Nosewheel Axle Failure

Air Canada

Airbus A321-211, C-GJWI

Toronto/Lester B. Pearson International Airport

Toronto, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 19 January 2004, at approximately 1410 eastern standard time, Air Canada Airbus A321-214 (registration C-GJWI, serial number 1772) operating as flight ACA 413, landed on Runway 06L at Toronto/Lester B. Pearson International Airport, Toronto, Ontario, after a flight from Montréal, Quebec. While taxiing to Gate 209 at Terminal 2, the flight crew heard a noise from the nose landing gear area. As the aircraft turned onto the lead-in line at the gate, the ground marshallers observed that the right-hand nosewheel was missing (see Photo 1) and immediately had the aircraft stopped. Maintenance personnel inspected the nose landing gear and determined that it was safe for the aircraft to proceed to the gate. Airport authorities closed Runway 06L to inspect for aircraft components and landing surface damage. The nosewheel was subsequently located on the ramp. There were no injuries and damage to the aircraft was limited to the nose landing gear assembly. The damaged components were removed from the aircraft and shipped to the Transportation Safety Board Engineering Branch for examination.

Factual information

Since 1989, there have been 67 occurrences worldwide related to nosewheel bearing failures on the A319, A320 and A321 aircraft. Of these occurrences, 43 resulted in axle damage and subsequent replacement of the nose landing gear sliding piston. Investigations into these occurrences did not reveal a definitive determining factor. Various modifications were implemented in an attempt to resolve this type of occurrence: stiffening of the nosewheel axle with a steel sleeve, a spacer inserted between the nosewheel halves, and a larger nosewheel to accommodate larger wheel bearings. These modifications reduced the frequency of failure, but did not completely eliminate the failures. The modifications were a result of coordinated efforts between the manufacturers of the aircraft, the wheel and the bearing.

Examination of Components

Following the occurrence on 19 January 2004, at approximately 1410 eastern standard time,Footnote 1 the Transportation Safety Board (TSB) Engineering Branch examined the two nosewheels, the fractured nosewheel axle, which remained partially inside the right nosewheel assembly, the nose landing gear sliding rod, and the flight data recorder (FDR).

The FDR was downloaded and information from the occurrence landing and the previous eight landings was examined. No abnormalities were noted during any of these landings.

The nose landing gear was manufactured by Liebherr, a company division of Messier-Dowty (part number D23592020, serial number L2212). The roller bearing was manufactured by the Timken Company (part number 42690H*2-629, not serialized). The suffix 629 indicates that the bearing is aerospace grade and meets higher standards in design and production.

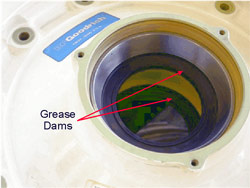

The inner wheel assembly was found to be covered with discoloured grease. The inner bearing grease dam, normally positioned next to the bearing to reduce grease migration and subsequent bearing damage or failure, was found dislodged and sitting against the outer bearing grease dam. The two contacting surfaces were clean and free of grease. The grease dams (see Photo 2) are rubber-like and are held in place by a protruding ridge moulded on the circumference of the dam. When installed, the ridge fits into a channel in the wheel assembly. The dam can be displaced during wheel installation as the wheel is being slid onto the nose landing gear axle. If this happens, the displacement may go undetected since the dam is not visible to the installer because of its location within the wheel assembly.

The nose landing gear wheel axle was examined and found to be fractured circumferentially in the vicinity of the collar (see Photo 3 and Appendix A). Both of the fracture surfaces appeared rugged with stains radiating from the inside diameter surface. In addition, the fracture was covered with a carbonaceous residue. There were indications that the axle had been subjected to high temperatures as the paint on both the inner and outer surfaces was blistered, flaking and discoloured, and the cadmium plating had melted and resolidified to form beads. The fracture originated on the inside diameter surface of the axle. The inner and outer diameters of the axle are cadmium plated for corrosion protection.

A scanning electron microscope was used to examine the fractured surface of the axle. The stained portion of the surface was a blocky, intergranular fracture typical of embrittled steels. The remaining surface was ductile in appearance.

The energy dispersive x-ray spectrum of the intergranular surface revealed the presence of cadmium, confirming that the mode of failure of the axle was a result of liquid metal (cadmium plating) embrittlement. The microstructures of the axle material conformed to a typical high-strength steel, as specified for this application.

The axle was removed from the wheel assembly to expose the roller bearing cone assembly. The rollers were loose, discoloured and severely worn. The roller bearing cage was substantially damaged, with only a small portion of the cage retaining its original shape. The fractured surfaces were damaged beyond recognition, and examination to determine the mode of failure was not possible. The surface of the inner bearing race was discoloured and appeared to be plastically deformed. Most of the rollers retained their shape, but their surfaces were mildly discoloured. Four of the rollers were misshaped and discoloured blue. Two of those exhibited evidence of skidding sideways on the inner race. There was also an indication that, at some point after the failure, the inner race was spinning in respect to the aluminum axle sleeve, and eventually the sleeve was dragged by the inner race.

The heat generated from the friction of the failed bearing raised the temperature of the axle beyond the melting point of cadmium, which is greater than 321°C. There were also indications that the aluminum alloy sleeve had partially melted, which would require a temperature greater than 660°C.

Information obtained from research into roller bearing failures revealed that the lubricant acts as a cushion between the cage and the rollers. The cage keeps the rollers parallel and prevents the roller's tendency to skid sideways with changes in loads. Proper axle nut torque maintains the bearing alignment and pre-loading. A reduction in lubrication, as a result of the grease migrating from the bearing, will increase the cage loads, which may lead to the premature failure of the bearing. It could not be proven that the roller bearing failed due to a lack of lubrication. However, during examination, there was no evidence of grease residue on the inboard bearing. Therefore, it is likely that the depletion of the lubricant was a contributing factor.

Lubrication Examination Results

There was concern that aircraft de-icing fluid, ethylene glycol, may have migrated into the bearing and affected the lubricity of the grease. To determine if the lubrication contributed to the bearing failure, samples of the lubricating grease (AeroShell® 22) were taken from different locations within the axle and wheel assembly. Two of these samples were examined for consistency with specifications. One fresh grease sample was also provided to be used as a reference. Neither of the two samples taken from the nosewheel assembly indicated unacceptable levels of water or ethylene glycol contents. As a result of the excessive friction temperatures produced from the bearing failure, no grease sample from the bearing was available for testing.

The following TSB Engineering Branch reports were completed:

- LP 012/2004 – Data Recorder Analysis

- LP 014/2004 – Nose Landing Gear Failure

These reports are available from the Transportation Safety Board of Canada upon request.

Findings

Findings as to causes and contributing factors

- The nosewheel right inboard roller bearing failed. It is likely that the lack of lubrication as a result of the grease dam being dislodged from its normal position was a contributing factor.

- The friction temperatures created by the failed roller bearing exceeded the cadmium melting point. Cadmium penetrated and weakened the intergranular structure of the nose landing gear axle, causing it to fail due to liquid metal embrittlement.

Finding as to Risk

- The dislodged inner-bearing grease dam allowed grease to migrate from the inboard roller bearing of the right nosewheel to the inside of the nosewheel assembly. A reduction in lubrication increases the cage loads and may lead to bearing failures.

Safety action

Safety action taken

Air Canada has taken steps to have the axles for its nose landing gears coated with SermeTel® to reduce the likelihood of axle failures from cadmium infusion as a result of high friction heat generated from bearing failures. SermeTel® is an anti-corrosive and chemical-resistant base applied as an initial coating prior to decorative coatings of epoxy resin and polyurethane paints. It is an inorganic formula, consisting of an aqueous carrier containing a mixture of magnesium chromate, phosphates and silicates, and aluminum powder.

Air Canada has also issued a maintenance alert and revised its wheel installation job card to stress the importance of a wheel inspection prior to installation and to ensure the recommended wheel installation tools and torques are used in accordance with the Aircraft Maintenance Manual. The Air Canada wheel shop manuals were revised to raise the awareness of the importance of grease dams and seal installations.

In May 2004, Goodrich released Service Letter 1991 that recommends Mobil SHC-100 grease for the wheel bearings due to its superior adhesion properties, which also increase corrosion protection and bearing lubrication. Goodrich also issued Service Bulletin 3-1531-32-3 in July 2004, with new inspection procedures for bearing grease seals on Airbus A318, A319, A320 and A321 aircraft.

Airbus has designed an integrated retaining ring and seal that is being tested for qualification purposes. Testing includes roll and landing tests under different loads, as well as high-pressure water tests to demonstrate the enhanced performance of the new design in protecting the seal and bearing from external contaminants.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .