Engine power loss and ditching

Helijet International Inc.

Sikorsky S-76A (Helicopter), C-GHJT

Langara Island, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

At 1301 Pacific Daylight Time, the Helijet International Inc. Sikorsky S-76A helicopter (registration C-GHJT, serial number 760052) departed Masset Airport, British Columbia, for a fishing lodge on Langara Island, British Columbia, with 1 pilot and 1 passenger on board. On final approach to land at the fishing lodge, 1 engine lost power. The pilot elected to ditch in the water with the emergency flotation system deployed. The helicopter settled on the water alongside a floating helipad, which was the intended landing site. After shutting down the helicopter, the pilot noticed that it was listing nose down and to starboard (right). The pilot and the passenger evacuated the helicopter into a small boat that was dispatched to help; no one was injured. About 4 minutes later, the helicopter rolled inverted in the water. The emergency locator transmitter activated for about 4 seconds.

Factual information

History of the flight

On the day of the accident, the helicopter was transporting an employee of the fishing lodge and cargo from Masset Airport, British Columbia, to the lodge on Langara Island, British Columbia, which is about an eighteen-minute trip. On short final to land at 1319,Footnote 1 there was a loud bang, the engine-out warning horn sounded, and the No. 2 engine (Allison/Rolls Royce 250-C30S) lost power.

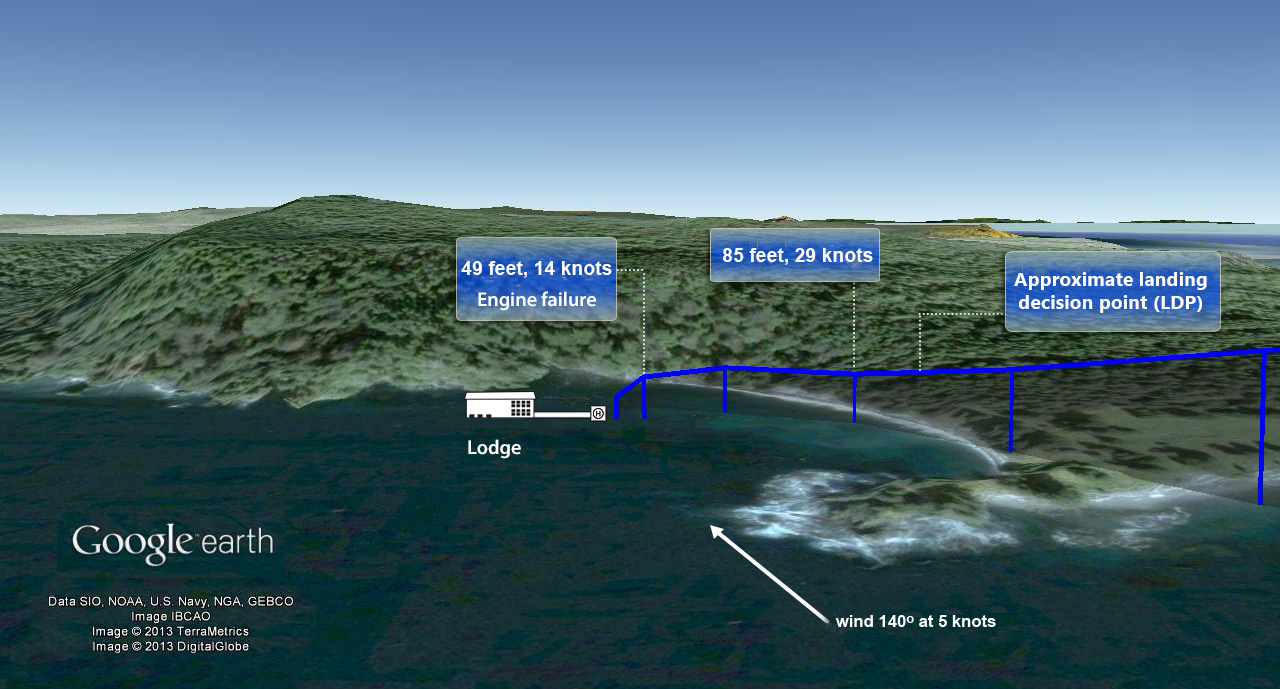

At the time of the power loss, the helicopter was about 75 feet away from the helipad and 49 feet above the water, with an indicated airspeed of about 14 knots. The pilot was in the process of beeping upFootnote 2 the No. 1 engine to match the torques, as the No. 2 engine torque was indicating 95% and the No. 1 engine torque was between 80 and 85%. In response to the power loss, the pilot pulled up on the collective to decrease the rate of descent and pitched the nose down in an attempt to land on the helipad. It became apparent that the helicopter could not be landed safely on the small floating helipad. Therefore, the pilot stopped the forward flight of the helicopter and ditched in the water beside the helipad with the emergency floats deployed (Figure 1).

The helicopter settled on the water with the main rotor blades turning, sweeping over the northeast side of the helipad. All 4 floats were inflated. The ditching was accomplished with low impact forces, and the emergency locator transmitter (ELT) did not initially activate. The ELT emitted a brief signal upon submersion in the sea water. The helicopter drifted away from the helipad, and the pilot shut down the other engine. The occupants were advised by an observer, via marine band radio, that smoke was emanating from the No. 1 engine. The pilot pulled the fire handle for that engineFootnote 3 and discharged the fire extinguisher. Both fire handles were found in the pulled/shut-off position after the helicopter was retrieved. It could not be determined when the No. 2 engine fire handle was pulled.

After the rotors stopped, the helicopter began to list to starboard, and the pilot called for the passenger to evacuate. The pilot and passenger exited without injury onto a small boat, which had been dispatched by the lodge.

The starboard floats continued to deflate, and about 4 minutes later, the helicopter rolled inverted in the water, floated by only the port floats. The helicopter was later dragged close to shore and secured to a tree with a rope. A containment boom was placed around the helicopter in case of fuel and oil leakage.

Damage

Damage to the helicopter was initially limited to the engine, but the damage sustained by its submersion in salt water, and subsequent salvage, rendered it beyond economical repair. The starboard nose float was torn on the front lower outboard side. Some of the fabric was missing, and there was wrinkling deformation, consistent with the fabric having been snagged on an object.

Pilot

The pilot was highly experienced, with about 20 000 hours total flying time and about 8000 hours on the helicopter type. The pilot held an airline transport pilot licence - helicopter, validated by a current medical certificate. The pilot had been trained and certificated to the appropriate standards and regulations.

Helicopter

The Sikorsky S-76A is a twin-engine, single main-rotor helicopter designed to operate with 1 or 2 pilots and carry up to 13 passengers. This helicopter type is certified to a maximum gross take-off weight (MGTOW) of 10 500 pounds. The occurrence helicopter was manufactured in 1980. Records indicate that it was maintained to the manufacturer's and regulator's standards. A weight and balance computation determined that the helicopter was being operated within its load and centre of gravity limits. At the time of the occurrence, the helicopter's gross weight was about 9725 pounds.

The S-76A helicopter flight manual indicates that the S-76A helicopter may be operated under Category A or B.Footnote 4 In this ocurrence, the helicopter was operated under Category B because Category A criteria could not be met at the intended landing site.

While the helicopter has 2 engines, its performance with 1 engine inoperative is affected by several factors, primarily weight. At higher gross weights, with 1 engine inoperative, the helicopter cannot hover or land without forward motion (run-on landing). In some cases, it uses more than 1000 feet of landing surface distance before stopping. Considerations for performance loss, when operating with only 1 engine, are found in many twin-engine aircraft manuals.

The landing decision point (LDP) for the S-76A is 100 feet above the touchdown elevation at 50 knots indicated airspeed (KIAS), and at a rate of descent no more than 750 feet per minute (fpm). During Category B operations, with an engine failure before or at the LDP, the pilot may perform a balked landing go-around. With an engine failure after the LDP, a forced landing or ditching must be performed.

Operators recognize critical flight envelopes where aborted approaches or normal landings are impossible. To mitigate the risk in these flight envelopes, pilots are trained to conduct a balked approach on 1 engine (fly away) or, if this is not possible and the aircraft is properly equipped, to carry out an emergency landing at sites not normally considered acceptable. In this case, the helicopter was equipped with an emergency flotation system to mitigate the risk of over-water approaches to small floating helipads.

The emergency flotation system consists of 2 pop-out-type floats folded in compartments near the nose landing gear and 2 floats for the aft/main landing gear, 1 in each gear door. Four 3000-pounds-per-square-inch (psi) helium- or nitrogen-charged bottles provide inflation gas; 2 supply the nose floats and 2 supply the main floats. There are lines interconnecting each pair of bottles and floats. Should one of the inflation bottles fail to activate, the other bottle in the pair can inflate a cell in both associated floats. To inflate the flotation system, there is an electrical switch on the pilot's cyclic control stick grip.

Weather

Masset is located about 35 nautical miles (nm) southeast of Langara Island. The weather reported at 1300 at Masset (close to departure time) was as follows: winds 150° true (T) at 12 knots, gusting to 22 knots, visibility 10 statute miles (sm) in light drizzle, temperature 14°C, dew point 13°C, and clouds broken at 800 feet above ground level (agl). At 1400, just after the accident, Langara Island automatic weather station was reporting the following: winds 140°T at 5 knots, temperature 14°C, and dew point 14°C. The flight was carried out under visual flight rules (VFR) at about 500 feet over water, and the visibility was described as good.

Aerodrome information

An aerodrome is defined in the Aeronautics Act as:

Any area of land, water (including the frozen surface thereof) or other supporting surface used, designed, prepared, equipped or set apart for use either in whole or in part for the arrival, departure, movement or servicing of aircraft and includes any buildings, installations and equipment situated thereon or associated therewith.

There are defined exceptions, but generally, most places in Canada can be designated an aerodrome for the purposes of landing a helicopter.

Since helicopters can land in a wide variety of areas other than certified or registered aerodromes, it is incumbent upon operators to assess the performance limitations of their helicopters in relation to the hazards present in any given landing area.

The company was carrying out a non-scheduled commercial service to several remote sites, including the fishing lodge. The company was not required by regulation to register the aerodromes located at the fishing lodges. The requirements for certification do not apply to these facilities. However, the company made approach and site information charts for the benefit of its pilots (Figure 2 ).

- direction of landing with south-easterly wind, take-off with west wind

- aircraft orientation while sitting on the helipad (90° to walkway)

- direction of landing with west wind, take-off with south-easterly wind

(Source: Helijet International Inc.)

The company reviewed the hazards associated with the operation of its helicopters at fishing lodges where runways are not available. This review prompted several upgrades to the landing sites. Most of the fishing lodges served by helicopters have floating helipads with nearby docks to access the lodging facilities. The company standardized the helipad dimensions and generally increased their size to 40 feet by 40 feet.

The topography around the helipad at the occurrence site limits the options for unobstructed missed approaches or balked landings. The 40 by 40 foot helipad was too small to allow any landing roll.

Flight recorders

The helicopter was equipped with a cockpit voice recorder (CVR) and a global positioning system (GPS) flight-tracking system. These systems were useful to the investigation.

Technical examinations – Engine

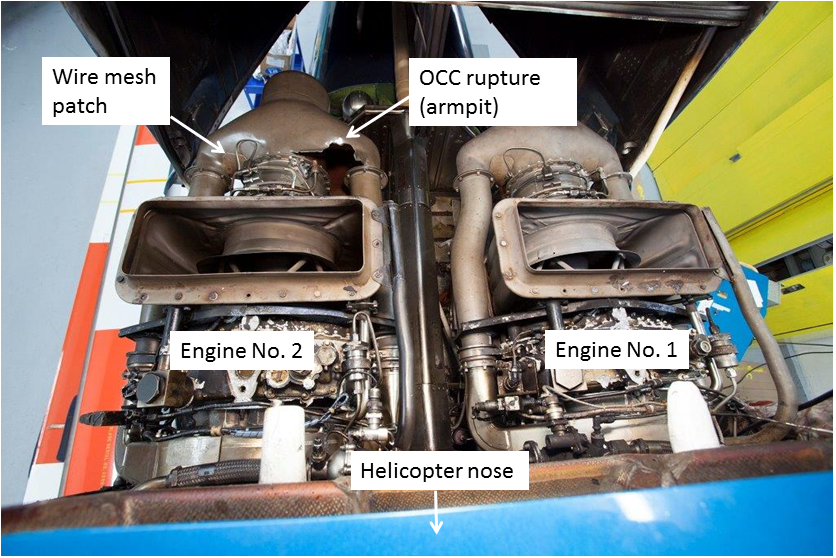

A preliminary examination of the engine during retrieval from the water revealed that the No. 2 engine (starboard) had experienced a catastrophic failure of the outer combustion case (OCC). Photo 1 shows the damage to the No. 2 OCC.

OCCs of Rolls-Royce 250 series engines are on-condition parts with no service life limit and are not required to be tracked by the total number of flight hours or cycles. The occurrence helicopter engine was fitted with the original OCC [part number (P/N) 6899237].

In 1984, the engine manufacturer issued Commercial Engine Bulletin (CEB) CEB-A-72-2113/3115. The CEB provided inspection details and reinforcement patch procedures for OCCs of 250-series engines. In 1986, the Federal Aviation Administration (FAA) issued Airworthiness Directive (AD) AD 85-25-07 Rl. This AD mandated that P/N 6899237 OCCs be modified with a re-inforcement patch installed on the armpit area of the OCC diffuser scroll elbow. OCCs modified in this manner were re-identified as P/N 23030910.

The occurrence OCC was identified as P/N 23030910 (S/N 24281), indicating compliance with the AD.

The engine was initially disassembled at Standard Aero in Richmond, British Columbia, under the supervision of the Transportation Safety Board of Canada (TSB); there were no other remarkable damage signatures. The OCC was sent to the TSB Laboratory in Ottawa, Ontario, where a more in-depth examination found the following:

- This OCC had undergone repairs (replacement of wire mesh patches) in the armpit areas.

- The rupture of the OCC occurred in the left-side armpit; it was the result of an overstress extension of a pre-existing fatigue crack when this crack had grown to a critical length.

- The main fatigue crack was formed by merging small cracks initiating from numerous separate points along the inside and outside surfaces of the horizontal butt weld and surrounding areas.

- Two other small cracks were observed in the left-side armpit. One fatigue crack was located at the circumferential seam weld under the gas producer attachment flange. This crack eventually merged with the main fatigue crack via an overstress crack. The other crack was parallel to the main crack on the other side of the horizontal butt weld.

- Two short cracks were also found in the right-side armpit region.

- The fatigue cracking was driven by pressure cycles (engine start-stop cycles) in the OCC as part of normal engine operation. The fatigue cracks were located under the reinforcing wire mesh patches, which made the cracks difficult to detect at the initial formation stage.

- At the main fatigue crack location, the OCC skin was thinner than elsewhere, and its thickness was below the minimum specified value for the skin wall thickness. It is likely that the thin areas facilitated fatigue cracking.

A copy of the Authorized Release Certificate, TCCA 24-0078 (dated 12 July 2004), indicates that the OCC (P/N 23030910, S/N 24281) was overhauled by Standard Aero Ltd. in Winnipeg, Manitoba. The details of the overhaul work were not recorded on TCCA 24-0078, but the manufacturer's instruction letter (PRPL 2-E002) referenced in the certificate indicates weld repairs of OCC cracks. The certificate also indicates that the number of hours since new, and since previous overhaul, were unknown due to the lack of records.

In this case, the right patch was 2.3 inches wide, while the left side-by-side patches were 1.89 inches and 0.47 inches wide. The different reinforcing patches in the 2 armpits of the occurrence OCC suggest that they were possibly repaired at different times.

According to information provided by the manufacturer, reinforcing patches can be replaced during OCC repairs. Revision 4 of CEB-A72-2113/CEB-A72-3115, issued in September 1994, indicates that the size of the patch is 1.75 to 1.85 inches by 4.45 to 4.55 inches. However, according to the manufacturer, slightly wider patches were commonly used.

Technical examinations – Emergency flotation system

The emergency flotation system allows for a safe emergency ditching on water. This was accomplished, and the occupants had enough time to evacuate safely. However, the starboard floats (nose and main) subsequently deflated. The floats were examined by the TSB Laboratory personnel and the following was found:

- Each float is divided into fore and aft air cells by a transverse bulkhead located roughly in the middle. The bulkhead in the starboard nose float had split open along the entire length of the longitudinal seam, as well as across partial lengths of the circumferential seams. The seam failures were all connected and continuous.

- Nothing was found to suggest that the strength of the float fabric had degraded significantly below the required minimum standard.

- The starboard main float had 1 tear caused by a sharp object. Another tear was a tearing type failure, and it was not determined how it occurred.

- The seams of the starboard main float did not exhibit any indications of weakness.

- The seam peel and shear strengths of the starboard nose float were both below expected values by a factor of 10, and the seams could be separated by applying minimal force with fingers.

- The starboard nose float seam separations had occurred at the interface between the glue and the urethane coating, with some of the glue remaining attached to each surface. The glue on this float exhibited extensive cracking, which most probably existed before the occurrence. Since the starboard nose float was over 30 years old, the possibility exists that the glue degradation was age-related.

- The initial float failure was most probably the seam failure in the starboard nose float.

- The manufacturer's current inspection method does not adequately identify degradation in seam strength.

Sikorsky does not assign a service life to these inflatable vessels and floats manufactured by the Air Cruisers division of Zodiac Aerospace. The floats manufacturer estimates that the life could be between 10 and 25 years of service. The expected life would vary greatly depending on weathering and handling issues.

Company

The company was operating under a Transport Canada (TC) issued company air operator certificate and carried out its maintenance through its own TC-approved maintenance organization.

The company's main operations facility in British Columbia is based at the Vancouver International Airport. This facility supports 4 sub-bases. One sub-base in Prince Rupert/Seal Cove and 1 sub-base in Sandspit service remote sites in the Queen Charlotte Islands and northern locations. Two other facilities in Victoria Harbour and Coal Harbour serve the Victoria-Vancouver flights. The company operates a variety of helicopters. Most are Sikorsky S-76A and S-76C types. The S-76C variant has better performance when 1 engine is inoperative.

An approved safety management system (SMS) is not required by TC for the operations carried out by the company. Nevertheless, the company has an SMS and considered the risk of an engine power loss during a critical phase of flight. The company concluded that twin-engine helicopters equipped with emergency flotation systems would facilitate a safe emergency landing and timely egress of persons on board in the event of a ditching. It should be noted that the standards and regulations allow for this operation to be carried out with a single-engine helicopter without any flotation equipment.

Maintenance – Engine

The manufacturer specifies that the OCCs are to be inspected visually at 150-hour intervals using a bright light and mirror as necessary. The OCCs are to be inspected more thoroughly every 2000 hours using Leak-Tek (soapy water) while motoring the engine to create some air pressure, and/or using the dye penetrant non-destructive test (NDT) method. The OCC is not required to be removed for these inspections. According to the information provided by the company, the last 2000-hour inspection of the occurrence OCC was performed using the Leak-Tek method on 03 October 2010 (1201.2 hours before the occurrence). This non-destructive inspection method includes applying the Leak-Tek solution after pressurizing the OCC and looking for bubbles on the outer surface of the case, which would indicate a crack. No cracks were detected during the October 2010 inspection. While this may indicate that no cracks existed at the time, based on knowledge of crack propagation, it is also possible that some cracks were in fact present, but had not propagated all the way through the OCC skin and reinforcing patch. The most recent 150-hour inspection was conducted on 27 July 2012 (38.1 hours before the occurrence). Again, no cracks were found, but it would be difficult to notice a crack on the rough patch surface if the cracks were completely within the area covered by the patch.

During the investigation, the company performed one-time inspections of its fleet to assess the condition of its helicopters equipped with Rolls Royce 250-series engines. These included 3 Bell 206L1 helicopters equipped with single 250-C28 or C30 engines, and 5 Sikorsky S-76A helicopters with 250-C30S engines. The company performed unscheduled Leak-Tek inspections on these helicopters and recorded the findings. A total of 6 engines were found to have cracked OCCs, with a mean time between failures (since last 2000-hour inspection) of about 1000 hours. The operator replaced all defective OCCs and returned the helicopters to service. It also instituted a mandatory inspection of OCCs using the Leak-Tek method every 150 hours for the S-76A model helicopters, and every 100 hours for the Bell 206L; this correlates with the scheduled compressor inspection times.

Since the new inspection cycle was initiated, a 150-hour inspection found 1 more cracked OCC (P/N: 6899237, modification 23030910). This OCC was on a 250-C30S engine in a Sikorsky S-76A.

History of outer combustion case cracking

In 2008, the Australian Transport Safety Bureau (ATSB) conducted an investigation into the rupture of an OCC on a Bell 407, which occurred immediately after take-off. This rupture resulted in a complete engine power loss and subsequent ditching. The helicopter was equipped with a Rolls Royce 250-C47 engine.

On 23 October 2008, the Australian Civil Aviation Safety Authority (CASA), in co-ordination with the ATSB, issued Airworthiness Bulletin (AWB) 72-003 “to urgently advise operators and maintainers of an unusual and catastrophic failure of the OCC of a RR [Rolls Royce] 250 C47 engine.”Footnote 5 The AWB specified that it applied to all Rolls Royce 250-series engines, with OCC part number 23030911, eligible for installation in all versions of model C28, C30, C40 series engines.

The AWB recommended that, in order to detect cracking at the earliest opportunity, “operators and maintainers immediately and frequently thereafter, conduct an inspection of the suspect areas of the duct, paying close attention to the area on inside bends of both sides of the duct.”Footnote 6 It suggested that “such inspections should be conducted using a suitable inspection technique, such as a close inspection using a 10X magnifying glass.”Footnote 7 One suggested inspection technique was to apply a leak check bubble solution to the area while motoringFootnote 8 the engine to pressurize the OCC. CASA called on the industry for proposals describing other effective inspection methods. The AWB requested the following:

All instances of cracked OCC's should be reported to CASA via the SDR [Service Difficulty Reporting] system. This includes cracked OCCs discovered during operation or overhaul, which may not have been previously reported. Such information will assist the ATSB in their investigation and allow CASA to develop a comprehensive response to the problem.Footnote 9

CASA received 1 service difficulty report of cracking in a C30 series engine OCC, where cracking occurred under (or in) the same reinforced area, located on the inside bend, as the occurrence OCC.

Maintenance – Floats

The Sikorsky S-76 maintenance instructions for checking the floats require that a visual check without the aid of special optical devices, unless otherwise found necessary, be performed on the float fabric and seams to check for cuts, tears, punctures, and abrasions. The integrity of the floats' individual cells is also checked across the transverse bulkhead with a static test. The test is completed by inflating the cells with air pressure at 3.50 pounds per square inch gauge (psig) and monitoring for 30 minutes to 1 hour. The pressure in the inflated cells must remain greater than 3.0 psig. If the pressure falls below 3.0 psig, maintainers are advised to return the float to the manufacturer for repair.

The starboard nose float was last inspected in May 2012 and deemed serviceable. A float with this part number requires a six-month inspection. Newer part number floats have an annual inspection requirement. The test does not simulate the forces experienced when the floats are deployed in flight or the loads experienced during ditching.

History of float deployment and survivability

Sikorsky reviewed more than 30 years of data and found 11 incidents where S-76 aircraft ditched on water using the emergency flotation system. There were no injuries in 10 of those events. The only event with injuries involved an S-76C++Footnote 10 in Myanmar (Burma) in 2011. In that case, the aircraft ditched successfully, and all occupants evacuated from the aircraft, but 3 survivors subsequently drowned due to a delayed rescue response. In 6 events, the aircraft eventually rolled over and/or sank. In 4 events, the aircraft remained upright and was salvaged. In 1 event, the aircraft slid off a rig, broke in 2 pieces, and sank, but the flotation system still functioned and the occupants were able to evacuate. The S-76 flotation system is intended for emergency use only, to allow occupants time to exit the aircraft; it is not intended to facilitate salvage or repair of the aircraft.Footnote 11

Transportation Safety Board Laboratory reports

The following TSB Laboratory reports were completed:

- LP 160/2012 – Tracker Analysis, Skytrac DSAT 300

- LP 161/2012 – Examination of Outer Combustion Case

- LP 162/2012 – Examination of Helicopter Floats

These reports are available from the TSB upon request.

Analysis

This analysis focuses on the loss of power event, subsequent ditching, and the post-ditching deflation of the starboard emergency flotation system.

The engine outer combustion case (OCC) failed in flight because cracks propagated without being detected. This resulted in a sudden loss of pressurized air and an engine flame-out. The No. 2 engine lost power after the landing decision point; therefore a single engine overshoot could not be performed. The pilot continued the approach for landing under limited power (1 engine inoperative). The landing pad at the lodge was close, but the pilot determined it was too small to allow for a run-on landing. The pilot therefore performed a controlled ditching.

The cracks in the OCC likely started because thin metal was exposed to pressure and heat cycles.

The thinning of the OCC skin also facilitated the propagation of fatigue cracks. The manufacturer-recommended inspections and period between inspections of the engine OCC did not provide an adequate means of detecting cracks. As demonstrated in this occurrence, undetected cracks can propagate and cause OCCs to fail in flight, thereby risking the safe termination of flight. With limited inspection standards and no life limits, there is an ongoing risk of OCC failures.

The flotation system functioned and deployed; however, it did not keep the helicopter afloat in an upright position after rotor shutdown because the starboard nose float cell failed. This failure was due to aged bonding that was not strong enough to maintain a seal. A single seam failure across the transverse bulkhead caused all the cells in the float to deflate. The tear in the starboard nose float may have been the result of contact with objects in the water after the ditching. This tear may have contributed to the deflation of the forward nose float cell. It is also possible that the tear occurred during the recovery process when the floats were cut from their attachments with a knife to expedite their removal. As the helicopter began to list, extra load was exerted on the starboard main float at irregular angles, likely puncturing or tearing the float and causing it to deflate. The subsequent imbalance in flotation caused the helicopter to roll inverted in about 4 minutes.

The manufacturer-recommended inspections of the emergency flotation system did not provide an adequate means of assessing the condition and integrity of the floats to assure the buoyancy of the helicopter when deployed. Since there is no life limit assigned to the emergency flotation system floats, it is likely that the degradation of the bonded seams over time was not considered. With limited inspection standards and no life limits for the floats, there is an ongoing risk of float failures.

Findings

Findings as to causes and contributing factors

- The No. 2 engine outer combustion case failed due to a fatigue crack that was not detected using the recommended inspection method and intervals.

- The in-flight failure of the outer combustion case resulted in a power loss after the landing decision point.

- A single-engine landing on the helipad was not possible, and the pilot conducted a controlled ditching with the floats deployed.

- After a succesful ditching and evacuation, the flotation system did not keep the helicopter upright because the starboard nose float cells deflated.

- The starboard nose float bonded seam was degraded; when subjected to ditching forces, it failed across both cells. The helicopter began to list, and extra load was exerted on the starboard main float at irregular angles, likely puncturing or tearing the float and causing it to deflate. The subsequent imbalance in flotation caused the helicopter to roll inverted about 4 minutes later.

Findings as to risk

- The manufacturer-recommended inspections and period between inspections relating to the engine outer combustion case did not provide an adequate means of detecting cracks. With limited inspection standards and no life limits, there is an ongoing risk of outer combustion case failures.

- The manufacturer-recommended inspections of the emergency flotation system did not provide an adequate means of assessing the condition and integrity of the floats. With limited inspection standards and no life limits for the floats, there is an ongoing risk of float failures.

Other findings

- The standards and regulations allow for this type of operation to be carried out with a single-engine helicopter without any flotation equipment.

Safety action

Safety action taken

Safety action taken by Helijet International Inc.

Helijet instituted more frequent and enhanced engine inspections and replaced all of the emergency floats that were more than 14 years old.

Safety action taken by Rolls-Royce

Rolls-Royce has amended the inspection cycle instructions for the M250-C30-series engine to require a Leak-Tek check or fluorescent penetrant inspection (FPI) every 150 hours. The inspection descriptions have been changed accordingly. Additionally, a new design for the outer combustion case with re-inforced armpits was released in December of 2013.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on . It was officially released on .