Collision with Water

Héli-Star Inc.

Bell 206 Jet Ranger (Helicopter) C-GNPI

Boucher Lake, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

The Bell 206B helicopter operated by Héli-Star Inc., registration C-GNPI, serial number 2353, took off from Boucher Lake at approximately 2015 eastern daylight time, bound for La Tuque Airport, Quebec. The pilot was the sole occupant. Shortly after take-off, the aircraft crashed into Boucher Lake. The pilot sustained minor injuries and the aircraft was substantially damaged.

Factual information

The records indicated that the aircraft was equipped and maintained in accordance with existing regulations, and that the pilot was certified and qualified for the flight. He had about 4000 hours on the Bell 206.

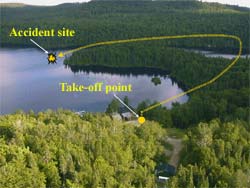

The meteorological conditions were suitable for visual flight, and the winds were calm. The pilot took off from the outfitter's parking at Boucher Lake, where four passengers had disembarked from the helicopter 30 minutes before. At a height of approximately 100 feet above ground level (agl), the helicopter commenced its flight in a south-westerly direction. When the aircraft reached translational speed, the pilot noticed that the power turbine rpm (N2) and rotor rpm (Nr) had decreased from 100 per cent to 95 per cent and were still decreasing. However, he did not hear the low rpm warning alarm. To reduce power demand and increase rotor rpm, the pilot lowered the collective and at the same time lowered the nose to accelerate. A short time later, the N2 indicator showed 85 per cent. The pilot, who was then over trees, steered the aircraft toward Boucher Lake, which was on his left. The aircraft descended over the lake and curved around a peninsula. After flying a distance of about one kilometre, a few feet above the lake, the pilot observed an increase in engine rpm in the normal operating range. However, he concluded that, because of the attitude, speed and altitude of the aircraft, the accident was unavoidable. The pilot raised the nose of the aircraft just before striking the surface of the water. Some of the outfitter's residents rescued the pilot a few minutes after the accident.

The instrument panel and console were torn off on impact. The overhead circuit breaker panel was bent downward. One of the main rotor blades struck the port side of the fuselage and engine. The main rotor mast failed in over-torque below the rotor head. The transmission shaft couplings failed. The damages observed suggest that the helicopter struck the surface of the lake at a certain speed.

No problem with the engine (Rolls Royce A250-C20B, serial number CAE83144) was observed or reported before the accident. The engine, fuel flow regulator and fuel governor were examined. Examination of the engine and its components revealed that all damages observed were caused on impact. The engine was receiving fuel and was operating at the time of the collision; no deficiencies that could have caused a loss of power were observed. The investigation did not determine the engine power output at the time of impact. The normal range of engine power output is between 95 per cent and 100 per cent of N2. According to the aircraft flight manual, a faulty fuel flow regulator or fuel governor causes a change in power or rpm. In the event of engine underspeed, the pilot should use the collective to maintain engine rpm and prepare for an autorotation landing.

The annunciator panel was examined at the TSB Engineering Laboratory. The annunciator panel contained 20 annunciator lights. Each light could contain two bulbs. Analysis of the filaments in each bulb established that no lights were on at the time of impact.

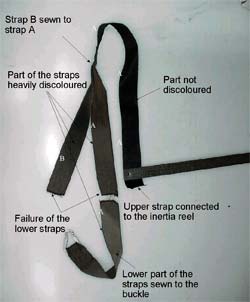

The pilot was wearing his seat belt, which consisted of a lap belt and shoulder straps connected to an inertia reel mounted on the back panel of the pilot's seat. As a result of the impact, the shoulder straps failed in overload. However, the lap belt remained intact. The pilot unfastened his seat belt before evacuating the helicopter. Although he was wearing a helmet, the pilot sustained substantial head injuries. Examination of the seat belt by the TSB Engineering Laboratory revealed that the shoulder straps were substantially discoloured. There were no signs of rubbing wear or tension. The thickness of the straps was relatively uniform. No date of manufacture was indicated on the shoulder straps; a label on the lap belt indicated that it was manufactured in December 1976. Strength testing established that the upper part of the strap failed under 1500 pounds of tension and the lower parts failed under 600 pounds. The applicable standard, Federal Aviation Administration (FAA) TSO C22, states that a strap two inches in width has a nominal strength of 1500 pounds and should not fail below 2250 pounds of tension. Seat belts are replaced when they are deemed to be in bad condition. Discolouration is not a criterion for belt replacement. According to the Bell Helicopter's company maintenance manual, proper operation, anchor security and the state of deterioration of belts should be checked on the 100-hour inspection.

Transport Canada (TC) issued Airworthiness Notice No. B050, dated 21 January 2000, to owners, operators and aircraft maintenance specialists concerning the degradation of seat belts due to long-term exposure to sunlight (ultraviolet degradation). However, this notice is under review and is no longer available. The Airworthiness Notice indicated that, in some cases, there has been a significant reduction in the strength of straps less than three years after installation. It recommended that seat belts in the cockpit be replaced if they were manufactured before 27 March 1987. The Airworthiness Notice further stated that any strap exhibiting signs of discolouration or degradation should be repaired or replaced in accordance with the manufacturer's recommendations. The second edition of Airworthiness Notice No. B050 should be available at the beginning of 2005; it will highlight the importance of signs of discolouration. All belts should have been examined on the 100-hour inspection and annual maintenance. They were considered to meet manufacturer's standards. According to the aircraft records, TC inspected the aircraft in March 2001 and November 2002. The inspection reports indicate that the condition of the seat belts was checked and met the manufacturer's standards.

The following laboratory reports were prepared:

- LP 124/03 – Light Bulb Examination

- LP 125/03 – Examination of Fractured Shoulder Belt - Bell 206 Jet Ranger

- LP 83/03 – Engine Examination

- LP 89/03 – GPS Examination

- LP 117/03 – Examination of Fuel Governor Components

These reports are available upon request from the TSB.

Analysis

The aircraft was equipped and maintained in accordance with existing regulations, and the pilot was certified and qualified for the flight.

The aircraft's engine was producing power at the time of the collision with the surface of the water. Examination of the wreckage and a detailed examination of various components revealed no evidence of a loss of power. Consequently, the investigation did not determine the cause of the transient decrease in rpm reported by the pilot.

The fact that the aircraft violently struck the surface of the water nearly one kilometre from where the rpm decrease occurred suggests that a precautionary landing or autorotation landing was not planned. A precautionary landing or autorotation landing would have reduced the horizontal impact forces.

The whitening of the lower shoulder straps was caused by ultraviolet rays from the sun. The upper part of the shoulder straps, which was less exposed to sunlight because it was rolled up on the inertia reel, was practically not faded. Since the lower parts of the straps failed at 600 pounds of tension and the upper portion failed at 1500 pounds, it is reasonable to conclude that the degree of weakening of the straps corresponded to the duration of their exposure to sunlight. Moreover, since the upper portion of the strap, although less exposed to sunlight, failed at 66 per cent of the limit required by standard TSO C22, it is reasonable to conclude that even a strap exhibiting no signs of discolouration may have sustained some ultraviolet degradation. Since their mechanical strength was reduced to about 26 per cent of their original strength, the lower shoulder straps failed before reaching the prescribed limit. Consequently, the pilot was subjected to greater deceleration forces than he should have sustained in the accident. The degree of discolouration of the lower shoulder straps was indicative of a degradation of their strength. However, since no signs of physical wear were found, the belts were considered to be in good condition on the aircraft maintenance and TC inspections. It appears therefore that the absence of specific evaluation criteria with regard to the ultraviolet degradation of the belts contributed to the return to service of seat belts that no longer met regulatory requirements.

Findings

Findings as to causes and contributing factors

- The investigation did not determine the cause of the transient decrease in engine rpm reported by the pilot.

- The attitude, speed and altitude of the aircraft did not allow the pilot to avoid a collision with the surface of the lake when the pilot raised the nose of the helicopter.

Other findings

- The pilot's seat belt shoulder straps failed at a tension level below regulatory requirements. The failure occurred as a result of degradation of the straps caused by prolonged exposure to sunlight.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .