Railway Investigation Report R14T0160

Main track derailment

Canadian National Railway

Freight train M-310-31-09

Mile 127.52, Kingston Subdivision

Brockville, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On 10 July 2014, at approximately 0410 Eastern Daylight Time, while proceeding eastward at 60 miles per hour, approaching Brockville, Ontario, Canadian National freight train M-310-31-09 derailed 26 cars at Mile 127.52 on the Kingston Subdivision. The derailed cars included 13 residue tank cars which last contained aviation fuel (UN1863). A small amount of product was released. There were no injuries.

Factual information

The accident

On 09 July 2014, at approximately 2205,Footnote 1 Canadian National (CN) freight train M-310-31-09 (the train) departed MacMillan Yard in Toronto, Ontario, destined for Montréal, Quebec (Figure 1). The train consisted of 2 head-end locomotives and 68 cars (29 loaded cars, 23 empty cars, and 16 residue tank cars). It weighed about 4664 tons and was approximately 4808 feet long. Prior to departure, the train received an inspection from a certified car inspector and a number 1 air brake test was performed.

After departure, the train proceeded on the Kingston Subdivision, stopping at Belleville, Ontario, (Mile 219.50) for a crew change. The new crew members, a conductor and a locomotive engineer, were both qualified for their respective positions, were familiar with the territory, and met established rest and fitness requirements.

On 10 July 2014, at approximately 0215, the train departed Belleville. During departure, the inbound train crew performed a pull-by inspection. At about 0410, as the train approached Brockville (Mile 126.60) on the south main track while travelling at about 60 mph, the locomotive engineer lightly applied the locomotive dynamic brakes (DB).Footnote 2 Shortly thereafter, the train experienced an undesired emergency brake application and then derailed.

The head end of the train came to rest at Mile 126.54. The crew followed emergency procedures and performed an inspection of the train. The inspection determined that the first 23 cars had remained attached to the head-end locomotives while the 24th to the 49th cars—26 cars in total—had derailed. Of the 26 derailed cars, 13 were residue dangerous goods tank cars, which last contained aviation fuel (UN 1863). Ten of these tank cars were leaning or overturned and 3 remained upright. A small amount of product was released. There were no injuries.

Between Toronto and Brockville, the train had travelled over 16 wayside inspection stations, 15 of which were equipped with hot wheel, hot bearing, and dragging equipment detectors, and 1 of which was equipped with a wheel impact load detector. No alarms from these wayside detectors had been issued for this train.

At the time of the derailment, the temperature was about 10 °C, and there was no precipitation. During the day preceding the derailment, the maximum temperature had been about 23 °C, and there was no precipitation.

Site examination

The first mark on the track was located at Mile 127.52, approximately 6 feet west of the switch point for the eastward crossover to the north main track. At this location, a wheel climb mark was observed on the gauge face of the south rail. At the mark, there was a ½-inch low spot (variance) in cross level, approximately 4 feet long (Figure 2), which was within the standard set by the Transport Canada-approved Rules Respecting Track Safety (TSR).Footnote 3

Intermittent wheel flange marks were observed on the running surface of the south rail eastward from the wheel climb mark for about 28 feet. Further east, marks were observed on rail securement appliances on the field side of the south rail and on rail securement appliances on the gauge side of the north rail. Most of the derailed cars came to rest in a pile starting about 500 feet east of the wheel climb mark.

UnloadedFootnote 4 gaugeFootnote 5 and cross-level measurements of the track were taken starting from the wheel climb marks and extending toward the west at 15½-foot intervals (Table 1).

| Measurement location (feet west of wheel climb mark) |

Gauge (inches) | Cross-level (inches) |

|---|---|---|

| Wheel climb mark | 56 3⁄4 | 1⁄2 |

| 15½ | 56 3⁄4 | 1⁄16 |

| 31 | 56 3⁄4 | 3⁄16 |

| 46½ | 56 7⁄8 | 1⁄8 |

| 62 | 56 5⁄8 | 1⁄4 |

| 77½ | 56 1⁄2 | 1⁄8 |

| 93 | 56 1⁄2 | 5⁄16 |

| 108½ | 56 7⁄8 | 1⁄2 |

| 124 | 56 7⁄16 | 1⁄4 |

| 139½ | 56 1⁄2 | 5⁄16 |

The first 3 derailed cars—the 24th to the 26th cars from the head end—were empty centrebeam bulkhead flat cars about 80 feet long. The first derailed car (BCOL 730558) had been dragged by the head-end portion of the train and came to rest at Mile 126.90. The following car (ATW 318366) came to rest on its side, just west of the signal bridge and main pile of cars. The third derailed car (AOK 29390) came to rest east of the signal bridge (Mile 127.36), askew of the south main track (Figure 3).

The 5 following cars—the 27th to the 31st cars from the head end—were loaded covered hopper cars. Three of these cars came to rest just east of the signal bridge and the other 2 cars came to rest just west of the signal bridge. The remaining cars, which included 13 derailed DG residue tank cars (the 37th to the 49th cars from the head end), came to rest in various positions in the vicinity of the main pile of cars.

Most of the trucks and wheel sets from the derailed cars had separated from the car bodies. As a result, it was not possible to identify the mating truck and wheel set components from each car.

Approximately 350 feet of track was destroyed on the north main track and on the south main track. Further east of the signal bridge, the south main track and a yard track were damaged for approximately 2450 feet.

Examination of the first 3 derailed cars revealed that the ALFootnote 6 car body side bearingFootnote 7 of car BCOL 730558 showed no signs of contact with the constant contact side bearing (CCSB) cap and only faint signs of contact with the AR body side bearing. The corresponding A-end CCSB caps could not be identified in the wreckage. The B-end body side bearings showed wear marks (Figure 4). Although the B-end truck was still with the car, the CCSB components were missing.

Examination of the underframe of the following 2 cars (empty centrebeam bulkhead flat cars) determined that the car body side bearings exhibited wear marks that indicated there had been contact between the car body side bearings and the CCSBs.

Recorded information

The locomotive event recorder data was reviewed. It was determined that:

- For about 5 minutes prior to the derailment, the train was travelling at speeds between 53 mph and 63 mph.

- At 0409:29, the dynamic brake was engaged while the train was travelling at 59 mph.

- At 0409:32, the speed had increased to 60 mph.

- At 0409:45, the train experienced an emergency brake application while travelling at 60 mph.

- At 0410:52, the head-end portion of the train came to rest at Mile 126.54.

Subdivision and track information

C's Kingston Subdivision extends westward from Mile 10.30 at Dorval East, in Montréal, to Mile 313.87, near Toronto. Train movements are governed by Centralized Traffic Control as authorized by the Canadian Rail Operating Rules and supervised by a rail traffic controller located in Montréal (from Mile 10.30 to Mile 127.40) and a rail traffic controller located in Toronto (from Mile 127.40 to Mile 333.80). Track throughout the subdivision is predominantly Class 5 track with, according to the TSR, an authorized speed of 65 mph for freight trains. However, between Mile 124.00 and Mile 127.50, the track is Class 4 track, with an authorized speed of 60 mph for freight trains.

In the vicinity of the derailment, the south track of the Kingston Subdivision consists of

136-pound continuous welded rail, manufactured in 2007 and installed in accordance with the TSR requirements. The rail was laid on 14-inch double-shoulder tie plates, supported by number 1 hardwood ties with 8 spikes per tie and box anchored every second tie. The ballast was crushed rock. The shoulders were 12 inches to 24 inches wide, and the cribs were full. The ballast and subgrade were contaminated with soil. Approaching the derailment location from the west, the track is mainly tangent, with a shallow S curve configuration between Mile 128.1 and Mile 127.7. The track gradually descends at up to a 1.12% (maximum) gradient to Mile 127.43, after which the track ascends at up to a 0.75% (maximum) gradient into Brockville Yard.

Track inspections were performed regularly in accordance with the TSR. The most recent visual inspection was completed on 08 July 2014, and the most recent ultrasonic rail test was completed on 30 June 2014. No anomalies had been noted in the vicinity of the derailment. The most recent track geometry car inspection was completed on 03 May 2014. A warp 31 spiral defectFootnote 8 was identified at Mile 127.57 and was subsequently repaired prior to the accident.

Centrebeam bulkhead flat car BCOL 730558

Centrebeam bulkhead flat cars are approximately 80 feet long and are relatively light when empty. These cars have a bulkhead at each end to prevent loads from shifting, and a centrebeam integrated into the car centre sill to secure loads. These cars, which are less torsionally rigid than other types of cars, are known to be more susceptible to excessive truck hunting.

Centrebeam bulkhead flat car BCOL 730558 was owned by CN. This car was built in 1994 by Trenton Works Inc. and was qualified for 50 years of service (Photo 1).

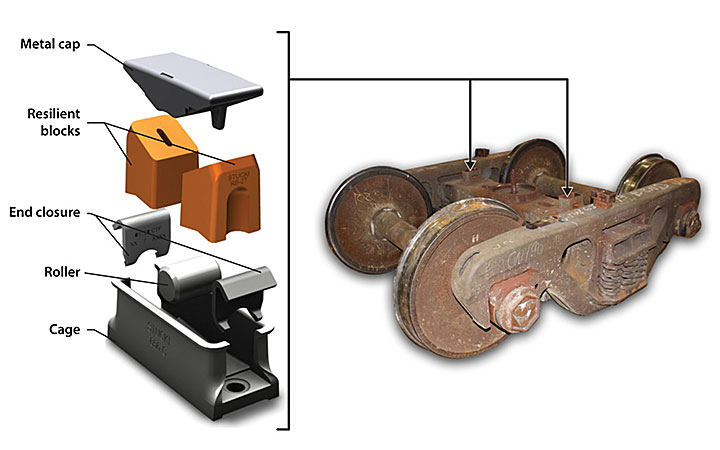

The car was equipped with standard Barber S2 trucks that had Stucki standard travel CCSBs installed. While there are several different CCSB designs, this type of CCSB comprises 2 resilient members (i.e. blocks), a roller, a metal cap, and a cage (Figure 5 ).

Car repair records indicate that on 18 June 2007, the car was taken to C's shop in Memphis, Tennessee, where broken A-end friction castings were repaired. There is no indication that CCSB components were inspected or replaced at that time. On 03 July 2014, the car was on a shop track at C's MacMillan Yard in Toronto, where several repairs were performed on the car, including the application of a carrier iron shim to its B-end to adjust the height. There is no indication that the side bearing clearance and the side bearing height were verified at that time.

Truck hunting

Truck hunting is the oscillation of the wheel set from rail to rail caused by the dynamic response of the railway car truck as it travels along the track. All wheel sets hunt until they achieve the optimal placement of the wheel tread conical taper on the rails. Under certain conditions, truck hunting can become excessive, resulting in hard contact between the wheel flange and the rail head, in wheel lift and, in some cases, derailment.

Truck hunting will typically become more severe when lightly loaded or empty cars that are 50 feet or greater in length travel at speeds in excess of 45 mph on dry tangent continuous welded rail track. Certain track conditions in close proximity to each other, such as narrow gauge and multiple minor-track cross-level perturbations, are known to initiate excessive truck hunting. However, excessive truck hunting can also occur on track in good condition.

For cars with worn wheels, truck hunting will normally begin when travelling around 45 mph to 50 mph. For cars with new wheels, truck hunting begins around 55 mph to 60 mph. In addition, truck hunting can be more pronounced for trucks with low warp stiffness. Certain older truck designs, such as the Barber S2, have low warp stiffness and are known to be prone to hunting. While truck component and wheel wear can exacerbate the phenomenon, truck hunting can also occur on cars where these components are in good condition.

Over the years, the railway industry has become more aware of the truck hunting phenomenon. Since the 1990s, to address the tendency for trucks to hunt excessively at high speeds, railway cars have been built with CCSBs installed. The type of CCSBs that were first installed are referred to as “standard travel” CCSBs.

In 2002, the Association of American Railroads (AAR) Manual of Standards and Recommended Practices adopted Specification M-976 (Truck Performance for Rail Cars), which introduced improved truck performance requirements. Specification M-976 included testing requirements for the control of truck hunting and placed limits on the lateral acceleration of the trucks. Freight car trucks built to this standard have improved warp stiffness and are less susceptible to excessive truck hunting. In addition, freight cars built since 2004 are also required to be equipped with “long travel” CCSBs, which provide more-effective damping to freight cars and reduce the risk of excessive truck hunting.

Truck hunting can cause car body lateral oscillation. The side-to-side motion of the truck as it hunts causes the car body ends to rotate about their centres of gravity. As both trucks do not hunt in unison, a torsional force along the length of the car can develop. The torsional force will load and unload in a spring-like manner as the trucks hunt along the track. Certain cars, such as the centrebeam bulkhead flat car with a torsionally flexible car body and a large bulkhead at each end, are more susceptible to this spring-like loading. This torsional force can contribute to wheel offloading. In extreme cases, truck hunting and wheel offloading can cause the wheel flange to climb the gauge face of the rail, derailing the truck. Low spots in the rail, narrow gauge, and a lateral force caused by dynamic brakingFootnote 9 can also contribute to a wheel climb event. When a truck hunting type of derailment has occured, long flange marks may be present along the running surface of the rail.

Constant contact side bearings

CCSBs are secured to the truck bolster below the car body side bearing, which is secured to the underside of the car. The CCSB cap serves as the bearing surface upon which the car body side bearing is in constant contact. Resilient members beneath the cap provide the vertical force (preload) to keep the cap in constant contact with the car body side bearing. The CCSB cap displaces vertically to allow a car body to roll relative to the truck. CCSBs increase the truck's turning resistance by placing a load between the truck and the car body side bearing, thereby minimizing truck hunting. CCSBs also limit the side-to-side oscillation of the car body.Footnote 10

A known problem with CCSB arrangements is designing a resilient member with characteristics suitable for the long term loads and stresses encountered during operation of the rail car. Resilient members are susceptible to thermal damage from the heat generated at the interface between the bearing cap and the car body side bearing. In 2007, Technology Digest published a study relating to the inspection and maintenance processes for CCSBs which noted that worn, melted, or deformed resilient members lessen the preload, lowering the rotational resistance of the truck.Footnote 11

A 2014 Transportation Technology Center, Inc. study for CN concluded that “decreasing side bearing preload for standard travel CCSBs was also shown to increase derailment risk due to vertical wheel unloading in track with cross-level perturbations.”

CCSB inspection and repair requirements

The Transport Canada (TC)-approved Railway Freight Car Inspection and Safety Rules require that all cars receive a safety inspection (visual) performed by a certified car inspector at, among other locations, the location where trains are made up. If that is not possible, the safety inspection is to be performed at a location en route. These rules also require that cars be taken out of service when more than 1 CCSB is not making contact.Footnote 12

To comply with the rules, CN provides instructional material to the certified car inspectors on how to visually inspect a train. As part of these inspections, the inspectors are instructed to ensure that all CCSB components are in place, in good condition, and are not loose, bent, broken, or missing. The car inspector should also look for contact between the CCSB and the car body side bearing. However, visual inspections cannot assess the preload force supplied by the CCSBs. As such, a CCSB can be in contact with the car body side bearing without providing effective support.

In addition to the Railway Freight Car Inspection and Safety Rules, the railways are guided by the Field Manual of the AAR Interchange RulesFootnote 13 (Interchange Rules) when repairing railway equipment. In 2007, the Interchange Rules (Rule 62) required the replacement of the CCSB's resilient members whenever repairs are made to the friction castings, bolster gibs, or the friction pocket due to, among other conditions, wear.

The 2007 Technology Digest study indicated that even in situations where the metal cap is in contact with the car body side bearing, visual observation has proven to be unreliable in identifying the CCSBs that are not applying an adequate preload force. The study further indicated that “some components and assemblies should be replaced or repaired even though individually, they may not be condemnable according to present standards and rules.”Footnote 14

By 2014, the Interchange Rules (2014) had changed and indicated that:

- CCSBs are condemnable at any time should the resilient member exhibit heat damage (Rule 62 A 1. d.), or should the sum-of-the-pairs height measurementFootnote 15 be less than 9¾ inches or greater than 10½ inches (Rule 62 A1. h. (1)).

- CCSBs are condemnable when the car is on a shop or repair track should the resilient member exhibit damage (Rule 62 A2. b),Footnote 16 or should the height for a single CCSB be less than 4 15⁄16 inches or greater than 5 3 ⁄16 inches (Rule 62 A2. a. (1)) (Figure 6).

- Damaged resilient members should be replaced.Footnote 17

- The resilient member should be replaced if the truck was identified as condemnable by a truck hunting detector (THD)Footnote 18 (Rule 46 B7. c.).

Truck hunting detectors

THDs identify cars that are hunting by measuring the angle of attack of the wheel and the lateral and vertical forces of each wheelset on a train. Based on the THD measurement, the detector assigns a truck hunting index absolute value to each truck; the more severe the hunting, the higher the value. THDs can be used to indirectly evaluate the effectiveness of CCSBs, including the resilient members. As excessive truck hunting typically occurs when long empty freight cars are travelling at speeds greater than 45–50 mph, THDs are primarily effective under these conditions.

Rule 46 A1.e. of the Interchange Rules (2014) indicates that a truck becomes condemnable if it receives a truck hunting index absolute value that is greater than or equal to 0.50, or if it receives 2 truck hunting index absolute values that are greater than or equal to 0.35 within a 12-month period. In both of these situations, the car must be taken to a repair facility and the truck must be repaired or replaced. Car owners must also be informed when a truck receives a truck hunting index absolute value that is greater than or equal to 0.20, to allow the car owner to act upon any potential problems that may be arising.

As cars can be interchanged between railways (i.e. operate on another railway's track), the AAR developed Railinc's Equipment Health Management System (EHMS), which is a centralized database system to facilitate notifications to car owners and operators of alerts assigned to their cars. This includes alerts identified by THDs from another railway. In 2014, there were about 80 THDs installed on the railway network throughout North America. CN subscribes to the EHMS service and receives these alerts.

At CN, THDs are integrated into wheel impact load detector sites, but only at locations where truck hunting is likely to occur (e.g., tangent track where speeds are greater than 50 mph). At the time of the derailment, CN had 1 THD installed on its Canadian railway network. This THD was installed at Mile 29.2 on the Kingston Subdivision, at Les Cèdres, Quebec, approximately 88 miles east of the derailment location. Also, as had been previously planned, 3 additional wheel impact load detector locations were upgraded since the accident to include a THD at:

- Clarke, Ontario – Mile 290.50 of the Kingston Subdivision;

- Shontz, Alberta – Mile 219.00 of the Wainwright Subdivision; and

- Ste. Anne, Manitoba – Mile 127.00 of the Sprague Subdivision.

All THDs were programmed to provide immediate alerts to the rail traffic control mechanical service representative when “hunting index” readings were greater than 0.35, so that speed restrictions could be applied.

A review of the EHMS data for car BCOL 730558 determined that it had travelled over

12 THDs between August 2013 and July 2014. For 6 of these events, the car was empty, and the highest truck hunting index absolute value recorded for the A-end was 0.036, on Burlington Northern Santa Fe Railroad on 07 October 2013 (Appendix A). The most recent truck hunting index absolute value recorded for the A-end was 0.03 on CSX Transportation on 11 June 2014, while the car was empty.

Other TSB occurrences involving truck hunting

In 1991, the TSB investigated an 11-car derailment that occurred near Coteau, Quebec (TSB Railway Investigation Report R91D0045). The investigation determined that severe truck hunting, de-synchronization of the carbody, and truck oscillation while traversing over a low section of rail were factors that contributed to the derailment. As a result, the Board made the following 2 recommendations:

The Department of Transport ensure that appropriate speed restrictions are in effect for all empty bulkhead flatcars and long gondola cars which are not equipped with constant contact side bearings.

Transportation Safety Recommendation R93-08

The Department of Transport assess the requirement for speed restrictions on other rail car types to reduce the likelihood of derailments related to truck hunting.

Transportation Safety Recommendation R93-09

Following the recommendations, CN and Canadian Pacific (CP) applied speed restrictions

(50 mph) to trains that included bulkhead flat cars and open top gondola cars. In addition, the Transportation Development Centre, in conjunction with industry suppliers and the railways, conducted research into freight car truck performance and into the development of a freight car truck with improved high-speed performance characteristics. The prototype was tested in Canada and submitted for further testing and development at the AAR test facilities in Pueblo, Colorado.

Following another derailment involving truck hunting (TSB Railway Investigation Report R96T0231), the TSB issued Rail Safety Advisory (RSA) 04/96. The RSA indicated that, considering that truck hunting is associated with high speed and, therefore, poses a greater risk of consequences in the event of a derailment, TC may wish to review operating restrictions (speed) on all empty open top gondola cars as they relate to truck hunting. TC responded that CN and CP were imposing further speed restrictions on additional types of cars identified as susceptible to truck hunting and that the AAR was continuing its research work on new truck designs and CCSBs.

The TSB has conducted investigations into other derailments involving truck hunting, including R95W0117, R96T0231, R96H0021, and R04Q0006. Each of these derailments was attributed to truck-hunting-induced wheel climb/lift involving empty cars travelling at speeds near or greater than 50 mph, some with truck wear and some encountering track deviations.

As part of the TSB's investigation into the 2004 derailment on the Montmagny subdivision (TSB Railway Investigation Report R04Q0006), the National Research Council of Canada conducted a high-speed stability study using NUCARS (New and Untried Car Analytic Regime Simulation).Footnote 19 Although the study was concentrated on truck hunting by empty gondola cars, it confirmed the relationship between excessive truck hunting, poor truck maintenance resulting in reduced truck warp resistance, and car speeds in excess of 45 mph. The TSB Engineering Laboratory also examined the effect of dynamic braking on truck hunting and wheel lift. It was determined that limited dynamic braking had only a minimal effect on the truck hunting performance of a car. However, dynamic braking can increase the risk of wheel climb or of a wheel shift when a wheel is already unloaded, which can lead to derailment.Footnote 20

Examination of the Class 111 tank cars

The 13 derailed tank cars were general service tank cars built to the United States (U.S.) Department of Transportation (DOT) specification 111A100W1 (Class 111) between 2000 and 2009. Shipping documents identified these tank cars as residue cars which last contained aviation fuel (UN 1863), a Class 3 flammable liquid, packing group (PG) III.

The tank cars met the design standards in effect at the time of their construction. Each tank car was equipped with a bottom outlet valve, bottom discontinuity protection,Footnote 21 a top fitting nozzle, a hinged and bolted manway, and a pressure relief device. Some of the tank cars were also equipped with top fittings protection. None of the tank cars were equipped with head shields, jackets, or thermal protection. The tank shells were made of 7⁄16-inch-thick non-normalized steel. The tank heads were made of 7⁄16- or 15⁄32-inch-thick non-normalized steel.

The examination determined that:

- Two tank cars sustained head punctures and 1 car sustained a shell puncture. The head punctures were located in the bottom half of the head.

- Two tank cars had top fittings (vapour valves) that were sheared off during the derailment. These tank cars were not equipped with top fittings protection,Footnote 22 nor were they required to be.

- On 7 of the tank cars, the bottom outlet valve (BOV) nozzle had sheared off at the mounting flange as designed, exposing the BOV ball. On 2 of these tank cars, the exposed BOV ball was partially open as a result of impact damage sustained by the handle assembly.

Similar tank car failures were observed in other derailment occurrences involving Class 111 cars, including Lac-Mégantic and White River (TSB rail investigation reports R13D0054 and R13T0060).

Industry and regulatory response to Class 111 tank car releases

Since April 2013, there have been a number of occurrences in Canada and the U.S. during which product was released from Class 111 tank cars following a collision, impact and/or fire (Appendix B). These occurrences highlight the vulnerability of Class 111 tank cars to accident damage and product release. With about 228 000 Class 111 tank cars in service in North America (June 2015), of which over 141 000 are used to transport DGs, these types of releases have continued to occur during derailments.

In 2011, the AAR tank car standards were amended to incorporate a number of enhancements to all Class 111 tank cars built after 01 October 2011 for the transportation of crude oil and ethanol in PG I or PG II.Footnote 23 These enhancements included the construction of tank cars to 286 000-pound standards, protection of the service equipment on the top shell, the use of reclosing pressure relief devices, the use of normalized steel for tank shells and heads, increased minimum thickness for all tank cars not jacketed and insulated, and at least ½-inch-thick half-head shields.

In 2012, following the Cherry Valley, Illinois, investigation,Footnote 24 the U.S. National Transportation Safety Board (NTSB) made the following recommendation to the Pipeline and Hazardous Materials Safety Administration:

Require that all bottom outlet valves used on newly manufactured and existing non-pressure tank cars are designed to remain closed during accidents in which the valve and operating handle are subjected to impact forces.

NTSB Recommendation R-12-6

As part of the 2013 Lac-Mégantic investigation, the TSB highlighted the vulnerabilities of Class 111 tank cars and recommended that:

The Department of Transport and the Pipeline and Hazardous Materials Safety Administration require that all Class 111 tank cars used to transport flammable liquids meet enhanced protection standards that significantly reduce the risk of product loss when these cars are involved in accidents.

Transportation Safety Recommendation R14-01

On 23 April 2014, TC announced a three-year phase-out of older, less crash-resistant Class 111 tank cars. On 02 July 2014, the TP 14877 standard was adopted by reference in the Transportation of Dangerous Goods Regulations, aligning federal regulations with the 2011 AAR CPC-1232 standard.

TSB Watchlist

Transportation of flammable liquids by rail is a 2014 Watchlist issue

The Watchlist is a list of issues posing the greatest risk to Canada's transportation system; the TSB publishes it to focus the attention of industry and regulators on the problems that need addressing immediately.

In November 2014, the TSB added the transportation of flammable liquids by rail to its Watchlist. The TSB reiterated that flammable liquids must be shipped in more robust tank cars to reduce the likelihood of a release of dangerous goods during accidents. Moreover, the TSB urged railway companies to conduct route planning and analysis, and to perform risk assessments to ensure that risk-control measures are effective.

On 01 May 2015, TC announced the Regulations Amending the Transportation of Dangerous Goods Regulations (TC-117 Tank Cars), which came into force when published in the Canada Gazette, Part II. These regulations detailed a new tank car standard (TC-117), retrofit requirements, and implementation timelines to modernize the Canadian tank car fleet in flammable liquid service. The new TC-117 tank car will be jacketed and constructed with thicker steel, thermal protection, a full head shield, top fitting protection, and a new bottom outlet valve (Appendix C). The regulations established the prescriptive requirements and the performance requirements to retrofit a tank car, as well as the retrofit schedule for Class 111 tank cars used to transport Class 3 flammable liquids.

On 01 May 2015, the U.S. DOT also announced its new tank car standard (DOT-117), retrofit requirements, and implementation timelines. These standards and timelines were generally harmonized with those of TC.

With the TC and the DOT announcements detailing the new tank car requirements and timelines, the Board reassessed the TC response to Recommendation R14-01 as Satisfactory Intent.

However, the Board noted that even with active management of risks during the transition period, until flammable liquids are transported in tank cars built sufficiently robust to prevent catastrophic failure when involved in an accident, the risk will remain high. Therefore, the Board called upon TC to ensure that risk control measures during the transition be effectively managed.

TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP164/2014 – Field Examination of Tank Cars

Analysis

A review of the operation of the train and the state of the track did not reveal any action or condition that, in itself, would have led to the derailment. The analysis will focus on the condition of the rolling stock, factors that were present that could have initiated excessive truck hunting, inspection of constant contact side bearings (CCSBs), and the performance of Class 111 tank cars.

The accident

Truck hunting is the lateral oscillation of the wheel set from rail to rail as it travels along the track. All wheel sets hunt until they achieve the optimal placement of the wheel tread conical taper on the rails. However, a number of conditions are known to initiate truck hunting that is excessive; this can result in hard contact between the wheel flange and the rail head, initiate wheel lift, and cause a derailment.

Many of the conditions that are known to initiate excessive truck hunting were present in this occurrence. For example, empty cars (i.e., light) in excess of 50 feet in length, designed with low torsional rigidity and equipped with low warp resistance trucks, were being operated at a speed of 60 mph on dry tangent continuous welded rail track. Moreover, the track in the vicinity of the derailment had minor cross-level perturbations and a zone of slightly narrow gauge. The long wheel flange mark observed along the running surface of the rail was also consistent with a truck hunting event. Consequently, the derailment likely occurred as a result of excessive A-end truck hunting on empty centrebeam bulkhead flat car BCOL 730558.

Car BCOL 730558 was an empty 80-foot-long centrebeam bulkhead flat car. Its original equipment at the time of construction (1994) included Barber S2 trucks and standard travel CCSBs. Certain truck designs, such as the Barber S2, have low warp stiffness and are known to be prone to hunting. Examination of the car underframe revealed that the CCSBs from the A-end trailing truck likely had lost much of their preload and were no longer providing effective damping, as they were not in full contact with the corresponding A-end car body side bearings. This suggests that the CCSBs were worn to near or past their condemning limits. The excessive truck hunting on car BCOL 730558 was influenced by the type of car, the speed of the train, the worn condition of the A-end CCSBs and a truck type with low warp stiffness.

The wheel-climb mark on the track observed on the gauge face of the south rail at Mile 127.52 was identified as the initial point of derailment (POD). There was a slightly narrow gauge condition located approximately 124 feet west of the POD. From that point eastward, unloaded gauge and cross-level track measurements leading up to the POD identified a number of non-condemnable track anomalies that are also known to induce excessive truck hunting. The non-condemnable slightly narrow gauge and multiple cross-level perturbations in the south rail likely contributed to the development of excessive truck hunting.

In the vicinity of the derailment, the track has an approximate 1% descending grade eastward to Mile 127.4, after which the track ascends to Brockville Yard. The POD was located at Mile 127.52, while the head-end locomotives and the first 23 cars came to rest at Mile 126.54. The remaining tail end cars not involved in the derailment were located west of the POD. Therefore, as the train approached Brockville Yard at 60 mph with the dynamic brake applied, the tail end of the train was on the descending grade while the head end was on the ascending grade.

The excessive hunting of the trailing truck on car BCOL 730558 exacerbated the natural car body oscillation. This condition is known to initiate wheel off-loading and can lead to wheel climb or wheel lift events. While the application of the dynamic brake likely had minimal effect on the severity of the truck hunting, the resulting run-in of the tail-end cars could have generated longitudinal in-train forces that were transformed to a slight lateral load, causing a wheel shift at a time when the car was already off-loading because of car body oscillation. As freight car BCOL 730558 passed over the low spot in the south rail, a lateral force resulting from the run-in of train slack was likely imparted on the south rail by a wheel in the A-end trailing truck at a time when the car was off-loading because of car body oscillation, resulting in a wheel lift/climb event.

Constant contact side bearing repair and inspection

Centrebeam bulkhead flat cars are known to hunt excessively under certain conditions. Consequently, CCSBs have been installed to reduce the likelihood of severe truck hunting.

In 2007, Rule 62 of the Interchange Rules required the replacement of the CCSB's resilient members whenever repairs were made to the friction castings. While 2007 records show that Canadian National (CN) repaired broken A-end friction castings on BCOL 730558, contrary to AAR Rule 62, no CCSB components were replaced at that time. The CCSB resilient members were not replaced as required in 2007, but were instead allowed to continue in service and likely deteriorated to the point where they no longer provided effective damping.

In 2014, a CN repair to car BCOL 730558 one week prior to the derailment provided an opportunity to inspect and measure the CCSBs. However, there was no indication that this work was conducted. The absence of the CCSB inspection and measurement in 2014 during a CN repair to car BCOL 730558 was a missed opportunity to evaluate the condition of the A-end CCSBs and may have contributed to the accident.

Railways continuously monitor their fleets of cars while in service, to ensure that the CCSBs are performing as intended. Visual inspection procedures, performed by certified car inspectors, are effective in identifying and remediating damaged or broken CCSBs on in-service cars. However, there is no method to visually evaluate the force exerted by the CCSB against the carbody. If CCSBs with inadequate preload force and ineffective damping cannot be identified, trucks that have the potential for excessive hunting will remain in service, increasing the risk of wheel climb or wheel lift events.

Installation of truck hunting detectors

Railways have begun to install truck hunting detectors (THDs) to monitor in-service cars for truck hunting. As of 2014, there were about 80 such detectors throughout North America, 4 of which are on C's track network, with 3 of these installed since the occurrence. In general, the implementation of this truck performance-based technology has been a positive safety enhancement, as it is capable of detecting at-risk trucks that may not be condemnable through visual inspection alone. But the technology is more suitable and more reliable when monitoring unloaded or lightly loaded cars that are travelling at speeds greater than 50 mph.

The first car to derail, BCOL 730558, had travelled over 12 THDs between August 2013 and July 2014 (the last reading was taken on 11 June 2014), but had been empty over only 6 of them. In each case, no condemnable truck hunting index absolute values were recorded. However, the A-end CCSBs were likely in a deteriorated state, because they were no longer providing effective damping for the car.

Since THDs evaluate the truck as a system, a single truck component (or partial group of components) that has deteriorated is difficult to detect. While THDs may not always identify cars at increased risk of excessive truck hunting, the technology does provide an additional means of evaluating the mechanical fitness of in-service cars and, consequently, serves to improve safety.

Tank cars

The damage sustained to the Class 111 tank cars was consistent with failures noted by the TSB in other investigations. While the damaged tank cars contained only residue amounts of product and, consequently, only a small amount of product was lost, the potential for catastrophic environmental impacts and loss of life remains. The damage observed in this derailment highlights the vulnerabilities of Class 111 tank cars and reinforces the need for improved tank car design standards.

Following the catastrophic derailment in Lac-Mégantic in 2013, Transport Canada (TC) improved the requirements for the design of Class 111 tank cars. In May 2015, TC and the U.S. Pipeline and Hazardous Materials Safety Administration introduced a new tank car standard, retrofit requirements, and implementation timelines to modernize and improve the tank car fleet for transporting Class 3 flammable liquids. If the new tank car standards are not fully implemented in a timely manner, there is an increased risk of product loss when tank cars carrying flammable liquids are involved in a derailment.

Findings

Findings as to causes and contributing factors

- The derailment likely occurred as a result of excessive A-end truck hunting on empty centrebeam flat car BCOL 730558.

- The excessive truck hunting on car BCOL 730558 was influenced by the type of car, the speed of the train, the worn condition of the A-end constant contact side bearings, and a truck type with low warp stiffness.

- The non-condemnable, slightly narrow gauge and multiple cross-level perturbations in the south rail likely contributed to the development of excessive truck hunting.

- As freight car BCOL 730558 passed over the low spot in the south rail, a lateral force resulting from the run-in of train slack was likely imparted on the south rail by a wheel in the A-end trailing truck at a time when the car was off-loading because of car body oscillation, resulting in a wheel lift/climb event.

- During the 2007 repair to BCOL 730558 A-end friction castings, the constant contact side bearing resilient members were not replaced as required, but were instead allowed to continue in service and likely deteriorated to the point where they no longer provided effective damping.

- The absence of the constant contact side bearing inspection and measurement in 2014 during a Canadian National repair to car BCOL 730558 was a missed opportunity to evaluate the condition of the A-end constant contact side bearings and may have contributed to the accident.

Findings as to risk

- If constant contact side bearings with inadequate preload force and ineffective damping cannot be identified, trucks that have the potential for excessive hunting will remain in service, increasing the risk of wheel climb or wheel lift events.

- If the new tank car standards are not fully implemented in a timely manner, there is an increased risk of product loss when tank cars carrying flammable liquids are involved in a derailment.

Other findings

- While truck hunting detectors may not always identify cars at increased risk of excessive truck hunting, the technology does provide an additional means of evaluating the mechanical fitness of in-service cars and, consequently, serves to improve safety.

Safety action

Safety action taken

TSB Rail Safety Advisory 09/14

On 14 August 2014, the TSB issued Rail Safety Advisory 09/14, which proposes that, given the potential consequences of excessive truck hunting, Transport Canada may wish to ensure that railways operating in Canada have appropriate measures in place to restrict train speed when the train is transporting empty centerbeam bulkhead flat cars.

Both Canadian National (CN) and Canadian Pacific responded by reintroducing 45-mile-per-hour speed restrictions for all empty centrebeam bulkhead flat cars.

Canadian National

In August 2014, CN used truck hunting detector data from across North America to evaluate the risk of excessive truck hunting for different types of cars. The BCOL 730 and GTW 623 series of centrebeam flat cars were identified as having the highest risk. CN undertook a program to target both series of cars for upgrading to long travel constant contact side bearings.

As of July 2015, about 2100 cars had been upgraded, with approximately 140 remaining to be upgraded. As a result of this action, the speed restriction was removed.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on . It was officially released on 5 November 2015.

Appendices

Appendix A – BCOL 730558 truck hunting detector readings

| Number | Date | Railroad | Load or empty | A-end reading | B-end reading |

|---|---|---|---|---|---|

| 1 | 03 August 2013 | UP | Load | 0.01 | 0.02 |

| 2 | 22 September 2013 | BNSF | Load | 0.022 | 0.024 |

| 3 | 04 October 2013 | BNSF | Empty | 0.016 | 0.016 |

| 4 | 07 October 2013 | BNSF | Empty | 0.036 | 0.076 |

| 5 | 09 November 2013 | NS | Load | 0.006 | −0.026 |

| 6 | 11 November 2013 | CSXT | Load | −0.01 | −0.03 |

| 7 | 16 November 2013 | CSXT | Empty | 0.03 | 0.01 |

| 8 | 16 November 2013 | NS | Empty | 0.03 | 0.022 |

| 9 | 22 April 2014 | UP | Load | 0.01 | 0.01 |

| 10 | 02 May 2014 | UP | Empty | 0.05 | 0.03 |

| 11 | 02 June 2014 | CSXT | Load | 0.03 | 0.01 |

| 12 | 11 June 2014 | CSXT | Empty | 0.03 | −0.03 |

Legend:

UP - Union Pacific

BNSF - Burlington Northern Santa Fe

NS - Norfolk Southern

CSXT - CSX Transportation

Appendix B – Occurrences involving product release from Class 111 tank cars

| No. | Date | Location | Number of Class 111 tank cars involved | Number of cars that released product | Product released | TSB occurrence number |

|---|---|---|---|---|---|---|

| 1 | 07 March 2015 | Gogama, ON | 39 | 32 (Preliminary) |

Petroleum Crude Oil | R15H0021 |

| 2 | 05 March 2015 | Galena, IL, U.S. | 21 | 12 | Petroleum Crude Oil | |

| 3 | 16 February 2015 | Mt. Carbon, WV, U.S. | 28 | 17 | Petroleum Crude Oil | |

| 4 | 14 February 2015 | Gogama, ON | 29 | 17 (Preliminary) |

Petroleum Crude Oil | R15H0013 |

| 5 | 02 October 2014 | Clair, SK | 6 | 2 | Petroleum Distillates | R14W0256 |

| 6 | 30 April 2014 | Lynchburg, VA, U.S. | 15 | 3 | Petroleum Crude Oil | |

| 7 | 07 January 2014 | Plaster Rock, NB | 5 | 2 | Petroleum Crude Oil, Methanol | R14M0002 |

| 8 | 30 December 2013 | Casselton, ND, U.S. | 21 | 13 | Petroleum Crude Oil | |

| 9 | 09 November 2013 | Aliceville, AL, U.S. | 25 | 23 | Petroleum Crude Oil | |

| 10 | 06 July 2013 | Lac-Mégantic, QC | 63 | 59 | Petroleum Crude Oil | R13D0054 |

| 11 | 21 May 2013 | Jansen, SK | 5 | 1 | Petroleum crude oil | R13W0145 |

| 12 | 03 April 2013 | White River, ON | 12 | 3 | Petroleum Crude Oil, Canola Oil (n-dangerous goods) | R13T0060 |

Appendix C – Comparative table of TC/DOT-111 and TC-117 tank car characteristics

| Specifications | Older TC/DOT-111 tank cars | TC/DOT-111/TP14877 built since 2011 to the standard published in Part II of the Canada Gazette on 02 July 2014 | TC-117 |

|---|---|---|---|

| 1. Head shields | No | Half | Full |

| 2. Top fitting protection | Optional | Mandatory | Mandatory |

| 3. Thermal protection (jacket) | Optional | Optional | Mandatory |

| 4. Steel thickness | 11.1 mm (7⁄16 inch) | 12.7 mm (½ inch) for non-jacketed cars 11.1 mm (7⁄16 inch) for jacketed cars |

14.3 mm (9⁄16 inch) |

| 5. Electronically controlled pneumatic brake system | No | No | No* |

| 6. Performance standard for bottom outlet valves | No | No | Yes |

| * Transport Canada indicated its intention, following consultations, to consider including braking provisions, such as electronically controlled pneumatic brakes, in train operating rules, as opposed to the new TC-117 tank car standard. | |||