Engine stoppage and forced landing on water

Air Tamarac Inc.

Cessna A185E C-FZNK

Bostonnais River, 10 nm

northeast of La Tuque, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 18 July 2011, at approximately 1448 Eastern Daylight Time, the Air Tamarac Inc. Cessna A185E floatplane (registered C-FZNK, serial number 18501822) left the La Tuque, Quebec, seaplane base for a 20-minute sightseeing flight. The aircraft took off towards the north and climbed to an altitude of approximately 1600 feet above sea level. After approximately 12 minutes of flight time, the engine failed, and the propeller began spinning in the air. The pilot decided to proceed with an emergency ditching in the Bostonnais River. During the descent, the pilot attempted to restart the engine, but without success. The terrain surrounding the river forced the pilot to execute a sharp left turn. The aircraft stalled, nose-dived and struck the surface of the water. The aircraft tumbled and came to rest inverted in the water. Local residents reacted quickly, contacting emergency services and offering assistance. Of the 5 passengers on board, the pilot and 3 passengers survived, and 1 passenger died. The emergency locator transmitter was triggered on impact, but no transmission was received.

1.0 Factual information

1.1 History of the flight

The day of the occurrence, C-FZNK, a Cessna A185E floatplane, was carrying out sightseeing flights in the area of La Tuque, Quebec. The occurrence flight was the third that day. Before the first flight, the pilot carried out an external inspection of the aircraft, during which the fuel system was drained to ensure it was free of contaminants.

At 1010, Footnote 1 the pilot carried out the first flight of the day, flying to Lac aux Trois Caribous and returning approximately 30 minutes later. Lac aux Trois Caribous is located some 25 nm north-east of La Tuque. Following this flight, the pilot measured the fuel quantity using the dipstick, which indicated that each tank contained approximately 15 gallons Footnote 2 of fuel. The second flight, which was the first sightseeing flight of the day, lasted approximately 20 minutes, and C-FZNK returned to base at around 1439.

Before the occurrence flight departed, the pilot did not measure the amount of fuel and estimated that the left and right tanks contained about 10 and 15 gallons, respectively. At approximately 1443, the pilot picked up 4 passengers for the 20-minute sightseeing flight. The aircraft was moored at the dock to allow boarding through the left door. The passengers were directed to their seats, one at a time. The pilot fastened the passengers' seatbelts while demonstrating their operation. The pilot boarded the aircraft and announced that the flight would undergo a little turbulence. The pilot indicated the location of the air sickness bags and the personal flotation devices (PFD).

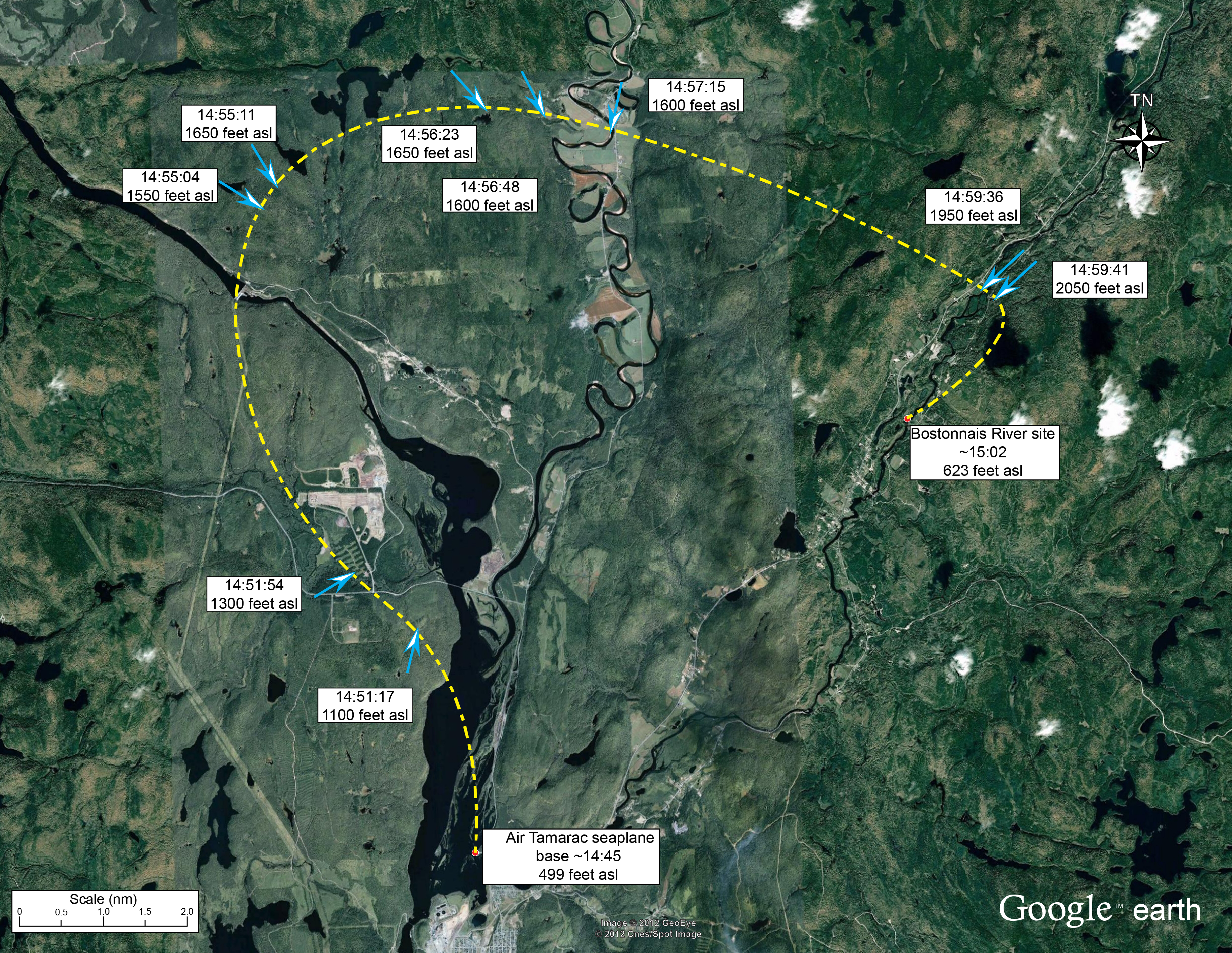

The pilot started the engine and left the dock. During the taxi, the pilot continued to provide the safety briefing, explaining how to lock and unlock the doors. The fuel tank selector was in the BOTH position to fuel the engine from both tanks. At approximately 1449, the aircraft took off and headed northward over the Beaumont dam. Approximately 5 minutes after take-off, the pilot placed the fuel tank selector in the LEFT position to fuel the engine from the left tank. The aircraft began a wide right turn towards the Croche River and then flew over the Bostonnais River (Figure 1).

At approximately 1501, or 12 minutes after take-off, the engine stopped. At this point, the aircraft was flying at approximately 1600 feet above sea level (asl). The propeller began spinning in the air, and the aircraft lost altitude. The pilot carried out emergency procedures from memory. The pilot returned the fuel tank selector to the BOTH position. The pilot then attempted several combinations and adjustments involving the power and engine mixture controls and different fuel tank selections. The attempts to restart the engine were not successful. During the descent, the pilot attempted radio communication with the company twice to inform them of the situation. He received no response. The pilot directed the aircraft towards the Bostonnais River to attempt an emergency ditching. The Bostonnais River is a narrow and winding river, with an approximate elevation of 620 feet asl.

At approximately 1502, the aircraft was observed taking a sharp left turn over the trees along the river bank. The aircraft nose-dived, struck the water and tumbled before coming to rest inverted with its floats on the surface of the water.

1.2 Deaths and injuries

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | - | 1 | - | 1 |

| Serious | - | 1 | - | 1 |

| Minor/None | 1 | 2 | - | 3 |

| Total | 1 | 4 | - | 5 |

1.3 Damage to the aircraft

The aircraft was inverted and in contact with the river bottom, which prevented it from sinking or travelling downstream. During wreckage recovery, major damage to the aircraft was observed, typical of occurrences involving a stall. The wings, fuselage, and tail were crumpled. The front of each float was severed. The right cabin door was missing.

1.4 Other damage

Other than the damage to trees which occurred while the aircraft was being removed from the river, there was no damage to property or to the environment.

1.5 Crew information

| Pilot-in-command | |

|---|---|

| Licence | Commercial Pilot |

| Medical expiry date | 1 April 2012 |

| Total flying time | 550 |

| Total last 90 days | 140.1 |

| Total on type last 90 days | 140.1 |

| Hours off duty prior to work period | 12 |

The pilot held the necessary licence and qualifications for the flight, in accordance with existing regulations. The pilot had accumulated 550 flight hours, approximately 400 of which were in a Cessna 185 floatplane. The pilot had been employed by the company since April 2010. There was no indication that fatigue contributed to this occurrence.

1.5.1 Training information

The pilot completed pilot training in April 2010. During this training, the pilot completed 225 flight hours and 22 simulator hours to obtain a commercial pilot licence with a seaplane rating. To obtain the seaplane rating, the pilot trained primarily on a Cessna A185F.

The flight training program was made up of theoretical and practical components. The practical training covered several topics, including simulated engine stoppage, engine-out ditching, and underwater evacuation, among others.

Upon completing this training, the pilot was hired by Air Tamarac and received initial training, in accordance with the company's training program as approved by Transport Canada (TC). This program included an overview of company procedures and initial ground and flight training on the Cessna 180 and the Cessna 185.

In May 2011, in accordance with the company's training program, the pilot underwent an annual pilot proficiency check (PPC). As part of the PPC, the pilot completed a theoretical exam as well as flight training on a Cessna A185E. The pilot underwent a total of 4.7 hours of flight training with the company's chief pilot. The theoretical exam and annual flight training covered emergency procedures. The pilot passed the PPC. All of the pilot's flight hours for the company were carried out on the Cessna A185E (C-FZNK).

1.6 Aircraft information

1.6.1 General

| Manufacturer | Cessna Aircraft Corporation |

|---|---|

| Type and model | Cessna A185E |

| Year of manufacture | 1970 |

| Serial number | 18501822 |

| Certificate of airworthiness | Valid |

| Total airframe time | 5611 |

| Engine/Number of hours since overhaul | Continental Motors IO-520, serial no. 293280-R / 126.2 hours |

| Propeller/Model | McCauley / D3A34C401 (three 86-inch blades) |

| Maximum allowable take-off weight | 3525 pounds |

| Recommended fuel type | 100LL |

| Fuel type used | 100LL |

1.6.2 Aircraft

On 30 June 2011, approximately 30 flying hours before the accident, C-FZNK underwent a 100-hour periodic inspection. An analysis of the aircraft's technical documents showed that it had been maintained in accordance with existing standards by an approved maintenance organization (AMO). The aircraft was equipped with a 6-cylinder injection Continental IO‑520-R engine. The engine had been reconditioned 126.2 flying hours before the accident. Analysis of the engine overhaul documents and subsequent maintenance documents did not reveal any anomalies.

C-FZNK had 2 main doors in the front and 1 left rear cargo door. It had 2 front seats with seatbelts and shoulder harnesses for the pilot and front passenger. The second row was made up of folding seats with waist belts. The third-row seat was also a folding seat and was equipped with a waist belt.

The aircraft was equipped with EDO3430 floats approved by a supplemental type certificate (STC) Footnote 3 for this aircraft type. The STC did not specify any degradation related to stalling. In addition, the wings of C-FZNK had been modified by the manufacturer in accordance with an STC approved by the Federal Aviation Administration (FAA). These wings increased the maximum load of the aircraft and contained large-capacity tanks. According to this STC, the wings did not alter the aircraft's aerodynamic stall characteristics. This modification was also approved by TC.

1.6.3 Aerodynamic stall

According to the aircraft manual, the aerodynamic stall speed of the Cessna A185E is 65 mph in straight and horizontal flight when the aircraft is at its maximum allowable weight of 3320 pounds, with flaps up. The stall speed increases to 70 mph at 30° of bank and to 93 mph at 60° of bank. During this occurrence, the weight of the aircraft at take-off was close to 3000 pounds and its centre of gravity was within the limits prescribed by the manufacturer. Following engine stoppage, the pilot maintained a speed of 80 mph.

1.6.4 Fuel system

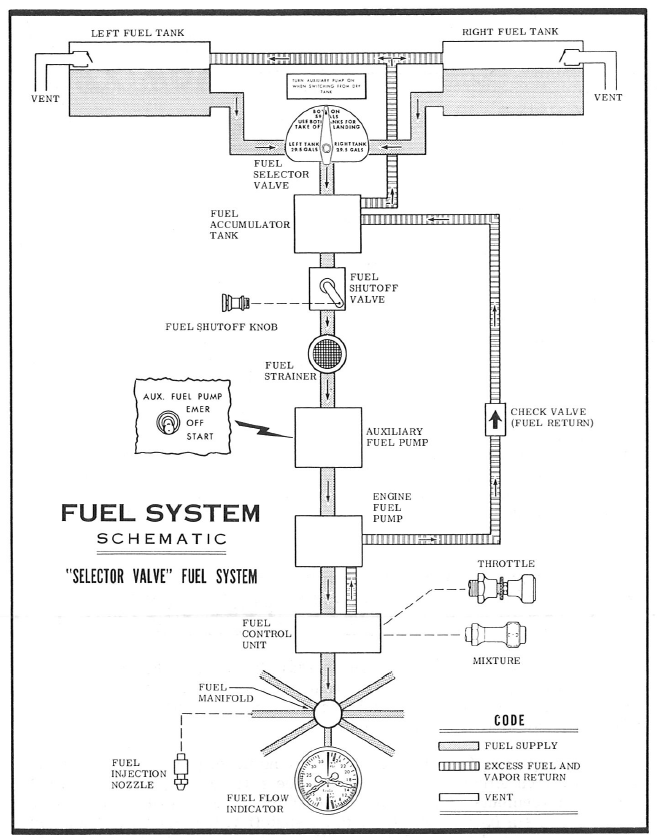

The fuel system was made up of several components, including a mechanical engine-driven fuel pump, an auxiliary electric fuel pump, and optional equipment such as a selector valve for the 2 fuel tanks.

The fuel tank selector valve has 3 positions (LEFT, BOTH, RIGHT). The pilot may select fuel supply from the left, the right, or both tanks. At the time of the engine stoppage, the valve was set on LEFT.

C-FZNK was equipped with 2 long-range fuel tanks. Since the fuel system included a tank selector valve, the total capacity of the tanks was 78 gallons. According to the manufacturer, each tank contains 3.0 gallons of unusable fuel. Footnote 4 Two indicators, one for each tank, transmit fuel levels to the pilot (Photo 1).

Fuel amounts are measured by quantity transmitters located in each tank. They, in turn, transmit the information to the fuel quantity indicators. The indicator displays empty (E) or its needle points to the red line when the float lever comes into contact with the transmitter's low mechanical stop. The indicators are calibrated annually, in accordance with the company's maintenance program. No anomaly in the indicators had been reported. Shortly before engine stoppage, the left tank indicator needle was near E.

1.6.5 Accuracy of the fuel quantity indicators

Owners and operators of Cessna 185 aircraft are aware that the indicators lack precision, particularly when a tank's fuel quantity is below the one-quarter mark. For this reason, the majority of owners of Cessna 185 and other small aircraft have turned to making dipsticks to measure fuel quantities. The dipstick provides a visual measurement of fuel amounts when inserted through the filler cap to the bottom of the tank. The dipstick is calibrated by observing the quantity of fuel placed into the tank when calibrating the aircraft's fuel quantity indicators. It is not possible to determine whether the fuel quantity indicated by the dipstick includes unusable fuel. C‑FZNK's dipstick had come with the aircraft when it was purchased by the operator in 2006.

Searches in various aviation accident databases show that many occurrences, particularly those involving general aviation, point to poor fuel management as a contributing factor to in-flight fuel starvation. Numerous comments in discussion forums also underline the fact that fuel quantity indicators are practically useless. This investigation leads us to believe that the industry has adapted to this situation through the manufacture and use of dipsticks to compensate for and complement imprecise indicators.

The Cessna 185 certification basis dates from 1961, under number 3A24. It is based on the regulations established by the Federal Aviation Administration, Part 3 of the Civil Air Regulations, as amended on 15 May 1956 and entitled Airplane Airworthiness: Normal, Utility, and Acrobatic Categories. Section 3.672 of the Civil Air Regulations addresses the certification of fuel quantity indicators and requires that the indicator be calibrated to read zero in cruise when the quantity of fuel remaining in the tank is equal to the unusable quantity as defined in section 3.437 of the Civil Air Regulations.

According to section 23.1337 (b) of the Federal Aviation Regulations (FARs), the indicator must be calibrated either in gallons or in litres, and the type of calibration must be marked. Each indicator must be calibrated to read zero in straight flight when the quantity of fuel remaining in the tank is equal to the unusable quantity as determined by the manufacturer. However, section 23.1337 (b) of the FARs does not address the precision of indicators in situations where the quantity of fuel present in the tanks is above the unusable fuel quantity. The regulations require that there be a source or a method to indicate to crew members the quantity of usable fuel in each tank during flight. The indicator must be calibrated and clearly marked to display the quantity and calibration.

1.6.6 Fuel consumed

The average fuel consumption of an aircraft in cruise flight depends on several factors, including altitude, engine speed and fuel mixture. The pilot had established that C-FZNK consumed between 15 and 16 gallons per hour in cruise flight.

From the first sightseeing flight of the day until engine stoppage, the aircraft had completed approximately 32 minutes of flight time. Assuming an average hourly consumption of 15.5 gallons, the aircraft would have consumed approximately 8.25 gallons of the 30 gallons measured by the pilot before the first sightseeing flight of the day. Consequently, there should have been approximately 21.75 gallons remaining in the tanks at the time of engine stoppage. However, approximately 1 gallon must be deducted from this quantity to take into account the time between engine start-ups and taxiing on the water prior to take-offs. Therefore, approximately 20.75 gallons of fuel should have remained in the tanks.

| Information | Flight time | Fuel consumed | Fuel on board | Method of measurement |

|---|---|---|---|---|

| Departure | N/A | N/A | 30 gallons | Measured |

| Sightseeing flight No. 1 | 20 minutes | 5.15 gallons | 24.85 gallons | Estimated |

| Sightseeing flight No. 2 | 12 minutes | 3.1 gallons | 21.75 gallons | Estimated |

| Taxiing on water and take-off (´2) | N/A | 1 gallon | 20.75 gallons | Estimated |

| Following the accident | N/A | N/A | 19 gallonsFootnote 5 | Recovered |

During examination of the wreckage, approximately 15 gallons were recovered from the right tank, and approximately 4 gallons from the left tank. It is therefore reasonable to believe that the quantities measured by the pilot with the dipstick had been relatively precise. However, the quantity recovered contained a small amount of water due to the aircraft being submerged, which may have resulted in some degree of error in measuring the actual quantity of fuel. It is also possible that some fuel could have transferred from the fuller tank to the other tank while the aircraft was submerged. As well, an amount of fuel—less than 0.5 gallon—was observed escaping from the right vent as the aircraft was being removed from the river.

1.7 Weather

Weather conditions were not a factor in this occurrence. On the day of the accident, weather conditions were suitable for visual flight: the skies were clear, and visibility was greater than 6 statute miles.

1.8 Navigation aids

Not applicable (N/A)

1.9 Communications

According to the Transport Canada Aeronautical Information Manual (TC AIM)Footnote 6, the first emergency call and distress message must be transmitted on the air-ground frequency in use at the time of the call. If the pilot is unable to establish communication on this frequency, the call and message must be repeated on the emergency frequency, 121.5 MHz, to establish communication with a ground station or aircraft in flight. Following engine stoppage, the pilot attempted 2 radio communications on the very high frequency (VHF) of the Air Tamarac floatplane base, 123.85 MHz. The communications received no response. They were neither heard by anyone nor recorded. The Canadian Aviation Regulations (CARs) do not provide that a company representative must constantly monitor the frequency in order to maintain flight following. There is no indication that the pilot attempted to transmit an emergency message on 121.5 MHz.

1.10 Aerodrome information

N/A

1.11 Flight recorders

The aircraft was not equipped with a flight recorder, and was not required to pursuant to existing regulations.

1.12 Wreckage and impact information

1.12.1 Preliminary wreckage examination

The aircraft was capsized in the river in a location that prevented it from sinking. The right cabin door was torn off on impact and was not recovered.

Before the wreckage was removed from the water, the following observations were recorded:

- Master switch: ON;

- Magneto switch: BOTH;

- Auxiliary electric fuel pump: OFF;

- Flaps raised to 0°;

- Fuel tank selector valve in the RIGHT position;

- Power shutdown control was in the normal position to supply fuel to the engine;

- Mixture lever: full rich;

- Throttle lever: maximum power;

- Propeller pitch control lever: fine pitch;

- The seatbelt and shoulder strap of the front right-hand passenger were still fastened;

- The main left-side pilot door was still locked;

- The other passenger and pilot seatbelts did not display any anomaly and were unfastened.

- The left and right windows behind the doors were broken;

- The left rear cargo door of the fuselage was open.

After the wreckage was removed from the water, the following information was gathered:

- The rear attachments of the front seats had been torn from the aircraft's floor rail.

- The padded seatbacks of the second row seats had been torn off from their fasteners.

- There was water in the Gascolator filter/water separator.

- No fuel supply line was damaged by the impact.

- The fuel tank selectors were fully functioning in every position.

- The mechanical engine fuel pump was in good condition and turned without displaying any anomaly.

- The fuel that was collected contained water; approximately 15 gallons of fuel were recovered from the right tank, and approximately 4 gallons were recovered from the left tank.

1.12.2 Engine examination

An examination of the engine and its components at the TSB Laboratory did not reveal any anomalies that could have prevented the motor from producing power. The examination revealed that the absence of fuel in the distributor to the fuel injectors could be interpreted as fuel starvation or fuel exhaustion.

1.12.3 Fuel system examination

Examination of the fuel system did not reveal any anomaly in the performance of the selector components, fuel tank air vents, ducts, attachments, purge drain and filter/water separator.

1.13 Medical and pathological information

The pilot had no history of medical problems, and the pilot's licence was valid.

1.14 Fire

No fire occurred after impact.

1.15 Survival aspects

At approximately 1502, the aircraft descended without engine noise and nosed-dived during a left turn towards the Bostonnais River. A 911 emergency call was received at approximately 1507, and police arrived at the reported location at approximately 1510.

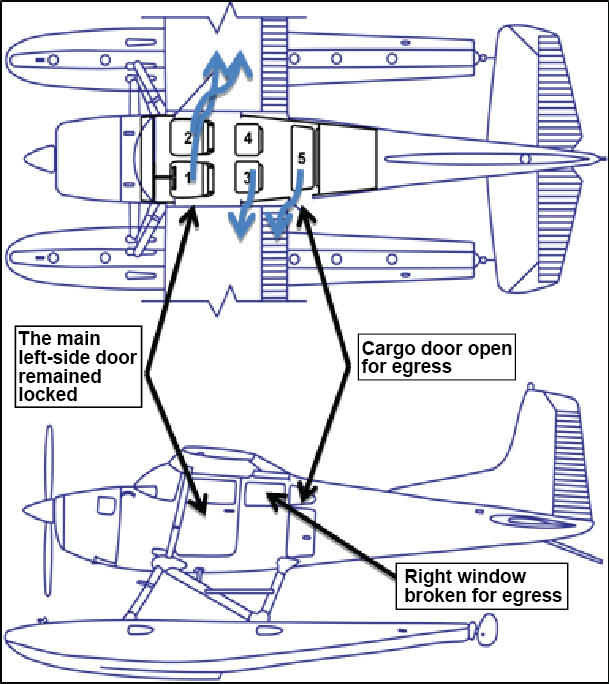

After impact, C-FZNK capsized and quickly filled with dark water. The right-side passenger door was torn from the aircraft on impact.

The pilot (No. 1 in the figure) released the seatbelt and moved towards the opening on the right side of the aircraft (Figure 2). In the darkness of the water, the pilot never saw, nor thought to unlock and open, the left-side pilot door. The pilot attempted to remove the front passenger (No. 2 in the figure) when passing by, but the latter was still held into the seat by the seatbelt and shoulder strap. The pilot continued to swim to the surface. The front passenger never thought to release the seatbelt. In the heat of the moment, the front passenger escaped by struggling free to reach the surface. The occupant (No. 3 in the figure) seated to the left behind the pilot, does not recall unfastening the seatbelt or escaping through the broken window on the left side of the cabin. This passenger did not know how to swim.

The pilot and one of the passengers carried out several dives in an attempt to evacuate the 2 children (Nos. 4 and 5 in the figure) trapped in the aircraft. The pilot dove towards the back of the aircraft and opened the cargo door located on the left side of the aircraft. The pilot saw one occupant's clothing (No. 5 in the figure), but ran out of breath before this occupant could be removed from the cabin.

The pilot returned to the surface, and one of the passengers dove and removed the child from the cabin through the cargo door. At that moment, a local resident arrived on the scene and started trying to resuscitate the child. The child (No. 5 in the figure) had major face and head injuries, which may have caused a loss of consciousness after impact.

The pilot and one of the passengers continued to dive for more than 5 minutes before they found the last child (No. 4). The passenger removed this child from the cabin. The child was then stretched out on one of the floats, and resuscitation manoeuvres were performed until emergency responders arrived at approximately 1512. Resuscitation proved unsuccessful. The child did not bear any signs of injury. Having been submerged for approximately 8 minutes, the child could not be resuscitated, and died as a result of drowning.

As they evacuated the aircraft, the pilot and passengers did not think of retrieving the inflatable PFDs that were located in the seat pockets on board the floatplane. Current regulations do not require that they be worn.

1.15.1 Emergency locator transmitter

C-FZNK was equipped with an Ameri-King Corp. emergency locator transmitter (ELT), model AK451-AF, serial number 1312, transmitting a signal on 406 MHz and 121.5 MHz. The ELT was certified and had been checked in accordance with regulations. When the wreckage was examined in the water, the ELT's warning light was lit, confirming that the transmitter had been triggered upon impact. The ELT was properly connected to its antenna and did not look like it had sustained any damage. The antenna was submerged and upside-down under water, which prevented it from transmitting its signal to satellites. Laboratory testing revealed that water and sand had penetrated the ELT casing, making it impossible to verify if the device worked. There is no reason to believe that the ELT could not function properly.

1.16 Tests and research

1.16.1 Attempt to restart engine in flight

On 12 August 2011, on its own authority, Air Tamarac carried out a test flight of a Cessna A185E floatplane whose propeller, floats and wing extensions are identical to the accident aircraft. The goal of the flight was to check the effect of the auxiliary electric fuel pump on engine start-up following in-flight fuel exhaustion.

During the test flight, the pilot purposely exhausted the right tank and the header tank. Footnote 7 The following observations were recorded:

- The engine stopped, and the propeller was spinning in the air.

- The engine gave no sign of restarting after the pilot positioned the selector valve on the BOTH position.

- At approximately 80 mph, the rate of descent was approximately 900 feet per minute.

- The engine gave no sign of restarting after the pilot positioned the selector valve on LEFT.

- After 3 minutes of flight, the pilot was unable to restart the engine.

- When the pilot placed the auxiliary electric fuel pump on EMER, the engine restarted instantly.

The test flight revealed that activating the auxiliary electric fuel pump re-engages the mechanical fuel pump mounted on the engine, where air is trapped following fuel exhaustion. The air cannot be expulsed by the mechanical pump. This stops fuel from being supplied to the engine's fuel monitor and prevents an engine restart.

1.16.2 Cessna 185A fuel starvation in 2009

TSB Investigation Report No. A09C0167 Footnote 8 on the engine failure of a West Caribou Air Services Cessna 185A revealed that the fuel quantity indicators of the occurrence aircraft were not reliable, and that they were not monitored during the flight. As a result, the pilot could not be sure of the quantity of fuel present during flight. The engine likely lost power due to the fuel starvation that occurred when the small quantity of fuel remaining in the left wing became displaced and could no longer reach the left tank's fuel supply lines during a gradual right turn. Following engine power loss, the pilot did not activate the auxiliary electric fuel pump, and was unable to restore power to the engine.

1.16.3 Studies on survival during submerged aircraft egress

According to previous studies on accidents involving submerged aircraft, 10 to 15% of occupants are unable to effectively carry out the required exit manoeuvres. Footnote 9 In another 10 to 15%, stress levels paralyze occupants and significantly reduce their chances of survival. As for the remaining 75%, they are either disoriented or traumatized, but are generally able to escape if they have undergone proper training in underwater evacuation and if they are prepared for such an eventuality.

Other factors that reduce the ability of occupants to egress a submerged aircraft include: blocked access to regular exits, water temperature, darkness and disorientation caused by the impact with water. Passenger safety briefings underline the importance of memorizing the location of exits, which are clearly marked on passenger safety-features cards. According to anecdotal evidence, even if this information is properly relayed, some passengers do not always pay attention or do not consult the relevant safety cards.

In addition, further research has shown that one's ability to hold one's breath is one of the major survival factors in an accident on water. Researchers have concluded that the inability to breath-hold has resulted in the 15% to 50% fatality rate in accidents into water. Footnote 10 One study revealed that the median breath-holding time in 25°C water is 37 seconds. However, this drops by 5 to 10 seconds in water that is close to freezing. Footnote 11In July, the average surface water temperature in this area is around 20°C. In addition, the study showed that divers trained in breath-holding could remain underwater for a period ranging from 47.4 seconds to more or less 21.6 seconds, compared to a range of 37.6 seconds to more or less 20.6 seconds, for untrained divers. Trained divers also demonstrated greater strength and ability and a higher comfort level in water.

The same study found that, in emergency situations, the ability to hold one's breath is dramatically reduced and is a major factor in the low survival rates in accidental submersions such as in an aircraft crashes. Once they are shown its proper use, occupants who use an underwater breathing apparatus can have more time to egress a submerged aircraft. Footnote 12

After an individual is able to egress an aircraft that is submerged in deep water, survival on the surface becomes a significant challenge. According to the TSB Safety Study of Survivability in Seaplane Accidents (SA9401), it is unlikely that people think to grab an onboard lifejacket when their first instinct is to reach the water's surface. Without a lifejacket, people expend a great deal of energy staying afloat on the water's surface. This physical exertion results in loss of body heat, shortness of breath and fatigue, and can lead to drowning. Those who are not wearing lifejackets have an even smaller chance of survival if they are injured.

1.16.4 TSB Recommendation A11-05

Following TSB Investigation No. A09P0397, concerning an accident involving a de Havilland DHC-2 MK 1 on 29 November 2009 in which 6 people drowned inside the aircraft, the TSB concluded that the risk of drowning is higher for occupants of seaplanes. Over the last 20 years, drowning was the cause of death in nearly 70% of fatalities in accidents in which the aircraft was damaged on impact with the water. Half of these accident victims were found in the submerged wreckage. It is not always possible to determine the facts with certainty; however, some investigations have been able to establish that certain occupants had been conscious and capable of moving about the cabin before drowning. These occurrences confirm the likelihood of physically-able people being trapped in a submerged aircraft and subsequently drowning.

This investigation concluded that some passengers survived the impact but drowned because 2 of the 4 regular exits were jammed. If all exits had been accessible or if other emergency exits such as jettisonable windows had been present, there is a good chance that a greater number of people would have exited the seaplane and survived the accident. One current safety measure involves developing jettisonable windows for the DHC-2 model, but this only addresses one of the many aircraft types operated from water. Furthermore, there is currently no regulatory requirement to install these types of emergency exits. For this reason, on 17 March 2011, the TSB put forward Recommendation A11-05, namely that:

The Department of Transport require that all new and existing commercial seaplanes be fitted with regular and emergency exits that allow rapid egress following a survivable collision with water. Footnote 13

Since then, TC has taken steps to deal with floatplane safety issues, initiating campaigns promoting safety awareness and implementing regulatory measures. TC published a Civil Aviation Safety Alert (CASA) on 3 June 2011, directed at private and commercial floatplane operators, recommending best practices for floatplane safety:

- upper body restraints to be used by front-seat occupants;

- briefing passengers on the proper usage of flotation devices during emergency egress;

- underwater emergency egress training for flight crew; and

- aircraft safety design improvements facilitating egress.

In its March 2012 response, TC indicated that during the summer of 2011, it had initiated a focus group with industry stakeholders to evaluate Recommendation A11-05 on installing regular and emergency exits on seaplanes that would allow for rapid egress following a survivable collision with water.

TC indicated that the focus group proposals were presented to TC senior management during a Civil Aviation Regulatory Committee (CARC) meeting. After an in-depth review, TC senior management agreed with the proposals. While TC indicated that an expedited process is currently under way to initiate the drafting of appropriate regulations, it did not provide a timeframe for these actions.

The TSB believes that the proposed measures could improve the emergency egress for commercial seaplanes and are likely to significantly reduce or eliminate this safety deficiency However, the measures have not sufficiently progressed to reduce the risks to transportation safety. The TSB assesses the response as Satisfactory Intent. Consequently, TSB personnel will monitor the progress of the planned actions and will reassess the deficiency on an annual basis or when otherwise warranted.

On 4 December 2012, TC indicated it had undertaken an in-depth review of TSB reports concerning collisions with water, as well as other studies and information on this issue. The goal is to assess the factors that have an impact on underwater egress and thereby determine viable design options for improving this type of evacuation.

TC also indicated that it would change the training provided to flight crews operating commercial seaplanes and examine the need to clarify requirements governing the use of upper body restraints by pilots. Legal drafting of the proposed amendments is moving forward, with publication in the Canada Gazette expected in 2014.

It is difficult to assess if and how TC plans to respond to Recommendation A11-05. The proposed actions may or may not result in improved emergency egress procedures for commercial seaplanes. However, the measures adopted so far are not sufficiently advanced to reduce the risks to transportation safety. As of 6 March 2013, the TSB feels that it is not possible to assess this response. Footnote 14

1.16.5 Egress

Research shows that the frequency Footnote 15and level of realism Footnote 16 of (formal or non-formal) training on underwater egress are major determinants in the success of an emergency egress. Greater frequency and realism help to promote more automatic emergency egress behaviour, which reduces egress time. While most adult airplane passengers have no formal emergency egress training, they have heard and seen pre-flight safety briefings, normally before each flight and often accompanied by a realistic video presentation. Repeated exposure to audio or video safety briefings is in fact a form of training designed to increase the chance of a successful egress.

Children normally are less experienced airplane passengers than adults. Consequently, they have received less emergency egress training (non-formal/briefings) than adults. It is therefore important to consider children separately when presenting them with safety and emergency egress procedures. It may be advantageous to repeat safety briefings once or twice to account for the frequency determinant. It could also be beneficial to conduct several emergency egress drills to increase the realism factor and compensate for the children's lack of experience.

1.17 Organizational and Management Information

1.17.1 Air Tamarac Inc.

Air Tamarac operates a fleet of 5 aircraft. Their models include the float-equipped Cessna 180, Cessna 185, and de Havilland Beaver DHC2. In accordance with its operating certificate, the company carries out its operations in compliance with subparts 702 and 703 of CARs. In this occurrence, the aircraft was operated under subpart 703. Footnote 17

TC conducted a program validation inspection (PVI) of the company in June 2011. The PVI revealed certain minor anomalies of an administrative nature in the company's operations manual with regard to its form and content. In July 2011, Air Tamarac responded with a corrective action plan to TC's satisfaction.

1.17.2 Safety Instructions

Air Tamarac had a guide titled Seaplane/Floatplane – A Passenger's Guide (TP 12365) Footnote 18 that it made available to passengers. However, the guide was not given to passengers before boarding. The information in the guide is intended to complement the safety briefing card and the passenger safety briefing. Among other information, the guide explains how to safely egress a submerged aircraft in 7 steps:

- Stay calm;

- Grab your lifejacket or PFD (do not inflate it);

- Open the exit door and take hold of the door handle (do not release your seatbelt and shoulder harness until you are ready to exit);

- Release your seatbelt/shoulder harness;

- Exit the aircraft;

- Get to the surface;

- Inflate your lifejacket.

Safety briefing cards were also available to passengers at each seat, either in the pocket of the seat in front of them or in a pocket near the front passenger door. These cards use pictograms to show:

- the location of emergency equipment;

- the location of emergency exits;

- the steps to follow when fastening and releasing seatbelts;

- the steps to follow when unlocking and opening doors; and

- the steps to follow when using PFDs.

The cards also indicate that PFDs are found in seatback pockets.

In addition, section 3-17 of the company operations manual requires that the pilot provide safety instructions before take-off. The manual indicates that customized information must sometimes be provided to visually-impaired or hearing-impaired persons, those with limited comprehension skills and persons responsible for a dependant, such as a baby or an injured person. Before each take-off and landing, the pilot-in-command must make a visual check to ensure all passengers are seated with their seatbelts fastened. The company operations manual states, among other things, that “[translation] it is not practical to provide passengers with safety instructions during the flight due to noise and other distractions. This information should normally be amalgamated and provided to passengers while on the ground and before starting the engine.”

The investigation revealed that the safety briefing was provided to passengers partly during boarding and partly while taxiing. The briefing included the use of seatbelts, the location of air sickness bags and PFDs, and a demonstration on the operation of the door locks. However, the company's safety briefing did not contain information on unlocking doors on approach during an emergency landing or ditching in water. This emergency procedure, which is included in the aircraft operating manual (AOM), allows first responders to gain access to the cabin. The pilot did not unlock the door and did not instruct the front-right passenger to unlock the door before initiating emergency ditching.

The investigation revealed that it was difficult to understand clearly the safety instructions that were provided. Engine noise, aircraft movement, and the children's excitement were too distracting to fully understand the importance of the safety instructions. During the safety briefing, it was not indicated that there were 2 doors in the front from which to exit the aircraft. In addition, the PFD operating instructions did not make it clear as to when and how these devices should be retrieved and used. The provided instructions did not refer to the safety features cards and did not cover PFD operating procedures during an underwater egress from a capsized aircraft.

1.17.3 TSB Recommendation A11-06

Investigation No. A09P0397 conducted by the TSB revealed that in many cases where occupants manage to escape from sinking aircraft, they egress without a life vest, which may result in drowning. It also showed that those inside a sinking aircraft understandably focus on escaping. In their haste, occupants often either do not have enough time to don a PFD, or they do not think to do so. In this accident (A09P0397), 2 of the seriously injured occupants were able to escape the aircraft, but neither person—including the pilot, who had been trained for underwater egress—managed to retrieve a PFD from the aircraft. Had they not used nearby boat bumpers to stay afloat, they could have drowned.

Some operators, notably TC for its fleet of aircraft, require all occupants to wear approved life vests on an aircraft that is taking off from or landing on water. Such a requirement eliminates the need for occupants to search for their PFDs, and the latter are then ready for use after occupants escape the aircraft. Without a PFD, and in the absence of other rescue equipment, it is very likely that survivors of a water impact will drown.

The TSB has previously recommended (A94-07) that seaplane occupants be required to wear PFDs while in flight. The regulator and industry stakeholders have raised a number of objections to this recommendation. They claimed that, in an emergency, a passenger could be hampered by a spontaneously inflated PFD, which could also impede the egress of other occupants. They were also wary of sizing issues, especially over thick outer clothing, and concerned for the passengers' potential discomfort. These objections may have some validity with regard to traditional life vest models. However, there have been several recent innovations in PFDs, including manually-inflated belt packs which are donned before they are inflated. Their operation would have to be clearly explained to all passengers, but such devices should effectively counter all these objections. The evidence shows that unless a person is wearing a PFD at the time of an accident, it is unlikely that one will be used after escaping a submerged aircraft.

For this reason, the TSB issued Recommendation A11-06 on 17 March 2011, which proposed that “The Department of Transport require that occupants of commercial seaplanes wear a device that provides personal flotation following emergency egress.” Footnote 19In its response of March 2012, TC indicated that it had initiated a focus group during the summer of 2011 with industry stakeholders to evaluate Recommendation A11–06 and to review the proposal that occupants of commercial seaplanes wear a device that provides personal flotation following emergency egress.

TC indicated that the focus group proposals were presented to its senior management during a CARC meeting. After an in-depth review, TC senior management agreed with the proposals. While TC indicated that an expedited process is currently under way to initiate the drafting of appropriate regulations, it did not provide a timeframe for these actions.

In its response of 4 December 2012, TC indicated that all commercial seaplane occupants would be required to wear a flotation device at all times. Legal drafting of the proposed amendments is anticipated to begin by the end of 2012 for planned publication in the Canada Gazette in 2014.

The new regulations could substantially reduce or eliminate the safety deficiency. However, for the present, the action has not been sufficiently advanced to reduce the risks to transportation safety. As of 6 March 2013, the TSB considers the response Satisfactory Intent. Footnote 20

1.18 Additional Information

1.18.1 Emergency Procedures and Emergency Procedure Management

1.18.1.1 Emergency and Abnormal Procedure Design Principles

In emergency situations, a pilot often begins by carrying out a series of vital actions in which speed is a critical factor (memory items); these are followed by secondary actions carried out with the help of an applicable checklist, if the latter is available and if time permits.

Studies have shown that pilots often forget memory items during emergency procedures due to short-term memory limitations and their natural vulnerability to distraction, Footnote 21 particularly during periods of high work load. Footnote 22 Performing memory items often leads to errors in identifying the emergency situation, choosing the proper procedure and executing the procedure. Footnote 23Sometimes, seemingly simple actions can become challenging when a person is overwhelmed by stress, and one's ability to analyse the situation and find solutions can be seriously compromised by short-term memory limitations. Footnote 24 For this reason, certain manufacturers have made attempts to reduce, if not eliminate, the need for memory items in emergency and abnormal situations. Footnote 25 In some cases, manufacturers assume that pilots will carry out certain actions without consulting the checklist, but they do not label these as memory items. This practice was brought to light in one particular case in which the European Aviation Safety Agency recommended that operators develop their own memory items in accordance with their operating philosophy. Footnote 26

1.18.1.2 Emergency Checklists

Subsection 602.60(1) of CARs stipulates that flight crews must have a checklist or placards on board that allow operation of the aircraft in accordance with the limitations specified in the aircraft flight manual, aircraft operating manual, pilot operating handbook or any equivalent document provided by the manufacturer. The checklist or placards must also include procedures for abnormal or emergency situations. The checklist allows the flight crew to determine the appropriate response quickly and effectively, and to carry out all necessary actions to contain and manage an abnormal or emergency situation. Footnote 27 An improperly used or poorly designed checklist can have disastrous consequences.

Section 3 of the Cessna A185E AOM lists emergency procedures that pilots are required to know. Air Tamarac had made laminated copies of these procedures, which were available on board the aircraft for quick reference. Although section 3 includes steps for responding to loss of engine power and a procedure for power-off water landings, it does not contain instructions on how to restart an engine in flight, nor does it refer to the use of an auxiliary electric fuel pump. This type of aircraft is known for requiring the auxiliary pump to help restart a heated engine. Using the pump eliminates the air pocket in the mechanical fuel pump driven by the engine.

Section 3 of the AOM makes no reference to using the auxiliary pump to restart an engine following fuel exhaustion because the fuel selector valve is an optional item on certain Cessna 185 models such as the Cessna 185E. When there is no selector valve present, the engine is fuelled from the 2 tanks through gravity. It is therefore unlikely that the engine would fail following the exhaustion of a single tank, requiring an engine restart using the auxiliary pump. Furthermore, if the engine failed due to exhaustion of both tanks, using the boost pump would be of no use in restarting the engine.

However, section 7 of the AOM Footnote 28 contains instructions for restarting the engine in flight following fuel exhaustion of 1 tank. The pilot is instructed to switch tanks, place the auxiliary fuel pump switch in the EMER position, and move the power lever forward until the fuel flow indicator reaches the green arc, which should take approximately 1 or 2 seconds. However, these written instructions are not in the emergency checklists in section 3 of the AOM, nor are they included in the laminated checklists. The investigation revealed that the pilot was familiar with the instructions outlined in section 7, but the pilot failed to activate the auxiliary electric fuel pump. This prevented the engine from restarting in flight.

Section 3 includes actions the pilot must take when all attempts to start the engine fail, and a water landing is imminent.

- Select a suitable location for an emergency ditching.

- Pull the mixture control to the idle cut-off position.

- Pull the fuel shut-off to the OFF position.

- Place all switches in the OFF position.

- Make the approach at 90 mph.

- Deploy the flaps as required, within gliding distance of the selected surface.

- Unlock the cabin doors prior to the final approach.

- Attempt a 3-point (water) landing.

1.18.1.3 Fuel Management

To prolong cruise flight through fuel management, section 7 of the AOM recommends using the fuel selector valve to alternate between the left and right tanks in order to completely empty one tank before selecting the other. Section 7 also indicates that if the pilot wishes to completely empty a tank in flight, the auxiliary electric fuel pump may be required to help restart the engine. In this situation, it is recommended the pilot check that the auxiliary electric fuel pump is functioning properly before emptying a tank, by briefly activating the pump and checking the indicator for a slight increase in fuel flow.

The Pilot Safety and Warning Supplement, published by Cessna and amended in March 1998, contains additional information that, according to Cessna, acts as an important complement to the AOM and provides good safety practices. However, the Pilot Safety and Warning Supplement does not replace the aircraft's certified AOM.

Chapter 6 of the Pilot Safety and Warning Supplement describes how improper fuel management often causes airplane accidents. It also mentions that pilots often employ improper fuel management techniques. The supplement recommends that pilots become completely familiar with the fuel supply system and fuel tank switching procedures. It emphasizes that running a fuel tank dry as a routine procedure is an unsafe technique, although there are exceptions. Any sediment or water not drained from the fuel tank could be drawn into the fuel system and cause erratic operation or even power loss.

The company operations manual indicates that pilots must operate company airplanes in accordance with the limits and conditions prescribed in the AOM, a copy of which is on board each aircraft. Section 7 of the Cessna A185E's AOM recommends that the fuel tank selector valve be set to BOTH during take-off and landing, to eliminate the risk of fuelling the engine from an empty tank. In other phases of flight, the pilot may make his own selection, at his discretion. However, the same section of the AOM also indicates that when the valve is set on the BOTH position for a long flight, this may result in an unequal flow of fuel from the tanks if the wings are not maintained at the same level. In such a case, it is recommended that the engine be fueled from the desired wing to ensure continuous fuel flow.

During the last flight, the selector valve was placed in the LEFT position once the plane was in cruise flight to reduce the quantity of fuel in the left tank to a minimum and maintain a greater quantity in the right tank. Because it was easier to moor the plane from the left, the left wing would be positioned over the dock. This would allow for a greater quantity of fuel to be added to the left tank, as it was easier to access, and reduced fuelling time for the right tank, which was more difficult to access.

1.19 Useful or Effective Investigation Techniques

N/A

2.0 Analysis

2.1 Introduction

The pilot held the necessary licence and qualifications to carry out the flight, and had received all training as required by regulations. The pilot was familiar with the type of aircraft, as the majority of the pilot’s training was carried out on a Cessna 185. There is nothing to indicate that fatigue, weather conditions or the airworthiness status of the aircraft played a role in this occurrence. The investigation did not reveal any operating anomalies in the engine or fuel supply system. Engine stoppage was caused by momentary fuel starvation of the left fuel tank. Consequently, the analysis will focus on the safety instructions, fuel management, engine stoppage management, egress of occupants and survival aspects.

2.2 Safety instructions

Passenger guides published by Transport Canada (TC) were available for distribution to passengers. However, these were not offered to passengers for consultation before boarding. Had occupants read this guide, it may have raised their awareness of emergency procedures in the event of an accident.

Although safety information was provided by the pilot, it was given in 2 parts, first as the passengers were boarding and then during the taxi. It is possible that the passengers were distracted from the pilot’s safety instructions by the children’s excitement, engine noise and the movement of the aircraft on water. In addition, the information did not refer to the safety features cards, nor did it cover procedures for using the personal flotation devices (PFD) when evacuating a submerged and capsized aircraft.

If the passenger guide had been provided, and the pilot had offered complete safety instructions, the passengers may have been better prepared for a quick egress, increasing their chances of survival. As children are generally less attentive when they are excited, it would have been advantageous to consider the children separately when providing safety instructions, and to repeat the briefing if necessary.

2.3 Fuel management

The fuel quantity indicators were serviceable for the flight and met the certification basis requirements for this type of aircraft. However, this equipment is known to be unreliable on this type of aircraft, particularly when the amount of fuel drops below the one-quarter mark. For this reason, operators of this type of aircraft have become accustomed to using dipsticks. The current practice of using dipsticks seems to have led the pilot to rely on dipstick measurements instead of the information provided by the fuel quantity indicators.

Considering the quantity of fuel recovered from the wreckage after its removal from the water and the amount of flying time following the first sightseeing flight, it is likely that the quantity measured before the first sightseeing flight’s departure was relatively precise.

Although the pilot used the dipstick to measure fuel quantities before the previous flight, the quantity was not checked again before the accident flight. Even though the quantity of fuel on board was sufficient to carry out the flight in question, its exact distribution was not known to the pilot. After the first sightseeing flight of the day, which lasted approximately 20 minutes, the pilot estimated that the left tank contained approximately 10 gallons and that the right still contained about 15 gallons. While the imbalance between the 2 tanks would suggest that the first sightseeing flight, like the accident flight, was carried out with the tank selection valve primarily in the LEFT position, the information collected indicates that the valve was in the BOTH position, except for the final 7 minutes of the flight.

The company operations manual (COM) and the aircraft operating manual (AOM) recommend supplying the engine primarily from both tanks. However, there is no restriction on making another tank selection in cruise. Although chapter 6 of the Pilot Safety and Warning Supplement emphasizes that purposely running a fuel tank dry in flight is a poor technique, it indicates that there are exceptions. In this occurrence, the pilot had placed the selector valve on the left tank to facilitate the aircraft’s refuelling when it was at the dock.

As in occurrence A09C0167, the pilot did not rely on the fuel quantity indicators due to their unreliability. Since the pilot trusted the estimation of the quantity of fuel remaining in the left tank, the pilot was unable to predict the precise moment at which the tank would run dry, particularly as the actual amount seems to have been overestimated. The quantity of fuel recovered from the left tank was approximately 1 gallon above unusable levels. However, it is very likely that C-FZNK’s engine experienced momentary fuel exhaustion in its left tank, causing it to shut down.

2.4 Engine stoppage management

In the event of an emergency such as engine stoppage in flight, the pilot must gather information, process it, make a decision, and implement this decision. When engine failure occurred, the pilot had little time to carry out the above 4 steps; the aircraft was approximately 1000 feet above the ground. Considering a rate of descent that can reach close to 1000 feet/minute, the pilot had at most 60 seconds to carry out the applicable emergency procedure, select an appropriate location for a safe water landing, send out a distress call and remind passengers of the steps to take in preparation for an imminent water landing, all while maintaining control of the aircraft. Furthermore, when the wreckage was examined, the position of the various switches and engine levers suggested that several steps in the checklist governing emergency power-off ditching were not carried out. The pilot spent the majority of the time attempting to start the engine and trying to communicate with the company to report the problem.

Although the pilot had received all the required training, was familiar with this type of aircraft and knew the emergency procedure to carry out during an engine stoppage, the pilot failed to activate the auxiliary electric fuel pump, just like the pilot in occurrence A09C0167. Consequently, the air that was trapped inside the mechanical pump following fuel exhaustion could not be expulsed, preventing an engine restart.

Regardless of the reliability of one’s memory or the quality of one’s training, everyone is prone to forget details, particularly under stress. It is possible that the stress provoked by the engine stoppage affected the pilot’s memory, causing the pilot to forget to activate the auxiliary fuel pump. The engine stoppage may have caught the pilot off-guard, because with the estimated quantity of fuel in the left tank, the pilot should have had approximately 38 minutes of flying time remaining on this tank, whereas he barely completed 12 minutes.

Checklists are the best defence in counteracting forgetfulness in flight. Although the laminated emergency checklist was available on board the aircraft, there is nothing to indicate that the pilot referred to it. Even if the pilot had read the list, there was no reference to using the auxiliary electric fuel pump to restart the engine. This use of the auxiliary electric fuel pump is referenced in section 7 of the AOM, which deals with the aircraft’s optional systems.

Following engine stoppage, the pilot’s first priority is to remain in control of the aircraft. Due to the river’s surrounding terrain, the pilot was forced to make a sharp turn in an attempt to ditch the aircraft. Given the proximity of the aircraft to the ground, the pilot very liked pulled back on the yolk to reduce the rate of descent during the turn. Consequently, the aircraft’s load factor and stall speed increased, resulting in an aerodynamic stall at an altitude that precluded recovery.

2.5 Egress of occupants

Egress was difficult as the aircraft was inverted and the cabin quickly filled with dark water, in addition to the occupants being stunned by the violent impact. However, the occupants’ egress was facilitated by the openings created when the right door was torn off and the left rear window was broken.

Although having undergone underwater egress training, the pilot failed to unlock the door and take hold of a PFD. None of the occupants who succeeded in evacuating the aircraft thought of taking a PFD. As TSB Safety Study SA9401 demonstrated, it is unlikely that occupants will think of retrieving a lifejacket from an aircraft in their haste to reach the water’s surface. When this happens, a person’s chance of survival is even slimmer when injured.

The pilot and one of the passengers tenaciously made several dives, eventually pulling the 2 children from the wreckage. Unfortunately, one of them could not be revived; the child’s death was attributed to drowning. Considering the water temperature at the time of the accident and the stress it caused, the divers’ ability to hold their breath may have been reduced. Consequently, the 2 divers did not have much time to dive to the cabin, find the children inside the wreckage, unfasten their seatbelts and bring them to the surface. The darkness of the water reduced visibility, making it more difficult to locate the children inside the wreckage. In addition, the front left door was locked from the inside, which impeded access to the cabin’s interior.

The child in the rear seat hit a seatback and incurred major injuries to the head and face; these injuries may have resulted in a loss of consciousness. The other child, who was sitting behind the front passenger, did not display any signs of injury. The seatbelt was unfastened and the child had drowned, like the passengers of occurrence A09P0397. It is likely that the child’s disorientation impeded evacuation. Had there been other emergency exits, such as jettisonable windows, it is possible that the child would have succeeded in evacuating the floatplane and surviving the accident like the other occupants.

2.6 Survival

Survival statistics are not very positive when it comes to evacuating an inverted and submerged aircraft, under reduced visibility in cold water, following the shock of impact. Broadly speaking, the chances of surviving such an accident are low, which is why the TSB has made considerable effort over the years to recommend changes in this sector of air transportation. Transport Canada (TC) has implemented several changes and produced guides for occupants to improve the communication of safety information and increase its effectiveness. The TSB believes that the measures proposed by TC following the TSB’s 2 recommendations Footnote 29 are likely to reduce significantly or eliminate the safety deficiencies. However, the action has not been sufficiently advanced to reduce the risks to transportation safety. In the case of this occurrence, the speed at which assistance was provided to the occupants most certainly increased their chances of survival.

3.0 Findings

3.1 Findings as to causes and contributing factors

- The pilot did not measure the quantity of fuel with the dipstick before departing on the accident flight. Relying only on an estimation of the remaining fuel in the tanks, the pilot could not predict the precise moment at which the left tank would run dry.

- The fuel quantity indicators on this type of aircraft were not reliable. As a result, the pilot could not be sure of the quantity of available fuel in the left tank during flight.

- The engine very likely lost power due to momentary fuel starvation in the left tank.

- Following the loss of power, the pilot did not activate the auxiliary electric fuel pump, and was not able to restart the engine.

- The pilot very likely pulled back on the yolk, contributing to an aerodynamic stall, which took place at an altitude that precluded recovery.

- The safety briefing provided by the pilot to the occupants was incomplete; the pilot did not point out the location of the safety features cards on board the aircraft and did not instruct the occupants on how to use the personal flotation devices (PFD).

3.2 Findings as to risk

- When the passenger guides available at the seaplane base are not distributed to passengers before take-off, there is a risk that passengers may not recognize or appreciate the importance of emergency procedures in the event of an accident.

- When safety instructions are provided during taxi with the engine running, there is a risk that the noise or other distractions may prevent passengers from clearly understanding the information provided and being better prepared in case of emergency.

- When the pilot does not provide complete safety instructions to occupants, there is a risk that passengers will not be adequately prepared in the event of an emergency.

- When passengers egress an aircraft without their PFDs, their risk of drowning increases, particularly if they are injured.

- If safety instructions are presented to children while they are distracted, there is a risk that they will not be able to egress the aircraft on their own.

- When information is not presented to occupants regarding emergency egress and the use of a PFD in the event of an inverted and submerged aircraft, there is a risk that occupants will not be able to egress the aircraft.

3.3 Other findings

- The airplane was equipped with an emergency locator transmitter (ELT) that activated on impact. However, no signal was received because the antenna was submerged.

- The rapid assistance provided by local residents likely increased the occupants’ chances of survival.

4.0 Safety action

4.1 Safety action taken

4.1.1 Air Tamarac Inc.

New safety measures have been incorporated into the company’s operating procedures since May 2012, and the operations manual (COM) has been modified as well. The company showed its support for TSB Recommendation A11-06 by amending its COM to indicate that the wearing of personal flotation devices (PFD) is mandatory at all times for all occupants, including the pilot. The PFDs provided to pilots and passengers must be inflatable and must not inflate automatically when they come in contact with water. The manual stipulates that the pilot must always remind passengers to only inflate their PFDs once they have evacuated the aircraft.

In addition, the COM specifies that passenger safety briefings must now be given prior to engine start-up and include a demonstration of the use of PFDs in the event of accidental capsizing. What’s more, the emergency procedures and passenger briefing for an emergency landing include the instruction to unlock doors prior to impact.

The company’s training program now includes mandatory initial training, for all its pilots, on emergency egress procedures for floatplanes, with particular emphasis on underwater egress from capsized floatplanes. In addition, company pilots will be required to take rescue training.

In response to TSB Recommendation A11-05, Transport Canada issued a safety alert recommending aircraft design improvements facilitating egress. To allow rapid egress following a survivable collision with water, Air Tamarac has acquired a Supplemental Type Certificate (STC) needed for the purpose of adding jettisonable windows and moving the door handles on its DHC-2 Beaver aircraft, thereby demonstrating its support for TSB Recommendation A11-05.

Appendices

Appendix A – List of Laboratory Reports

The following TSB Laboratory reports were completed:

- LP 088/2011 – Engine Examination

- LP 094/2011 – Cessna 185E Illustration

- LP 089/2011 – GPS and ELT Analysis

- LP 177/2011 – Photo Analysis

Appendix B – Fuel System Footnote 30

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on . It was officially released on .