Crude oil pipeline leak

Enbridge Pipelines Inc.

Line 2, Mile Post 474.7335

Near Odessa, Saskatchewan

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

At approximately 0240 Mountain standard time on 29 September 2009, a crude oil leak occurred on the Enbridge Pipelines Inc. 610-mm outside diameter Line 2 at Mile Post 474.7335, immediately downstream of the Odessa pump station near Odessa, Saskatchewan. The leak occurred at a crack within a shallow dent at the 6 o'clock position on the pipe. There were indications of gouging associated with the dent. The release occurred in a low lying, densely vegetated marsh. Approximately 175 cubic metres of crude oil was released, of which most was recovered. There were no injuries.

Factual information

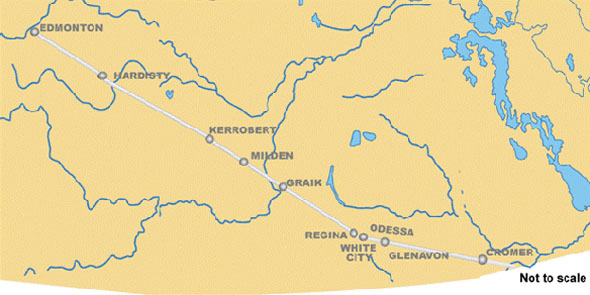

Line 2 operates continuously out of Edmonton with intermediate injection and delivery locations at Hardisty, Alberta and Kerrobert and Regina, Saskatchewan. The pipeline consists of 1242 km of 610-mm outside diameter pipe of varying wall thicknesses. It transports batches of crude oil of varying viscosities. Just prior to the leak, Line 2 had been shut down as part of normal operations from 0030 to 0230.

The response

At approximately 0445Footnote 1 on 29 September 2009, a landowner left a voicemail with a contractor working on an Enbridge Pipelines Inc. (Enbridge) construction project indicating that there was a strong petroleum odour immediately downstream of the Odessa pump station (see Figure 1).

At 0458, the contractor passed the message to the Enbridge Control Centre operator in Edmonton, Alberta. At 0505, the Enbridge pipelines flowing past the Odessa pump station were shut down. By 0520, isolation procedures were completed. Field personnel was sent to the site. At approximately 0540, it was confirmed that crude oil was present in a marshy area at Mile Post (MP) 474.7335. Shortly afterwards, Enbridge began to recover the pooled oil using vacuum trucks.

The failed section of pipe was cut out and replaced with pre-tested pipe. When Line 2 was returned to service on 1 October 2009, Enbridge voluntarily implemented a pressure restriction on the Line 2 discharge at Odessa pump station equal to 80 per cent of the highest pressure in the 30 days prior to the release. Enbridge committed to maintain the discharge pressure at that level until it received concurrence from the National Energy Board (NEB) to increase the operating pressure to the previously established levels.

Enbridge hired an environmental consultant to develop and implement a remedial action plan and a surface water and groundwater monitoring program for the site. Following remediation and reclamation (to be completed by October 2010), Enbridge will continue to monitor the site until 2012.

Laboratory examination of failed pipe

A section of the failed pipe, approximately 3 m long, was sent to the Acuren Group Inc. (Acuren) laboratory in Edmonton, Alberta for metallurgical analysis. Acuren's examination included visual inspection, non-destructive testing, dimensional measurements and destructive metallurgical testing. The laboratory analysis determined that:

- Pipe diameter, ovality and wall thickness measurements met the specification in place at the time of pipe installation.

- Chemical composition and material properties (including strength) of the pipe met the specification in effect at the time the pipe was manufactured.

- The leak occurred at a 160 mm long crack associated with a dent and gouge located at the 6 o'clock position on the pipe. The maximum depth of the dent was 3.1 mm (0.51 per cent of the pipe diameter).

- The coating in the immediate vicinity of the leak was missing. However, the coating on the rest of the pipe section was in relatively good condition.

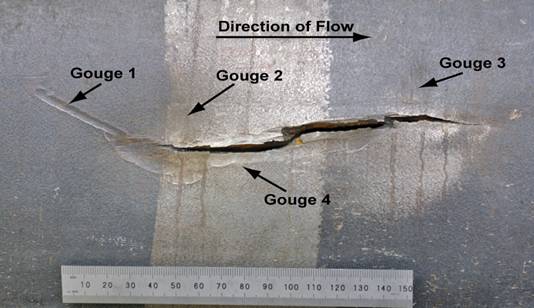

- Gouges in four separate directions were present in the immediate vicinity of the crack (see Photo 1). One of the gouges crossed into a relatively shiny circumferential band on the pipe that contained less carbon and oxygen than the surrounding black pipe surface. Cracking had initiated at three major points from the base of the depression formed by the gouge that was parallel to the pipe axis. The maximum depth of this gouge was approximately 0.4 mm. The outer pipe surface in the vicinity of this gouge exhibited high hardness.

- Most of the crack surface was mechanically damaged, the result of a growing crack closing in on itself due to compressive stresses associated with cyclic loading. The rough crack surface and presence of secondary cracks were consistent with fatigue crack propagation under high stress/low cycle conditions.

- Two shallow dents (depths of 0.46 per cent and 0.43 per cent of the pipe diameter) were present on the side of the pipe at the 3 o'clock position in the vicinity of the dent that leaked. Mechanical scoring parallel to the pipe axis was associated with both these dents but there was no damage to the pipe coating, nor was cracking found in the dents.

Staff from the Transportation Safety Board (TSB) were present at Acuren's laboratory and found the nature of the work performed and methodologies used consistent with good failure analysis practice.

The pipeline

The section of Line 2 in which the leak occurred was pipe grade 359 and had a nominal wall thickness of 7.14 mm. It was manufactured by A.O. Smith with a flash weld longitudinal seam. The pipe was coated in the field with coal tar enamel. Following construction in 1953, the pipe was hydrostatically tested with water to a minimum test pressure of 7136 kilopascals (kPa) (85 per cent specified minimum yield strength [SMYS]) for a maximum operating pressure (MOP) of 6240 kPa (74 per cent SMYS).

A flow test was conducted in 1970 with a pressure of 6374 kPa (76 per cent SMYS) and the MOP was reduced to 4654 kPa (55 per cent SMYS). In 1985, a hydrostatic test was conducted as part of an expansion project with a test pressure of 7439 kPa (89 per cent SMYS). The MOP was increased to 5950 kPa (71 per cent SMYS).

No maintenance requiring excavation has been done on this joint of pipe after its construction in 1953.

Line 2 operations

The majority of Line 2 shutdowns are done for scheduled deliveries. Other shutdowns are for scheduled maintenance with occasional shutdowns due to emergency situations. Line 2 typically experiences one or two scheduled delivery shutdowns every one to two days.

The pipeline experiences low amplitude cyclic pressure fluctuations in the course of normal operations. The pressure cycles associated with the start-stop operation are typically greater in amplitude than those associated with continuous operation. The cyclic loading due to transportation of batches as well as cyclic loading caused by start-stop operations associated with deliveries is moderate to aggressive and is considered typical of current Line 2 operations.

To reduce frictional pressure loss along the line and to improve flow, a drag-reducing agent (DRA) is occasionally injected into Line 2 at Craik, White City and Glenavon, Saskatchewan. At the time of the occurrence, injections were being made at all three locations.

Line 2 is operated by a pipeline controller at the Enbridge Control Centre in Edmonton, Alberta, using a supervisory and data acquisition (SCADA) system. The pipeline controller also responds to alarms generated by the pipeline's leak detection system, the material balance system (MBS). The smallest average leak rate that would trigger an MBS alarm is 107 cubic metres per hour (m³/hr). The average leak rate for this occurrence was 76 m³/hr, resulting in a product loss of 175 m³. No high pressure events had occurred during normal operations. No unusual operating conditions had been noted during the time leading up to the leak.

At 0431, on 29 September 2009, the pipeline controller for Line 2 received a two hour MBS alarm in the Milden to Cromer section of the pipeline. This alarm indicated that over the previous two hours, commencing at approximately 0240, the volume balance had gone outside of acceptable limits. During this time, DRA was being injected into the pipeline at a rate of 20 parts per million (ppm). The MBS analyst at the control centre determined that the modelled effectiveness of the DRA differed significantly from the actual effectiveness which resulted in the leak alarm. The MBS analyst then adjusted the MBS settings which reduced the imbalance and the alarm eventually cleared. During 2009, the MBS alarm was triggered 18 times across the Enbridge system due to DRA inconsistencies.

Regulatory requirements regarding pipeline integrity management

The National Energy Board (NEB) requires federally regulated pipeline companies to develop pipeline integrity management programs and to take corrective action when defects are found that exceed certain criteria allowed by Canadian Standards Association Z662 – Oil and gas pipeline systems (CSA Z662). Section 10.9.4 of CSA Z662 (see Appendix A) specifies in part:

The following dents shall be considered to be defects unless determined by an engineering assessment to be acceptable:

- dents that contain stress concentrators (gouges, grooves, arc burns, or cracks);

- dents that are located in the pipe body and exceed a depth of 6 mm in pipe 101.6 mm OD or smaller or 6 % of the outside diameter in pipe larger than 101.6 mm OD.

Enbridge's pipeline integrity management program

Enbridge's pipeline integrity management program is aimed at minimizing the possibility of failure due to corrosion, stress corrosion cracking, or fatigue cracking associated with longitudinal weld anomalies and geometrical discontinuities, such as ovality, dents and buckles. Inspections consist of periodic in-line inspections (ILI) using an appropriate ILI tool followed by field digs. The field digs verify ILI results and allow for the repair of injurious anomalies.

In the late 1990s and early 2000s, Enbridge sponsored research to identify shape characteristics, in addition to depth, of dents that fail. Following this work, Enbridge recognized that the shape characteristics considered in the research, including depth, are not the most significant contributor to failed dents, and that secondary damage from gouges and scrapes are a larger contributor. Enbridge therefore requires ILI companies to report dents with depths of more than two per cent of pipe outside diameter, as well as dents coincident with metal loss, cracking or a stress riser.

Inspection of Line 2 prior to the occurrence

The most recent inspections on Line 2 between Regina and Cromer were:

- In 1998, a geometrical discontinuity inspection was conducted using a caliper tool.

- In 2004, a metal loss inspection was conducted using a magnetic flux leakage (MFL) tool.

- In 2008, a geometrical discontinuity inspection was conducted using a caliper tool.

- In 2008, a crack inspection was conducted using an ultrasonic crack detection tool.

These inspections did not result in any digs at the leak location.

The MFL tool used in 2004 was capable of detecting dents, wrinkles and buckles, in addition to detecting internal and external metal loss. However, this tool could not provide a direct measurement of deflection. During the 2004 inspection, the MFL tool detected the dent, but did not identify the gouging, as the gouge depth of 0.4 mm was below the detection capability of the tool.

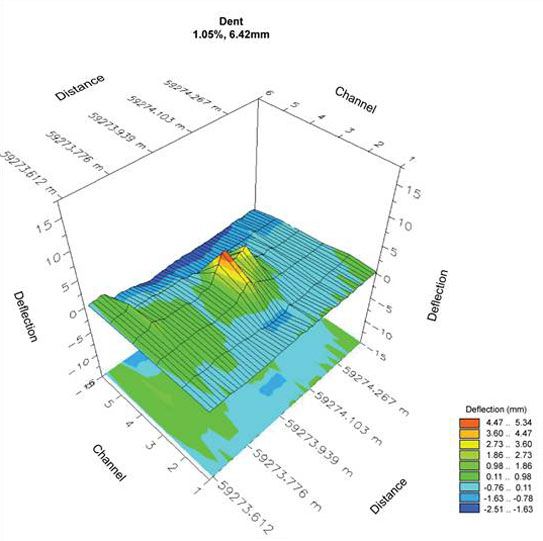

The caliper tool used in 2008 detected a double apex dent at the location of the leak. However, the dent was not reported to Enbridge since the measured deflection was below the reporting threshold of two per cent.

The crack detection tool used in 2008 was designed to detect axially oriented crack-like features and was also capable of detecting metal loss and dent features. It could not, however, detect secondary features in dents (e.g. gouging) with any reliability and would not have been used to do so. During the 2008 inspection, the tool did detect the dent, but did not report it. It did not detect either the gouge or crack.

In addition to reviewing the results of individual inspections, data is also compared between different inspections to identify secondary features. For Line 2, the following comparisons were conducted:

- Data from the 2004 metal loss ILI was cross-referenced to data from the 1998 geometrical discontinuity ILI to identify secondary features. Two features met Enbridge's excavation criteria and the locations were excavated in 2005.

- Data from the 2008 geometrical discontinuity ILI was cross-referenced to data from the 2004 metal loss ILI to identify secondary features. No features met Enbridge's excavation criteria.

At the time of the 2008 inspections, although Enbridge recognized the possibility that double apex dents or dents in close proximity to each other could be linked to stress risers, it did not require ILI companies to report such dents if the depths were less than two per cent of the pipe outside diameter.

Post accident review of ILI data and associated follow-up

Following the leak, Enbridge re-examined data from the 2004 MFL and the 2008 caliper ILI to identify any unique features of the dent that failed and to identify other locations that exhibited the same features. From the 2008 geometrical discontinuity ILI, the plot of the failed dent exhibited a complex shape (i.e., a double apex) (see Figure 2).

Following this re-evaluation, Enbridge identified and excavated all locations where there were known dents with multiple apexes or in close proximity to one another, regardless of their depth.

Field information from one location that met these criteria confirmed the presence of three dents in close proximity to one another. The coating was in good condition prior to removal, indicating that the dents had been formed at the time of construction. A non-destructive examination indicated that the depths were less than one per cent of the pipe diameter. All three dents were associated with sharp gouges and two of the gouges contained cracking up to 27 per cent of the wall thickness.

Enbridge also re-evaluated the data for all of Line 2 from the 2008 MFL ILI to identify dents that coincided with features identified by the crack detection tool; none did.

Analysis

The accident

The pipeline failure occurred at a location where dents and gouges had been present prior to the pipe being coated in the field. Mechanical damage in the form of dents and gouges can occur either during or after construction. Mechanical damage after construction typically occurs on the top of the pipe from third-party excavation activities between the 8 and 4 o'clock positions and results in coating and pipe damage. In this occurrence, the dent and gouges occurred at the 6 o'clock position. Judging from the nature and location of the damage, it likely occurred at the time of construction.

Following the initial hydrostatic pressure test in 1953, the dent would have re-rounded to some degree, resulting in high tensile strains in the root of the gouged area. The pipe material deformation from the gouge resulted in high hardness near the pipe surface which contributed to crack initiation. Because the dent did not fully re-round, it continued to fluctuate with changes in normal line operations and operating pressures. The crack progressed through-wall by pressure cycle induced fatigue.

The dent was detected during the 2004 metal loss in-line inspection. However, the metal loss associated with the gouge was below the detection limit of the ILI tool and the location was not flagged as a dent with secondary damage. No follow-up was performed after the 2004 inspection as the size of the dent was within company specifications. In 2008, the dent was again detected during the geometrical discontinuity in-line inspection. Again, as it did not meet Enbridge's damage reporting criteria, it was not flagged for further follow-up. In addition, although Enbridge had recognized that double apex dents or dents in close proximity could be indicative of mechanical damage , it had not recognized that such dents, regardless of depth, should be included in its reporting criteria.

Pipeline integrity management

CSA Z662 provides dent depth as one criterion for identifying dents that require repair. This standard also states that any dent containing a stress concentrator, such as a gouge, shall be repaired. Detection of those dents, however, becomes problematic when the dent is detected but the metal loss associated with the stress concentrator is below the detection limit of the inspection tool, as occurred in this situation. For such dents, features which could be indicative of mechanical damage, other than depth or associated metal loss, need to be determined and be part of a company's dent acceptability criteria.

Enbridge has recognized that secondary damage from gouges and scrapes contributes to the failure of dents that may meet CSA depth acceptability criteria. In an effort to identify such dents, it relies on metal loss information from other ILI runs to supplement information from a geometry discontinuity ILI. Although the MFL tool detected a dent, the damage at that location was below the detection capability of the tool. Therefore, the secondary damage associated with the dent was not identified and the area was not flagged as needing attention. In addition, since the depth of the dent was within the limits allowed by the CSA Z662 standard, it was not flagged as a location requiring further evaluation.

After the occurrence, Enbridge re-evaluated the caliper tool ILI data and determined that other dent features, such as the presence of a double apex or other dents in close proximity, can be indicative of secondary damage. When all available in-line inspection data involving dent features is not considered when determining the presence of secondary damage, there is a risk that a critical dent will not be identified in a timely manner, leading to the initiation of a crack at the dent location and to the eventual failure of the pipe.

Interpretation of material balance system leak alarms

Since Line 2 transports batches of crude oil of varying viscosities, Enbridge occasionally injects a DRA into the pipeline to reduce frictional pressure loss along the line and to improve flow characteristics. On the day of the occurrence, the MBS received a leak alarm in association with the injection of DRA. The MBS analyst then adjusted the MBS settings to reduce the volume imbalance. The imbalance eventually corrected and the alarm cleared. The MBS analyst believed that the leak alarm was caused by a modelling issue between the actual and the modelled effectiveness of the drag-reducing agent in Line 2 and not by a potential leak in the pipeline system. Material balance system leak alarms can occur when the modelled effectiveness of drag-reducing agents in the pipeline system differ from actual effectiveness.

The following TSB Laboratory report was completed:

- LP 173/2009 – Pipeline Failure, Enbridge Line 2 Odessa

This report is available from the Transportation Safety Board of Canada upon request.

Findings

Findings as to causes and contributing factors

- The pipeline failure occurred at a location where dents and gouges had been present from the time the line was constructed in 1953.

- The dents and gouges created a work-hardened area where a crack initiated. The crack then progressed through-wall by pressure cycle induced fatigue during operations that are typical to Line 2.

- Although the dent was detected during the 2004 metal loss in-line inspection, the metal loss associated with the gouge was below the detection limits of the tool and the location was not flagged as a dent with secondary damage.

- Although the dent was detected during the 2008 geometrical discontinuity in-line inspection, it did not meet Enbridge's damage reporting criteria and was not flagged for further follow-up.

- At the time of the 2008 geometry in-line inspection, although Enbridge recognized that stress risers (such as those associated with mechanical damage) could potentially be present in double apex dents or dents in close proximity, it had not determined that all such dents, regardless of their depth, should be included in its reporting criteria.

Finding as to risk

- When all available in-line inspection data involving dent features are not considered in determining the presence of secondary damage, there is a risk that a critical dent will not be identified in a timely manner, leading to the creation of a crack at the dent location and to the eventual failure of the pipe.

Other finding

- Material balance system leak alarms can occur when the modelled effectiveness of drag-reducing agents in the pipeline system differs from their actual effectiveness.

Safety action

Safety action taken

Enbridge

Following this occurrence, Enbridge made the following changes to the mechanical damage prevention portion of its pipeline integrity management program:

- in-line inspection vendor reporting criteria were revised to include dents with multiple apexes or dents in close proximity to each other, regardless of depth;

- guideline documents were developed to incorporate the modified reporting criteria data into it mechanical damage program; and

- its construction group was informed of the lessons learned from this occurrence.

Enbridge is continuing to develop in-line inspection capabilities by participating directly with in-line inspection vendors and research organizations.

Enbridge is continuing to support the development of models to predict the formation of cracks in dents through active involvement in the Pipeline Research Council International, a non-profit corporation comprising 37 pipeline companies from around the world.

Enbridge imposed maximum limits on drag-reducing agent injection rates to ensure the material balance system model is working within its design range.

Transportation Safety Board

In May 2010, the Transportation Safety Board sent a Safety Advisory to the National Energy Board (NEB) advising it of this occurrence and suggesting that since dents of less than six per cent of pipe outside diameter can fail, the NEB, in consultation with CSA, may wish to review the pipe body dent repair requirements of CSA Z662-07 – Oil and gas pipeline systems.

National Energy Board

In June 2010, the NEB issued an advisory (NEB SA 2010-01: Fatigue Crack Failure Associated with Shallow Dents on Pipelines) to all companies under its jurisdiction, as well as to the Canadian Energy Pipeline Association (CEPA), the Canadian Association of Petroleum Producers (CAPP) and provincial regulators. The advisory highlights the need for pipeline companies to review and update their integrity management programs to consider the failure of shallow dents. The advisory also provides preventative actions to be included as part of the integrity management program reviews.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on 27 July 2010.

Appendices

Appendix A

CSA Z662-07 – Oil and gas pipeline systems

10.9.4 Dents in pipe

10.9.4.1

Dents shall be inspected using visual and mechanical measurement methods capable of determining the location of the dent with respect to mill and seam welds, the depth and shape of the dent, and the presence of gouges and grooves. Where considered appropriate, nondestructive methods capable of detecting cracks and internal corrosion imperfections shall also be used.

10.9.4.2

The Following dents shall be considered to be defects unless determined by an engineering assessment to be acceptable:

- Dents that contain stress concentrators (gouges, grooves, arc burns, or cracks);

- Dents that are located on the pipe body and exceed a depth of 6 mm in pipe 101.6 mm OD or smaller or 6% of the outside diameter in pipe larger than 101.6 mm OD;

- Dents that are located on the mill or field weld and exceed a depth of 6 mm in pipe 323.9 mm OD or smaller or 2% of the outside diameter in pipe larger than 323.9 mm OD;

- Dents that contain corroded areas with a depth greater than 40% of the nominal wall thickness of the pipe; and

- Dents that contain corroded areas having a depth greater than 10% up to and including 40%, of nominal wall thickness of the pipe and a depth and length that exceed the maximum allowable longitudinal extent determined as specified in ASME B31G.

Pipe containing such defects shall be repaired using one or more of the acceptable repair methods given in Table 10.1.

Notes:

- Failure can occur in dents with acceptable depths if they are caused by very sharp rocks, are subjected to large pressure fluctuations over a very long period of time, or are located on a seam weld in low frequency (less than 1 kHz) electric resistance welded pipe. For such situations, an engineering assessment should be performed to determine if a repair is necessary.

- Dents in the top half of buried piping can contain gouges caused by excavating equipment. Consideration should be given to excavating dent features located in the top half of the pipe that are reported by in-line inspection and performing visual and nondestructive inspection of such dents.

- When piping containing a dent is excavated, the change in external loading can reduce the depth of the dent.

- Pressure should be reduced to the lowest feasible level before removing rocks that caused dents near the bottom of pipe (see Clause 10.9.1.3).

10.9.4.3

Engineering assessment of dents shall include consideration of pipe design and manufacturing, service history and loading (including fatigue), anticipated service conditions, the mechanism of dent formation, dent shape and dimensions, failure modes, and material properties (including fracture toughness properties).

Notes: An analysis method applicable to dented pipe that can be used as part of an engineering assessment is described in PRCI PR-218-9822.