In-Flight Engine Fire

Buffalo Airways Limited

Douglas C-54G-DC (DC-4) C-GXKN

Norman Wells, Northwest Territories (CYVQ)

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

The Buffalo Airways Limited Douglas C-54G-DC (DC-4), registration C-GXKN, serial number 36090, departed from Norman Wells, Northwest Territories, at 1749 mountain standard time for a visual flight rules flight to Yellowknife, Northwest Territories, with a crew of four and 2000 pounds of cargo. While climbing through an altitude of approximately 3500 feet above sea level, the crew experienced a failure of the number 2 engine and a nacelle fire. The crew carried out the Engine Fire Checklist, which included discharging the fire bottles and feathering the number 2 propeller. The fire continued unabated. During this period, an uncommanded feathering of the number 1 propeller and an uncommanded extension of the main landing gear occurred. The crew planned for an emergency off-field landing, but during the descent to the landing area, the fuel selector was turned off as part of the Engine Securing Checklist, and the fire self-extinguished. A decision was made to return to the Norman Wells Airport where a successful two-engine landing was completed at 1804 mountain standard time. The aircraft sustained substantial fire damage, but there were no injuries to the four crew members on board.

Factual information

Records indicated that the aircraft was certified, equipped, and maintained in accordance with existing regulations and approved procedures. The captain was licensed in accordance with existing regulations. He held a valid airline transport pilot licence, endorsed for multiple types, including the Douglas DC-4. He also held a valid instrument rating and an approved check pilot authority (Type B). His flying experience was estimated to be in excess of 15 600 hours, including approximately 500 hours in the Douglas DC-4 (C-54). The first officer was certified and qualified for the flight in accordance with existing regulations.

The Norman Wells hourly weather at 1800 mountain standard timeFootnote 1 was reported as winds calm, with clear sky and temperature of −25°C. Weather is not considered a factor in this incident.

C-GXKN was configured as a cargo aircraft, and was dispatched from Yellowknife on a scheduled supply flight with stops at Deline, Fort Good Hope, and Norman Wells before returning to Yellowknife. Aircraft weight on departure from Norman Wells was 49 660 pounds, with the maximum allowable take-off weight of 66 700 pounds. The centre of gravity was within limits.

Approximately seven minutes after take-off (1756), the crew noticed increasing vibrations, indicating an impending engine failure. While identifying and verifying the problem as the number 2 engine, a fire became visible in the number 2 engine nacelle followed by a fire warning light. The Engine Fire Checklist was completed from memory and the fire bottles were discharged; however, the fire persisted. The crew then planned for an emergency off-field landing on the shore of Dot Lake. During the descent to the landing area, the Engine Securing Checklist (see Appendix A) was completed, which included turning off the fuel selector. The fire self-extinguished shortly thereafter. A decision was then made to attempt a return to the Norman Wells Airport.

An uncommanded feathering of the number 1 propeller occurred shortly after the shutdown of the number 2 engine. Attempts to unfeather the number 1 propeller and restart the engine were unsuccessful as the feathering system was unresponsive. The feathering system relays, wiring, and other components for engines 1 and 2 were located in a junction box in the number 2 engine nacelle.

On approach to Norman Wells, the landing gear down selection was followed by an unusual, immediate main gear down indication. Nose gear extension time appeared to be normal, although a gear unsafe indication remained on during landing. Flaps would not extend beyond the 10° setting due to hydraulic system damage. A successful two-engine landing was made on Runway 27 at a higher-than-normal speed, touching down about 750 feet from the threshold of the 6000-foot runway.

Normal braking was not available during the landing roll and emergency braking was applied. Tread markings indicated braking action on both main landing gears. At 1700 feet from the threshold, the aircraft began to veer to the right. At 2600 feet from the threshold, the right turn increased, and approximately 100 feet later, the aircraft departed the runway surface. The aircraft came to a full stop, in deep snow, approximately 60 feet from the edge of the runway.

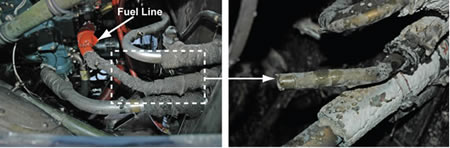

The Engine Fire Checklist procedures (see Appendix A) contained steps to shut down the engine, close the firewall shutoff valves to stop the flow of fuel, oil and hydraulic fluids to the engine, and discharge the CO2 fire extinguishers into zones 2 (engine accessory section) and 3 (nacelle section). Closing the firewall shutoff valve had no effect on the flow of fuel into Zone 3 because the fire had compromised the fuel line between the tank and shutoff valve (see Figure 1).

Examination of the number 2 engine area (Pratt & Whitney USA, R-2000) indicated that the fire originated in the lower left-hand accessory section (Zone 2). The intensity of the fire was consistent with a fuel-fed fire accelerated by engine oil and hydraulic fluid. The fuel source was the main fuel inlet line assembly, which is routed from the outboard firewall area to the engine-driven fuel pump. The line assembly consisted of a rigid tubular aluminum line connected with rubber hose couplings at the firewall and fuel pump fittings secured with hose clamps. There was no record of when the rubber couplings were last replaced, or their time in service. This assembly (see Figure 2) was wrapped and water-glassed from the firewall to the pump fitting. A fire shield sleeve was installed over the connector and fitting at the fuel pump. No special inspection criteria or schedule for this assembly is specified except for a leakage test at engine change. In June 1948, Douglas Aircraft issued Service Bulletin (SB) DC-4 No. 66 regarding engine fire prevention on aircraft specified by Civil Air Regulations amendments 41-3, 42-2, and 61-2. The SB specified a replacement flexible hose assembly to eliminate the aluminum line/rubber couplings/hose clamp assembly. An Airworthiness Directive (AD 48-12-01) was subsequently issued mandating the implementation of SB DC-4 No. 66 for aircraft used for air carrier operations. The modification had not been incorporated on C-GXKN.

The ignition source could not be identified, but the generator (with arcing at the brushes) and the exhaust system were in close proximity to the fire initiation area.

Fuel pressure fluctuations had been noticed on the number 2 engine pressure gauge during previous flights and had been assumed to be gauge problems; as such, they had not been reported to maintenance. During the incident flight, the fluctuations increased in frequency and excessive vapours were also observed venting from the number 2 engine vent stack. The troubleshooting chart contained in the Douglas DC-4 maintenance manual lists one of the possible causes of fuel pressure fluctuations as loose lines or fittings between tank and pump.

There was substantial airframe fire damage in and around the number 2 engine, with perforations of the nacelle upper and lower skins, air intake scoop, and the main wing spar web. The flap panel behind the nacelle was burned through, and all the left elevator fabric covering had burned away. Left main gear drag link and hydraulic components were damaged or missing, the oil tank had burned and detached, the oil cooler was missing, and the electrical junction box had burned away. The left-hand main landing gear tires were not burned away. The fire travelled inboard along the wing leading edge, D section, to the fuselage and outboard to the number 1 engine nacelle. The structural integrity of the engine mount and nacelle was compromised, as indicated by the engine droop below the thrust line.

The mechanical failure of the number 2 engine was evident by the fracture of the number 6 cylinder base and the uncontained failure of the associated connecting rod (master rod). Damage was consistent with oil starvation caused by the compromised oil return line to the cooler. There was no burned residue in the oil tank and the oil quantity gauge indicated empty.

A database search for DC-4 engine fires revealed that this is the eleventh reported occurrence of an uncontrollable in-flight fire in the number 2 or number 3 engines and nacelles since the issue of AD 48-12-01. These occurrences resulted in 23 fatalities. The specific causes of the fires in most cases could not be documented due to the extent of the damage. In nine cases, the aircraft crashed, in two occurrences, the number 2 or 3 engines departed the aircraft in-flight, and in one occurrence, the aircraft broke up in flight.

Analysis

A vital action with an in-flight fire is to remove the source of fuel immediately. Closing the firewall shutoff valve in accordance with the Engine Fire Checklist did not cut off the flow of fuel to the fire area. When the fuel selector was closed as per the subsequent Engine Securing Checklist, the fuel flow stopped. If the fuel selector had been turned off as part of the initial Engine Fire Checklist, the fire would have been extinguished earlier.

The fuel line assembly of metal tubing, rubber hose couplings, and hose clamps increased the possibility of leaks due to the different expansion rates of materials. The sealing characteristics would be more critical when subjected to drastic in-service temperature changes, rubber hose aging, and heat deterioration. The wrapping and fire sleeve would conceal any evidence of minor seepage until the leakage had progressed substantially. The SB and AD that mandated the replacement of the fuel line had not been implemented on C-GXKN.

The indication of fluctuating fuel pressure before the occurrence was attributed to an indication fault, and had not been reported to maintenance. Investigation as per the troubleshooting chart in the maintenance manual may have revealed the fuel pressure line leakage.

The immediate main gear down indication when the gear was selected down revealed that the main gear had previously deployed, uncommanded and without the crew's knowledge. This would be consistent with the loss of hydraulic pressure in the gear retraction system due to fire damage in the accessory section. Extension early in the occurrence sequence is indicated by the left-hand tires not having burned away as would have been the case if they had remained in the nacelle.

Had this aircraft been operating at a higher gross weight, the power loss from two engines, combined with the additional drag from the extended main gear, may have precluded a return to the airport, or resulted in an in-flight loss of control.

Findings

Findings as to causes and contributing factors

- Airworthiness Directive AD 48-12-01 mandates the replacement of the potentially hazardous fuel line, but the line had not been replaced on this aircraft.

- A fuel leak from the main fuel inlet line in the engine compartment of this cargo DC-4 caused an in-flight fire that spread into the nacelle and wing.

- The fuel-fed fire burned for an extended period of time because turning the fuel selector off is not required as part of the primary Engine Fire Checklist.

Safety action

The Transportation Safety Board of Canada (TSB) issued two aviation safety information letters to Transport Canada addressing the following concerns in this occurrence:

- Aviation Safety Information Letter A060003-1 (A06W0002) Emergency Checklist - Engine Fire Procedure for Douglas C54G-DC Aircraft, was sent to Transport Canada on 23 February 2006. This letter highlighted the concern regarding the checklist timing for the fuel selector valve shutoff.

The operator has amended the Engine Fire Checklist and the standard operating procedures for Engine Fire in the Air, with the addition of "Fuel Selectors Off "immediately after "Mixtures to Idle Cut Off."

- Aviation Safety Information Letter A060005-1 (A06W0002) - Fuel Line Installation Configuration and Maintenance, was sent to Transport Canada on 02 March 2006. This letter addressed the concern regarding the applicability of AD 48-12-01 to C-54G-DC cargo aircraft.

On 06 June 2006, Transport Canada sent a response regarding Aviation Safety Information Letter A060005-1 (A06W0002) to the TSB. Transport Canada indicated that it had contacted the only operator of this aircraft type in Canada to determine if Airworthiness Directive AD 48-12-01 had been incorporated on its aircraft. Two of its four aircraft were found not in compliance with the subject AD and the company initiated the necessary steps to correct this.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendices

Appendix A - Buffalo Airways Limited DC-4 Engine Fire and Engine Securing Checklists

ENGINE FIRE CHECKLIST

| 1 | MIXTURE | ICO |

| 2 | PROP | FEATHER |

| 3 | BOOST PUMP | OFF |

| 4 | ALCOHOL | OFF |

| 5 | GENERATORS | OFF |

| 6 | FIREWALL SHUT-OFF | PULL |

| 7 | COWL FLAPS: ZONE 1 | OPEN |

| 8 | COWL FLAPS: ZONE 2 & 3 | CLOSED |

| 9 | CO2 EXTINGUISHER (ZONE 2 & 3) | PULL |

ENGINE SECURING CHECKLIST

| 1 | COWL FLAPS | CLOSED |

| 2 | FUEL SELECTOR | OFF |

| 3 | CROSSFEED | OFF |

| 4 | BOOST PUMP | OFF |

| 5 | GENERATOR | OFF |

| 6 | IGNITION | OFF |

| 7 | VACUUM SELECTOR | AS REQUIRED |