Runway Overrun

Trans States Airlines LLC

Embraer EMB-145LR N847HK

Ottawa/MacDonald-Cartier International Airport, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

An Embraer EMB-145LR (registration N847HK, serial number 14500857), operated by Trans States Airlines LLC as United Express Flight 8050 from Washington Dulles International Airport, landed at 1430 Eastern Daylight Time on Runway 07 at the Ottawa/MacDonald-Cartier International Airport, and overran the runway. The aircraft came to rest 550 feet off the end of Runway 07 and 220 feet to the left of the runway centreline. The nose and cockpit area were damaged when the nose wheel collapsed. There were 33 passengers and 3 crew members aboard. Two of the flight crew and 1 passenger sustained minor injuries.

1.0 Factual information

1.1 History of the flight

After a 29-minute delay on the ground, the United Express Flight 8050 (LOF8050) Embraer EMB-145LR regional jet, operated by Trans States Airlines LLC (TSA), departed Washington Dulles International Airport (KIAD) at 1326 Footnote 1 on a regularly scheduled flight to the Ottawa/MacDonald-Cartier International Airport (CYOW), Ontario. On board were 33 passengers, 2 pilots, and 1 flight attendant. This flight was the crew's second of 4 legs to be flown that day. The first officer was the pilot flying.

Before commencing descent, the flight crew received the Ottawa weather from the automatic terminal information service (ATIS). ATIS information Yankee was received at 1405, and Zulu at 1414.

ATIS Yankee included the following information: Ottawa International Information Yankee, weather at 1336: wind 100° magnetic (M) at 8 knots, visibility 15 statute miles (sm), broken ceiling at 2800 feet above ground level (agl), overcast at 5000 feet agl, temperature 18°C, dew point 13°C, and altimeter 29.90 inches of mercury (in Hg); approach instrument landing system (ILS) Runway 07; landing and departing Runway 07 and 04; land and hold short operation (LAHSO); advise air traffic control (ATC) if unable; inform ATC that you have information Yankee.

ATIS Zulu included the following information: Ottawa International information Zulu, weather at 1400: wind 100°M at 9 knots, visibility 15 sm, broken ceiling at 2700 feet agl, overcast at 5000 feet agl, temperature 18°C, dew point 13°C, and altimeter 29.86 in Hg; approach ILS Runway 07; landing and departing Runway 07 and 04; LAHSO; advise ATC if unable; inform ATC that you have information Zulu.

The crew briefed for an ILS approach for Runway 07 at CYOW.

The aircraft was vectored by ATC to a base leg at approximately 10 nautical miles (nm). At 1426, ATC advised the crew that the wind was 160°M at 10 knots gusting to 16 knots, with a visibility of 10 sm in light rain.

During the final turn to intercept the localizer, the airport controller informed the crew that they were in the process of switching the active runway to Runway 14. The crew was given the option of continuing for Runway 07 or switching to Runway 14. Considering the increased flight time, the extra fuel that would be used to manoeuver the aircraft for Runway 14, and the fact that the aircraft was already established on approach to Runway 07, the crew elected to continue for Runway 07.

The final approach course was intercepted at 7 nm. The aircraft began its final descent upon interception of the glideslope, at a position approximately 4.7 nm from the threshold, with the autopilot coupled. Nearing the final approach fix, 3.9 nm from the threshold, the landing gear was extended, the landing flaps were selected to 22°, and the autopilot was disconnected. At 1428, the control tower provided the crew with updated wind information of 160°M at 10 knots gusting to 16 knots. At approximately 1000 feet agl and 2.9 nm from the threshold, the airspeed was stable at 150 knots indicated airspeed (KIAS). Shortly thereafter, the windshield wipers were turned on, and the crew indicated that they had the runway in sight.

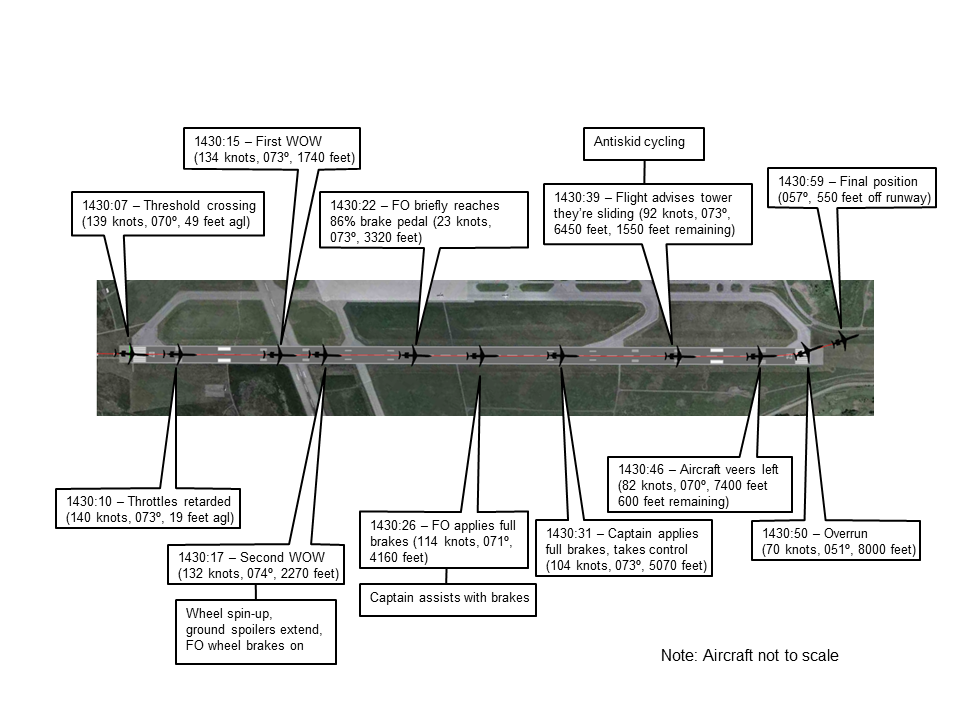

When the aircraft descended through approach minimums, 200 feet agl and 0.3 nm from the threshold, the airspeed was 144 KIAS. The aircraft crossed the threshold of Runway 07 at 49 feet agl, at a speed of 139 KIAS. The aircraft did a very smooth touchdown, and the weight on wheels (WOW) switch momentarily activated at 1430:15, 1740 feet from threshold. At that point, the nose was still in the air, and the aircraft floated. Two seconds later, 2270 feet from the threshold and at a speed of 132 KIAS, the second WOW activated and the nose wheel came down (Appendix B). Video recordings at the time of landing showed that the runway was wet.

The first officer was depressing the brake pedals during the second WOW activation; all spoilers automatically deployed after the nose wheel was lowered to the ground. The first officer continued to apply brakes until maximum braking was commanded. Sensing a lack of deceleration, the first officer informed the captain, who then took control of the aircraft and applied maximum braking as well. The aircraft could not be slowed during brake application.

he aircraft was on the centreline until approximately 200 feet before the end of the runway, where it veered left. The aircraft exited the paved surface of the runway at approximately 62 KIAS. It continued through the grass for approximately 120 feet, at which point there was a sharp downward change in elevation of about 2 feet. The nose gear collapsed rearward, but the aircraft continued to skid. It came to a rest 550 feet from the end of the runway and 220 feet left of centreline. The flight attendant initiated the evacuation procedure for the passengers.

1.2 Injuries to persons

There were 33 passengers and 3 crew members aboard. Two of the flight crew and 1 passenger sustained minor injuries (Table 1)

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | − | – | – | − |

| Serious | – | – | – | – |

| Minor | 2 | 1 | – | 3 |

| None | 1 | 32 | – | 33 |

| Total | 3 | 33 | 36 |

1.3 Damage to aircraft

The aircraft was substantially damaged after it exited the runway.

1.4 Other damage

During the accident, there was no damage to the runway or blast pad at the exit end; 1 runway end light was damaged.

1.5 Personnel information

1.5.1 Flight crew

The flight crew on board the aircraft consisted of a captain, a first officer, and a flight attendant. Both the captain and the first officer of LOF8050 held United States airline transport pilot (ATP) licences. The crew was assigned for a 4-day pairing, which commenced the day before the occurrence.

Records indicate that the flight crew was certified and qualified for the flight in accordance with existing regulations (Table 2).

The captain and the first officer had been employed by TSA for approximately 10 years and 4 years, respectively. The flight attendant had been employed by TSA for approximately 8 years.

| Captain | First officer | |

|---|---|---|

| Pilot licence | ATP | ATP |

| Last medical | 11 January 2010 | 15 February 2010 |

| Total flying hours | 11 400 | 3000 |

| Hours on type | 3645 | 2691 |

| Hours, last 6 months | 450 | 500 |

| Hours on type, last 30 days | 70 | 79 |

| Hours on duty before occurrence | 5 | 5 |

| Days off duty before start of pairing | 8 | 3 |

1.5.2 Pilots' 72-hour history

Although the captain's normal sleep pattern varied, his average sleep duration was reported as 6 to 7 hours of sleep between the hours of 2130 and 0800. On 15 June, the captain awoke at 0500 (0400 local), and commuted by aircraft from home in Sand Springs, Oklahoma, to Dallas, Texas, and then to KIAD, where the duty day started at 1601.

After flying 3 legs, the crew ended their duty day at Greenville−Spartanburg International Airport (KGSP). The flight crew's original duty day was scheduled to end at 2238 in KGSP. However, due to weather and flight delays, they did not arrive at the hotel in Greenville until 0030 on 16 June.

The captain slept from 0230 to 0630 on 16 June 2010, and after taking the 0900 bus, started the duty day at 0925 and flew from KGSP to KIAD, and then to CYOW. This sequence provided the captain with 4 hours of sleep (2 to 3 hours fewer than normal) during the 33.5 hours before the accident occurred.

The first officer reported normally obtaining an average of 7.5 hours of light sleep, which included a couple of awakenings per night. On 15 June, the first officer woke at 0400 and commuted from home in Charleston, South Carolina, to KIAD. The first officer obtained 4.5 hours of unbroken rest in the crew duty room from 0730 to 1200, followed the same work schedule as the captain, and went to sleep at the hotel in Greenville, South Carolina, at 0230. The first officer slept lightly, waking twice during the night for about 15 minutes each time, finally awoke and got up at 0800, took the 0900 bus, and started the duty day at 0925. The first officer likely obtained 5 hours of sleep in the 26.5 hours before the occurrence.

The crew was provided with the minimum rest period of 9 hours, which included travelling to and from the airport. These work schedules conformed to the work/rest rules prescribed in United States Federal Aviation Regulations (FAR) Section 121.471. Nevertheless, the investigation determined that the pilots were concerned about experiencing fatigue during the work period before the accident.

1.6 Aircraft information

| Manufacturer | Embraer Inc. |

|---|---|

| Type and model | EMB-145LR |

| Year of manufacture | 2004 |

| Serial no. | 14500857 |

| Certificate of airworthiness | Issued 10 February 2004 |

| Total airframe time/cycles | 14 782.3 hours/13 829 cycles |

| Engine type (no.) | Rolls Royce AE3007A1 (2) |

| Maximum allowable take-off weight | 48 501 pounds |

1.6.1 General

Records indicate that the aircraft was certified, equipped, and maintained in accordance with existing regulations and approved procedures. Nothing was found to indicate that there was any airframe failure or system malfunction before or during the flight. The investigation team calculated the landing weight of the aircraft as 39 352 pounds, using actual baggage weights and standard passenger weights. The weight and centre of gravity were within the prescribed limits for a flaps-22 landing on Runway 07.

The EMB-145LR is a 50-seat regional jet manufactured by Embraer of Brazil. All EMB-145LRs are equipped with wing spoilers and an antiskid braking system to slow and stop the aircraft. On the ground, with the weight on the aircraft wheels, all 4 spoilers deploy automatically. Spoilers increase drag and assist braking by causing loss of lift by the wing, resulting in transfer of the weight of the aircraft from the wings to the landing gear. All operated normally.

As an option, the EMB-145LR can be equipped with thrust reversers. Of the 28 EMB-145s operated by Trans States Airlines, approximately half of the fleet is equipped with thrust reversers; the occurrence aircraft was not.

Thrust reversers have been shown to play a significant role in reducing accelerate-stop distances on wet and contaminated runways, and provide a stopping force that is not dependent on runway friction. When landing on a runway with poor braking action, the effect of reverse thrust can make a dramatic difference, and has contributed positively to the accelerate-stop safety record of the transport-category airplane fleet. Footnote 2,Footnote 3

1.6.2 EMB-145 brake system

The main brake system of the Hydro-Aire Mark V is a fully digital, brake-by-wire system with an antiskid function. The brake system includes a brake control unit (BCU), inboard/outboard brake-control valves, pedal transducers, brake assemblies, pressure transducers, and wheel-speed transducers. The BCU contains the circuitry to control, monitor, and test the system's components. Application of the brake pedals by either pilot sends a signal to the BCU, which then sends a signal to the valves that control the supply of hydraulic fluid to the brake assemblies in proportion to the amount of brake-pedal pressure. Brake control through the brake pedals is tiered. The first portion of pedal movement gives very little brake authority; the second portion gives moderate authority; and the third portion gives the most authority. If both pilots activate the brakes at the same time, the brake pressure is proportional to the pedals with the most deflection. Pressure-feedback signals from the pressure transducers are used to ensure close correlation between commanded and resulting brake pressure.

The brake system also includes touchdown protection, which inhibits brake actuation before the main wheels spin up during landing. Brake actuation is allowed either 3 seconds after wheels have spun up to 50 knots or until 3 seconds after the last WOW activation, whichever occurs first.

The antiskid system modulates the hydraulic pressure commanded by the brake pedals, forcing the wheels to operate at or near the critical slip ratio,Footnote 4 where the maximum friction coefficient is developed. The system does not apply pressure on the brakes, but rather relieves it to avoid skidding. The BCU receives signals from the wheel-speed transducers located in each of the 4 main wheel hubs. When any one of the signals indicates a decrease in speed to below the average speed of the other 3 wheels, a skidding condition is assumed, and the brake pressure for the associated wheel is relieved. When that specific wheel's speed returns to the average speed of the others, the commanded braking pressure is restored.

The brake-system components from the aircraft were tested by the brake manufacturer, with Transportation Safety Board of Canada (TSB) investigators in attendance. Nothing was found to indicate that there was any brake system failure or system malfunction.

1.6.3 Main wheel tires

The pressure of the main landing-gear tires was taken shortly after the occurrence. Tires 1, 2 and 3 indicated 160 pounds per square inch (psi), and tire 4 showed 158 psi, all of which were within the required 160 psi +/− 4 psi.

A detailed examination of the tires revealed only minor damage (cuts and chunking). This type of damage is typical for tires striking foreign objects on the runway or on the ground after an excursion from the runway.

1.6.4 Aircraft performance

Before departure, the crew received a flight-release package from the company dispatch. The flight-release package contained all information pertinent to the flight, including current and forecast weather, winds aloft,notices to airmen (NOTAMs), and airport/runway analysis data.

The flight-release package depicts performance data in the form of aircraft weight for take-off or landing, and any additional restrictions that may apply. On the day of the occurrence, the maximum landing weight permitted for Runway 07 at CYOW, with a flaps setting of 22°, was 42 549 pounds. The landing weight was calculated by the crew to be 39 262 poundsFootnote 5, which was well within the limits for a flaps-22 landing on Runway 07.

TSB requested calculation of the aircraft's landing performance from Embraer. Embraer based its calculations on an aircraft configuration of flaps 22, a speed of 139 KIAS at 49 feet over threshold, the relevant runway data, the environmental conditions that existed at the time of the occurrence, and the same touchdown point of 2270 feet. As well, Embraer used the wet runway braking coefficient of friction for a smooth wet runway provided in FARs Part 25 for accelerate-stop distance. Footnote 6 Using only brakes and spoilers (landing performance excludes the use of thrust reversers), the aircraft should have come to a stop 6216 feet from the threshold, with slightly less than 1800 feet of runway remaining. However, according to the flight data recorder (FDR), the occurrence aircraft's speed was still 96 KIAS at that point.

1.6.5 Braking performance from flight data recorder

The operation of the in-flight brake function was recorded during the initial climbout following the occurrence take-off from KIAD, indicating that the brake-control valves were supplying pressure to the individual brake assemblies.

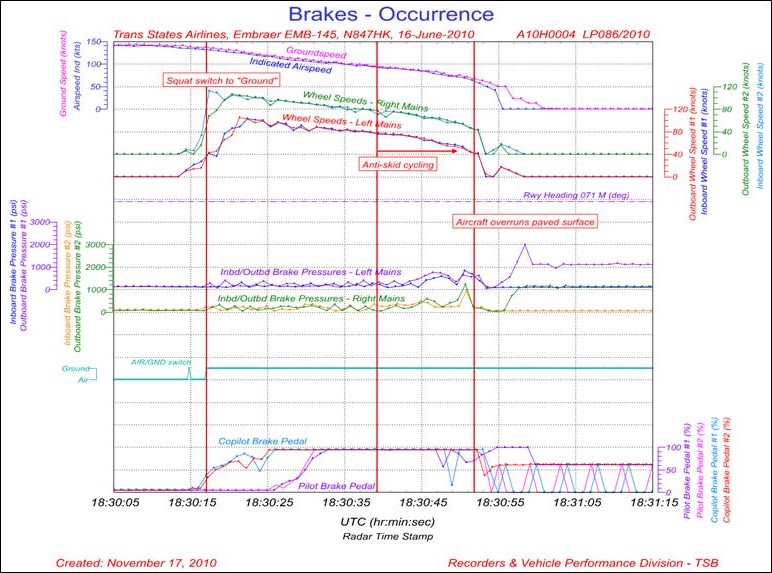

The FDR data showed that the main landing-gear wheels started spin-up approximately ½ second before the first WOW indication. The first officer's brake pedals were being depressed as the second WOW was recorded. The wheel-speed parameters indicated increasing wheel spin-up, with the right wheels accelerating faster than the left wheels.

The first officer continued to depress the brake pedals as the nose landing gear touched down. Approximately 5 seconds after the second WOW indication, the pedal position increased momentarily to 86% Footnote 7 of maximum travel. At this point, the left main wheels were accelerating, matching the speeds of the right main wheels, which were decelerating. All 4 main wheel speeds declined at similar rates from this point. The brake pressures became active as wheel speeds increased above 50 knots. All 4 of the brake pressures recorded values between approximately 200 and 400 psi, which were significantly lower than the maximum possible brake pressure of 3000 psi. Typically, the peak brake pressure varies between 1000 and 2000 psi during landing, depending on the conditions.

The first officer's brake pedals reached 95% of maximum travel at 1430:26, remaining at that position until near the end of the runway. The captain started to apply wheel brakes at 1430:26, following indications that the aircraft was sliding; both pilots were applying the brakes from this point on until the aircraft overran the runway. For the last 1500 feet, the antiskid system was cycling, attempting to modulate the brake pressure (Appendix I).

The aircraft was approximately 600 feet from the end of the runway, proceeding at a ground speed of 82 knots, when the antiskid system let the brake pressures on the main wheels increase. The brake pressures increased to a range of 600 to 750 psi on the left main wheels and to a range of 300 to 500 psi on the right main wheels, indicating that there were better friction characteristics on the left side than on the right side. At this point, the aircraft's heading of 070°M began to decrease at a rate of approximately 6° per second. The captain's rudder force increased to nearly 120 pounds on the right pedal, while the first officer's rudder force increased to approximately 80 pounds on the right pedal. At the same time, the control wheel was being turned to the right by about 6° to 7°. The lateral acceleration recorded increasing negative g, Footnote 8 initially reaching approximately −0.3 g. The negative lateral g was consistent with a nose-left skidding motion as the aircraft approached the end of the runway. The FDR did not provide any parameters to determine if the tiller was used to steer the aircraft to the left of centreline.

1.6.6 Aircraft braking coefficient

Braking coefficient is a measure of the friction between the runway and the aircraft tires during braking. It is expressed as a number from 0 to 1, with a higher number indicating higher friction. The aircraft braking coefficient was calculated using FDR data and aircraft information provided by the manufacturer. This calculation was done both for the occurrence landing and for the previous landing that took place in KIAD.

To understand the operation of the brake system during the previous landing on a dry runway and during the occurrence landing on a wet runway, the calculated braking coefficient for both landings was compared with the brake pressure and brake-pedal position. During the previous landing, the braking coefficient and the brake pressure increased with an increase in brake-pedal position. When the brake-pedal travel increased from 5% to 50%, the braking coefficient increased from 0 to 0.3, and the brake pressure increased from approximately 200 psi to approximately 900 psi. These values of brake-pedal position, brake pressure and aircraft braking coefficient were typical for an aircraft landing on a dry runway.

For the occurrence landing, the brake-pedal position went from 0% to 95%, while the braking coefficient and brake pressure remained constant at 0.07 and 200 psi, respectively. These values were much lower than those for the previous landing.

The aircraft braking coefficient of friction calculated for the occurrence ground roll was compared with the wet runway braking coefficient of friction (adjusted for a fully modulated antiskid system) used by Embraer as per FAR 25.109(c). The comparison showed that the occurrence aircraft had a braking coefficient significantly lower than that predicted by the smooth wet runway equations in FAR 25.109(c)(1).

Another comparison was made between the FDR data from the occurrence ground roll and brake-system test data obtained from Honeywell for the ground-roll phase of wet runway landing. The test was conducted in an aircraft under the same conditions and with the same configuration as the occurrence aircraft. The test showed that braking performance by the occurrence aircraft was as expected, and that the brake system on the occurrence aircraft performed as designed. The test also indicated that the braking coefficients of friction for both landings were similar and significantly lower than that predicted by the smooth wet runway equations in FAR 25.109(c)(1).

As well, investigations by the National Transportation Safety Board (NTSB) into a number of occurrences indicated that the wet runway braking coefficient of friction during the landing phase was significantly lower than that defined in the FAR 25.109(c)(1).

1.7 Meteorological information

1.7.1 General

On 16 June 2010, light rain was reported on the 1100, 1200 and 1300 aviation routine weather reports (METARs), but not on the 1400 observation. Rain had started falling again at CYOW at 1418, and continued to fall after the accident occurred. The 1418 special weather observation (SPECI), issued at 1426, reported the following conditions: wind 150° true (T) at 12 knots, visibility 10 sm, light rain, overcast at 2300 feet agl, temperature 16°C, dew point 13°C, altimeter 29.86 in Hg.

1.7.2 Forecast weather

A terminal aerodrome forecast (TAF) for CYOW, valid from 0800 on 16 June 2010 until 0800 on 17 June, was issued at 0738 on 16 June, with the following information: wind 100°T at 8 knots, visibility 6 sm, and overcast ceiling at 12 000 feet agl; from 1100: wind 100°T at 10 knots, visibility 6 sm in light rain, scattered clouds at 3000 feet agl, and overcast ceiling at 6000 feet agl; from 1200: wind 120°T at 10 knots gusting to 20 knots, visibility 6 sm in light rain and mist, scattered clouds at 800 feet agl, and overcast ceiling at 3000 feet agl; temporary condition between 0800 and 1400: visibility 3 sm in moderate rain showers and mist, and overcast ceiling at 2000 feet agl.

An updated TAF for CYOW was issued on 16 June 2010 at 1044, valid from 1100 on 16 June until 0800 on 17 June, as follows: wind 070°T at 8 knots, visibility 6 sm in light rain, scattered clouds at 3000 feet agl, and overcast ceiling at 6000 feet agl; from 1200: wind 120°T at 10 knots gusting to 20 knots, visibility 6 sm in light rain and mist, scattered clouds at 800 feet agl, and overcast ceiling at 3000 feet agl; temporarily between 1200 and 1400: visibility 3 sm in moderate rain showers and mist, and clouds overcast at 2000 feet agl; from 1400: wind 120°T at 10 knots gusting to 20 knots, visibility 6 sm, and clouds overcast at 2000 feet agl; temporarily between 1800 and 0300 on 17 June: visibility 6 sm in mist, and overcast ceiling at 800 feet agl.

The TAF for CYOW issued on 16 June 2010 at 1338, valid from 1400 on 16 June until 1400 on 17 June was as follows: wind 090°T at 12 knots, visibility 6 sm in light rain, broken ceiling at 4000 feet agl, and overcast at 6000 feet agl; temporarily between 1400 and 1700: visibility 2 sm in moderate rain showers and mist, and overcast ceiling at 700 feet agl.

All of the foregoing TAFs indicated a possibility of rain during the expected arrival time of LOF8050.

1.7.3 Accident check observation

The weather observation office is not connected to the crash bell system, and was not immediately informed that an accident had occurred. One of the items on the control tower checklist requires the weather observer to be informed of an aircraft accident,Footnote 9so that an accident check weather observation Footnote 10can be made immediately. This item was overlooked by tower personnel when the accident call-out checklist was initially performed. As a result, an accident check observation was not recorded until 1455, or 25 minutes after the accident.

1.7.4 Precipitation

Precipitation is reported by type and by intensity, which is described as light, moderate or heavy. Intensity is determined either by visual evaluation or by measurement of rate. The intensity of rainfall at CYOW is determined by visual evaluation.

The amount of rainfall at CYOW is normally measured and recorded in 6-hour periods to satisfy synoptic Footnote 11 reporting requirements; a standard rain gauge with a funnel and graduated cylinder is used. The observer must visually read the amount of water in the collection cylinder.

The Stormwater Unit of the City of Ottawa maintains its own automatic rainwater-measuring system across the city, part of which is located on CYOW property in the compound holding other meteorological equipment. The system consists of a tipping-bucket rain gauge that sends electronic impulses to a computerized recording system. The resulting information is not provided to the CYOW aerodrome weather-observing station.

Using information provided by the City of Ottawa, the TSB determined that the total accumulated rainfall from 1418 until the aircraft landed was approximately 2.0 mm. A review of the 5-minute cumulative data for this period reveals a rainfall intensity of 4.8 mm/hour Footnote 12 over the first 5 minutes of rainfall, increasing to approximately 7.2 mm/hour at the time LOF8050 landed. Based on the Environment Canada Manual of Surface Weather Observations (EC MANOBS) chart in Section 3.9.5 (Appendix C), this intensity would equate to moderate rainfall at the time that the occurrence aircraft landed.

The onset, or end, of precipitation is one of the criteria identified in EC MANOBS 10.3.5.6[c] for issuing a SPECI observation. However, at the time of the occurrence, in accordance with EC MANOBS, once rainfall intensity was reported, there was no requirement to report a change in the intensity until the next METAR was issued. In this occurrence, light rain was reported on the 1418 SPECI observation. Since November 2010, when Amendment 75 to Annex 3 of the International Civil Aviation Organization (ICAO) took effect, a SPECI shall be issued at the onset, at cessation, or upon a change in intensity of freezing precipitation, moderate or heavy precipitation, and thunderstorms (with precipitation).Footnote 13

1.8 Aids to navigation

There were no reported outages of navigation aids at the time of approach and landing of LOF8050 on Runway 07. As a precautionary measure, the ILS for Runway 07 was shut off shortly after the accident, subsequently checked, and returned to service at 0918 on 18 June 2010.

1.9 Communications

Communications between LOF8050 and Canadian ATC services were normal.

The flight crew initially had some difficulty reaching TSA Ottawa operations personnel to advise TSA of the flight's arrival time and to receive any further instructions. This communication was not established until the aircraft received vectors from ATC and turned 5 miles final for Runway 07.

1.10Aerodrome information

1.10.1 Airport

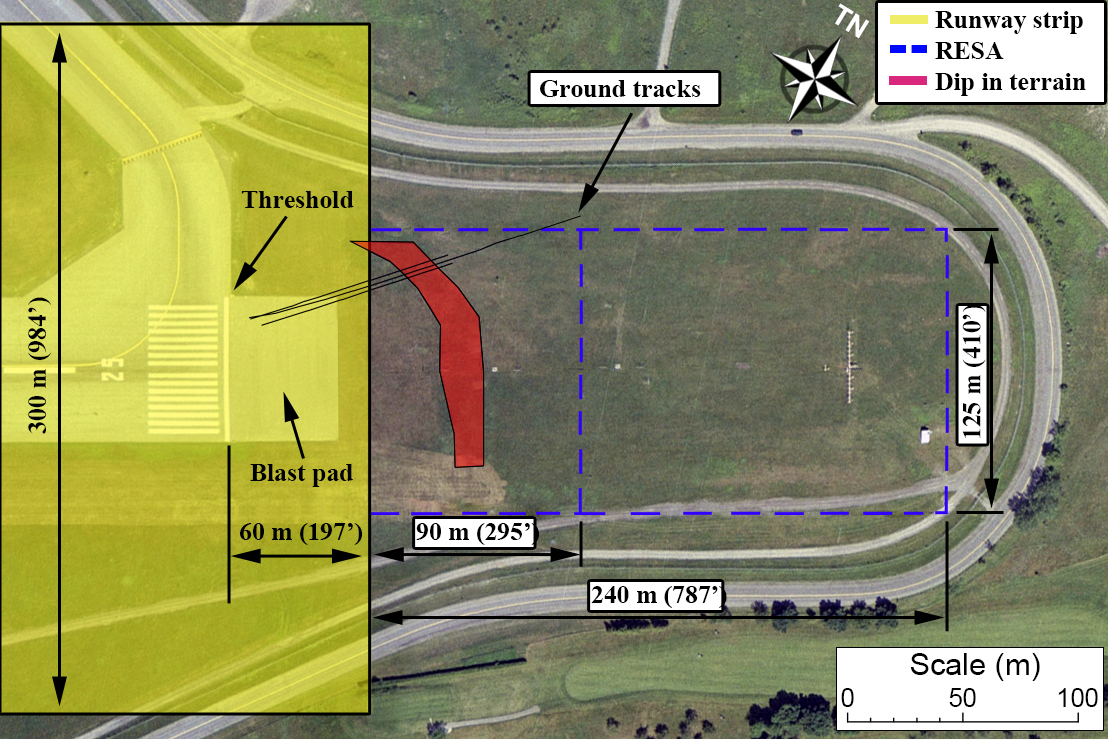

CYOW is leased and operated by the Ottawa International Airport Authority, under a 60-year lease from Transport Canada. There are 3 runways: 07/25, 14/32, and 04/22. The active runway for arrivals on the day of the occurrence was Runway 07, a reference code 4E Footnote 14 runway. The runway is 8000 feet long by 200 feet wide, with an asphalt surface. The longitudinal slope is <1% overall average for the full length of the runway. The touchdown zone elevation is 373 feet asl. Runway 07/25 has an asphalt blast pad measuring 150 feet long by 200 feet wide before each runway threshold.

The runway strip for Runway 07 is 1000 feet wide, and extends 200 feet (60 m) past each end of the runway, with a grass surface. These dimensions meet the standards for a runway strip of the Transport Canada (TC) publication Aerodrome Standards and Recommended Practices (TP312E). Footnote 15

1.10.2 Runway end safety area

TP312E defines a runway end safety area (RESA) as

an area symmetrical about the extended runway centreline and adjacent to the end of the strip, primarily intended to reduce the risk of damage to an aeroplane undershooting or overrunning the runway.

Before 1999, Canada was in compliance with the RESA criteria as described in ICAO Annex 14. In 1999, ICAO elevated the recommended practice of a 90-m RESA to the status of a standard, with a recommendation that "a runway end safety area should, as far as practicable, extend from the end of a runway strip to a distance of at least 240 m where the code number is 3 or 4 …" As a result of the change in status in the ICAO specification, Canada filed a difference with ICAO, in accordance with the Chicago Convention, stating that Canada does not provide RESAs, but does provide a 60-m graded strip beyond the runway end. While TP312E recommends 90-m RESAs, they are not required. At the time of the occurrence, no runway at CYOW had a RESA.

If an airport decides to install a RESA, TP312E provides additional guidance for grading, strength and desired slopes of the RESA surface. For the longitudinal slope, the recommended practice limits the downward slope to 5% or less, and specifies that it should be a gradual slope and there should not be any abrupt changes or reversals of slope. Similarly, any transverse slopes should not exceed an upward or downward slope of 5%, and should be as gradual as possible.

Across the end of Runway 07 at CYOW, beyond the end of the runway strip, there was an abrupt dip in the ground, with a sudden downward slope of approximately 9.5%. The dip had a drop of just over 0.8 m, over a run of about 8.5 m. The occurrence aircraft ran over this dip, at which point the nose gear collapsed, resulting in substantial damage to the underside of the aircraft. The aircraft came to rest approximately 55 m beyond the dip (Appendix F).

As a result of the runway overrun accident of an Airbus A340 at Toronto/Lester B. Pearson International Airport in 2005, the Board issued Recommendation A07-06, Footnote 16 which stated that

"The Department of Transport require all Code 4 runways to have a 300-m runway end safety area (RESA), or a means of stopping aircraft that provides an equivalent level of safety."

The latest response Footnote 17 from TC regarding Recommendation A07-06 states that TC plans a risk assessment to establish RESA criteria at Canadian airports. The stated objective for this risk assessment is to collaborate with industry to establish a RESA length on a case-by-case basis.

No details are provided from TC as to how a RESA length would be established for Code 4 runways as stated in the recommendation.

Presumably, the results of this risk assessment would affect the current version of TC's Notice of Proposed Amendment (NPA) 2010-012, Footnote 18 which currently has been deferred as a result of a meeting of the Civil Aviation Regulatory Committee (CARC), dated 12 January 2011. This approach will result in further delays and a protracted period in which Canada is not in compliance with international standards.

As the proposed risk assessment may address RESA requirements for Code 4 runways, it will reduce but not eliminate the deficiency as described in Recommendation A07-06 if fully implemented. This latest response from TC has been assessed by the Board as Satisfactory in Part. Footnote 19

1.10.3 Preferential runway

Due to published noise-abatement procedures for turbojet aircraft at CYOW, Runway 07/25 is used a large percentage of the time.

A chart showing the maximum crosswind component for continued operation of a particular runway was available to help the tower controllers select the most operationally suitable runway. Runway 07/25 is the preferred runway when windspeed is 15 knots or less with a 90° crosswind. The wind at the time that LOF8050 landed was reported as 160°M at 10 knots gusting to 16 knots. The tower had coordinated a change to Runway 14, which was to take effect after LOF8050 landed, because the crosswind component, including the gust, exceeded the maximum value specified in the chart.

1.10.4 Runway maintenance

The Ottawa International Airport Authority has in place a program to evaluate the condition of airside surfaces; the program includes airfield-pavement structural-condition surveys and runway friction testing. Both the surface condition and surface quality of runways are evaluated. Daily, periodic visual inspections of the airfield are conducted by the airport duty managers, field foreman and manager of airfield operations. Aircraft movement surface-condition reports are not normally issued during nonwinter months. There are no specific instructions in TP312E for airport personnel to conduct a runway surface condition assessment immediately after the start of rainfall or during periods of rainfall.

Over time, the skid resistance of runway pavement deteriorates due to a number of factors, such as mechanical wear, polishing action from aircraft tires rolling or braking on the runway surface, and accumulation of contaminants. Runway contaminants include rubber deposits, dust particles, jet fuel, oil spillage, water, snow, ice, and slush, all of which can cause loss of friction on runway pavement surfaces. The effect of these factors is directly dependent on the volume and type of aircraft traffic. Footnote 20

Done on a regular basis, runway friction testing assists in determining whether corrective maintenance action is required to restore a runway's friction characteristics, or whether such maintenance must be planned. The runway coefficient of friction is measured using a Saab Surface Friction Tester with a self‑wetting capability that, as per TC guidelines, creates a 0.5-mm layer of water on the runway.

TP312E contains the following standards, Footnote 21 which require the airport to react when the average friction values for a runway fall below specified levels:

9.4.2.4 Standard − Corrective maintenance action shall be taken [emphasis added] when:

- the average coefficient of friction for the entire runway is below 0.50; or

- any areas of a runway surface that are 100 metres or greater in length have an average coefficient of friction less than 0.30.

9.4.2.5 Standard − Corrective maintenance action shall be programmed [emphasis added] when:

- the average coefficient of friction for the entire runway is below 0.60; or

- any areas of a runway surface that are 100 metres or greater in length have an average coefficient of friction less than 0.50.

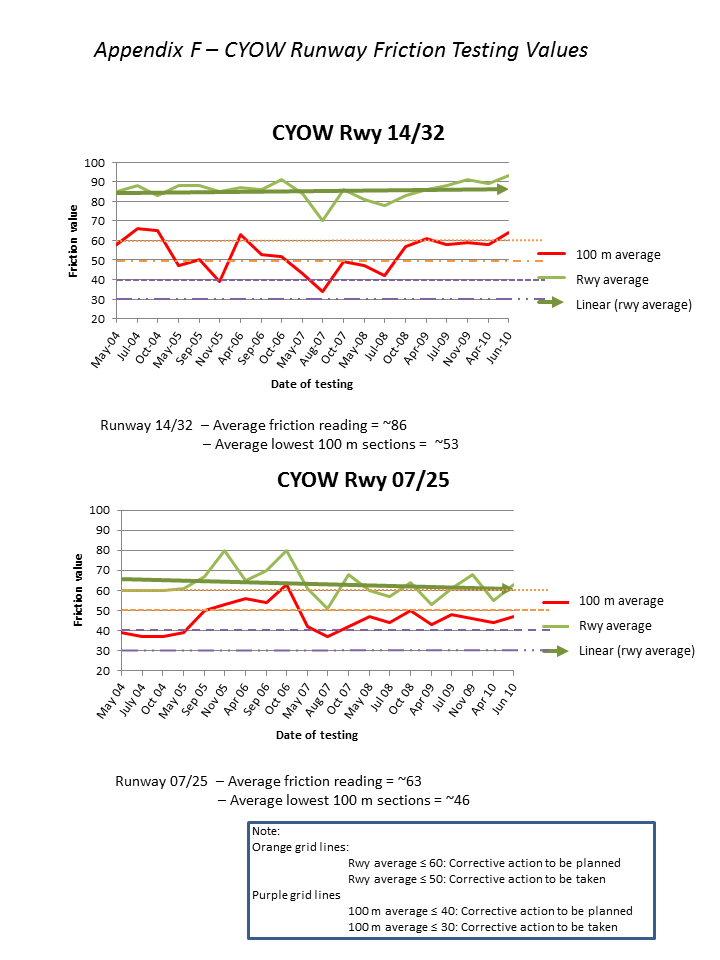

The Ottawa International Airport Authority periodically conducts friction tests of all runways through a contractor. This testing is done at least 3 times per year in nonwinter months. The results of the testing provide trend information. The last friction test performed at CYOW before this accident was in April 2010 (Appendix F). The average coefficient of friction for the entire length of Runway 07/25 was 0.55, Footnote 22 and the minimum 100-metre section average was 0.44. These values are the averages of 4 measurements taken at 3 metres along each side of the centreline of the runway. Based on these results, the Airport Authority only planned further friction testing of 07/25 within a period of 2 months. TP312E does not provide a time frame within which corrective maintenance action must be taken.

Before the accident, no corrective maintenance action took place. A runway friction test was completed on 25 June 2010. This test revealed an average runway coefficient-of-friction value of 0.63, which was a 14.5% improvement over the April test. The lowest average coefficient of friction for a 100-m section was 0.47. Rubber removal was completed on 21 July 2010.

The average coefficient of friction since 2004 for Runway 07/25 and that for Runway 14/32 were compared (Appendix F). Runway 14/32 shows significantly higher friction readings when compared with Runway 07/25. The readings over the past 6 years have been fairly stable for Runway 14/32; however, for Runway 07/25, the friction readings have shown a slow but steady decline over the same period.

The investigation determined that many countries use the ICAO-recommended 1.0-mm layer of water when measuring the runway coefficient of friction; Canada uses 0.5 mm. The threshold criteria for taking corrective action to restore runway friction characteristics (Table 4) were developed using a surface-friction tester vehicle with a smooth tire, at a pressure of 210 kPa, travelling at 65 km/h.

| Threshold criteria | Minimum friction values | ||

|---|---|---|---|

| TC Footnote 23 | FAA Footnote 24 | ICAO Footnote 25 | |

| Runway average − corrective action programmed | 0.60 | 0.60 | 0.60 |

| Runway average − corrective action required | 0.50 | 0.50 | 0.50 |

| Lowest 100-m average − corrective action programmed | 0.40 | 0.60 | 0.60 |

| Lowest 100-m average − corrective action required | 0.30 | 0.50 | 0.50 |

The Ottawa International Airport Authority conducted monthly friction testing on Runway 07/25 from April to August 2011, using both 0.5-mm and 1.0-mm layers of water. Six different testing sessions were conducted, and the results were provided to the investigation. Based on the minimum friction values for the lowest 100-m average in the above table, immediate corrective action would have been required 5 times out of 6 when using values from the ICAO / Federal Aviation Administration (FAA). However, when using TC criteria, the 2011 results indicated that no corrective action would have to be planned or taken.

Based on these test results, the Ottawa International Airport Authority took corrective action and issued a "runway slippery when wet" NOTAM. The Airport Authority also ordered rubber-removal operations twice during the test period, and engaged an asphalt re-texturing service to treat the runway surface. Footnote 26

1.10.5 Runway surface texture

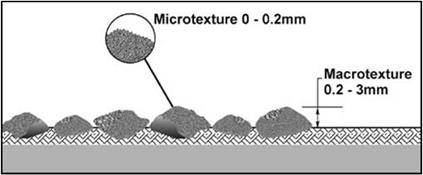

Runway surface texture is considered to be the main factor in the braking friction coefficient of a wet runway. Runway surfaces contain both macrotextures and microtextures (Figure 1 Footnote 27).

Macrotexture is the coarse texture evidenced by the aggregate or by artificially applied texture such as grooving. Its primary purpose is to enhance bulk-water drainage, thereby reducing the tendency for aeroplane tires to be subject to dynamic hydroplaning. Footnote 28

Microtexture is the texture of the individual stones and is hardly detectable by eye. It can be felt, but cannot be directly measured, and it is one of the most important factors in reducing the onset of viscous hydroplaning. Footnote 29

Degradation of microtexture, caused by the effects of traffic, rubber deposits, and weathering, may occur within a comparatively short period compared with the time required for degradation of surface macrotexture. Footnote 30

Both ICAO Annex 14, Volume I, and Section 3.1.4.4 of TP312 recommend that the average macrotexture depth of a new surface be not less than 1 mm, to provide good friction characteristics when the runway is wet. Although a depth of less than 1 mm may still provide good drainage, a depth greater than the minimum value must be chosen when constructing a new surface, because normal wear will result in surface deterioration. The last reconstruction of Runway 07/25 before the occurrence was in 1994. Testing completed at CYOW after the accident indicated that macrotexture depth on Runway 07/25 varied from 0.418 mm to 1.262 mm, with an average depth of 0.928 mm.

1.10.6 Runway surface condition

ICAO Annex 14, Volume 1, Chapter 2 recommends that:

Whenever water is present on a runway, a description of the runway surface conditions on the centre half of the width of the runway, including the possible assessment of water depth, where applicable, should be made available using the following terms:

DAMP — the surface shows a change of colour due to moisture.

WET — the surface is soaked but there is no standing water.

WATER PATCHES — significant patches of standing water are visible.

FLOODED — extensive standing water is visible.

TP312E states, in section 2.5.1.1:

Standard — Information on the condition of the movement area and the operational status of related facilities shall be provided to the appropriate aeronautical information service units, and similar information of operational significance to the air traffic services units, to enable those units to provide the necessary information to arriving and departing aircraft. The information shall be kept up to date and changes in conditions reported without delay.

The term "wet," when referring to the condition of a runway surface, is used in many publications, including the Canadian Aviation Regulations (CARs) and the TC Aeronautical Information Manual. However, there is no common definition in Canada. NAV CANADA, in its Air Traffic Control Manual of Operations, defines a wet runway as one that "is covered with sufficient moisture to cause it to be reflective, but is not contaminated." Footnote 31 The word "contaminated" is not defined. A paper submitted to the 2009 conference of the International Society of Air Safety Investigators stated that "the only information that a pilot gets is based on the assumption that the water depth is less than 3 mm when the runway is reported wet."Footnote 32 The 3-mm depth of water appears to be the generally accepted dividing line between a wet runway and a contaminated runway. According to the FAA Aeronautical Information Manual Pilot/Controller Glossary, "a runway is considered contaminated whenever standing water, ice, snow, slush, frost in any form, heavy rubber, or other substances are present."Footnote 33 TC does not have a definition of a contaminated runway.

TC has drafted a notice of proposed amendment, NPA 2005-034, for CAR Standard 725.55: General Requirements − Runway Operations, which is currently undergoing legal review. In this proposed standard, the terms "damp runway," "wet runway," and "contaminated runway" are defined. The proposed definitions of "damp runway" and "wet runway" include:

Damp Runway

- A damp runway is considered to be a wet runway.

- A damp, properly designed, constructed and maintained grooved runway … is considered to be a dry runway.

Wet Runway

- A wet runway is covered with sufficient moisture to cause it to appear reflective, but is not "contaminated" …

- On a wet runway, the braking friction is reduced compared to that for a dry runway.

- The braking friction on a wet, properly designed, constructed and maintained grooved runway … is higher than on a wet smooth surfaced runway.

Neither TP312E nor the Ottawa International Airport Operations Manual contains specific direction on how to assess the runway surface condition for the amount of water on the runway. Friction testing of wet runways using decelerometers is not done on an operational basis, due to the unreliability and high variation of friction readings on purely wet surfaces.

Light rain started to fall again approximately 12 minutes before the accident, and the wind was blowing directly across Runway 07 at 10 knots gusting to 16 knots. The runway was not grooved. After the rain started, only 1 aircraft preceded the accident aircraft onto Runway 07. There were no pilot weather reports (PIREPs) related to braking action before the accident. No report on the condition of the runway surface was done after the rain started, nor was one required. Video recordings of the ramp area in the vicinity of the TC hangar and of the area in front of the fire hall showed surfaces that were wet and that appeared shiny or reflective. Considerable spray could be seen from the landing of LOF8050 on Runway 07. Aircraft Rescue and Firefighting (ARFF) personnel noted that the runway at the time of the initial response was wet with puddles in the vicinity of the threshold of Runway 25.

1.10.7 Slippery when wet

Information on the condition of the runway surface is important, and is required when evaluating factors affecting landing performance. Both ICAO Annex 14 and TP312E address the requirement for airports to conduct sufficient tests and observations of the runway surface to determine whether, based on their results, a runway should be designated as slippery when wet. Action should then be taken by the airport operator to restore friction levels to above the minimum levels specified by TP312E. If it is determined that a runway is slippery when wet due to reduced friction levels, the information must then be made available to aircrew, preferably before the flight-planning stage. The Ottawa International Airport Authority did not provide information to indicate that Runway 07/25 was to be considered slippery when wet, nor was it required to do so, based on the minimum friction criteria published in TP312E.

In 2004, the TSB investigated a runway excursion involving the same model of aircraft, also without thrust reversers, that overran Runway 25 on landing. Footnote 34 There were heavy rain showers at the time, and the most recent METAR had reported wind from 220°T at 5 knots. The TSB learned of another EMB-145 that landed on Runway 07 at CYOW, on 15 August 2010, without thrust reversers and with suspected braking problems. The crew felt that there was no effective braking during the initial landing roll; however, the aircraft was stopped before it reached the Foxtrot high-speed exit. There was light rain falling, and the winds were reported on a SPECI report (12 minutes before landing) as 130°T at 5 knots.

1.10.8 Runway transverse slope

Part 3 of the ICAO Aerodrome Design Manual recognizes that a properly cambered runway is a critical design parameter. Footnote 35It states:

All new runways should be designed with uniform transverse profile in accordance with the value of transverse slope recommended in Annex 14 and with a longitudinal profile as nearly level as possible. A cambered transverse section from a centre crown is preferable but if for any reason this cannot be provided then the single runway crossfall should be carefully related to prevailing wet winds to ensure that surface water drainage is not impeded by the wind blowing up the transverse slope.

… Particular attention should be paid to the need for good drainage in the touchdown zone since aquaplaning induced at this early stage of the landing, once started, can be sustained by considerably shallower water deposits further along the runway.

In TP312E, there are no minimum or maximum standards for transverse runway slopes. However, it specifies the following recommended practices:

3. 1. 2. 8 Recommendation — To promote the most rapid drainage of water, the runway surface should, if practicable, be cambered except where a single crossfall from high to low in the direction of the wind most frequently associated with rain would ensure rapid drainage. The transverse slope should not exceed:

− 1.5 per cent where the runway reference code letter is C, D or E; … nor be less than 1 per cent except at runway or taxiway intersections where flatter slopes may be necessary.

3. 1. 2. 9 Recommendation — For a cambered runway surface, the transverse slope on each side of the centreline should be symmetrical.

Note — On wet runways with cross–wind conditions the problem of aquaplaning from poor drainage is apt to be accentuated.

3. 1. 2. 10 Recommendation — The transverse slope should be substantially the same throughout the length of a runway except at an intersection with another runway or a taxiway where an even transition should be provided taking account of the need for adequate drainage.

For the last 6000 feet of Runway 07, the crown shifts to the left of the centreline, such that 75% or more of the crossfall is on the right side of the runway. During times of rainfall from April to September at CYOW, the wind is primarily from the right. This is in the opposite direction to the crossfall, and would result in water building up or draining more slowly from Runway 07.

TP312E recognizes the value of having adequate transverse slope on a runway to facilitate the rapid drainage of water. Wet runways are considered a contributing factor in many runway-overrun accidents. The transverse profile of Runway 07 for the first 1700 to 1800 feet complies with the recommended practices outlined in TP312E. However, the remainder of Runway 07, as constructed, does not meet the minimum recommended practices in the following ways:

- The minimum transverse slope of the left side of the runway is less than 1%;

- The transverse slope on each side of the centreline is not symmetrical;

- The slope is not substantially the same throughout the length of the runway; and

- The apex of the runway crown moves left of centreline, reaching the left edge by the end of the runway.

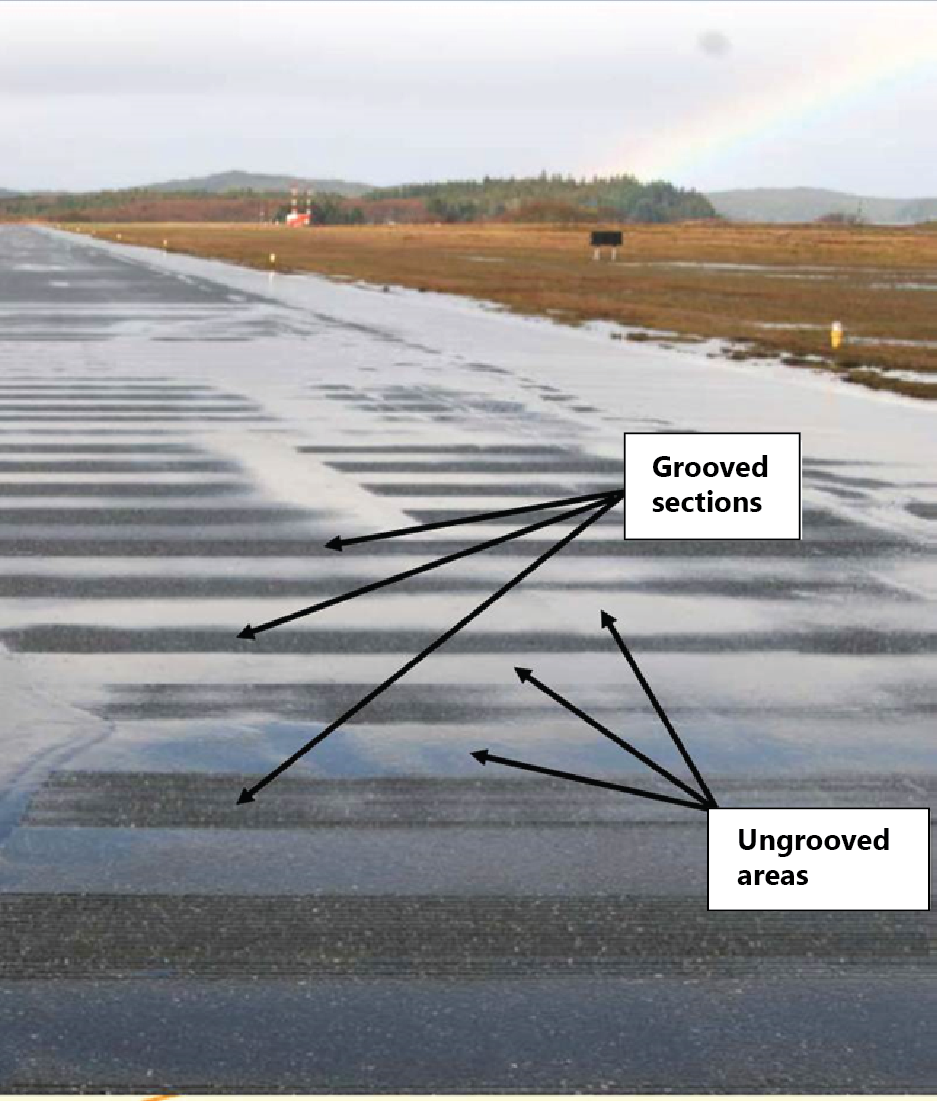

1.10.9 Grooving of runways

Grooving reduces the potential for both dynamic and viscous hydroplaning, by providing a place (i.e., grooves) for the water to escape from underneath tires. Grooving is applied to both the macrotexture and microtexture of the runway surface.

Annex 6 of the ICAO defines a grooved or porous friction course (PFC) Footnote 36runway as "a paved runway that has been prepared with lateral grooving or a porous friction course surface to improve braking characteristics when wet." Footnote 37TP312E states that "the surface of a paved runway shall be so constructed as to provide good friction characteristics when the runway is wet." Footnote 38 However, there is no requirement in Canada that runways be grooved as a means to provide good friction characteristics during wet conditions.

The TC Aerodrome Safety Circular 2004-024, published in 2004, links hydroplaning with the well-known possibility of excessive water on the runway. It suggests that:

Where such conditions are deemed to exist on a runway surface or portion thereof for excessive periods of time, runway grooving may be considered by the Airport Operator as an option for minimizing surface water depths and reducing the potential for hydroplaning [see Appendix G]. However, surface grooving is not a requirement for new or existing runway pavements in Canada.

None of the runways at CYOW are grooved. There are no grooved runways at any major civil airport in Canada.

TC has indicated that runway grooving is not practical in Canada, due to challenges associated with winter maintenance. A limited survey of airports was conducted in areas of the United States where weather conditions similar to the Ottawa area can be expected. Of the 23 airports that were sampled, 18 had grooved runways, 2 had a PFC overlay, and 3 had no surface treatment. The airports included a mix of asphalt runways and concrete runways (Appendix H).

In 1997, the FAA published Advisory Circular (AC) 150/5320-12C: Measurement, Construction, and Maintenance of Skid-resistant Airport Pavement Surfaces, which stated the following, in support of pavement grooving:

Pavement grooving was the first major step in achieving safer pavement surfaces for aircraft operations in wet weather conditions … a high level of friction could be achieved on wet pavement by forming or cutting closely spaced transverse grooves on the runway surface, which would allow rain water to escape from beneath tires of landing aircraft.

Grooving of all runways, serving or expected to serve turbojet aircraft, is considered high priority safety work and should be accomplished during initial construction. Such existing runways without grooving should be programmed as soon as practicable.

FAA AC 150/5200-30C: Airport Winter Safety and Operations, dated 09 December 2008, states:

Grooves cut into the pavement will trap anti-icing/deicing chemicals, reduce loss, and prolong their actions. Grooves also assist in draining melt water and preventing refreezing. There is empirical evidence that grooves and porous friction courses modify the thermal characteristics of a pavement surface, probably by reducing the radiant heat loss, and delay the formation of ice. There do not appear to be any negative effects from grooving pavements.

1.11 Flight recorders

1.11.1 General

The solid-state flight data recorder (FDR) (SSFDR Honeywell, model 980-4700-042, serial no. SSFDR-10741) and solid-state cockpit voice recorder (SSCVR Honeywell, model 980-6022-001, serial no. CVRE120-06900) were removed from the aircraft on the same day as the occurrence, and forwarded to the TSB Laboratory for download and analysis. Both recorders provided good-quality recordings. The SSCVR provided 2 hours of recordings. Approximately 26 hours of data had been recorded by the SSFDR. A number of parameters recorded were of key interest, including brake-related parameters such as brake pressures, wheel speeds and brake-pedal positions.

1.11.2 Wheel speed versus ground speed

On the occurrence landing, following spin-up, the recorded wheel speeds were generally 20 to 25 knots below the recorded ground speed. Although some differences are expected during braking (e.g., due to tire slip or changes in tire radius), the 25-knot discrepancy appeared excessive. On the previous landing at KIAD, the deceleration and wheel-brake pressures suggested good runway-tire friction that was consistent with dry runway conditions. When the brakes were momentarily released at a ground speed of 73 knots, the wheels stopped decelerating; however, there was no significant increase in wheel speed, as recorded by the FDR. This information suggests anomalous behaviour, with a difference of 11 knots remaining between the wheel speeds and the recorded ground speed.

The wheel-speed transducers generate an alternating-current voltage in proportion to the rotational velocity of the wheels. The signals are fed to the BCU for processing (which includes conversion to linear velocity in knots via the velocity converter) and sent to the FDR. The linear velocity is not used by the BCU to modulate the brake pressures during antiskid operation, but rather is used by the BCU for activation and deactivation of the antiskid function.

The aircraft manufacturer indicated that FDR data from other EMB-145 aircraft exhibited the same discrepancy between wheel speed and ground speed, suggesting that the discrepancy was a fleet-wide anomaly. All 4 of the wheel-speed transducers from the occurrence aircraft were subsequently tested by the BCU manufacturer, and all were found to be functioning correctly. The reason for the anomalous wheel-speed data could not be determined. Although the wheel-speed values recorded on the FDR were suspect, the data were still considered useful in assessing wheel-speed trends. Although there is no regulatory requirement to record wheel-speed data, the information can be useful in determining initial wheel spin-up, braking performance, antiskid operation, etc.

1.12 Wreckage and impact information

The aircraft's nose section was substantially damaged when the nose gear collapsed shortly after the aircraft exited the runway. The rearward collapse of the nose gear resulted in deformation of sections of the nose-cockpit area and structural damage to the nose area (Photo 1).

1.13 Medical and pathological information

For many companies, it is standard practice to carry out testing for drugs and alcohol following any work-related accident. FAR Part 120.109 requires that employers carry out post-accident testing of this type. However, FAR Part 120.123 specifically precludes any collection or testing outside the territory of the United States. Following this accident, the company reviewed its requirements and abilities to conduct drug testing as a matter of standard practice, but decided that it was not empowered to carry out tests, because the pilots were in Canada. Currently, there are no regulations in Canada that require mandatory drug-and-alcohol testing following an aviation occurrence. The available information collected during the course of this investigation did not indicate that drugs or alcohol were used or played any role in this occurrence.

1.14 Fire

There was no fire either pre- or post-impact.

1.15 Survival aspects

1.15.1 Aircraft evacuation

When the aircraft came to a stop, the flight attendant initiated the evacuation procedure. The passengers made use of the forward left main-cabin door, the forward right emergency-exit catering door, and both the left and right over-wing emergency exits. The evacuation was quick and orderly, except for several passengers taking their carry-on baggage with them despite repeated shouting to them by the flight attendant of specific instructions to the contrary.

This insistence by passengers on retrieving their carry-on baggage is not unique to this accident, as identified in the TSB Recommendation on carry-on-baggage (A07-07). Footnote 39 Any delay in evacuation during an emergency can present a significant risk to the safety of passengers.

The passengers were directed to one central location away from the aircraft until help arrived. Within 3 minutes after the aircraft came to a stop, the ARFF units arrived on scene. There were only minor injuries, which were sustained by both pilots and 1 passenger. The first officer, whose leg was pinned between the rudder pedals and the bottom of the instrument panel, initially had some difficulty evacuating the right seat in the cockpit.

1.15.2 Aircraft rescue and firefighting

The CYOW Authority maintains a Category 8 ARFF response capability (Table 5).

| Aircraft category | Overall aircraft length | Maximum fuselage width | Quantity of water | Quantity of complimentary agents | Minimum number of ARFF vehicles | Total discharge capacity |

|---|---|---|---|---|---|---|

| 8 | At least 49 m but less than 61 m | 7 m | 18 200 L | 450 kg | 3 | 7200 L/min |

Response is available 24 hours per day, 7 days per week, from the airport fire hall located on the airfield. A minimum of 4 firefighters is available at all times.

The ARFF unit received the alarm, which was initiated by the control tower, at 1430:46. By the time the 4 ARFF vehicles arrived at the scene, all of the passengers were out of the aircraft and grouped together near the right front of the aircraft.

A temporary shelter was erected to shield passengers from the rain. The captain, the first officer, and 1 passenger were treated for minor injuries. A request was made for bus transportation and a paramedic unit to transport the injured to hospital. Three ARFF vehicles were released at 1745; the last one stayed behind to provide fire protection for the remaining on-site personnel.

1.16 Tests and research

Not applicable.

1.17 Organizational and management information

1.17.1 Trans States Airlines LLC

Resort Air was founded in 1982 and changed its name in 1989 to Trans States Airlines LLC, with its corporate headquarters located in St. Louis, Missouri. Originally operating various types of turboprop aircraft, TSA started operating the Embraer EMB-145 in 1998, and has a fleet of approximately 28 aircraft. TSA is a FAR Part 121, regional feeder airline that conducts flights for United Airlines and US Airways to approximately 39 destinations.

Training and Use of Flap by Trans States Airlines LLC

- TSA 's initial new-hire training program consists of

61 hours of non−aircraft-specific training; - 138 hours of aircraft-specific ground training; and

- 57 hours of aircraft-specific flight training.

Aircraft performance on wet and contaminated runways is addressed in the general aircraft-performance modules for both initial and recurrent training. Flight crews are also exposed to aircraft-performance charts, found in TSA 's Flight Operations Training Manual, Volume 1. Also discussed in the training curriculum is hydroplaning as it pertains to performance considerations on take-off and landing on contaminated runways. Night landings on contaminated runways are listed as an element of TSA 's initial simulator training program.

Training in relation to operations on grooved and ungrooved runways, or in relation to the fact that Canada lacks grooved runways, is not specifically addressed in the training curriculum. TSA does not do specific company line checks on the flight crews that are flying into Canada.

The flap-selector lever on all TSA EMB-145 aircraft provides 4 detent settings, which are at 0°, 9°, 22°, and 45° positions, respectively. Intermediate positions cannot be selected. Flaps increase lift, resulting in lower stalling speed and permitting lower touchdown speed. They also increase drag, permitting a steeper approach without increasing airspeed. The extra drag results in a shorter landing roll. The greater the flap setting, the lower the speed for landing.

When TSA began operating the Embraer EMB-145 in 1998, crews were trained to use a flaps setting of 45°, unless a flaps-22 setting were called for to meet specific performance requirements or as required in an emergency. At the time of the occurrence, TSA Standard Operating Procedures (SOP) indicated that flaps 22 was the preferred flap setting for landing. It allowed for a wider speed range, thus reducing the likelihood of exceeding the maximum flap speed. Also, a reduced flap setting creates less drag, resulting in less thrust being used with a commensurate decrease in fuel consumption. Use of a flaps-45 setting was still encouraged in situations where

- braking action was degraded;

- there was standing water on the runway; or

- the runway was not grooved and was wet.

Three other operators of the EMB-145 model were surveyed on their standard landing flap settings. Two of them used flaps 22 similarly to TSA . The third operator required flaps 45 as its standard landing flap setting, unless flaps 22 was required to achieve certain performance criteria, or as directed in the quick reference handbook (QRH).

1.18 Additional information

1.18.1 Approach and landing

The guidance Footnote 40 given to TSA flight crews for calculating the VAPP Footnote 41 states that the VAPP is equal to the VREF Footnote 42 plus the wind correction. The wind correction is considered to be one half of the headwind component plus the full gust increment. The winds at the airport were 160°M at 10 knots gusting to 16 knots, which indicates zero headwind component and a 6-knot gust component.

The flight crews have access to a landing V-speed chart (Appendix D) in the cockpit as well as in the SOP. This chart has the landing weights listed, as well as the VREF speeds for flaps 22 and flaps 45. The note on the bottom of the TSA chart states that "Wind Correction = ½ headwind + full gust," whereas the Embraer aircraft operations manual indicates that "Wind correction = 1/2 steady headwind component + gust increment above steady wind." For a landing weight of 39 352 pounds and a flaps setting of 22°, the chart gives a VREF of 131 KIAS and a VAPP of 137 KIAS. The VAPP speed planned by the crew was 146 KIAS.

TSA provides guidance in the General Operations Manual (GOM), Section 3-1, 8.5: Stabilized Approach, stating that: "… the aircraft must be in an approved configuration and must maintain the proper approach speed and the proper flight path before descending below the minimum stabilized approach height." The minimum stabilized approach height in instrument meteorological conditions (IMC) is defined as 1000 feet above touchdown zone elevation.

The GOM also states:

Anytime one of the following conditions is exceeded when below the "stabilized approach height," a missed approach will be initiated:

- − airspeed +/− 5 knots

- − localizer and/or glide slope deviation exceeds one dot deflection

- − one dot deflection for VOR or RNAV approaches

- - Aircraft not properly configured

TSA SOP (Section 1, page 33, paragraph 4.2 – Landings), states in part:

The key factor for a successful landing is a stabilized approach and proper thrust/flare coordination. At an average weight and VREF, the aircraft is traveling down the runway at over 150 feet per second while in the flare. Long flare times can lead to a touchdown outside the touchdown zone (TDZ) and/or subsequent hard braking.

When the aircraft is approximately 200 feet above the touchdown zone, the PF should … reduce thrust slightly to cross the runway threshold at 50 feet and VREF.

The desired touchdown point is within the first 800 to 1500 feet beyond the landing threshold. Aircraft must touchdown in the first third of the available landing distance, but in no case more than 3 000 feet down the available landing distance. If this is not accomplished, a go-around must be executed.

The Flight Safety Foundation, in its study on approach-and-landing accidents, found that a 5% increase in final-approach speed increases the landing distance by 10% if a normal flare and touchdown are conducted with deceleration of the aircraft on the ground. Footnote 43 The study also found that extending the flare and allowing the aircraft to float and bleed off excess airspeed can also increase the landing distance, because the excess speed must be bled off in the transition from the threshold crossing to the touchdown. This measure typically uses 3 times more runway than decelerating on the ground. Footnote 44

1.18.2 Wet runway operations

The Embraer EMB-145 General Publication GP145/1650 was provided as guidance material to operators when developing their own operating procedures. Regarding hydroplaning, it stated in part:

Since it is difficult to land at lower speeds than the NASA Footnote 45 critical speedFootnote 46, it is necessary that certain landing techniques be used to minimize the hydroplaning effects, namely:

- Land at the lowest possible speed. Whenever possible, use 45 degree flaps to obtain lower speeds.

- Land firmly, never gently.

- Once the main landing gear is fully on the ground, lower the nose onto the runway without delay.

- Keep the NASA critical speed for your airplane in mind to avoid excessive braking when above it.

- Retract the flaps right after touchdown to place more of the airplane's weight on the tires.

- Go to an alternate airport if conditions point to a serious likelihood of hydroplaning.

- A stabilized approach is of vital importance.

- Be aware that landings on a runway contaminated with water, ice, snow, etc., will imply an increase in the necessary distance for a safe landing, with the values being from 40 to 100% above the normal distance.

TSA SOP Section 2: Landing on Wet or Slippery Runways (page 69), provides guidance and states in part:

Wet runways can cause airplane hydroplaning. This is primarily a factor on runways that are not grooved, which is rare. It can also be a factor if the runway grooves are blocked by ice on the runway edges. When hydroplaning occurs, it causes a substantial loss of tire friction and wheel spin-up may not occur.

Always apply a maximum braking effort initially when landing on potentially slick runways in case hydroplaning or skidding becomes a factor.

Anticipate the approach procedures and speeds: a well-planned and executed approach flare and touchdown minimize the landing distance. It is particularly important to slow to ref speed crossing the threshold when runway conditions are less than optimal. Make it a habit on every approach to slow to the appropriate speed as per the SOP procedures. Landing with Flaps 45 should be considered when landing on wet, un-grooved runways.

Landings should be firm, on the runway centreline and in the touchdown zone. Do not prolong the flare in an attempt to get a smooth landing.

Embraer GP 145/1650 recommends the use of NASA critical speed and the retraction of flaps on landing; this information is not included in the TSA SOP or in the approved Embraer EMB-145 manuals. As well, Embraer GP 145/1650 recommends avoiding excessive braking, whereas the TSA SOP and the approved Embraer EMB-145 manuals advise using maximum braking initially when landing on a slick runway to avoid hydroplaning.

1.18.3 Use of flaps-22 versus flaps-45 setting

TSA SOP Section 1: Landing with Non-Standard Flap Settings (page 34, paragraph 4.2.C) states in part:

Standard flap setting for landing are flaps 45 and flaps 22. The preferred setting for most normal operations is flaps 22. Both flaps 22 and flaps 45 are considered ‘normal' by Embraer (ref. Embraer Ops Bulletin #145-005/05). Flaps 45 setting is encouraged if braking action is degraded, if there is standing water, or if the runway is not grooved and is wet. The dispatch package performance section and the landing speed charts will contain data for both. Flaps 22 approaches require strict adherence to VAPP and VREF as the low drag configuration results in slow deceleration rates, and any excess speed at the threshold can result in float and extra ground roll.

1.18.4 Hydroplaning

Hydroplaning, also referred to as aquaplaning, occurs when a layer of water builds between the aircraft tires and the runway surface, leading to a loss of traction and preventing the aircraft from responding to control inputs such as steering or braking. Landing at higher-than-recommended touchdown speeds will expose the aircraft to a greater potential for hydroplaning. Once hydroplaning starts, it can continue well below the minimum, initial hydroplaning speed. Generally, 3 types of hydroplaning are distinguished: dynamic, viscous and reverted rubber.

Dynamic and viscous hydroplaningFootnote 47 are described as follows:

Dynamic hydroplaning is caused by the buildup of hydrodynamic pressure at the tire-pavement contact area. The pressure creates an upward force that effectively lifts the tire off the surface. When complete separation of the tire and pavement occurs, the condition is called total dynamic hydroplaning, and wheel rotation will stop. … Total dynamic hydroplaning usually does not occur unless a severe rain shower is in progress. There must be a minimum water depth present on the runway to support the tire. The exact depth cannot be predicted since other factors, such as runway smoothness and tire tread, influence dynamic hydroplaning. Both smooth runway surface and smooth tread tires will induce hydroplaning with lower water depths. While the exact depth of water required for hydroplaning has not been accurately determined, a conservative estimate for an average runway is that water depths in excess of 0.1 inch (2.54 mm) may induce full hydroplaning.

Viscous hydroplaning is more common than dynamic hydroplaning. Viscous hydroplaning may occur at lower speeds and at lower water depths than dynamic hydroplaning. Viscous hydroplaning occurs when the pavement surface is lubricated by a thin film of water. The tire is unable to penetrate this film, and contact with the pavement is partially lost. Viscous hydroplaning often occurs on a smooth runway pavement or where rubber deposits are present, usually in the touchdown area where a thin water film can significantly reduce the coefficient of friction.

Reverted-rubber hydroplanning is described as follows:

Reverted rubber hydroplaningFootnote 48 occurs when a locked tire skids along the runway surface generating sufficient heat to change water into steam and revert (melt) the tire rubber to its original uncured state. Only this type of hydroplaning produces a clear mark on the tire tread in the form of a burn; a patch of reverted rubber. This type of hydroplaning is also known to produce steam-cleaned marks on the runway due to the steam cleaning effect of the water vapor between the tire and the runway surface.

A review of literature on aircraft-tire hydroplaning shows that, while reverted-rubber

hydroplaning is usually accompanied by steam-cleaned marks on a runway, the opposite is not necessarily true. That is, steam-cleaned marks are not direct evidence of this type of hydroplaning, and occurrences have been reported where steam-cleaned marks were observed on runways, but there were no reverted-rubber burns on the tires. Footnote 49Footnote 50 This phenomenon could be explained by the temperature difference between water steam formation and tire reversion. At normal atmospheric pressure, water boils at 100°C. The rubber-reversion temperature, however, is about 204° to 316° C. Footnote 51 Thus, there is a temperature range in which steam could form under the tire and clean the runway, but the tire rubber would not be melted. Steam-cleaned marks were observed on the runway, as indicated by the photographs taken shortly after the occurrence (Photo 2).

Embraer had a section in Embraer GP145/1650 that described these 3 types of hydroplaning. This document went on to describe the NASA critical speed, or hydroplaning speed, formula to calculate the hydroplaning speed of the tires. The NASA critical speed formula is equal to 9 times the square root of the tire pressure. The main tire pressure for the EMB-145LR is 160 psi, which equates to a hydroplaning speed of 114 knots. A second formula is used to calculate the hydroplaning speed if rain is encountered at the moment of touchdown, when the wheels are not yet turning. The formula changes to 7.7 times the square root of the tire pressure, which equates to 97 knots for the EMB-145LR. The occurrence aircraft touched down at 132 KIAS on a wet runway.

1.18.5 Fatigue

People normally require 7.5 to 8.5 hours of continuous sleep per 24-hour period. Footnote 52 Research has reliably demonstrated that acute sleep loss results in fatigue and performance decrements. For example, shortening a person's total sleep time to less than one's biological need results in fatigue, Footnote 53,Footnote 54 and when total sleep time is reduced to less than 6 hours, performance is reliably decreased due to fatigue.Footnote 55

1.18.6 Other occurrences involving CYOW Runway 07/25

Since 2000, there have been 3 other overruns of Runway 07/25 when the runway was wet or contaminated (Appendix J). As per Appendix F, friction-test results for Runway 07/25 have been inferior to those for Runway 14/32 since 2004. Because of those 3 overruns, TSB decided to look more closely at the runway's construction and maintenance.

1.18.7 TSB Watchlist

In March 2010, the TSB issued its Watchlist, which identified the safety issues investigated by the TSB that pose the greatest risk to Canadians. Landing accidents and runway overruns, taken together, was one of the 9 safety issues identified. The number of landing accidents and runway overruns has not significantly declined since 2010, and the TSB has again highlighted this issue in its Watchlist in 2012. The TSB Watchlist highlighted the importance of having an adequate "safety area" beyond the runway's end and the provision of timely information about runway surface conditions to pilots.

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

2.1 Introduction

It is widely acknowledged that a wet runway may be slippery and require additional landing distance over and above that required for a dry runway. National and international efforts to closely correlate surface-friction measurements on wet runways to aircraft braking effectiveness have not been successful.

There were no mechanical discrepancies found with the aircraft. A thorough examination of the aircraft's wheel-brake system was completed, and no abnormalities were found. The tires were examined, and there was no sign of reverted rubber. Wet runway conditions, steam-cleaned marks, and a lack of deceleration indicate that viscous hydroplaning occurred.

The analysis will focus on aircraft braking coefficient, operational procedures, fatigue and runway characteristics.

2.2 Aircraft braking coefficient

The brake system of the occurrence aircraft performed as designed. The action of the braking system during the occurrence ground roll is consistent with the aircraft encountering poor braking conditions. The aircraft deceleration was low due to the lack of braking force caused by viscous hydroplaning. The aircrew sensed this low deceleration, and attempted to increase it by applying maximum brakes. The antiskid system, however, reacted to the low coefficient of friction by reducing brake pressure to prevent the wheels from locking up and the aircraft from skidding.

Embraer's performance calculations were based on the coefficient of friction included in United States Federal Aviation Regulations (FAR) 25.109(c)(1), and gave a significantly shorter landing distance than that of the occurrence aircraft. Both the occurrence landing and the Honeywell actual landing test data exhibited a significantly lower braking coefficient of friction than that predicted by the smooth wet runway equations in FAR 25.109(c)(1). These results are consistent with the findings of the National Transportation Safety Board (NTSB) for similar landing-related occurrences.

2.3 Approach and landing

During the approach, the wind veered from 100° at 8 knots to 160° at 10 knots gusting to 16 knots. The crew was offered a choice to continue for Runway 07 or proceed for Runway 14. For a variety of reasons, the crew elected to continue the approach for Runway 07. The airport analysis data charts provided in the flight release package supported this decision, as the conditions were within the aircraft's performance criteria.