Rail transportation safety investigation report R18H0039

Uncontrolled movement of rolling stock

Canadian Pacific Railway

Remote control locomotive system

Yard assignment T16-13

Mile 195.5, Belleville Subdivision

Toronto Yard

Toronto, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Executive summary

The incident

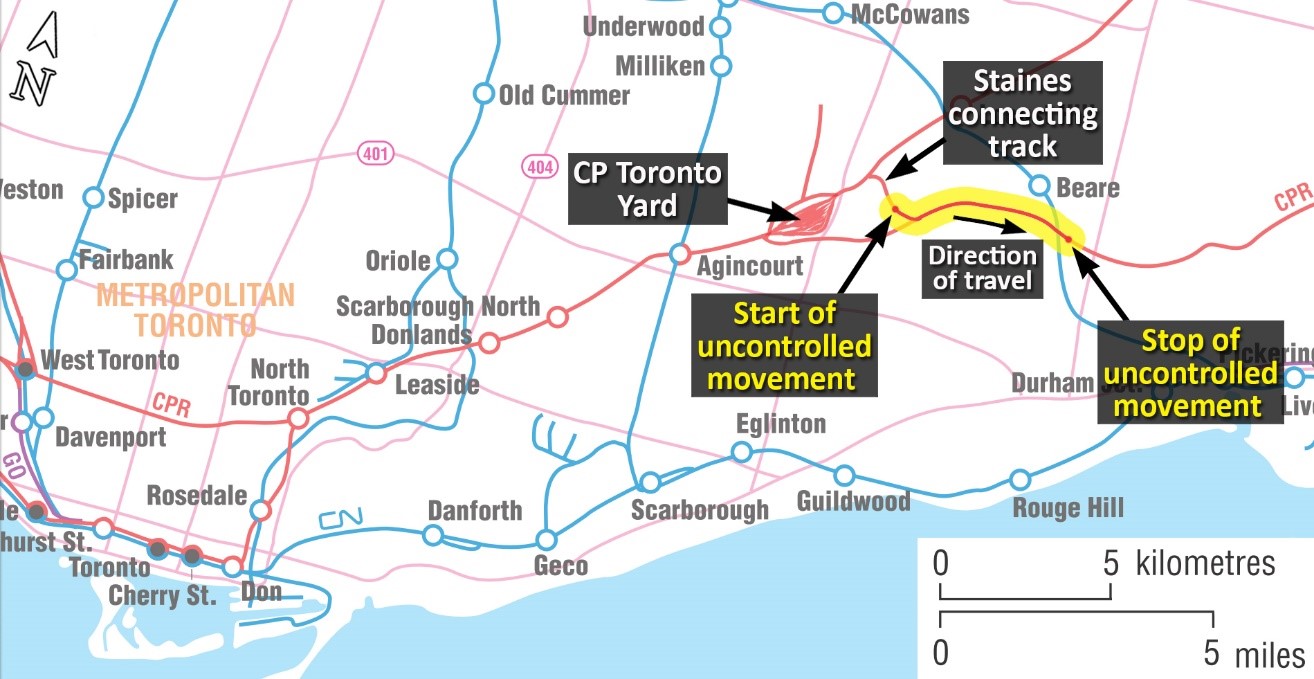

On 14 April 2018, at about 0215 Eastern Daylight Time, a Canadian Pacific Railway (CP) yard foreman and a CP yard helper were performing switching operations at CP’s Toronto Yard in Toronto, Ontario using a remote control locomotive system (RCLS). The yard foreman was operating yard assignment T16-13 (the assignment) when it began to roll uncontrolled eastward on the Staines connecting track.

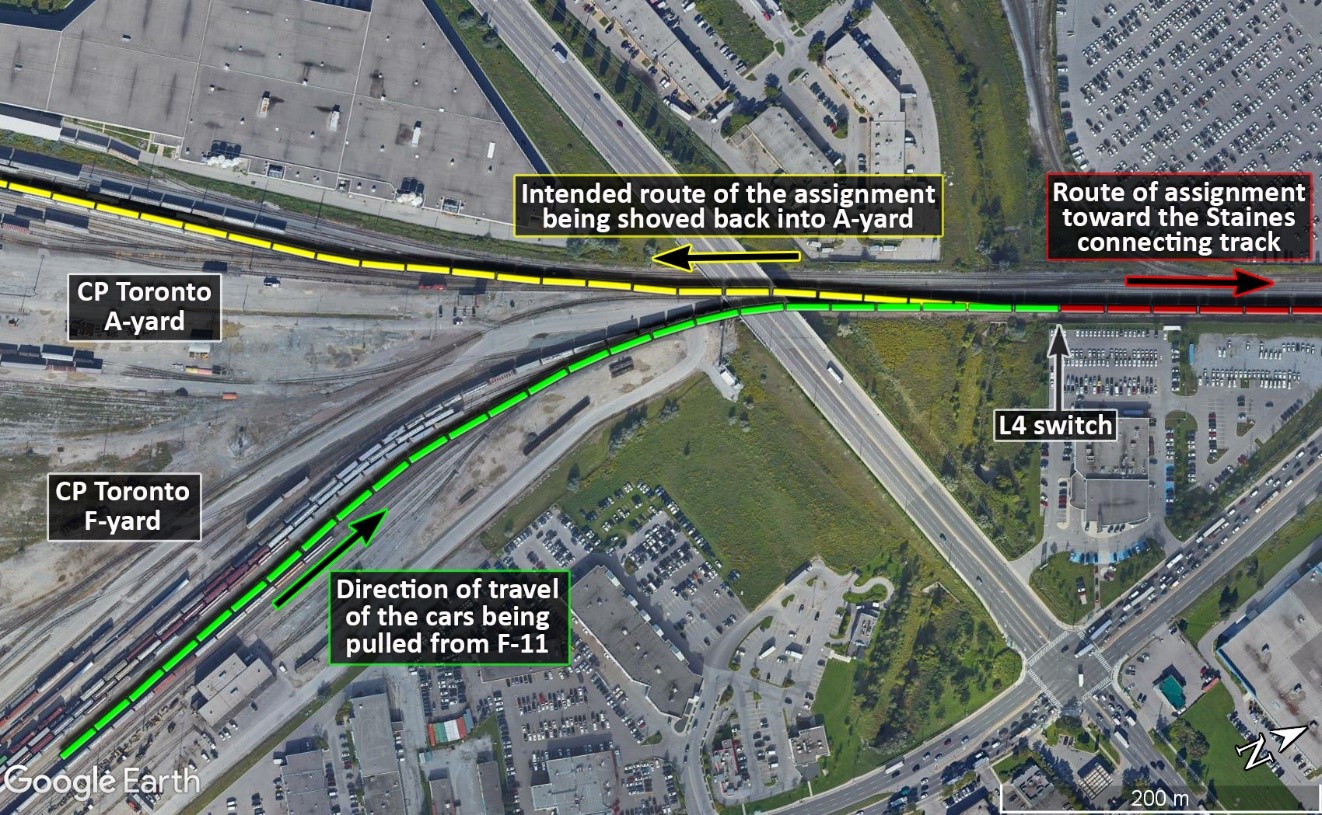

The plan had been for the assignment to pull 88 cars, weighing 6400 tons and measuring 6250 feet in length, from track F-11 eastward on the Staines connecting track. This move required the assignment to proceed past the Tapscott Road public crossing and to continue until the last car was past the L4 switch. The assignment was then to be reversed back into the A-yard (Figure S1).

After coupling the locomotives onto the freight cars in track F-11, the foreman had difficulty connecting the air hoses between the locomotives and the lead car in the track because the air hose on the lead car was not properly aligned. Consequently, the foreman did not connect the air hoses and decided to switch the cars on a descending grade without operative freight car air brakes. The foreman did not communicate the plan to the helper or to trainmaster 1.

As the assignment pulled out of track F-11, the foreman was riding on the tail end car and controlling the assignment remotely using the RCLS. Given the foreman’s position, he was unaware of when the head end of the assignment was on the descending grade of the Staines connecting track. After disembarking near the L4 switch, the foreman attempted to stop the movement using the RCLS. This attempt was unsuccessful, even after placing the brake selector in the “Emergency” position, since there was no supply of air in the freight car air brakes.

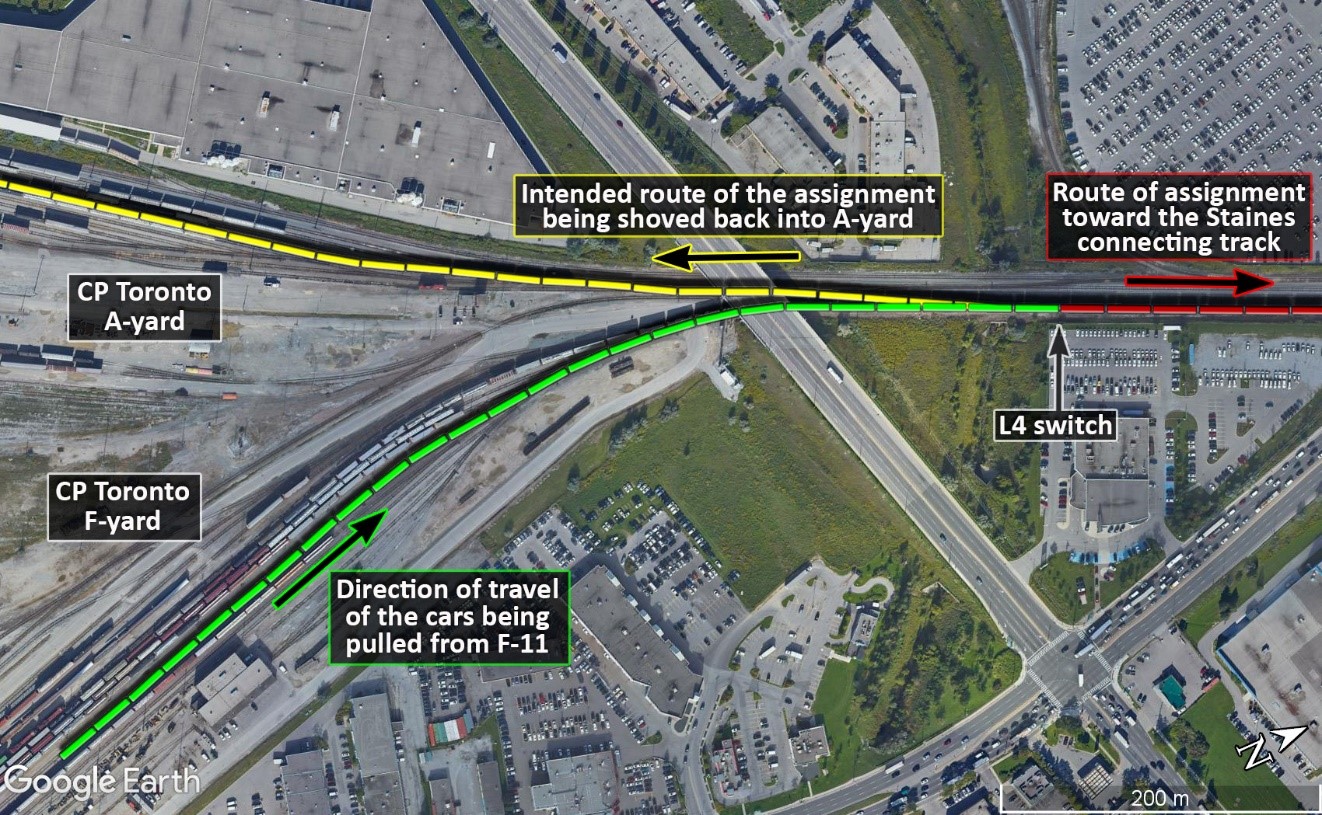

Consequently, the assignment did not slow down and continued to roll uncontrolled on the 0.88% descending grade toward Signal 1952B, which displayed a stop indication, where the Staines connecting track joins the Belleville Subdivision main track. The assignment ran through the main track switch, entered the main track, and rolled uncontrolled for an additional 3 miles with the helper positioned on the head end. After the helper applied hand brakes on the 2 locomotives and on the 1st car and the assignment encountered an ascending grade, it came to a stop near Mile 192.5 of the Belleville Subdivision. There was no derailment or collision and there were no injuries.

Use of train air brakes when switching

Trainmaster 1 had held a job briefing with the assignment crew at the beginning of the shift as well as a second one later by radio to discuss the move to pull the cars from track F-11. Following discussion, trainmaster 1 advised the assignment crew that track F-11 had to be cleared to avoid further delays and that all 88 cars had to be pulled from track F-11 in one move. There was no discussion about the use of air brakes for the move.

The foreman believed that the use of air brakes was required only when the assignment was kicking cars westward into the yard. Although the foreman had previously proceeded past Tapscott Road without any air brakes applied to freight cars, he had never handled as many cars as the assignment had that day. The foreman was also unaware of the risks associated with proceeding past Tapscott Road on the descending grade of the Staines connecting track without air brakes connected to the freight cars.

Crew training

The 2 assignment crew members were qualified with 5 to 7 months of operating experience, primarily in the yard. Each wore a green vest to identify themselves as a new employee.

CP’s conductor training program includes classroom training for Canadian Rail Operating Rules (CROR), company instructions and an on-the-job training (OJT) portion where new trainees are paired with more experienced employees who provide coaching and mentorship. During OJT training in the yard, new trainees are advised on specific details about the yard and specific locations that are unique to the area where the trainees will be working. Many of these location-specific instructions would not necessarily be taught during the classroom portion of the training.

In 2014, at Toronto Yard, CP posted a sign on the signal bungalow at the remotely controlled derail located just west of Tapscott Road. The sign was intended to inform operating crews that when handling movements that weigh at least 3000 tons and/or are at least 3000 feet long, a minimum of 5 cars with trainline air were required to have operative brakes to control the movement on the approaching descending grade. However, the use of the sign was non-standard, as it was not a rule or an operating instruction and did not provide context on why air was required. As a result, the posted air brake instructions at Tapscott Road would not have been discussed during the classroom portion of the training. Instead, it would have been up to qualified conductors to provide such location-specific information to trainees during the OJT portion of the training.

However, during training, the yard crews worked mainly at the west end of the yard, since it was better suited for switching longer cuts of cars. Local freight assignments switched at the east end of the yard normally consisted of fewer cars and would often be operated on the Havelock Subdivision. These assignments rarely passed the Tapscott Road crossing or handled enough cars to require air brakes. As a result, despite his training and experience, the foreman lacked the knowledge to safely handle long, heavy cuts of cars on the descending grade at the east end of the yard when accessing the Staines connecting track.

Pairing of inexperienced operators

There is no company or regulatory requirement outlining the time or experience required before a conductor assumes the role of yard foreman. At CP, the member of the crew with the most seniority at the railway would typically be assigned the role of foreman, regardless of the employee’s experience at the task. Because CP’s scheduling system typically assigns operating employees to yard positions based on seniority, it is not uncommon for yard foremen to have limited operational and RCLS experience.

In this occurrence, despite the relative inexperience of both the foreman and the helper, the yard foreman was designated as such because he had the most seniority. If experience with the task involved is not specifically considered when the roles are assigned to operating crew members, inexperienced operating employees can be scheduled to work together or can be put in charge of unfamiliar tasks, increasing the risk of error.

Since 2007, the TSB has completed 7 investigations (including this one) that highlight the risks associated with conductors with low levels of experience being paired together to carry out yard assignments. The TSB determined that the experience level of the conductors contributed to these occurrences through increased likelihood of errors and insufficient knowledge to make effective decisions with respect to planning and train handling. Further, the TSB determined that the practice of pairing junior employees for yard assignments meant that the coaching and mentoring required to develop the effective judgment needed for train handling were not being provided. Following an investigation into a fatal yard accident, the Board issued a safety concern related to the pairing of inexperienced RCLS operators. Footnote 1

Unplanned/uncontrolled movement statistics

As a result of the TSB investigation into the Lac-Mégantic accident,Footnote 2 the Board recommended that Transport Canada (TC) require Canadian railways to put in place additional physical defences to prevent runaway equipment (TSB Recommendation R14‑04). In response, TC implemented a number of initiatives, including strengthening securement requirements in CROR Rule 112 and introducing a comprehensive oversight plan for the new rule. Although the Board was encouraged by the TC initiatives related to securement, it noted that the desired outcome of significantly reducing the overall number of uncontrolled movements has not yet been achieved.

In another TSB investigation reportFootnote 3 involving an uncontrolled movement, the Board issued a safety concern stating that the current defences are not sufficient to reduce the number of uncontrolled movements and improve safety.

This was reinforced by the TSB investigation into the December 2017 uncontrolled movement that resulted in a CN employee fatality in Melville, Saskatchewan, which primarily dealt with uncontrolled movements that occur as a result of switching without air. On 10 June 2020, the Board recommended that TC work with the railway industry and its labour representatives to identify the underlying causes of uncontrolled movements that occur while switching without air, and develop and implement strategies and/or regulatory requirements to reduce their frequency (TSB Recommendation R20-01).

Of the 562 occurrences that resulted in unplanned/uncontrolled movements from 2009 to 2018 inclusive, loss of control, as in this occurrence, was the causal category in 20 (4%) of them. While uncontrolled movements due to loss of control are low-frequency events, 60% of them (12 out of 20) affected the main track. In these cases, there is an increased potential to encounter the public at crossings and the possibility of collision with main-track freight and passenger trains. Consequently, these are considered to be low-frequency–high-risk events. Therefore, if effective strategies are not implemented to improve safety during switching operations, uncontrolled movements involving loss of control will continue to occur, increasing the risk of accidents, particularly when the uncontrolled movement continues onto the main track.

1.0 Factual information

On 14 April 2018, Canadian Pacific Railway (CP) yard assignment T16-13 (the assignment), operated using a remote control locomotive system (RCLS), was performing switching operations at the east end of CP’s Toronto Yard in Toronto, Ontario (Figure 1).

The assignment regularly operated from 2330 to 0730 Monday to Friday each week and worked primarily from the east end of the yard. The assignment consisted of 2 locomotives (CP 4434 and CP 4426) and 88 cars (53 loaded cars and 35 empty cars). The assignment, including the locomotives, was 6250 feet long and weighed about 6400 tons, with the weight relatively equally distributed throughout its length. CP 4434 was the controlling locomotive, positioned at the east end of the movement.

The crew consisted of 2 conductors—one acting as the yard foreman who was in charge of coordinating the switching activities, and the other as the yard helper. The crew members were qualified for their positions, met fitness and rest standards, and were familiar with Toronto Yard. Both crew members were wearing green vestsFootnote 4 and were equipped with a BeltpackFootnote 5 from which either crew member could operate the locomotive.

1.1 Toronto Yard

Toronto Yard is located in the Agincourt/Scarborough suburb in the Greater Toronto Area. Movements within the yard are conducted under Canadian Rail Operating Rules (CROR) Rule 105, Operation on non-main track.Footnote 6 According to this rule, movements are restricted to speeds of up to 15 mph and must be able to stop within half the range of vision of equipment.

At the time of the occurrence, CP employed a total of 168 operating employees (conductors and locomotive engineers) at Toronto Yard. These employees were responsible for operating a combination of yard assignments, local switching assignments, and main-track freight trains on various shifts.

Toronto Yard had previously been the location of CP’s largest hump operation. However, in 2012, CP discontinued the use of hump yards throughout Canada, including the one in Toronto Yard. Initially, when the hump yards closed, the 72 classification tracks at Toronto Yard were used for storage. However, the classification tracks have since been removed. Presently, at Toronto Yard, yard work is all flat switching, performed primarily using RCLS.

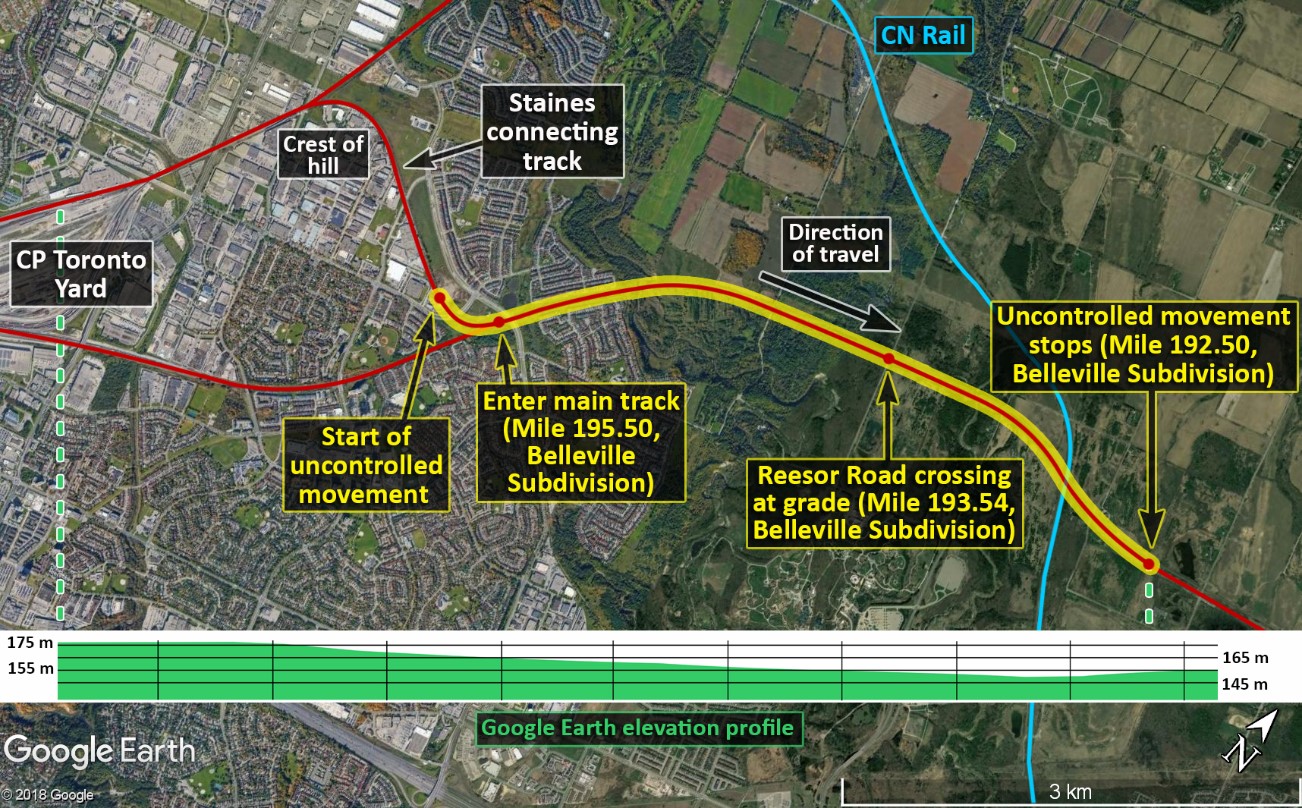

Toronto Yard is generally separated into a north area (A-yard) and a south area (F-yard); each has a grade that descends toward the centre of the yard, giving Toronto Yard a bowl-shaped profile. At the east end of the yard, the A-yard and F-yard converge at the L4 switch just east of the Finch Avenue overpass.

When switching between the A-yard and the F-yard (at the L4 switch), yard crews at the east end use the Staines connecting track, which connects to the main track of the Belleville Subdivision at Mile 195.50.

1.2 The incident

On 13 April 2018, just before 2330,Footnote 7 the assignment crew reported for work at Toronto Yard. The foreman was the regular foreman on the assignment. The helper, who was assigned to the spare board, had been called at approximately 2130.

Upon arrival, the crew members reported to the east pulldown tower,Footnote 8 where they received the switching instructions by fax from a terminal trainmaster (trainmaster 1) who was located in the west control tower. The crew members conducted an initial job briefing with trainmaster 1 to discuss the work to be performed. Following the job briefing, the assignment crew commenced switching activities.

On 14 April, at about 0140, trainmaster 1 provided a new switch list by fax to the crew for cars in track F-11 that were to be set off in the A-yard. A job briefing with trainmaster 1 was conducted by radio, during which the number of cars (88), the tonnage (6400 tons), and the length (6250 feet) were discussed.

Due to the large number of cars to be moved, the foreman suggested initially taking half of the cars, placing them in the A-yard, and then returning for the remaining cars. However, trainmaster 1 advised that CP train 240 was stopped west of the yard and was waiting to enter track F-11 from the west end. Since all other tracks in the F-yard that could accommodate train 240 were full, a track needed to be cleared to avoid further delays to train 240. Trainmaster 1 indicated that the crew had to pull all 88 cars from track F-11 at once. There was no discussion about the use of air brakes for the move.

The crew planned to reverse the locomotives into track F-11 and connect onto the cars at the east end of the track. The assignment would then pull all 88 cars out onto the Staines connecting track and stop once the assignment cleared the L4 switch to shove back into A‑yard (Figure 2).

The helper was positioned on lead locomotive CP 4434 to protect the point of the movement (the end leading the movement) while the assignment occupied the Staines connecting track, as the assignment was not within the point protection zone.Footnote 9 The helper was required to disengage the remotely controlled derailFootnote 10 at Tapscott Road to allow the assignment to proceed eastward.

The foreman remained on the ground and controlled the movement with the Beltpack. The foreman reversed the locomotives into track F-11 and then coupled them to the lead car at the east end of the track.

After testing the coupling, the foreman attempted to connect the air hoses to engage the air brakes on the cars. However, the foreman was unable to connect the hoses between the locomotives and the lead car. After several attempts, the foreman decided to release the hand brakes and pull the cars without connecting the air brake hoses. As a result, the assignment cars did not have any functioning air brakes.

The foreman did not advise the helper or trainmaster 1 that the air brake hoses could not be connected and that there would be no air brakes on any of the cars when they proceeded eastward onto the Staines connecting track.

At about 0200, the foreman activated the Beltpack and the assignment began to pull eastward out of track F-11. The helper remained on the lead locomotive and disengaged the remotely controlled derail at Tapscott Road, then advised that the derail was in the non-derailing position. The helper sounded the locomotive bell for the automated public crossings at grade that traversed the Staines connecting track at Tapscott Road and Nielsen Road,Footnote 11 as required in a non-whistle area.

As the assignment pulled eastward, the foreman, who was now positioned at the F-11 switch, verified the assignment car numbers against the switch list. As the tail end of the assignment approached, the foreman slowed the assignment, boarded the last car, and then moved the speed selector to the “Max” positionFootnote 12 (15 mph).

At about 0214, as the last car approached the L4 switch, the foreman placed the speed selector to the “Coast” position, disembarked the car, and then placed the speed selector to the “Stop” position. Upon realizing that the assignment was not slowing down, the foreman promptly put the brake selector to the “Emergency” position, but the assignment continued to move eastward. The foreman contacted the helper by radio to ask if the lead locomotive was slowing down. The helper replied that it was not.

The assignment continued to accelerate when approaching Signal 1952B, which was displaying a stop indication, and when approaching the main track switch located at Mile 195.50 of the Belleville Subdivision. The helper contacted trainmaster 1 to say that the assignment was rolling uncontrolled toward the main track of the Belleville Subdivision and was unable to stop. The assignment then ran through the main-track switch, which was lined against it, and continued onto the main track.

In the west control tower, a second, more senior trainmaster (trainmaster 2) took control of the situation. After calling and informing the rail traffic controller (RTC) that the assignment was about to enter the main track without authority, trainmaster 2 requested that the main track switch be lined for the uncontrolled movement if there were no other trains approaching.

The RTC responded that an unauthorized occupancy was displayed on the RTC screen, indicating that the assignment had already entered the main track. The RTC advised trainmaster 2 that there were no nearby trains on the Belleville Subdivision.

The assignment continued to roll uncontrolled on the main track, reaching a speed of 17 mph. The assignment travelled over the Reesor Road public crossing, located at Mile 193.54 of the Belleville Subdivision. The crossing was equipped with flashing lights, bell, and gates, which operated as intended. The helper, who was still positioned on the lead locomotive, sounded the bell and whistle as the assignment travelled over the crossing.

Trainmaster 2 instructed the helper on the lead locomotive to start applying hand brakes to stop the assignment. The helper applied the hand brake on the 2 locomotives. The hand brake on the 1st car was also applied, by reaching the hand brake wheel from the locomotive platform.

At about 0230, the assignment came to a stop near Mile 192.50 of the Belleville Subdivision, after having rolled uncontrolled for about 3 miles on the main track (Figure 3).

During the uncontrolled movement, the assignment crew did not make an emergency radio broadcast, as required by CROR Rule 125, Emergency communication procedures.Footnote 13

At the time of the occurrence, there was rain and fog, winds were 16 km/h from the northeast, and the temperature was 2.8 °C.

1.3 Subdivision information

The CP Belleville Subdivision extends from Smiths Falls, Ontario (Mile 0.0), to Leaside, Ontario (Mile 206.3). Toronto Yard is located at Mile 197.0. There is a single main track east of Toronto Yard where the Staines connecting track joins to the Belleville Subdivision. Train movements on the Belleville Subdivision are controlled by the centralized traffic control system (CTC), as authorized by the CROR, and supervised by an RTC in Calgary, Alberta.

1.3.1 Track profile between Toronto Yard and the Belleville Subdivision

From the L4 switch to just west of Tapscott Road, the track was relatively level, with a slight downward grade of 0.02%. From the L4 switch to the crest of a hill located about 500 feet east of the Tapscott Road crossing, the track had a slight upward grade of 0.16%. From the crest of the hill, the track descended for about 1.24 miles toward the Belleville Subdivision main track switch (Mile 195.50). Throughout this area, the descending grade varied between −0.88% at the crest to −0.52% approaching the main track switch. The average descending grade was −0.68%. The descending grade continued eastward on the main track with an average descending grade of about -0.4% until about Mile 193.0, at which point the main track began to ascend to Mile 192.50, where the locomotive came to a stop (Figure 4).

1.4 Work at Toronto Yard

In February 2018, to address a high volume of work due to an increase in traffic and with the availability of newly hired conductors, CP increased the number of RCLS yard jobs from 3 to 6, with 2 crews working simultaneously—one crew at the west end of the yard and the other crew at the east end.

Previously, a total of 3 yard assignments (1 assignment for each 8-hour period to provide 24-hour coverage) worked primarily at the west end of the yard because of its longer yard leads, including the former hump lead. At the east end of the yard, switching was generally limited to shorter cuts of cars and was performed primarily by local assignments to service local industries. These assignments, which normally handled a limited number of cars, often operated on the descending grade of the Havelock Subdivision and had air connected to the freight cars to operate the air brakes and assist with braking during operations.

1.5 Air hoses and glad hands

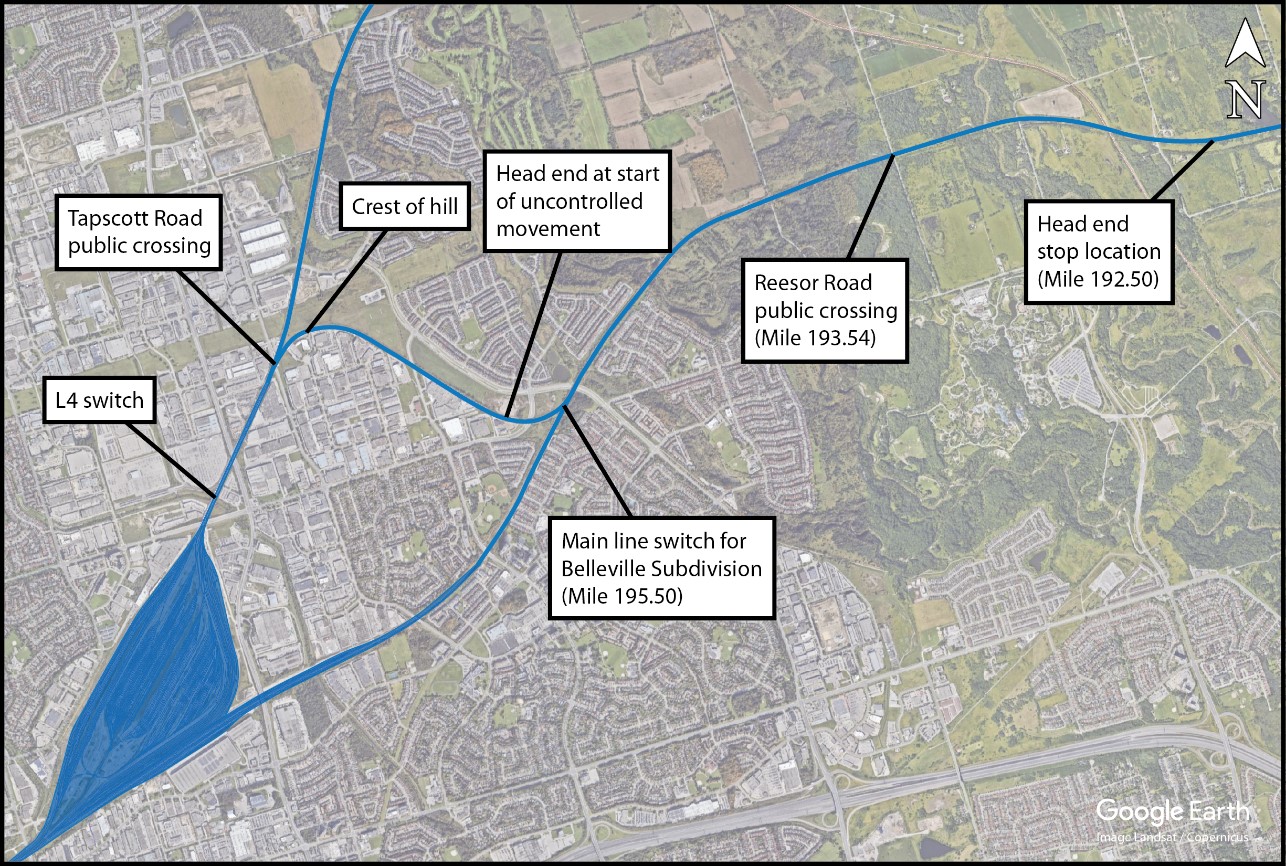

To apply and release the brakes on rail cars, air pressure supplied by an air compressor on the locomotive is required. To have air from one end of a train to the other, air hoses are connected from car to car by air hose glad hands (Figure 5).

When air hoses are mounted to a rail car, care must be taken to ensure that the glad hand is properly positioned so it is in line with the glad hand on the connecting car. Otherwise, the glad hands may be difficult to connect.

Following the occurrence, a CP manager attempted to connect the air hoses between locomotive CP 4434 and the lead car of the assignment to determine why they could not be connected. After one unsuccessful attempt, the manager was able to connect the air hoses. It was noted that the freight car hose did not line up with the connecting air hose on the locomotive. The air hose on the freight car was later adjusted.

1.6 Canadian Pacific Railway’s Train & Engine Safety Rule Book

To connect air hoses, the following instructions are provided in CP’s Train & Engine Safety Rule Book:

Safe Work Procedure: Coupling Air Hoses

Step 1: Ensure equipment is secure, if equipment is attached to a locomotive, ensure 3-point protection is in place.

Step 2: Step between the cars.

Step 3: Make sure that both glad hands have gaskets.

Step 4: Bend at the knees and hips while maintaining a neutral spine (i.e. keeping your lower back, mid-back and neck curves in proper alignment) grasp the air hose nearest you firmly behind its glad hand and bend it upward

Step 5: Grasp the hose farthest away and pull it toward the bent hose.

Step 6: Match the glad hands into opposite contoured slots and push them downward.

Step 7: Make certain that the glad hands are seated.

Step 8: With your head turned away, gradually open the angle cock.Footnote 14

1.6.1 Reporting unsafe conditions

In CP’s Train & Engine Safety Rule Book, the following core safety rules are indicated:

- We inform each other of known unsafe conditions and corresponding control measures.

- We correct unsafe conditions or protect against them and report them to a supervisor.Footnote 15

1.7 Canadian Rail Operating Rules emergency procedures

The CROR contain instructions pertaining to emergency procedures to be followed to protect against unauthorized movements.

CROR Rule 80 states in part:

[…]

(b) If a movement occupies or fouls a main track or siding controlled territory without authority, or passes a block or interlocking signal indicating stop without authority to pass such signal; it must be stopped and protection as required by Rules 35 and 125 initiated. The RTC or signalman must be advised as soon as practicable.Footnote 16

CROR Rule 35 states in part:

This rule does not authorize main track occupancy or track work.

(a) Any employee discovering a hazardous condition, which may affect the safe passage of a movement, must by the use of flags, lights, fusees, radio, telephone, or other means, make every possible effort to stop and/or provide necessary instructions to any movement that may be affected. […]Footnote 17

When a radio is used to provide emergency protection, CROR Rule 125, Emergency Communication Procedures, states the following:

- An employee will transmit the word “EMERGENCY” three times at the beginning of the transmission to indicate the report of;

- an accident involving injury to employees or others;

- a condition which may constitute a hazard to employees or others;

- a condition which may endanger the passage of movements; or

- a derailment which has occurred on, or is fouling, a main track.

- When an emergency communication, which is directed to a specific person or movement, has not been acknowledged, any other employee hearing it will, if practicable, relay the communication by any means available. Other employees must not interfere with such communication.

- An emergency communication has absolute priority over other transmissions.Footnote 18

In this occurrence, the crew members had been communicating by radio using the dedicated Toronto Yard channel. When it became apparent that the assignment was not coming to a stop and was about to enter the main track, the crew members did not make an emergency radio call on the train standby channel.

While conductors receive training on emergency procedures, there had not been any additional specific training on emergency communication procedures for RCLS operators. However, a job aid for emergency broadcast was available in the locomotive cab.

Upon being informed of the occurrence, both trainmasters in the west control tower turned their attention to the situation at hand. Trainmaster 2 contacted the RTC, who stopped all train movements on the Belleville Subdivision east of Toronto Yard. As no movements were directly affected, there was no need for immediate evasive action.

1.8 Operating personnel information

In the rail industry, conductor positions are generally unionized positions governed by collective agreements between an employer and the employee union. Each week, CP posted local assignments for bidding by operating employees. Positions were awarded by seniority, with the most senior employees who submitted bids having 1st choice of the jobs. If no job bids were received for a specific position, the position was typically awarded to the employee with the least seniority, in accordance with the collective agreement.

Because there had been extensive employee turnover in the rail industry in the past few years, it was not unusual for the 2 most junior, and least experienced, employees at a terminal to work together in yards, particularly during the evening and night shifts. The pairing of inexperienced crew members is not uncommon in the Canadian rail industry. There is no regulatory requirement to consider the experience of the operating employees who may be paired for work.

In this occurrence, the assignment crew consisted of 2 employees who each had about 7 months of experience as qualified conductors. The crew met rest standards. An evaluation of their work history did not identify any potential for fatigue.

After the occurrence, CP testedFootnote 19 the crew members to determine if they were under the influence of alcohol and drugs, which would have impaired their performance at the time of the event. Test results were negative for both crew members.

1.8.1 Foreman

The foreman began training in April 2017 and qualified as a conductor in September 2017, after completing classroom training and approximately 70 on-the-job training (OJT) trips.

Starting in August 2017, as part of the conductor training, the foreman attended the classroom portion of the RCLS training course and participated in RCLS OJT by working various assignments, mainly at the west end of the yard. In November 2017, the foreman became qualified as an RCLS operator.

The foreman had been proficiency tested 21 times with 42 observations, 2 of which were not successful. One unsuccessful observation was related to insufficient hand brakes to secure a cut of cars and the other was related to inter-crew communication. The foreman had no prior record of receiving discipline from the railway.

The foreman was familiar with the Tapscott Road area. Before this occurrence, the foreman had taken 30 to 40 cars in this area without having air supplied to the cars. The foreman had been assigned to that night assignment for the past 3 weeks.

1.8.2 Helper

The helper began training in April 2017 and qualified as a conductor in September 2017, after completing classroom training and approximately 70 OJT trips.

In August 2017, during conductor training, the yard helper attended the classroom portion of the RCLS training. In December 2017, the helper became qualified as an RCLS operator.

The helper had been proficiency tested 16 times with 29 observations, 1 of which was an unsuccessful observation relating to not checking that all cars were included in a train consist. The helper had no prior record of receiving discipline from the railway.

The helper had worked regular shifts in the east end of the yard for 6 weeks before being placed on the spare board.

1.8.3 Trainmaster 1

Trainmaster 1 started working for CP in 2010 and had occupied a number of track maintenance–related roles. In November 2017, this employee accepted the trainmaster 1 position. Although trainmaster 1 was rules-qualified, he had not worked directly in operations before accepting this post. He later qualified as a conductor and locomotive engineer.

Trainmaster 1 was responsible for overseeing operations, including ensuring train crew compliance with the CROR and CP’s rules and instructions. Trainmaster 1 worked with locomotive engineers and conductors to ensure the effectiveness and timeliness of train movements. In the current position, trainmaster 1 was required to perform at least 20 proficiency tests and 16 footboard safety meetingsFootnote 20 each month.

On the night of the occurrence, trainmaster 1 was one of 3 trainmasters on duty in the west control tower. Just before the occurrence, trainmaster 2, who was the most senior trainmaster at the terminal, was performing train planning at a computer station while trainmaster 3 was away from the control tower, transporting a crew. At the time of the occurrence, trainmaster 1 was controlling all yard movements from the west control tower.

1.9 Requirements to conduct job briefings

A job briefing helps ensure that all work is understood between crew members. One of the core safety rules in CP’s Train & Engine Safety Rule Book states:

Job briefings are conducted before performing work and when activity and/or conditions change from initial briefing.Footnote 21

CP’s Train & Engine Safety Rule Book provides further details on conducting job briefings, including the following:

- Before performing any job, a job briefing led by the foreman/conductor must be held to ensure that all employees involved have a clear understanding of:

- The task to be performed;

- Your individual responsibility; and

- Situational awareness concerns

Additional verbal job briefings must be carried out as necessary, while the work progresses or as the situation changes.Footnote 22

Crews conduct job briefings verbally.

In this occurrence, after the foreman was unable to connect the air hose to the car directly behind the locomotives, the crew did not conduct a job briefing to discuss how to proceed without air brakes on the movement.

1.10 Remote control locomotive system

The RCLS consists of 3 components:

- one or more remote control locomotives (RCL);

- an onboard control computer, which is mounted inside the RCL to interface with the controls; and

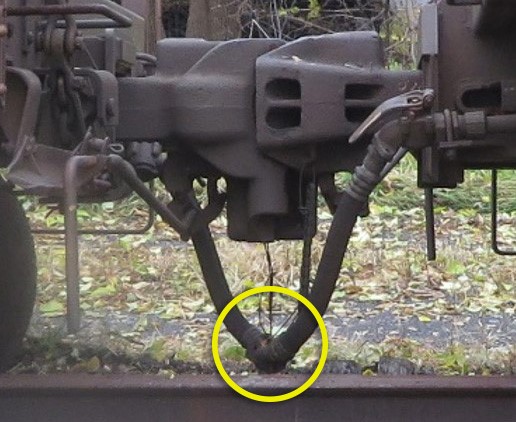

- an operator control unit (OCU), commonly referred to as a Beltpack (Figure 6).

The Beltpack is a remote control device that attaches to the operator’s safety vest and controls the RCL. As RCLS yard crews work in teams of 2, the crew members can pass control of the locomotives back and forth as required (pitch and catch). Only 1 crew member will have control at a time. During RCLS training, it is recommended that the employee protecting the point of the movement be in control of the Beltpack. The Beltpack is equipped with a speed selector that includes preadjusted speeds of 4 mph, 7 mph, 10 mph, and maximum speed (15 mph). The OCU is also equipped with a forward and reverse selector and a brake selector that includes an emergency brake feature. The Beltpack does not display the actual speed of the locomotive.

Once a speed is selected, the Beltpack applies either the throttle or the brakes of the locomotives to first attain the preselected speed and then to maintain it, ± 0.5 mph. The system adapts reactively to the characteristics of the train and the terrain (without proactively taking into account the train length, tonnage, or slack).

1.11 Canadian Pacific Railway remote control locomotive system instructions

In the mid-1990s, RCLS was first introduced at Toronto Yard. At that time, CP provided general RCLS instructions, with additional local instructions governing RCLS operations for specific yards within the applicable railway timetable. The 2008 Belleville Subdivision timetable, which included Toronto Yard, contained many specific instructions for RCLS operations at Toronto Yard. For example, for assignments working at the east end of the yard and handling cars east of Tapscott Road, the timetable contained the following special instruction for RCLS operations:

When drafts of cars are pulled east of Tapscott Road crossing you must always be aware of the downgrade and have your train under control at all times. i.e. when handling 60 cars of mixed freight or more than 4000 tons, 5 to 10 cars for train brake air will be utilized.

The maximum tonnage allowed when pulling drafts of cars east of Tapscott Road restricted to 4500 tons.Footnote 23

In 2010, to streamline information in timetables, CP removed the specific RCLS operating instructions for all yards from the timetables and replaced the instructions with a generic job aid that applied throughout the CP system. The job aid was incorporated into RCLS training.

In August 2012, CP ceased using RCLS in Toronto Yard, as the technology in place at that time did not deliver the anticipated operational benefits. By mid-2016, the technology had improved, and CP reimplemented RCLS in Toronto Yard. However, the location-specific RCLS instructions were not added back into the Belleville Subdivision timetable. Instead, CP introduced the CATTRON RCLS Special Instructions, which applied to the entire CP system. The new CATTRON RCLS Special Instructions essentially contained the instructions from the CP RCLS job aid issued in 2010, but without any location-specific information.

The September 2017 version of the CATTRON RCLS Special Instructions states the following:

Whenever there is doubt that locomotive brakes can control or stop the movement, then sufficient air brakes must be cut-in and tested to ensure adequate braking ability exists.Footnote 24

With regards to the handling of long cuts of cars, the CATTRON RCLS Special Instructions include the following:

YSE [yard service employees] and YSH [yard service helpers] must pay careful attention to the approximate number of cars being handled in relation to loads and empties in order to ensure proper train handling practices can be followed.Footnote 25

In 2014, at Toronto Yard, CP had posted a sign on the signal bungalow at the remotely controlled derail located just west of Tapscott Road (Figure 7). The sign was intended to inform operating crews that when handling movements weighing at least 3000 tons and/or at least 3000 feet long, a minimum of 5 cars were required to be supplied with air to have operative air brakes that would help control the movement on the approaching descending grade. However, the use of the sign is not a rule or an operating instruction, as referenced in CROR General Rule B, and does not provide the context of why the additional operative freight car air brakes were required.

CROR General Rule B states the following:

Special Instructions will be found in time tables, general operating instructions, operating bulletins or GBO [general bulletin orders]. They may be appended to or included within copies of the Canadian Rail Operating Rules but do not diminish the intent of the rule unless official exemption has been granted.Footnote 26

The CROR recognize that rules cannot cover all situations and specify that train crews must exercise some judgment to provide for safe operations. Specifically, CROR Rule 106 states:

All crew members are responsible for the safe operation of movements and equipment in their charge and for the observance of the rules. Under conditions not provided for by the rules, they must make take every precaution for protection.Footnote 27

1.12 Federal Railroad Administration report on the safety remote control locomotive system operations

In 2002, to better understand the safety implications of RCLS operations, the Federal Railroad Administration (FRA) launched a multi-study research program. In March 2006, the FRA published the Final Report: Safety of Remote Control Locomotive (RCL) Operations.Footnote 28 Although the study focused primarily on the practices of U.S. railroads, one of the focus groups included Canadian railways.Footnote 29 The report analysis and results were applicable to the North American railway industry. The report addressed issues relating to human factors, including RCLS operator training, preparation, and experience. The report stated:

The combination of increase in new hires with no prior railroad experience (especially switching experience) and self-reported and observed (via Foster-Miller research) inadequacies in RCO [RCLS operator] training and preparation have the potential to be problematic and may lead to RCO errors, as well as accidents/incidents due to a lack of knowledge or understanding of RCL operations, including switching operations.Footnote 30

Examples of inadequacies identified in the training included

- lack of training for a specific move to be made or for a specific area of a yard,

- inadequate on-the-job training, and

- an insufficient amount of hands-on training.

The report also expressed concerns about the large influx of new workers into the railways. It noted that the abundant experience that the current RCLS operators had when they were learning to operate RCLS was extremely important in maintaining a safe working environment. The FRA expressed concern that the current workers learning RCLS operations would not be afforded the “traditional breaking-in periods” when learning their jobs, especially RCLS jobs.

Among others, the report identified the “pairing of inexperienced crew members” as a critical safety issue. Given the industry shortage of switchmen and locomotive engineers, it was thought that this may be a significant safety issue in the future.

In the past, many of the employees who were initially trained in the use of RCLS technology already had significant railway experience to draw on. Experienced employees were familiar with railroad safety, operating rules, and the intricacies of working within busy classification yards.Footnote 31

1.13 Training and qualification of railway operating employees

At CP, new conductor training initially consists of 8 weeks, based on the following components:

- The first 2 weeks of conductor training consist of general classroom orientation and basic safety instructions.

- Trainees continue their training in the field for an additional 2 weeks, where they observe and conduct some limited tasks.

- The trainees then return to the classroom for 4 weeks, where they receive comprehensive rules and instructions training on various subjects, including safe work procedures, CROR, company general operating instructions, and special instructions.

Following the classroom training, new conductor trainees begin the practical portion of the training program. During OJT, qualified conductors coach and mentor the trainees on the rules and instructions pertaining to the work and on the specifics of the yard and/or territory. The trainees then put into practice what they learn in the classroom. Trainees complete approximately 70 OJT trips over a 6-month period or until a company manager who observes them in the field deems them to be qualified.

When RCLS was first introduced at CP, third-party consultants provided the classroom and practical training. In June 2015, CP introduced online RCLS training, which replaced the initial classroom instruction training.

Online modules are completed in a classroom in the presence of a local CP trainer over 3 or 4 days. The trainer provides support to the trainees. Some of the modules that are covered include these tasks:

- safely start and shut down an RCLS locomotive;

- identify the RCLS components on a locomotive and the OCU (Beltpack);

- set up the locomotive and Beltpack for operation;

- conduct locomotive inspections and carry out preliminary tests;

- identify, troubleshoot, and reset faults that may occur during a work shift; and

- control the speed and braking of a train.

The practical OJT portion of the RCLS training occurs after trainees complete the online conductor training program. New conductors are scheduled for RCLS OJT shifts and work with qualified RCLS crews. After the initial trips, a field placement coordinator rides with a trainee to evaluate their progress. Employees take as many OJT trips as needed to confirm they are ready. Final sign-off is provided by a CP supervisor once the field placement coordinator recommends qualification. The OJT portion of the training typically lasts 1 to 2 weeks, but can be extended by 1 or 2 weeks if the trainees believe they need more time.

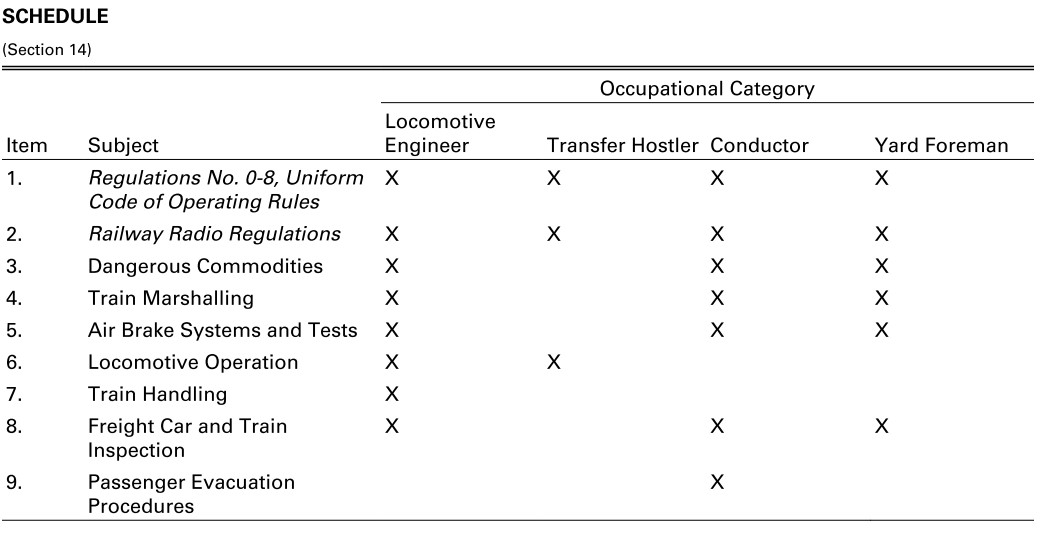

1.13.1 Railway Employee Qualification Standards Regulations

In Canada, the Railway Employee Qualification Standards RegulationsFootnote 32 (the Regulations), which came into force in 1987, establish the minimum qualifications for locomotive engineers, transfer hostlers, conductors, and yard foremen. They apply to all federally regulated railway employees performing the duties of the specified occupational category (Appendix A).

Since the Regulations came into force, there have been significant operational changes in the rail industry, including crew size being reduced and RCLS operations being widely implemented across the country. Despite these significant changes in railway operations, the Regulations have not been modified in more than 30 years.

At the time the Regulations came into force, operating employees typically followed a graduated promotion approach from brakeman / yard helper to conductor / yard foreman, and then to locomotive engineer. As the industry and technology evolved, the role of brakeman was phased out and new operating employees were typically hired as conductor trainees. As a result, when the new employees completed their conductor training, they were considered qualified as yard helper, conductor, and yard foreman. Over the years, training delivery has changed, to the point that some new conductor candidates can now qualify within 6 months.

Training programs for operating occupational categories, such as RCLS operators and RTCs, are not covered by the Regulations, but most railways have training plans and manuals in place for those positions.

The Railway Safety Act review panel examined the training and qualification issue in its report entitled Stronger Ties: A Shared Commitment to Railway Safety – Review of the Railway Safety Act, which was released in 2007. The panel examined the Railway Employee Qualification Standards Regulations as they related to operating employee qualification standards, graduated qualification, training, and regulatory oversight. The review panel’s report identified the fact that the regulatory framework for railway employee qualification had not kept pace to reflect the significant changes in the railway operating environment.

The training and qualification issue was again examined by the 2018 Railway Safety Act review panel. Its report, entitled Enhancing Rail Safety in Canada: Working Together for Safer Communities, included the following observations and conclusions:

The 2007 RSA Review looked at training for operating crews and ultimately refrained from making a recommendation on the matter, as it recognized that although the applicable regulations had not been updated since 1987, industry programs are updated on an ongoing basis and monitored by Transport Canada, which is still the case today.68 […]

Although Transport Canada certifies aviation and marine crew members, there are no provisions for certifying railway employees or approving railway training programs. As such, each company is awarded considerable latitude in preparing and providing training and certification tailored to the specific needs of its employees. The Review heard from some Transport Canada inspectors that they occasionally note gaps in the consistency of training (e.g., knowledge) of railway personnel, and while CN and CP have taken steps to address training gaps through company training centres in Winnipeg and Calgary, further efforts could be made to strengthen training requirements of railway personnel. […]

[…] The Review is satisfied and encouraged by Transport Canada’s current efforts to update and broaden its approach to the railway employee qualification and training framework, with a view to revising/replacing the existing regulations. This is an important undertaking, given the number of railway industry changes in the areas of new technology, increased staff turnover, and associated new hires.Footnote 33

_______

68 2007 Railway Safety Act Review. Stronger Ties: A Shared Commitment to Railway Safety, Review of the Railway Safety Act. November 2007. pp. 163–164.

1.13.2 Operational experience of crew members

Knowledge, skill, judgment, and experience are critical factors that directly affect an operating crew’s ability to perform work safely. For example, operating crews that work in yards must understand how switching manoeuvres can be directly affected by train length, tonnage, and speed. Operating crews must be able to control a train using automatic air brakes, locomotive independent brakes, or a combination of both. To accomplish this, hands-on experience with operating equipment and familiarity with the topographic features of the yard (and/or territory) are essential.

The crew members believed that air was required to allow the locomotives to stop more quickly while kicking cars in the yard. In this occurrence, both crew members were aware of the need to use air when operating past Tapscott Road. However, they did not understand that air was needed to help with braking on the descending grade of the Staines connecting track when the assignment proceeded past Tapscott Road.

In this occurrence, the foreman had previously worked with other, more experienced foremen who had operated assignments past Tapscott Road and had not applied air to the cars when they exceeded the weight or length requirements identified on the sign. In those situations, there had been no adverse consequences. However, those prior movements did not involve a train as long or as heavy as the cut of cars involved in this occurrence. Furthermore, as conductors, the assignment crew had received little training on train handling,Footnote 34 nor was such training required.

1.13.2.1 Adaptations to rules or procedures

An adaptation can be defined as a deliberate decision to act against a rule or procedure. Routine adaptations occur every day as people modify or do not strictly comply with work procedures, often in an effort to improve productivity or efficiency. In the analysis of error, an adaptation can be categorized as an unsafe act when the adaptation takes place before an accident. The TSB defines an unsafe act as an error or deliberate deviation from prescribed operating procedures, which, in the presence of a potential unsafe condition, leads to an occurrence or creates occurrence potential. The TSB defines an unsafe condition as a situation or condition that has the potential to initiate, exacerbate, or otherwise facilitate an undesirable event, including an unsafe act.

People rarely follow rules or instructions precisely, for reasons and in ways that make sense to them given their circumstances, knowledge, and goals.Footnote 35

While a company prescribes policies and procedures to set boundaries for safe operations, individuals may push the boundaries to become more productive or obtain some other benefit. This can lead to adaptations of procedures and to a shift beyond the prescribed boundaries described in the procedures, toward unsafe practices.Footnote 36 Without intervention, the communication of successful adaptations between crew members tends to lead to their spread throughout an organization.

Such adaptations are unlikely to be recognized as deviations by those within the group employing them. The adaptations slowly become normal behaviour, and the risk associated with them is unlikely to be recognized.Footnote 37

1.14 TSB Railway Investigation Report R16T0111 and Recommendation R18-02

The TSB investigated another occurrence involving an uncontrolled movement that entered onto the main track. On 17 June 2016, at about 2335 Eastern Daylight Time, the Canadian National Railway Company (CN) RCLS 2100 west industrial yard assignment was performing switching operations at the south end of CN’s MacMillan Yard in Vaughan, Ontario. The assignment, handling 72 loaded cars and 2 empty cars, was 4537 feet long and weighed 9116 tons. The assignment was pulling southward from the yard onto the York 3 main track in order to clear the switch at the south end of the Halton outbound track to gain access to the west industrial lead track (W100) switch. The assignment helper attempted to stop the assignment to prepare to reverse into track W100, in order to continue switching for customers. However, the assignment could not stop and continued to roll uncontrolled for about 3 miles, reaching speeds of up to 30 mph before stopping on its own at about Mile 21.1 of the York Subdivision. There were no injuries. There was no release of dangerous goods and no derailment.

The investigation highlighted deficiencies in the current Railway Employee Qualification Standards Regulations. The Board noted that Transport Canada (TC)’s 2017–18 Departmental Plan highlighted its intention to update the Railway Employee Qualification Standards Regulations, but there has been little progress to date. Consequently, the regulations have not kept pace with the significant changes in railway operations over the years. The Railway Safety Management System Regulations, 2015, which require railways to have processes for managing knowledge, cover some of the training elements. However, gaps in training remain.

If the gaps in the current Railway Employee Qualification Standards Regulations are not addressed, railway employees in safety-critical positions may not be sufficiently trained or experienced to perform their duties safely. Also, TC will not be able to conduct effective regulatory oversight and enforcement of training programs. Therefore, the Board recommended that

the Department of Transport update the Railway Employee Qualification Standards Regulations to address the existing gaps for railway employees in safety-critical positions related to training, qualification and re-qualification standards, and regulatory oversight.

TSB Recommendation R18-02Footnote 38

1.14.1 Transport Canada’s updated response to Board Recommendation R18‑02 (December 2019)

In December 2019, Transport Canada provided an update to its response to the recommendation. It stated the following:

The Department continues work to improve its regulatory regime for railway employee qualification and training regime. Transport Canada published in 2019 the Guideline for Remote Control Locomotive Operation. The guideline, which is available on the department’s website (https://www.tc.gc.ca/eng/railsafety/guideline-78.html), makes recommendations in the area of training and qualification for employees involved in remote control locomotive (RCL) operations.

More broadly, the Department’s objective is to ensure Canada’s federally-regulated railway companies have training programs that adequately train their employees for safe railway operations. To this end, the Department consulted with stakeholders, and conducted site visits to observe best practices with respect to training programs. In addition, the Transport Canada reviewed Transportation Safety Board (TSB) data on rail occurrences to better understand the role that the lack of training played in incidents and accidents as well as reviewing the regulatory regimes in the United States, Australia and E.U. on employee training.

During 2020, Transport Canada will begin consultations with stakeholders on policy options for amendments to the Railway Employee Qualification Standards Regulations, with draft regulations to follow sometime in 2021.

While this work is underway, Transport Canada will continue to oversee railway companies’ obligations with respect to training under the Railway Safety Management System Regulations, 2015.

1.14.2 Board reassessment of Transport Canada’s updated response to Board Recommendation R18-02 (March 2020)

In March 2020, the Board reassessed TC’s updated response to Recommendation R18-02 and stated that the:

In 2020, TC will begin consultations with stakeholders on policy options for amendments to the Railway Employee Qualification Standards Regulations. It is expected that the preparation of draft amendments to the regulations will continue into 2021. While this work is underway, TC will continue to oversee railway companies’ obligations with respect to training under the Railway Safety Management System Regulations, 2015.

The Board assesses the response to Recommendation R18-02 as having Satisfactory Intent.Footnote 39

1.15 Guideline for Remote Control Locomotive Operation

In April 2019, TC published a Guideline for Remote Control Locomotive Operation, which “promotes industry best practices and provides federally regulated railways, and those providing services to railways, with guidance on the continued safe use of remote control locomotives (RCLs).”Footnote 40

The guideline addresses training, qualifications, compliance, and operational parameters. With regard to the initial training of employees, the guideline suggests that employees receive training on RCL operation, air brake operation, and train handling, and that they gain an understanding of forces acting on the movement and of train-handling techniques in various weather conditions and grades.

With regards to crew experience, section 1.1 of the guideline indicates that consideration should be given to

- Implementing RCL training and qualification programs separately from training for other occupational categories (e.g., conductor training)

- Establishing separate RCO qualification standards for yard and outside-of-yard operations (“outside of yard” includes main track, spurs and subdivision track)

- Ensuring an RCO operating an RCL outside of a yard is trained to have equivalent competencies as a locomotive engineer

- Establishing criteria, such as minimum experience of each crew member and amount of supervision required, for when less experienced RCOs may work together

- Criteria should take into account the job position (conductor or assistant conductor), and whether the work is happening in a yard or outside of a yardFootnote 41

Section 2.2, Establishing operational parameters, recommends that railways

- Develop instructions, in collaboration with labour, and based on an assessment of risk, for all locations where RCLs are operated (including yards, spurs, subdivisions and main tracks)

- Examples of parameters to use in the analysis:

- grade at the location, in each direction of travel

- locomotive axle count and horsepower

- train length and tonnage

- types of rail cars and equipment

- method of complying with CROR 115

- Standardize RCL speed to a maximum of 15 mph, to reflect current operating practices

- Have procedures in place that guide employees to work safely in the event one of the two OCUs fails during a shift (for example, the RCO with the working OCU has direct sight of the other crew member)

- Note: If this happens, the railway should use all reasonable means to immediately replace the inoperative OCU

- Have minimum standards for air to be used through every rail car outside of yards with RCL operation, regardless of the method of control

- Ensure RCLs outside of yards have features that allow the RCO to apply the air brakes while under tractive effort, to better allow them to control the RCL’s movementFootnote 42

1.16 Railway Safety Management System Regulations, 2015

On 01 April 2015, the Railway Safety Management System Regulations, 2015 (SMS Regulations) came into force, replacing the 2001 SMS Regulations. Under these regulations, federally regulated railway companies must develop and implement a safety management system (SMS), create an index of all required processes, keep records, notify the Minister of Transport of proposed changes to their operations, and file SMS documentation with the Minister when requested.

1.16.1 Risk management

The SMS Regulations require that a company develop and implement a risk assessment process that identifies risks that require remedial action as well as the remedial action taken. Paragraph 5(f) of the SMS Regulations states:

A railway company must develop and implement a safety management system that includes

[…]

(f) a risk assessment process; […]Footnote 43

Subsection 15(1) of the SMS Regulations states:

A railway company must conduct a risk assessment in the following circumstances:

[…]

(c) when a proposed change to its railway operations […] may affect the safety of the public or personnel or the protection of property or the environment.Footnote 44

Such changes include but are not limited to

(i) the introduction or elimination of a technology, or a change to a technology;

[…]

(v) a change affecting personnel, including an increase or decrease in the number of employees or a change in their responsibilities or duties.Footnote 45

To assist railways with implementing SMS, TC had developed a document entitled Safety Management Systems Industry Guide (April 2016). With regards to the components of a risk assessment,Footnote 46 the guide identifies that the risk assessment must

- describe the circumstances that triggered the requirement to conduct the risk assessment;

- identify and describe the risks associated with those circumstances;

- identify the factors taken into account in the risk assessment, including the persons who may be affected and whether property or the environment is affected;

- indicate, for each risk, the likelihood that the risk will occur and the severity of its consequences;

- identify the risks that require remedial action; and

- identify the remedial action for each of those risks.

In accordance with the SMS Regulations, CP developed and implemented an SMS, which includes conducting risk assessments when changes to operations occur. Currently, CP’s risk assessment policy and risk assessment procedures require a risk assessment to be conducted whenever

- A Safety Concern” (i.e. a hazard or condition that may present a direct safety risk to employees, or pose a threat to safe railway operations) is identified through analysis of safety data;

- A proposed change to CP Operations that could

- introduce a new hazard to the workplace resulting in adverse effects;

- negatively impact or contravene any existing policy, procedure, rule or work practice used to meet regulatory compliance or any CP requirements or standards;

- create or increase a direct safety risk to employees, railway property, property transported by the railway, the public or property adjacent to the railway; and

- require authority by a regulatory agency to implement.Footnote 47

In May 2016, as a result of the reintroduction of RCLS operations in Toronto Yard, CP conducted a risk assessment that covered both RCLS operations and the introduction of a point protection zone. The risk assessment was led by a superintendent and 12 other participants that included 2 locomotive engineers, a conductor, a consultant involved in the implementation of RCLS, and a number of managers from Operations, Engineering and Mechanical.

The risk assessment identified a number of potential hazards associated with the proposed changes, such as trains passing stop signals at the west end of the yard and trains passing the point protection zone at both ends of the yard, including at Tapscott Road. The risk assessment addressed uncontrolled movements at the west end of the yard passing Signal 1823, where the majority of switching operations occurred before February 2018. The mitigating strategies included the installation of derails to protect against uncontrolled movements. There was a remote-controlled derail already in place at Tapscott Road. However, uncontrolled movements were not specifically identified as a risk at the east end of the yard. As a result, no additional mitigating strategies (such as additional derails) were implemented beyond Tapscott Road.

In February 2018, due to an increase in the volume of work at Toronto Yard, CP raised the number of yard assignments from 3 to 6. This meant that, at any given time, there would be 2 yard assignments working in Toronto Yard. To avoid conflicts between the assignments, the 2nd yard assignment crew worked primarily at the east end of the yard. As CP did not consider this additional yard assignment to be a change to its operations that might affect the safety of the public or personnel or the protection of property or the environment, an additional risk assessment was not conducted.

Since 2015, the TSB has investigated 4 other occurrences in which CP had made changes to its operations. In some, CP had not considered some of the changes to be significant enough to require a risk assessment, while in others, not all hazards were identified and mitigated (Appendix B).

1.16.2 Managing knowledge

With regard to crew training, sections 25 to 27 of the SMS Regulations require a railway to have a process for managing knowledge. A railway company must establish a list setting out

- the duties that are essential to safe railway operations;

- the positions in the railway company that have responsibility for the performance of each of those duties; and

- the skills and qualifications required to perform each of those duties safely.

A railway company must also include in its SMS a plan for ensuring that employees who perform any of the duties in the list have the skills, knowledge, and qualifications required to perform their duties safely, as well as a method for verifying this.

With regard to managing knowledge, CP had a detailed list of essential duties for locomotive engineers and conductors, and a process for ensuring and verifying the required skills and qualifications for the performance of their duties that are essential to safe railway operations. However, CP did not have such a list or process for RCLS operators and related Beltpack operations. While CP conducted efficiency testing to ensure that employees had the requisite skills, qualifications, and knowledge for safe operations, CP did not consider RCLS to be an essential service, and it was not contained in CP’s SMS plan for managing knowledge.Footnote 48

1.17 Crew resource management

Crew resource management (CRM) focuses on providing crews with the interpersonal skills required to carry out their tasks safely: “CRM training typically consists of an ongoing training and monitoring process through which personnel are trained to approach their activities from a team perspective rather than from an individual perspective.”Footnote 49

Significant safety benefits were experienced in the aviation and marine industries with the introduction of CRM and bridge resource management, respectively. Given the prevalence of human factors in rail accident statistics, this type of training could yield significant safety benefits in the rail industry.Footnote 50

Following a 1998 collision between 2 freight trains, the U.S. National Transportation Safety Board recommended that a number of railway stakeholders, including the regulator, operators, industry associations, and labour organizations, collaborate to develop and require CRM training in the railway industry. That training would cover, at a minimum, crew member proficiency; situational awareness; effective communication and teamwork; and strategies for appropriately challenging and questioning authority.Footnote 51

Subsequent to this recommendation, the FRA, in cooperation with academic and industry partners, developed and piloted rail CRM training.Footnote 52 Initial assessment of the pilot training showed increases in knowledge and improved attitudes toward CRM principles.Footnote 53

However, this type of training has not been made mandatory in Canada or the U.S. A review of the adaptation of CRM principles outside of aviation in 2010 found that, in the North American railway industry, “interest in CRM training principles remains sporadic.”Footnote 54 The review also described voluntary initiatives by specific railways to implement CRM training, as well as industry initiatives to develop training materials for operators to use. For example, the review indicated that CP implemented a CRM training program targeted at new-hire conductors and trainmen in 1999.

More recently, since 2013, VIA Rail Canada Inc. has been providing its locomotive engineers with an 8-hour course known as locomotive cab awareness, followed by recurrent training every 3 years. The objective of the course is to improve safety by providing locomotive engineers with the principles of CRM.

1.17.1 Crew resource management training at Canadian Pacific Railway

All existing operating employees were required to take CRM training when it was introduced in 1999. The CRM training program has been regularly provided to new operating employees since that time. It consists of a 1-hour presentation during the 1st week of the classroom portion of the conductor program and is 1 of 11 modules presented on the same day. There is no practical component to CP’s CRM training.

The course objective is to provide “a greater awareness of the concepts, philosophies, and objectives of CRM [to] enhance safety, leading to the prevention of incidents and accidents as well as encourage commercially efficient train operations.”Footnote 55 The CRM training is divided into the following fundamental principles:

- human factors

- situational awareness

- technical proficiency

- communication

- teamwork

The training provides tools to help employees maintain situational awareness, which will contribute to a safe work environment by ensuring that employees are aware of their surroundings at all times. One of the tools to maintain situational awareness emphasizes peer-to-peer communication between crew members. The training states:

Crews who communicate well will commit fewer errors because talking to each other enables them to make more accurate assessments of problems, and they are more coordinated in their actions for dealing with them.Footnote 56

Further, CP’s CRM training presentation states the following:

Job briefings are a critical step in defining your tasks and responsibilities, which will allow you to plan your work and will contribute to your situational awareness.Footnote 57

The helper and foreman had received CRM training in April 2017 and May 2017, respectively. However, CP does not provide recurrent CRM training to its operating employees when they requalify.

1.18 Supervision

Supervision is an administrative control that supports or reinforces human factors aspects, including compliance with procedures, priorities, workload, fatigue, engagement, and motivation. Supervisors can have a significant impact on many of the factors that influence behaviours in the workplace.Footnote 58

There are several ways of supervising; different forms of supervision are appropriate in different circumstances. For example, traditional hierarchical team structures generally provide effective command and control, but lower levels of employee involvement.Footnote 59 Supervision by authority figures has a key influence on the way employees perform. Individuals with any form of supervisory role need to be trained and competent. Competence includes technical skills as well as non-technical skills such as planning, communication, and delegation. Technical competence should include an understanding of the hazards and control measures.

1.18.1 Supervision at Toronto Yard

At Toronto Yard, the west control tower and the east control tower were equipped with cameras to provide tower personnel with views of the yard. During switching operations, trainmasters would regularly monitor the screens to be aware of the progress of the yard crews. Trainmasters would communicate with the yard crews as needed to ask questions based on their screen observations.

The use of proficiency tests was another mechanism for CP to oversee crew operations. CP conducted proficiency testing on its train crew members to evaluate their skills in train operations and to verify their adherence to rules. Supervisors, including trainmasters, were required to conduct about 20 proficiency tests per month, which allowed for observations on the ground and face-to-face discussions between supervisors and crew members.

1.18.2 Authority gradients

Authority gradientsFootnote 60 exist in organizations when a team member feels that an important safety issue cannot be brought forward with another member on a higher level. The Flight Safety Foundation’s research on authority gradients identifies conformity as one of the potential risks of authority gradients. Specifically, this research highlighted that

Conformity is […] used to describe certain situations in which team members who could have contributed useful safety information, at the time, failed to do so. Authority gradients can play a key role in facilitating attitudes of conformity amongst team members.

- Obedience – this is often in response to a perceived authority, or in reaction to an authoritarian leader (steep gradient).

- Majority Rule – going along with others’ views rather than voicing one’s own. This may be in response to an overly democratic style of leadership (shallow gradient) or because it’s easier than speaking up (steep gradient). Footnote 61

In the railway hierarchy, a yard crew will normally regard the trainmaster (or such a position) as the “perceived authority.”

1.19 Safety culture

Safety cultureFootnote 62 is a critical determinant of both the overall level of risk in an organization and the organization’s ability to effectively manage safety, since it

- influences the level of risk through the creation of norms, which influence how work is accomplished on a day-to-day basis; and

- defines the environment in which safety management structures are implemented. Values and beliefs are key elements of safety culture and determine how much individuals will trust, and participate in, safety management activities.

There are many descriptions of what constitutes a supportive effective safety culture. One characterization describes 4 elements:Footnote 63

- Reporting culture: Hazards, occurrences, and safety issues are freely reported within the organization without fear of recrimination.

- Just culture: Normal human error is viewed as a systemic problem and therefore is not punished. Malicious behaviour or negligence is punished. The methods of making the distinction are clearly stated and understood.

- Learning culture: The organization and individuals within it are continually learning to improve operational skills and to better understand their role in safety management. Lessons learned through experience are actively shared throughout the organization.

- Informed culture: Hazards and risks associated with an operation are well understood and people within an organization are provided with the necessary knowledge and skills to work safely. Employees understand how to participate in the safety management of the organization.

Aspects of a company’s culture are revealed in its selection policies, operating procedures, and operational oversight, all of which can affect human performance. Practices that encourage operator responsibility, professionalism, and participation in safety matters can enhance operator attention to safety details; punitive practices do not. The way the process of issuing blame hinders the learning process is explained as follows: “where there is blame, there is no learning […] open minds close, the inquiry tends to cease, and the desire to understand the whole system diminishes.”Footnote 64

A company’s culture can also be reflected in its response to employee transgressions. Over time, companies that manage through fear of discipline increase the probability of unsafe operations. In contrast, companies that implement programs which allow employees to report mistakes without retributionFootnote 65 and use a decision tree for determining the culpabilityFootnote 66 of unsafe acts can reduce the risk of unsafe operations. The culpability decision tree is a tool used to understand the mindset of the personnel involved, the context of the situation, and the organizational influences that may have affected their decisions and resultant behaviour.

The content of the organization’s disciplinary procedures plays a large part in the development of a just or open culture. A just or open culture is difficult to develop if disciplinary procedures place error fault entirely with the individual involved and do not acknowledge system-induced faults.Footnote 67 The relationship between safety culture and safety management is reflected in part by the beliefs, attitudes, and behaviours of a company’s management.

In April 2016, the TSB held a Transportation Safety Summit that brought together more than 70 senior executives and leaders representing operators, labour organizations, industry associations, and regulators from all modes of transportation. A broad consensus emerged from the discussions that, to effectively improve safety, SMS must clearly identify the systemic issues underlying the behaviour. Further, effective communication and collaboration were key elements in building the trust necessary to address safety issues at this level. However, the biggest challenge identified in terms of bringing about this type of “just” culture was the need to build trust and respect in organizations that may have a history of blame.Footnote 68

1.19.1 Safety culture at Canadian Pacific Railway

In parallel with implementing an SMS, CP recognized the importance of building an effective safety culture. To help strengthen its safety culture, CP introduced the Home Safe initiative, which promotes both safety engagement and feedback: “By instilling […] the importance of [employees] taking responsibility for their own safety as well as the safety of their co‑workers, [CP] can better ensure everyone goes home safe after each and every shift.”Footnote 69 Through CP’s Home Safe initiative, employees are trained to offer and ask for help, warn co‑workers if they believe they are putting themselves or others at risk, as well as identify, report, and remove hazards.

The yard foreman and helper were suspended on discipline notice for 4 weeks for a number of violations of CP rules and instructions.

1.20 TSB occurrence statistics involving unplanned/uncontrolled movements

From 2009 to 2018, there were 562 occurrencesFootnote 70 reported to the TSB related to unplanned/uncontrolled movements among all railways in Canada (Table 1).

| Reason for unplanned or uncontrolled movement | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Loss of control | 0 | 2 | 3 | 0 | 3 | 0 | 1 | 4 | 2 | 5 | 20 |

| Switching without air | 14 | 10 | 16 | 12 | 24 | 21 | 22 | 18 | 21 | 27 | 185 |

| Securement | 37 | 25 | 32 | 44 | 42 | 38 | 37 | 29 | 39 | 34 | 357 |

| Total | 51 | 37 | 51 | 56 | 69 | 59 | 60 | 51 | 62 | 66 | 562 |

Note: The data summarizing the number of uncontrolled movements each year have not been adjusted for variations in annual rail traffic volumes.