Collision with Terrain

Cessna 210A C-FNTH

Princeton, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

The Cessna 210A aircraft (C-FNTH, serial number 21057591) with a pilot and one passenger aboard was on a visual flight rules (VFR) flight from Prince George to Princeton, British Columbia. On reaching Princeton, the pilot joined a left-hand downwind pattern for Runway 03 and intercepted the final approach path at approximately five nautical miles from the aerodrome. Approximately three nautical miles from the aerodrome, the aircraft was slightly high and the pilot selected idle power and extended the landing gear. When the throttle was selected to idle, the pilot smelled fuel fumes. On final approach for Runway 03, the pilot advanced the throttle to correct the descent, but the engine (Teledyne Continental Motors IO-470-E) did not respond, even at full throttle.

The pilot checked that the fuel selector valve was in the left-tank detent, confirmed that the propeller was in fine pitch, and that the mixture control was selected to rich. Before he could turn on the auxiliary fuel pumps, the aircraft's landing gear contacted the tops of a stand of trees. The aircraft continued its descent, struck an unoccupied house and a large pine tree, and came to rest less than half a nautical mile short of the runway. The aircraft remained wings-level before and after the aircraft struck the trees. The accident occurred at approximately 1638 Pacific daylight time. The pilot and the passenger suffered serious injuries; both were wearing seat belts and shoulder harnesses. There was no fire following the accident.

Factual information

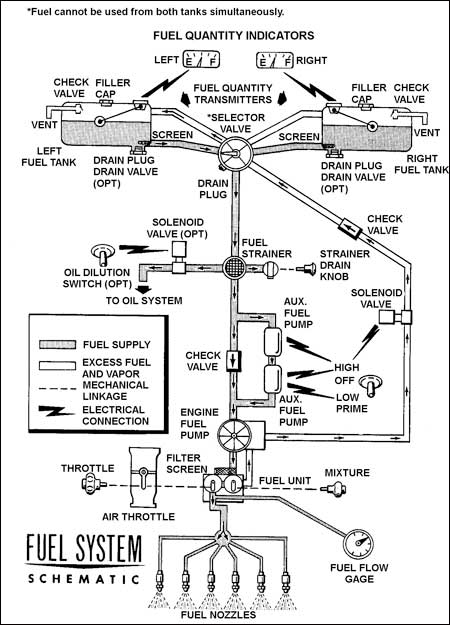

The pilot held a valid commercial pilot licence, a category 1 medical certificate and a valid aircraft maintenance engineer (AME) licence, categories M1/M2. In the days leading up to the accident flight, he had carried out an annual inspection on the aircraft. During that inspection, the fuel unitFootnote 1 (P/N 625219-2A3) was found to be leaking. It was removed for repair, which involved the replacement of o-rings and a leak check. The fuel unit was then reinstalled as part of the inspection and airworthiness certification process. Removal of the fuel unit required the disconnection of a number of fuel lines and the removal of the aircraft air induction system. The air induction system controls the source and amount of induction air being delivered to the engine.

After completion of the annual inspection, the aircraft was flown on a test flight to confirm its airworthiness. During final approach on the test flight, when the throttle was retarded to idle, the pilot/AME noted the smell of fuel inside the cabin. After landing, the engine cowls were removed and all fuel components and lines were checked for leaks; no leaks were found. The engine was then ground-run and no further fuel smells were noted. No entries were made in either the journey log nor the aircraft technical logs regarding the annual inspection, the removal and repair of the fuel unit, or the maintenance action taken to identify and correct the fuel smell in the cabin.

The accident occurred the following day as the aircraft was being flown to Princeton, by the same pilot/AME. The aircraft departed Prince George with full fuel for the 280 nautical miles visual flight to Princeton. There were no indications of any aircraft system or performance problems during the take-off, cruise, or enroute descent phases of the flight. The fuel mixture had been leaned while en route at 7500 feet above sea level (asl) and the mixture had been enriched during descent. The engine, propeller and associated controls were reported to have worked properly for the two-hour period prior to the accident.

The pilot used fuel from the left tank for engine start and taxi at Prince George. He then selected the right tank for the engine runup, departure, and for the first hour of the flight. After an hour in the air, he selected the left tank and, about one hour later, observed on approach into Princeton that both fuel gauges were reading similar values between ½ and ¾ full.

At the accident site, investigators found that the throttle was advanced to FULL, the mixture control was RICH, and the propeller control was FINE. All of these positions are consistent with an attempt to increase engine power to maximum. The fuel selector valve was found in the left position, and first responders reported seeing fuel leaking from the left-side fuel lines. Some fuel had also spilled forward and to the right side of the aircraft and that area had been foamed by the fire department. The fire department collected a fuel sample from the left tank. It was clear and bright and confirmed to be 100 low-lead aviation fuel. Following the field inspection, the aircraft wings were removed to allow the wreckage to be transported to an examination facility; a number of fuel lines had to be disconnected to accomplish that removal.

An inspection of the engine identified a number of discrepancies that were not consistent with the aircraft having just been through an annual inspection. However, none of the identified problems would be expected to cause the engine to stop in flight.

The fuel supply system was checked in detail. Both fuel tanks had been breached during the crash and were empty. All four fuel tank vents were clear, and the wing did not display any indications of collapse that would normally be associated with a blocked fuel tank vent system. The fuel strainer bowl had been damaged at impact and did not contain fuel, although the fuel screen in the bowl, as well as all other fuel screens within the system, were found clean and free of debris. The fuel distributor (P/N 631427A15) and engine fuel pump contained fuel, but the fuel supply line from the engine fuel pump to the fuel unit did not. Both electric auxiliary (aux) fuel pump switches were found in the OFF position, but these pumps operated correctly when tested.

The aircraft's fuel unit and engine fuel pump were removed and bench tested at an approved repair facility. Results of the bench test identified performance variances relative to the bench test standards, but these anomalies would not be expected to cause the engine to fail.

The aircraft's fuel selector valve assembly (P/N 1216001-1) was removed and forwarded to the TSB Engineering Branch for further examination. It was considered possible that a fault in this component was a source for the smell of fuel noted during the descent into Princeton. There was no indication of external fuel leakage found during the engineering examination; however, o-rings internal to the unit contained localized deposits of dirt and debris and were no longer pliable. The deteriorated condition of the o-ring installed in the left-tank supply port prevented the fuel selector valve from operating normally and would have allowed fuel to be supplied to the engine when the selector valve was in the OFF position. Despite these discrepancies, this fault would not have stopped the engine from operating, nor is it likely the cause of the fuel smell on approach to Princeton.

The induction air system was removed and examined. Impact marks on the unit confirm that an internal door connected to the induction air manual control was partially closed at time of crash and yet the manual control lever was selected to the fully-open position. The position of the door would cause a richer than normal fuel mixture to be delivered to the engine. Based on impact damage, the door was likely in this abnormal position before the accident.

Analysis

The reason(s) for the fuel smell and for the engine failure could not be determined.

Fuel quantity was not likely a problem. The aircraft had started with full tanks and had only flown for two hours. Based on the pilot's reported fuel selections, each tank should have been more than half full at the time of the engine stoppage. Additionally, even if all the fuel for the trip had been inadvertently taken from one tank, there still should have been sufficient fuel remaining in that tank to keep the engine running.

Fuel starvation because of a technical malfunction is also unlikely. To operate, an engine requires an appropriate fuel/air mixture to be supplied to the cylinders. Because fuel was confirmed to be available at the fuel distributor, which is immediately in line and upstream of the fuel nozzles, it is unlikely that fuel starvation was the cause of the loss of engine performance. The fact that fuel was not found further upstream, between the engine fuel pump and the fuel unit, is likely related to accident damage or post-crash movement and transport. Specifically, because a number of the fuel components had been damaged in the crash and, subsequently, because some lines had to be disconnected to allow removal and transport of the wreckage to an examination facility, it is likely that one or more of these breaches of the fuel system could have allowed fuel to escape from various locations within the system.

The following TSB Engineering Branch report was completed:

- LP 114/03 – Fuel Selector Valve Examination

Findings

Finding as to Causes and Contributing Factors

- On approach, when the pilot attempted to add power, the engine did not respond and the aircraft struck trees before the pilot could identify and correct the situation. The engine stopped for undetermined reasons.

Finding as to Risk

- The deteriorated condition of the o-ring installed in the left-tank supply port prevented the fuel selector from operating normally, such that it could allow fuel to be supplied to the engine when the selector was in the OFF position.

Other findings

- No fault was found that would be expected to prevent the engine from producing power.

- It is unlikely that either fuel tank venting, fuel starvation, or fuel exhaustion of one tank precipitated this event.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .