasing the stall speed of the aircraft. No aircraft is certified or approved to depart with frost, ice, or snow adhering to its critical surfaces, with the sole exception of a small amount of frost on cold-soaked fuel tanks on specified aircraft.Footnote 41

1.7.3.4.2 Terminology related to ground icing

The underlying source of the ground icing phenomenon can be very complex. The following description has been simplified to aid general understanding, but is by no means a complete technical presentation of the subject.

Frost or ice formation without visible precipitation generally requires that the water vapourFootnote 42 in the air be near saturation conditions. An abbreviated description of the relevant concepts follows.

Water vapour pressure

Air is a mixture of nitrogen, oxygen, water vapour, and other trace gases. Water vapour pressure is a measure of the amount of water vapour in the air (“humidity”). It is typically less than 1% of the total air pressure.Footnote 43

Saturation

There is a theoretical limit to the amount of water vapour in the air at any given temperature. At this limit, the water vapour is saturated.Footnote 44 The saturation limits differ depending on whether one is considering transition into liquid water or into ice.

Condensation

When air is saturated with water vapour, condensation occurs.Footnote 45 Condensation is the transition of gaseous water vapour into liquid water droplets or solid ice crystals.Footnote 46 Condensation from water vapour directly to ice is called deposition or sometimes desublimation; ice conversion directly to water vapour is called sublimation.

Nucleation

Condensation commonly occurs on object surfaces or around microscopic dust particles in the air. These non-gaseous surfaces, called nucleation sites,Footnote 47 provide the necessary molecular structure for water molecules to organize into liquid droplets or ice crystals.

Dew point

The saturation limit is lower at lower temperatures.Footnote 48 If air containing under-saturated water vapour cools at a constant pressure and by a sufficient amount, the water vapour will become saturated and condensation will occur, either as mist droplets suspended in the air or as dew on surfaces. The temperature at which saturation occurs is the dew point. At high relative humidity, water vapour is close to the saturation limit; therefore, the air temperature is close to the dew point.

Supercooled liquid water

Water that remains liquid when cooled below 0 °C instead of transitioning to ice is called supercooled liquid water. It also can form when condensation occurs at dew points below 0 °C.Footnote 49 The temperature to which liquid water can be supercooled depends, in part, on the size of the droplets. Smaller droplets can persist as liquid at lower temperatures than larger ones before freezing.Footnote 50 In the atmosphere, the first cloud droplets may not begin to freeze until −10 °C to −20 °C. The smallest droplets may remain liquid until almost −40 °C.Footnote 51 Therefore, saturated atmospheric conditions below freezing can involve a combination of water vapour, supercooled liquid water droplets suspended in the air (as mist, fog, or cloud), and ice crystals suspended in the air.

Frost point

Similar to dew point, cooling air with under-saturated water vapour can reach the saturation limit with respect to ice. If conditions are suitable for ice-crystal nucleation, water vapour will condense as ice crystals (frost). This temperature is the frost point, which is always higher than the dew point temperature, by approximately 10%. For example, an air mass with a dew point of −10 °C has a frost point of −8.9 °C.

The frost deposition rate depends on a number of factors, including the temperature difference between the surface and the air, and the amount of over-saturation (the “surplus” water vapour beyond the saturation limit).Footnote 52

Latent heat

The condensation or freezing of water releases thermal energy, known as latent heat, into the surrounding air. This energy can affect the rate of freezing. Although it may slow the initial deposition of frost or ice, it will not prevent it. The thermal energy released from condensation will eventually diffuse away from the aircraft by convectionFootnote 53 and conduction within the air.

Mist or fog

The only distinction between mist and fog is the visibility level, as fog is denser. Both mist and fog are liquid water droplets suspended in the air that form as the result of condensation of saturated water vapour. If the temperature is below 0 °C, they are supercooled droplets. Mist droplets (about 0.02 mm diameter)Footnote 54 are about 100 times smaller than rain drops, and individual droplets are generally not discernible to the naked eye.Footnote 55 Mist droplets are about 25 times smaller than drizzle, which has the smallest precipitation drops that fall by gravity.

1.7.3.4.3 The cooling process

As an air mass that contains water vapour cools, whether the water vapour transitions to liquid water, supercooled liquid water, or ice depends on the vapour pressure and the temperature (Figure 5).

At temperatures above 0 °C, the saturation curve (line labelled vapour pressure over water in Figure 5) represents the transition boundary between water vapour and liquid water, with water vapour below the curve. The closer the temperature is to the curve, the higher the relative humidity. Directly on the curve, the water vapour is saturated with respect to liquid water (100% relative humidity), and, above the curve, the water vapour condenses into liquid water droplets in the air (mist or fog) or on an object’s surface (dew).

Below 0 °C, there are 2 saturation curves to consider. The first, the ice-vapour saturation curve (line labelled vapour pressure over ice in Figure 5), represents the transition boundary between water vapour and ice. Below the curve, the water is vapour. On the curve, the water vapour is saturated with respect to ice. Above the curve, the water vapour condenses directly to ice (frost deposition), provided suitable nucleation sites are available for ice crystals to form.

For example, in Figure 5, consider air with water vapour at point A that cools (at constant vapour pressure) upon contacting a cold surface. When it meets the ice-vapour saturation curve at point B, the water vapour will transition to frost crystals. The temperature at point B is the frost point.

If suitable nucleation sites are not available, ice crystals cannot form. Water can remain in the air as vapour that is over-saturated with respect to ice.

The second saturation curve below 0 °C is for supercooled liquid water (line labelled vapour pressure over supercooled water in Figure 5). At point C, the water vapour becomes saturated with respect to liquid water. This temperature is the dew point, below which the water vapour will condense into supercooled liquid water droplets (sub-zero mist).

Supercooled droplets will transition into ice as soon as suitable nucleation conditions are encountered. This can occur rapidly as clear ice forming on contact with any cool surface.Footnote 56 If such supercooled mist droplets at point D encounter an aircraft surface, they will freeze instantly as clear ice.

1.7.3.4.4 Formation of frost versus clear ice

Because supercooled mist droplets will freeze on contact with a cool surface, water vapour close to saturation (high relative humidity) presents a high risk for ground icing at sub-zero air and surface temperatures.

If the air contacts a sub-zero surface that causes the air temperature to drop, the water vapour will be saturated and transition to ice crystals as frost.

If, instead, the air cools on its own, the water vapour will be over-saturated with respect to ice until the dew point is reached. Once the dew point is reached, the vapour will condense to supercooled liquid water droplets as mist. If these supercooled mist droplets then contact a cold surface, they will instantly transition to ice crystals as clear ice.

1.7.3.4.5 Aircraft surface temperature

During WEW282’s flight from CYPA to CZFD, the aircraft climbed to FL220. During the flight, the aircraft was in air below −10 °C for about 1 hour 40 minutes, of which more than an hour was in air from −35 °C to −38 °C. The aircraft structure would have cooled during the flight in the colder air at altitude.

Aircraft surface temperature following landing depends mainly on the air temperature and time spent at altitude. Although an aircraft descends into generally warmer air at lower altitudes, surface temperature change takes time. Some surfaces can still be colder than the surrounding air after the aircraft has landed. In particular, cold-soaked fuelFootnote 57 in the tanks can keep some surfaces colder than the ambient temperature.

On the ground, there can be significant temperature differences across aircraft surfaces and between surfaces and the surrounding air, and these can change over time. Freezing conditions can be encountered on some, all, or none of the aircraft’s surfaces at any given moment.

After the aircraft shuts down, surface temperatures will continue to change in a complex way. Both cold and warm surfaces tend to approach the surrounding air temperature. Heat sources such as engines, an auxiliary power unit, or warm fuel can cause local areas of the aircraft to remain warmer than the ambient temperature. Ambient wind or propwash can carry heat to or away from the aircraft. Changes in air temperature, wind conditions, precipitation, and cloud cover can all affect the local surface temperatures over time. Surfaces ultimately tend to settle at several degrees below the ambient temperature because of radiational cooling.Footnote 58

Any spot on the aircraft with a sub-zero surface temperature is vulnerable to ice formation.

1.8 Aids to navigation

All aids to navigation were serviceable and had no effect on this occurrence. WEW282 was using RNAV navigation for the flight to and from CZFD.

1.9 Communications

CZFD is an uncontrolled airport located within uncontrolled airspace. The airport has an aerodrome traffic frequency (ATF) area with a radius of 5 NM that is centred on the airport and extends vertically up to and including 3900 feet ASL. The ATF is 123.2 MHz.

The crew of WEW282 made all the required ATF calls during their arrival at and departure from CZFD.

1.10 Aerodrome information

The Fond-du-Lac Airport (CZFD) is owned and operated by the Saskatchewan Ministry of Highways and Infrastructure. The airport is located approximately ½ km north of the Fond Du Lac Denesuline First Nation.

CZFD is available for use 24 hours a day, 7 days per week, supporting both day and night visual flight rules and instrument flight rules operations. The airport is normally unattended, and hours of operation are at the discretion of the local contractor, who carries out daily inspections and maintenance work at the airport for the Ministry. There is no de-icing/anti-icing facility or service provider at CZFD, nor is such a facility or provider required by regulations.

1.10.1 Runway 10/28

CZFD has a single runway, Runway 10/28, and at the time of the occurrence Runway 28 was in use. The take-off run, accelerate-stop distance, and landing distance available are all 3805 feet, whereas the take-off distance available is 4297 feet, accounting for a 492-foot clearway at the end. The runway is 75 feet wide and has a treated gravel surface with an uphill slope of 0.43%.

Runway 10/28 at CZFD was reconstructed and sealed in 1999. Before the reconstruction, the runway surface was straight gravel. The process involved spreading and packing gravel over the sub-base before applying the seal (consisting of liquid asphalt and aggregate) to the runway, followed by compaction using a rubber tire roller. After a setting period, the loose gravel was swept off and a second layer of seal was applied using the same process.

1.10.2 Treated gravel guidance

A treated gravel surface, sometimes called chip seal, differs from both gravel and paved surfaces. The surface consists of a firm base of gravel pavement structure, covered with a thin layer of asphalt-stabilized material that helps to keep the moisture out. A variety of asphalt emulsions and cover aggregate combinations can be used when applying a treated (seal) coat, resulting in a surface that can accommodate varying loads.

Since the treated surface is not bonded to the sub-surface, as asphalt is, TC does not consider the runway surface as paved, stating in its 2012 Advisory Circular (AC) 700-011, that

[s]eal coated runways may lack the surface bearing strength of paved hard surface runways, and in this respect are more characteristic of runways with unpaved surfaces.Footnote 59

Since the most common cause of operational problems on unpaved runways is failure of the surface layer caused by shear under high tire pressure, a measurement of the surface shear strength of the runway surface, called the California bearing ratio (CBR), is often used to determine a tire pressure limit for a given runway surface.

This ratio can be expressed as a percentage or as a whole number from 0 to 100. In the summer of 2009, Runway 10/28 at CZFD was measured and determined to have an average CBR value of 44.4. This measurement met the requirements in the ATR 42 AFM for inclusion of a penalty when calculating take-off performance; however, the 44.4 CBR summer measurement may not have been representative of the actual surface strength during the winter season at CZFD.

1.11 Flight recorders

The occurrence aircraft was equipped with a flight data recorder (FDR) and cockpit voice recorder (CVR), both installed in racks in the empennage. The FDR and CVR were recovered from the aircraft wreckage in undamaged condition and examined at the TSB Engineering Laboratory in Ottawa, Ontario. The data from both recorders were successfully recovered.

The FDR contained more than 536 hours of flight data, including the entire occurrence flight and 502 previous flights. The CVR had recorded 2 hours 4 minutes of audio from 4 separate microphones, including recordings from the captain’s and FO’s microphones, a cockpit area microphone, and an extra channel.

Further flight data were recovered from the aircraft’s EGPWS, and 2 separate FMS units. Additionally, ground-based radar data were recovered from NAV CANADA.

1.11.1 Flight data analysis

The aircraft’s detailed flight path was reconstructed using information from the aircraft’s FDR, CVR, FMS, and EGPWS, as well as the ground radar data.

The aircraft’s FMS recorded highly accurate 3-dimensional geodetic position data; however, it was recorded at a sampling rate of only 1 Hz. This sampling rate was sufficient to represent the trajectory of non-dynamic flight, such as the flight from CYPA to CZFD, but insufficient for the dynamics of the trajectory during the occurrence flight.

The FDR recorded longitudinal, lateral, and vertical accelerations relative to the aircraft body’s frame. By transforming these accelerations into the Earth’s frame of reference, and correcting for biases, an accurate flight path of the aircraft on departure was determined.

While reconstructing the flight path was relatively straightforward, accurately assessing the aircraft’s drag and lift performance, the performance of the roll control system, and the actuation of stall protection were significantly more complicated.

1.11.1.1 Drag and lift performance

1.11.1.1.1 Background

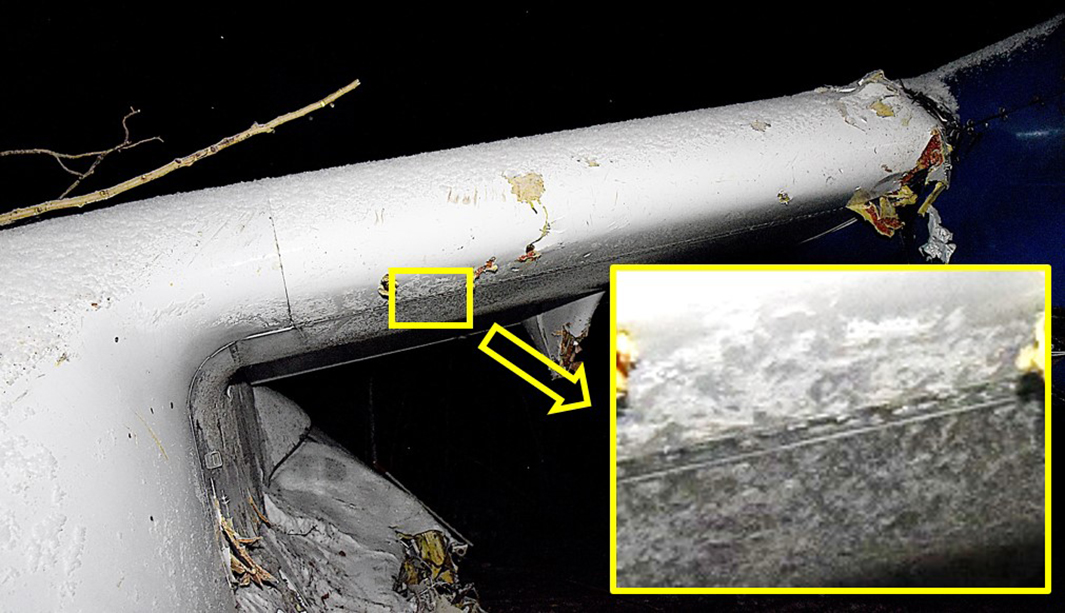

Ice contamination, even in seemingly small amounts, can lead to significant aerodynamic penalties, primarily related to drag and lift.